Been around since 2011 when i researched for my LCR builds but largely a lurker since then so hello again and remember I'm in Australia.

Certainly this thread is a good reference now

https://www.diyaudio.com/community/...-design-your-own-speaker-from-scratch.332688/

Just a little history to show that i'm not really a newb in this, built my first bass reflex cabinets for DJ use back in the mid 80's using Etone (for aussies that remember) 18" woofers. these were built from chip board of the era from basic guidance from the manufacturer on cab and port sizing, using a circular saw, jigsaw and lots of glue. this was before the internet

🙂 and software design tools. The port was tuned by playing bass heavy music in the driveway and changing the port length by hand till they sounded good! Went on to build W-Bins and other assorted cabinets mainly using the Etone 15" bass drivers and basic piezo tweeters noting this was all for mobile DJ use not hifi. Those 18" cabinets are still in use behind the tv unit as quasi subs

🙂

When a local picture theater was upgrading and as i knew the owner I got hold of a working pair of Altec voice of the theatre A7 horns and the matching 811b flared horns, these were set up in a small venue we had permanently at the time with the W-Bins above to fill in the bottom end. The A7's are long gone but i still have the 811b's in storage.

That was the early years and it tuned my ears to like high efficiency pro speakers and horn loaded compression drivers as the years rolled on.

This drove the LCR build in 2011 that uses Pro sound drivers with 100db(+)/1w for the LCR. When i added some basic surrounds they were poorly matched efficiency wise Audyssey in multiple pioneer apps has always set the LCR at -12 and everything else at +2 or there abouts

🙂.

So to today.......

These days the main use for the sound system is HT, it's rare that music is played. So the purchase of a new 85" tv a few months back opened up the pandora's box of dolby vision and dolby atmos which drove the upgrade of the 6yr old amp to a new Pioneer LX505 Elite so we could consider using/building some atmos speakers.

This then led into the rabbit warren and what components to use.

Taking the dot points from Step one of the design and build.

- SAF - important, very, she puts up with a lot and surrounds/ceilings intrude very much into her space.

- Space constraints - the SAF drove the need to minimise space used, bass extension was the main compromise ut consider i cross all speakers at 80hz at the amp this wasn't a huge deal.

- How loud - now this was a biggy to match up to the front LCR and be capable past reference levels. We go close to reference levels watching movies.

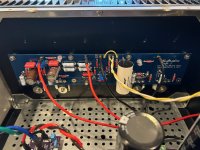

- Amps - well nothings cheap in AU and i hate fan noise so the existing Pioneer amp does all the floor level channels, the atmos ceilings will be handled by 300w class D amps. The Tapped Horn and bass bins are already driven with 600w Class D.

- What sort of box - Bass reflex, didn't need to think hard on this, mind you the Atmos speakers will sealed just to further reduce size.

- build my own cabinets

- budget - i'm a cheap man for this stuff and currently not working so budget was a factor. Some of you may argue this as/if you read more 🙂

So re-installed WinISD and off to parts express PE to do some research and modeling, all initial searches limited to 94db or better efficiency and aim of 2-way and speaker size around 10 to 12 litres maybe a bit more depending on the tweeter.

Believe it or not I did find suitable drivers that modeled well in WinISD, added them to cart along with some bits such as banana sockets.......... went to checkout....

Then some reality set in with freight cost, on an US$800 order freight was north of US$600 !!!!!! That was the cheapest option and no real change from AU $1900 to land it at my door in Australia.

Ouch, not happening, I envy the free freight options for the US members

So back to the Rabbit burrow and WinISD ...... for info, there is no real options for PE range here in AU. A week of research finally lead me into car audio options but finding anything with even vague TS parameters was hard, not buying something i can't model..... till i stumbled on these

https://hertz-audio.com/product/car-audio-coaxials-mille-pro-mpx165-3/ with a full set of TS parameters.

Just a little low on the desired efficiency but it was a small compromise in the end. Now 8 drivers ended up costing AU $1200 so still not in the budget range

🙂

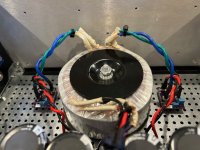

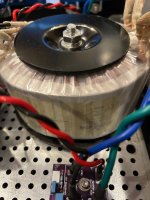

So decision made more time with WinISD to nail down port sizing. Ended up with a 60mm port close to 300mm long with the aim for a box tune of 60hz. I have always tuned below the sub cross over point, personal preference.

Now that port in a box 200mm wide 160mm deep and 330mm tall resulted in more compromises not to mention the desire to have angled sides.... In the end we got a 64Hz box tune, not bad considering sizing and volume used by the port (see photo's below)

Onto build it.... Sorry nothing prior to glueing ports in, I had build one box and played with the port using DATSv3 to check variants.

port is 65mm OD 60mm ID PVC with a 90 elbow hard against the rear wall bore going up to behind the speaker, the speaker mount cutout got sealed with the excess resin i had mixed up.

The banana plug mount is 3D printed and is at the top of the bax as it was the only place left, it is also for resin glued in place for an airtight seal.

Yes that is what we call MDF but is technically High Density MDF, crappy from a dust perspective but i do run some good dust collection as woodwork is a hobby.

The sides are 10 degree angled and round over i think was a 1/2 inch.

Undercoated but haven't yet drilled the holes for the magnets for the front grills, yeah i know a bit backwards.

On the right is the Harvey 10" cabinet saw with a digital measured fenced to 0.1mm, going back to repeat a cut is not a problem.

As you can see the port tubing ate into the internal space and the angled cut on the entry was needed to clear the banana socket. Can't prove it but it seems the angled entry helps with the closeness to the internal walls. a slightly better view.

Finished surrounds at least....

I have measured them with DATS and REW but have no graphs to post, sorry

The sides are on stands at the ends of the 4 seat MLP that we sit in the middle of. The rears for the 7.x are a compromise on height due to the near full width glass doors 4.5M behind the MLP but they are angled down and in at the MLP, Mounts are standard VESA wall mounts using 5mm threaded inserts in the speakers

Here is the rear of the speaker

I may 3D print some cable management. the right angle plugs have a 3D printed spacer holder to stop them shorting.

The grills use a 3D printed from with magnetic attachment, they are 220x200mm. Grill cloth is held in with fly screen

This makes them easy to put on and remove.

So foot notes.

These were fully designed in Fusion 360 including drill templates for all screw and magnet holes. Clamped and glued only. have used a few brads in the overheads in progress to stop glue movement.

Besides small bits we ended up buying two small cordless palm sanders just to not change paper. a HVLP spray gun as all the others are buried in storage. On top of that the existing compressor developed a leak so a new 15cfm 150l Tank silent compressor made it's way into the garage

🙂 Hey any excuse for new tools.

Questions and comments welcome