Many diyAudio projects generate significant amounts of heat, particularly the ones which operate in Class A. Builders work very hard to get rid of this heat, most often by using the largest heatsinks they can find. However, this approach only cools the exterior of the chassis; the air within the box is usually not cooled by active means. Builders simply select a chassis with ventilation holes, and hope the arrangement will be adequate.

On the other hand, there are many DIYers who believe: why build it safe when you can instead build it

extra safe? "More cooler is more better"; you can never have too much heat removal.

I decided it would be a fun project to create an active cooling fan for the interior of an audio chassis. A sensor (NTC thermistor) measures the temperature of the air inside the box, and this continuously varies the speed of a DC fan. When the interior air is very hot, the fan spins at its maximum speed, cooling the interior as much as possible. On the other hand, when the interior air is quite cool, the fan spins at its minimum speed, since no cooling is needed. At in-between temperatures, fan speed smoothly varies from slowest to fastest. It's a continuous, analog, quantity.

Since fans also create unwanted acoustic noise, this scheme keeps the fan as quiet as possible while still doing its necessary job. When the interior air is cold there is no need for cooling and no need for fan noise; this circuit slows down the fan to minimum speed. When the interior air is hot, the fan speeds up and makes more noise, while preventing the electronics inside from damage due to overheating. It's only loud when it's preventing disaster.

A fan control circuit using a 24V DC power supply seemed like a reasonable choice. 24 volts is a good match to quite a number of Class A amplifier projects here on diyAudio, which all run on ~ 24V supplies, including several First Watt designs such as ACA, F5, Aleph J, M2, etc. The 24V DC fans themselves are plentiful and cheap: not only does Mouser carry them, so do DigiKey, AliExpress, eBay, and Amazon. You can use a "2 wire" or a "3 wire" or a "4 wire" fan with this all-analog circuit. It only connects to two of the fan wires: red and black. All other fan wires are left unconnected and floating.

For experimental purposes, I bought three 24V DC fans from Mouser.com, shown in Figure 1 below. Connecting them to a lab power supply, I measured the minimum voltage required to guarantee each fan would start spinning from a dead stop. Below that voltage, a stationary fan "stalls", and fails to begin spinning:

- 40mm fan: starts reliably at VCC >= 6.3V

- 60mm fan: starts reliably at VCC >= 8.1V

- 92mm fan: starts reliably at VCC >= 7.9V

Thus it seems that many 24V fans will be happy as long as the analog control circuit never gives them less than 8.1V (34% of their 24V nominal supply). I decided to add a little margin-of-safety and so I set the Vmin to 37% of the supply. If you hate this decision you can redesign as discussed below (zener diode section).

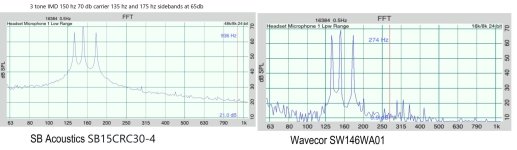

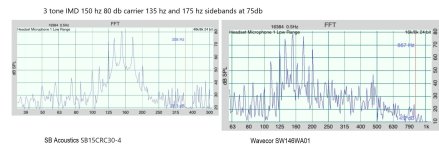

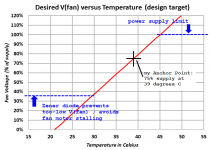

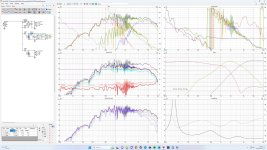

My answer to the question "How Hot Is Too Hot" is shown in Figure 2. This is the

design target I chose, shown in red. I've tried to make an analog fan controller circuit which actually implements the red curve in Fig 2, as closely as possible

The fan voltage hits 100% when the thermistor reaches 45 degrees C. In my circuit design the fan voltage cannot exceed 100% of the supply, so further increases in temperature do not cause further increases in fan voltage. This is shown by the dotted blue horizontal line at top right.

At about 30 degrees C the fan voltage has fallen to 37% of the supply voltage. Then a zener diode in the circuit prevents it from falling any further, so the fan voltage remains at 37% even when the temperature falls well below 30C. The horizontal blue line at bottom left shows this effect. The zener diode's spec is (100-37 = 63%) of 24V, namely, 15.1V. Buy a 1N5929B and be happy.

If you remember algebra from school, you know there are several ways to define the red straight line on Figure 2. I choose to define it this way:

- The line MUST pass through the Anchor Point at (39 degrees C, 75% fan voltage)

- The slope of the line is 4.2% per degree C

Other designers might choose other ways to define the red line, and that's okay with me. This is just the definition I happen to prefer.

For the temperature sensor, I chose an NTC thermistor made by Vishay. Mouser.com has tens of thousands of these in stock, even in Portugal and Finland. It is Vishay part number NTCLE100E3104JB0 . Resistance at 25C is 100 Kohms, a relatively high resistance, chosen to reduce self-heating. Vishay's datasheet presents the (nonlinear) equation of the thermistor's (nonlinear) resistance vs temperature response. Here is a summary:

Code:

Temp R_thmstr Temp R_thmstr

====================================

19 132200 40 51750

20 126100 41 49610

21 120300 42 47580

22 114800 43 45640

23 109600 44 43790

24 104700 45 42020

25 100000 46 40330

26 95540 47 38720

27 91310 48 37180

28 87280 49 35710

29 83450 50 34310

30 79810 51 32960

31 76340 52 31680

32 73050 53 30450

33 69910 54 29280

34 66920 55 28160

35 64080 56 27080

36 61370 57 26050

37 58790 58 25070

38 56330 59 24130

39 53980 60 23220

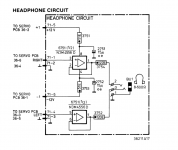

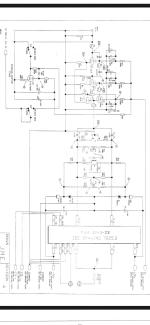

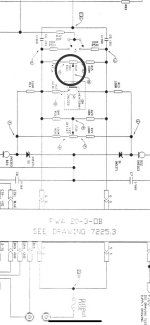

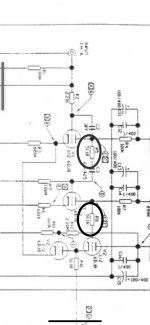

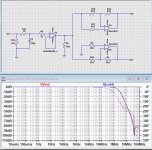

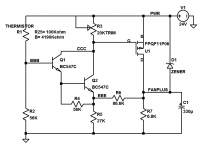

A circuit schematic is presented in Figure 3. The thermistor and resistor R2 form a voltage divider at node BBB. When the temperature goes up, thermistor resistance goes down {it has a NEGATIVE temperature coefficient}, and so the voltage at BBB goes up. The rest of the circuit amplifies and offsets this temperature dependent voltage, then applies it to the fan. When temperature goes up, fan voltage goes up, and so do fan speed and airflow.

The fan is driven by a P-channel MOSFET called "U1". This allows the circuit to apply all 24 volts of supply across the fan when it's really hot, without any voltage loss due to VCEsat or emitter/source follower drops. Capacitor C1 filters the fan voltage and absorbs any "spikes" that may occur as the fan motor rotates. I selected a special electrolytic capacitor rated for more than 1 ampere of ripple current (Panasonic EEU-FS1V331LB), yet it's in a modest 8mm diameter package. C1 also provides frequency compensation for the negative feedback control loop as a whole.

Adjusting the trimpot R3: let's hit the Anchor Point!

The goal in setting R3 is to make sure the temperature versus voltage curve does in fact pass through the Anchor Point: (39 deg C && 75% of VCC). See Figure 2. To get 39C, a resistor is needed whose value is 53.98 Kohms according to the table above. However instead of 53.98 Kohms, I found very it convenient to simply connect two 27K 1% resistors in series. 54.0K, close enough.

Then I temporarily remove the thermistor, terminal block screw connectors make this easy. I replace it with my 54.0K fixed resistor. To adjust the fan controller's R3 for actual field use, connect the circuit board (and the fan itself!) to the internal 24V power supply network of the audio equipment to be cooled. The adjustment can be performed with the chassis open and its top plate & bottom plate removed, we're not measuring stagnant air temperature just yet.

MEASURE the supply voltage inside the audio gear. It's probably a little bit above or below 24.00 volts. Then switch the voltmeter probes to measure the voltage directly across the fan, and dial R3 up and down. Stop dialling when the fan voltage is exactly 75% of the supply. Done! R3 is now set to the correct value for *this* power supply voltage, and for the device parameters of *this* particular Pchannel MOSFET, on *this* specific fan controller board. Yes, Virginia, two MOSFETS of the same part number really CAN have threshold voltages that differ by two thousand millivolts, just as the datasheets warn. Replace the fixed 54K resistor by the thermistor and its umbilical cable, job done.

A word of caution: this circuit contains so few parts, that each individual part has an effect upon several different aspects of circuit behavior. In other words, everything interacts. Strongly. When designing or redesigning a circuit like this one, it takes a lot of tweaking and adjusting and juggling to get the circuit to work well. Fortunately for you, I have already performed this miserable job; it took me about a half a day to get it completely dialled in. The schematic in Figure 3 works nicely ... but only for THIS supply voltage (24V), and only for THIS choice of thermistor, and it only implements one specific design target curve of Temperature-versus-FanVoltage (shown in Figure 2).

If you want to modify the circuit to operate at a very different supply voltage, or to use a different thermistor, or to hit a different design target T-vs-F curve ... then you will need to tweak and adjust and iterate and juggle component values, to get your new circuit working and meeting your new specifications. It will take effort. Do I know of any time saving procedure(s) for this? Not really; all I can suggest is to thoroughly explore and experiment and keep good notes. And don't forget to have fun!

Fortunately, if all you want to do is change the supply voltage a little bit (for example: use this analog fan controller inside an Aleph J which runs on a 22V power supply instead of 24V), and if you leave all other design goals alone, then you will only need to adjust R3 using the procedure above. Just hit the Anchor Point. I haven't personally tested every single possibility but I do think a simple R3 adjustment is probably all you need, if you keep the power supply voltage within plus or minus 15% of the design value, 24V. That is, (20.4V <= VCC <= 27.6V) only requires a simple twist of R3 to make it work. If you go outside this range, adjusting R3

might be all you need to do, but honestly I would be a little surprised.

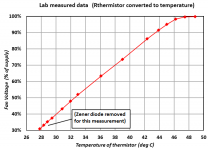

To test out the circuit, I bought some fixed resistors in the range (40K < Rfixed < 80K) and labeled each one with its corresponding Thermistor temperature from the table above. This let me measure the data shown in Figure 4. Eyeballing Fig 4 and Fig 2, it seems to me this design hits the target reasonably well.

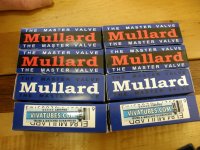

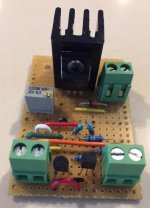

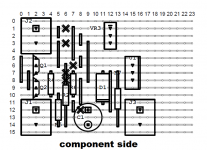

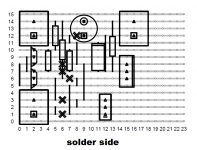

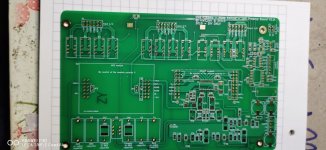

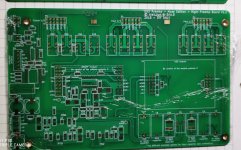

I built the circuit on "Stripboard" sometimes called "Veroboard"; Figure 5 shows a photo. The MOSFET's heatsink is from Tayda, 17mm x 17mm x 25mm, to give me the option of connecting a really high current, high power, high airflow fan ... someday, if I feel like it. The puny little fans in Figure 1 don't actually need an aggressively heatsinked power transistor to drive them. VeeCad cuts-and-jumps CAD drawings of the Stripboard are shown in Figures 6 and 7.

Finally, I suppose I owe readers an answer to the question "Why on earth build this as an

analog circuit?" After all there already are LOTS of temperature controlled fan PCBs for sale on eBay and AliExpress and Amazon, at super cheap prices. There are also four hundred budjillion Arduino projects to make a temperature controlled fan.

It's true. There are. Unfortunately, all of these use PWM (pulse width modulation) which commutates the fan between 100% ON and 100% OFF, using digital circuitry. The relatively high-current, relatively fast-risetime digital pulses driving the fan, can couple into other nondigital circuits, creating electromagnetic noise which corrupts low level music signals. Indeed many diyAudio members refuse to include any digital circuitry of any kind, inside their all-analog audio equipment. For them a PWM fan controller is utterly forbidden, therefore an all-analog solution is required. Additionally, some fan manufacturers explicitly state that PWM control of their fans results in greater acoustic noise than analog control, at certain speed settings. Who wants a noisier fan? Nobody.

I should mention that Microchip sells a wonderful family of embarrassingly simplistic non-PWM chips, called MC620/MC621. These implement a bang-bang control system for thermal control of a DC fan, exactly like the HVAC heating and cooling system in office buildings. It's digital, but not PWM. Also, Maxim makes the MAX31740 chip which is a full featured, ultra simple, thermal fan controller using PWM. If you don't hate PWM, check it out. If you are both ambitions and a little masochistic, you could figure out a way to do it with a pair of NE555 timer ICs. Those chips were literally

made for PWM.

If you despise PWM, but for some reason don't like the 3 transistor discrete circuit in this message, you could consider designing yourself a new circuit using opamp chips. It's an ambitious project but diyAudio members are brave souls. You'll want ICs that work on 24V supplies, such as LM324 or OP07 or even uA741. Oh and you'll need to pay careful attention to frequency compensation / instability / unwanted oscillation, since opamps have lots of gain while common source power transistors have lots of phase shift. Especially when you decide to keep the deluxe 330uF smoother outer capacitor! You win extra bragging rights if your design does not require or use "single supply" opamps, "rail to rail" opamps, or "over the top" opamps. When you're all done be sure to compare the parts list of your opamp design, against the parts list of this discrete design. I bet you'll find that both need a fan-driving transistor, so the difference becomes (opamps + resistors) versus (two NPNs + resistors). Which is cheaper? However perhaps a circuit with opamps can eliminate the trimmer pot, whose cost is surprisingly high for its mundane function. Have some fun with it!!

_