thread index at the end of this post!

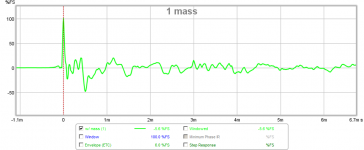

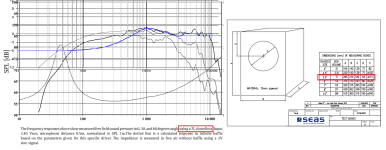

When planning, simulating, building and measuring bass reflex enclosures for 2-way speakers one difficulty is dealing with port resonances in the midwoofer’s passband.

I thought it should be possible to absorb resonances with Helmholtz resonators in/at the bass reflex port.

Obviously I am not the first to come up with this idea, but I also didn’t find very much about it on the internet.

Thus I decided to make my own measurements, see the following posts!

some web references:

Short thread about this issue on diyaudio. note that the thread starter wrongly refers to the "1/4 wavelength resonance" of a port. This is not correct! The fundamental resonance of an open tube happens at the frequency that has a wavelength equal double the tube length.

A german thread about port tube resonators.

various web references for resonance of open tubes and helmholtz resonators:

https://en.wikipedia.org/wiki/Helmholtz_resonance

https://en.wikipedia.org/wiki/Acoustic_resonance#Open_at_both_ends

https://www.physicsclassroom.com/class/sound/Lesson-5/Open-End-Air-Columns

https://en.wikipedia.org/wiki/End_correction

http://troelsgravesen.dk/vent_tuning.htm (including end correction values!)

calculating resonance of bass-reflex port (open tube resonance):

occurs at frequency that has half wavelength equal to end corrected reflex port length and respective frequency multiples.

Oscillation node (pressure maximum) is at center of port (or further divisions for multiples).

pressure absorber works best at the respective node.

Option 1: tube absorber

Simple tube, one end closed, it should thus have roughly half the length of port for absorbing resonance of port fundamental; can either be parallel (and inside) the port or 90° perpendicularly mounted at port. Open end should be located at half port length.

Option 2: Helmholtz absorber

Mounted at half bass reflex port length, connected by its own small Helmholtz port to the bass reflex port

-------------------------------------------------------------------------------------------------

Thread index

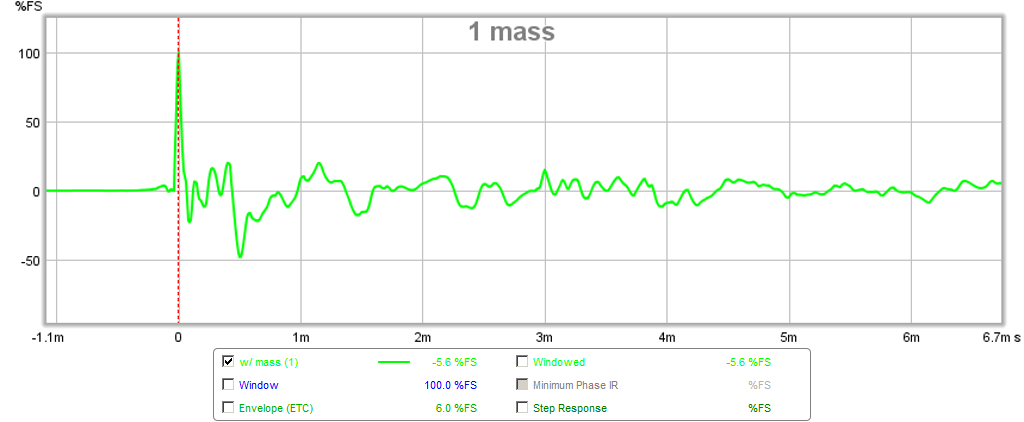

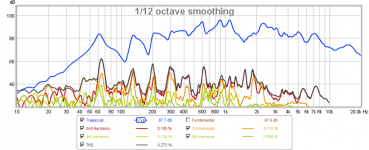

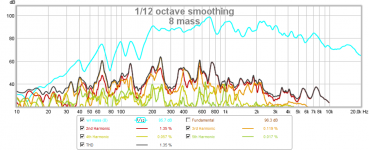

#3 - first resonance absorber tests with tube test setup

#5 - decay plots of test bass reflex box

#8 - resonance absorber results by

@augerpro

#11 - link to a relating message by

@rdf including link to roozen/philips-paper

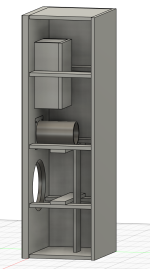

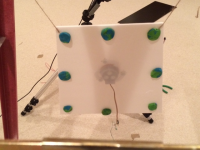

#19 - new parallel 6th order bandpass test box for further investigations

#22 - dealing with enclosure resonances

#25 - chuffing audibility test

#42 - particle photos (using water sprayer)

#48 - port 2 variants and measurement results

#50 - port stalling test

#54+

55 - influence of smoothed port flange

#56 - port 2 impedance results

#58 - port resonance absorber test

#81 - link to bryce doll paper by

@Hearinspace

#103 - port 2 variants resulting in the same tuning frequency, with geometry drawing

#104 - photo of port 1 variants

#141 - port wall stiffening influence

#157 - port 1 variants response measurements

#159 - chuffing RTA measurement of straight port 1

#161 - chuffing RTA measurement of rectangular curved wall port and big 3d printed port

#165 - chuffing RTA measurement of flat port and small straight port

#166 - resonance absorber setup

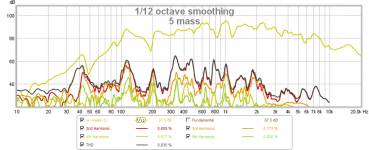

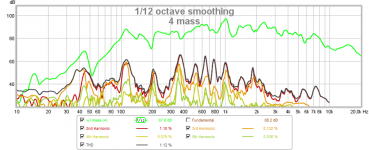

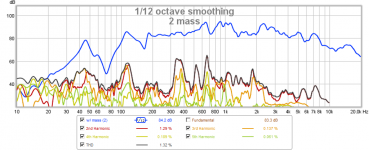

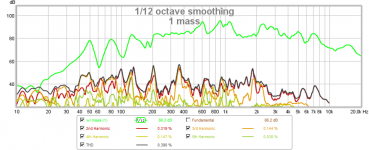

#167 - measurment of resonance absorber lenght variations

#202 - resonance absorber filled with melamine foam

#206 - chuffing RTA measurement of 3d printed port with resonance absorber

#214 - influence of port diameter/dimension for enclosure resonance transmission

#228 - small 3d printed port drawing and measurments

#230 - testing noise of roughened port surface

#236 - port with resonance absorber documentation by

@Kwesi

#249 - chuffing RTA measurements in singe dB steps (small 3d printed port)

#251 - separating resonance absorber from the port with latex membrane

#288 - link to salvatti devatier button paper

#302 - explanation of boundary layer thickness by

@andy19191

#310 - impedance measurements for port 1 variants at different input levels

#320 - "progressive port geometry" concept

#324 - progressive geometry port measurements

#328 - progressive geometry port length correction

#329 - progressive geometry port impedance measurements at different levels

#330 - progressive geometry port response

#331 - progressive geometry port chuffing RTA measurement at 100 Hz

#341 - output level measurement / comparison

#349 - is airspeed the main chuffing factor? progressive port chuffing RTA measurement at 50 Hz

#350 - new particle photos

#352 - explanation of turbulent air motion by

@andy19191

#363 - relating chuffing to particle displacement

#367 - first GIF-excepts of 120 fps particle videos

#390 - port variants with sound recordings by

@Tenson

#391 - correct port particle displacement calculation formula by

@David McBean

#395 - (1) first slow motion video: hard edge port

#407 - (2) second slow motion video: flared port

#434 - flange variant video

#438 - (3) third slow motion video: progressive geometry port

#448 - influence of air particle displacement for the excitement of low frequency noise

#449 - differences of a big and small (optimized) port for a small 2-way midwoofer

#460 - (4) fourth slow motion video: small straight hard-edge port

#468 - small very flat port - checking for boundary layer flow resistance

#503 - how to calculate the strouhal number using max port air velocity data, CORRECTION see #591

#504 - water tank simulation

#522 -

@Dmitrij_S Karlson couple port

#526 - flared port geometry definition

#529 - 2 way speaeker test ports to be measured ...

#531 - ... response measurements ...

#546 - ... chuffing measurements (RTA) ...

#591 - correct calculation of strouhal number, related to peak-displacement instead of p-p- displacement (thanks to by david mc bean)

#595 - how to find a suitable port exit diameter using the Strouhal number (corrected version!)

#616 - first beta version of a simple excel sheet for tuning calculation of NFR=0.5 ports

#621 - relating the strouhal number to compression and distorsion

#624 - parametric fusion 360 model for a NFR=0.5 port by

@augerpro

#627 - augerport with resonance absorber by

@augerpro

#646 - parametric NFR=0.5 port model for freeCAD, including STEP and STL model

#652 - announcement by

@David McBean: stouhal curve included in the port exit air velcity graph.

#654 - how I make my 3d printed ports

#680 - chuffing/noise audibility comparison: straight and flared port

#704 - big collection and evaluation of 3 speaker and 14 port variants - proposed MID PORT STROUHAL NUMBER

(MPSN) parameter

#747 - updated excel calculation tool with correction and variable NFR ...

#748 - ... and the imperial version of the same calculator

#753 - comparison ports vs passive radiators

#811 - compressing the optimum geometry definition to two relevant parameters

#812 - The breakthrough: Finding compression behaviour patterns

#847 - Iterative port geometry optimizer tool

(will be updated)

![2022-02-05 13_25_24-TinyCad - [7189 Amp Phase Inverter.dsn].png](/community/data/attachments/930/930349-016819641f9ca17af5918a9b5a3133be.jpg?hash=AWgZZB-coX)

)

)