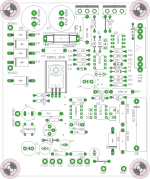

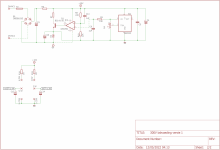

Hi guys, as per the title I'm looking for some opinions on box construction methods. I recently created a prototype box for my new active monitor build using B&C 8NDL51, SB26ADC in 8" Augerpro Waveguide and Hypex FA122 in sealed box with F3 around 80hz as per THX spec.

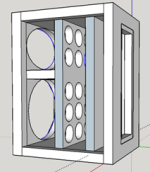

So far I'm very happy with the results, although the unbraced MDF test box does seem to emit a far amount of sound, especially the rear of the box. For the final version of the speaker, I would like to use Baltic Birch instead of MDF, as I absolutely hate working with MDF. I have been designing a few different box construction examples in Sketcup and also doing some reading on here. It seems I can't find an answer about this subject.

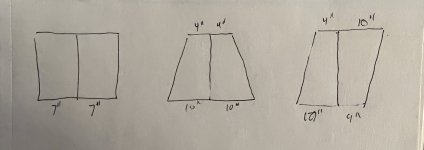

I have a few possible construction methods, I'd love some input about which one you would choose and why. Attached is a side picture of the box design. The compartment at the rear is for the Hypex amplifier, meaning there will be around a 50mm gap between the woofer rear wall and the actual rear wall of the cab. All of the options will be with the box stuffed with some type of acoustic wadding material.

Option 1) 18mm BB (Baltic Birch) box with 30mm front baffle. 18mm center brace glued directly to the sides, top and bottom of the box and an extra 18mm brace between the front baffle and the vertical brace.

Option 2) 24mm BB box with 30mm front baffle. 24mm center brace glued directly to the sides, top and bottom of the box and an extra 24mm brace between the front baffle and the vertical brace.

Option 3) 18mm BB box with 30mm front baffle. 18mm center brace but 1mm short to the sides and to the top and bottom to allow a loose fit and a layer of flexible adhesive glue around the brace to the box. ie CLD brace.

Option 4) 24mm BB box with 30mm front baffle. 24mm center brace but 1mm short to the sides and to the top and bottom to allow a loose fit and a layer of flexible adhesive glue around the brace to the box. ie CLD brace.

Option 5) 18mm BB box all around. 12mm MDF inner box with a layer of flexible adhesive and or rubber matting. CLD box.

So far, option 3 seems the most sensible and the most straightforward form of CLD.

What do you guys think? As I mentioned, most of the sound leakage seems to be from the rear of the test box, however, the test box doesn't have the separation of the amp compartment. I'm thinking that in the final design, even without CLD, the rear of the box is separated from the rear wall of the driver box, and so should mean that there would be very little leakage to the rear regardless, its wether CLD will benefit the sides of the box, whether a CLD brace would be useful or whether the normal stiff brace and glue method would be sufficient.

- seemed to work see #2 above

- seemed to work see #2 above