Maybe, there can be gold in them grooves! Personally I'm more into listening than experimenting, fortunately people like Wayne, Pa and others design top quality products that don't need much fussing, but as long as @tonyEE is having funI doubt that changing U1 is going to afflict my listening experience in any adverse sense on these 40+ year old LP's.

I fully expect that the 40 year old DG LPs will not change... those DDA LPs will sound as flat as pancakes, just as they did on day one. The only recordings that sounded better in CD. I know, I got them...

But I got some Warner Brothers, and that awesome Frank Sinatra Live in Las Vegas... and another one from Tom Jones Live! ( Also in Vegas ) that I believe will sound better if I flip to using single opAmps. Imagine Nelson Riddle at 11..... Tom Jones chest... you'll see it, not just hear it ( hmm... )...

Heck, how about changing op amps on the Left and Right channels? Play a mono recording. Then wire the speakers out of phase, put them facing each other and hear the difference?

I Did It My Way

I still want to know what they call those single to dual DIP sockets! Where can I get them?

But I got some Warner Brothers, and that awesome Frank Sinatra Live in Las Vegas... and another one from Tom Jones Live! ( Also in Vegas ) that I believe will sound better if I flip to using single opAmps. Imagine Nelson Riddle at 11..... Tom Jones chest... you'll see it, not just hear it ( hmm... )...

Heck, how about changing op amps on the Left and Right channels? Play a mono recording. Then wire the speakers out of phase, put them facing each other and hear the difference?

I Did It My Way

I still want to know what they call those single to dual DIP sockets! Where can I get them?

I guess my P3 is as silent as it can be. No hum at all. Only slight "hiss" if I set vol. to max. That is only audible if I am close to speakers. I have no complaints so far 🙂 ......now I "only" have to find "perfect" records 🙂 .....working at it.MEPER....don't know if anyone has answered this to date but I was getting a slight hum when the preamps volumes were turned to max which was bothersome, similar to your situation. Couldn't hear anything at normal preamp levels for playing music but it bothered me anyway. It was independent of turntable being connected, preamp, amp, PS driving the P3, any grounding schema, or opamp. I'm using a Grado Green 3 cartridge (moving iron?). I just tried changing R22 to a ~47R resistor (had them in my stash; bringing the total gain down to ~ 37dB). One channel is now completely silent and the other's hum was decreased dramatically. I'll drop R22 to 40R as soon as my order gets here from Mouser. I'll then do opamp rolling to see which I prefer although the standard 2068 is perfectly fine&dandy.

Cheers

There simply is no such thing as a perfect vinyl record.

No such thing. And it never will be.

It is a horrybly flawed analog medium wich distorts, wows, hisses, flutters, and rumbles. It pops, crackles and klicks. It feeds back sounds from the listening room.

So, the best thing to do is to see all these flaws as actual analogue features, wich makes it all a little more special:

And then just live more happy, the rest of your vinyl listening lifetime.

🎺🙂🎸

(I actually nowdays see all these obvious flaws as features of this ancient medium. 🙂)

No such thing. And it never will be.

It is a horrybly flawed analog medium wich distorts, wows, hisses, flutters, and rumbles. It pops, crackles and klicks. It feeds back sounds from the listening room.

So, the best thing to do is to see all these flaws as actual analogue features, wich makes it all a little more special:

And then just live more happy, the rest of your vinyl listening lifetime.

🎺🙂🎸

(I actually nowdays see all these obvious flaws as features of this ancient medium. 🙂)

All true, but pretty amazing that we can get such beautiful sound by jiggling a little stylus in those grooves! FM, F$@king Magic!It is a horrybly flawed analog medium wich distorts, wows, hisses, flutters, and rumbles. It pops, crackles and klicks. It feeds back sounds from the listening room.

When music source for e.g. FM radio broadcast was from vinyl records I don't remember a lot of "pops" etc.?

Or do I have a bad memory?

I remember that sometimes (rarely) the stylus playing same groove again and again until it was corrected......

Or do I have a bad memory?

I remember that sometimes (rarely) the stylus playing same groove again and again until it was corrected......

I guess my P3 is as silent as it can be. No hum at all. Only slight "hiss" if I set vol. to max. That is only audible if I am close to speakers. I have no complaints so far 🙂 ......now I "only" have to find "perfect" records 🙂 .....working at it.

Noise is the nature of the beast.

Noise comes from multiple sources; JFETs, Op-Amps, resistors, cartridge ...... then it is amplified by 50-70dB's in the P3 then amplified more in the preamplifier plus the power amplifier.

Even in the best case there will be noise, hopefully it will be only at the level of ear in the speaker hiss.

That is the nature of vinyl playback. It is all music to me.

Thanks DT

I think my hiss level it quite low. With vol. set to max (12 dB gain after P3) I need to be close to speaker to hear it. I can't hear the "hiss level" at listening position with vol. set to max. So I think I am as fine as i can get.

Regarding groove noise / clicks from dust on record etc. the records that are recorded loud sounds the most "silent". This is quite natural as vol. is set lower playing a loud recorded record. It is a metal process to accept a few clicks and pops now and then. Dust will land on record surface even during play back.

Wonder if the strange arms with a brush that cleans the grooves during playback really works?

Regarding groove noise / clicks from dust on record etc. the records that are recorded loud sounds the most "silent". This is quite natural as vol. is set lower playing a loud recorded record. It is a metal process to accept a few clicks and pops now and then. Dust will land on record surface even during play back.

Wonder if the strange arms with a brush that cleans the grooves during playback really works?

Yes it does.

I have what you call a JR "strange arm with a brush" that, once adjusted (putting it on the right location) follows the groove at the same speed as the cartridge and cleans off the dust from the record just before the cartridge reads it. I use it since over 2 decades and have still not used the spare brush that came with it.

I wouldn't do without it. This is the best (passive, not mentioning cleaning machines obviously) system I know to remove dust just before playing. It is of course connected to the ground of the Phono preamp, as it should.

It also looks good IMHO and is very effective (I removed it during half a record play and put it straight back). It shouldn't slow your platter due to the low additional friction, and it has to be put in the right location in the corner -requires a bit of play- so that A) the brush gets the right angle and distance to follow the groove until its end, B) the brush gets the right angle and distance to progress at the same speed as the cartridge. Easily done, just playing with distance and angle where you put the base of the brush...

I hope this helps

Claude (never used a handbrush since, except at friend's)

I have what you call a JR "strange arm with a brush" that, once adjusted (putting it on the right location) follows the groove at the same speed as the cartridge and cleans off the dust from the record just before the cartridge reads it. I use it since over 2 decades and have still not used the spare brush that came with it.

I wouldn't do without it. This is the best (passive, not mentioning cleaning machines obviously) system I know to remove dust just before playing. It is of course connected to the ground of the Phono preamp, as it should.

It also looks good IMHO and is very effective (I removed it during half a record play and put it straight back). It shouldn't slow your platter due to the low additional friction, and it has to be put in the right location in the corner -requires a bit of play- so that A) the brush gets the right angle and distance to follow the groove until its end, B) the brush gets the right angle and distance to progress at the same speed as the cartridge. Easily done, just playing with distance and angle where you put the base of the brush...

I hope this helps

Claude (never used a handbrush since, except at friend's)

Is it a design like this:

https://www.amazon.com/Vinyl-Record-Cleaning-Arm-Accessories/dp/B07FFCGVCS?th=1

Is "JR" a specific brand?

https://www.amazon.com/Vinyl-Record-Cleaning-Arm-Accessories/dp/B07FFCGVCS?th=1

Is "JR" a specific brand?

I assume deionized water is used to clean a pcb before soldering on components and not for cleaning flux afterward.Hello All,

I taught soldering and brazing among other things to the Building Trades for more than a few years. It is about being clean, as in bright and shinny, and using flux core solder. In the spirit of bright and shinny buff the solder as it comes off the roll with #0000 steel wool.

I wash the PCB's with Deionized water and Dawn detergent. Rinse with D.I. water and then a final rinse with 90% alcohol. The PCB's dry quickly with nothing but shine on them. Keep your grimy oily mitts off the clean PCB's.

Many of the resistors in the crate on my shelf are years Old New Stock. Again in the spirit of bright and shinny I use #0000 steel wool to buff up the component leads.

With everything clean you can watch the solder wick (capillary action) through the hole forming that perfect cone on the PCB top side.

Sometimes I cheat and put a little dab more solder on the top side of the PCB. However there is always that little puddle of flux that tells on me when I do.

Thanks DT

I had a student job many years back in time where I did various task (mainly soldering jobs). One task was to clean 2-3m long PCB's with acetone before soldering. They were used for some very large constructions for particle physics measurement at CERN. I did not clean the P3 PCB's before soldering but i did afterward using 99% propanol to remove flux. But maybe I will clean PCB's with acetone next time before soldering as I assume that they knew what they ask me to do. It was done with head-mask etc. for protection.

I assume deionized water is used to clean a pcb before soldering on components and not for cleaning flux afterward.

Yes, prior to soldering clean the PCB down to the shine wash and rinse with DI water plus Dawn detergent. Then rinse with 90-99% alcohol No dirt no grease only shine.

In my experience I use LOCKTITE / Multicore, Alloy 63/37, CRYSTAL 400 2% (flux) solder. If everything is clean the solder flows readily. Using 2% rather than 3% flux there is 1/3 less flux to clean. In recent months I am also reducing the amount of solder used, as a result there is less flux to clean.

Sure wash off the flux with DI water if you like. I have not done that. Intel uses a lot of RO/DI water to clean computer chips.

Also use a, dedicated to PCB cleaning, electric toothbrush. I do this with alcohol.

Thanks DT

My liver prefers alcohol to acetone.

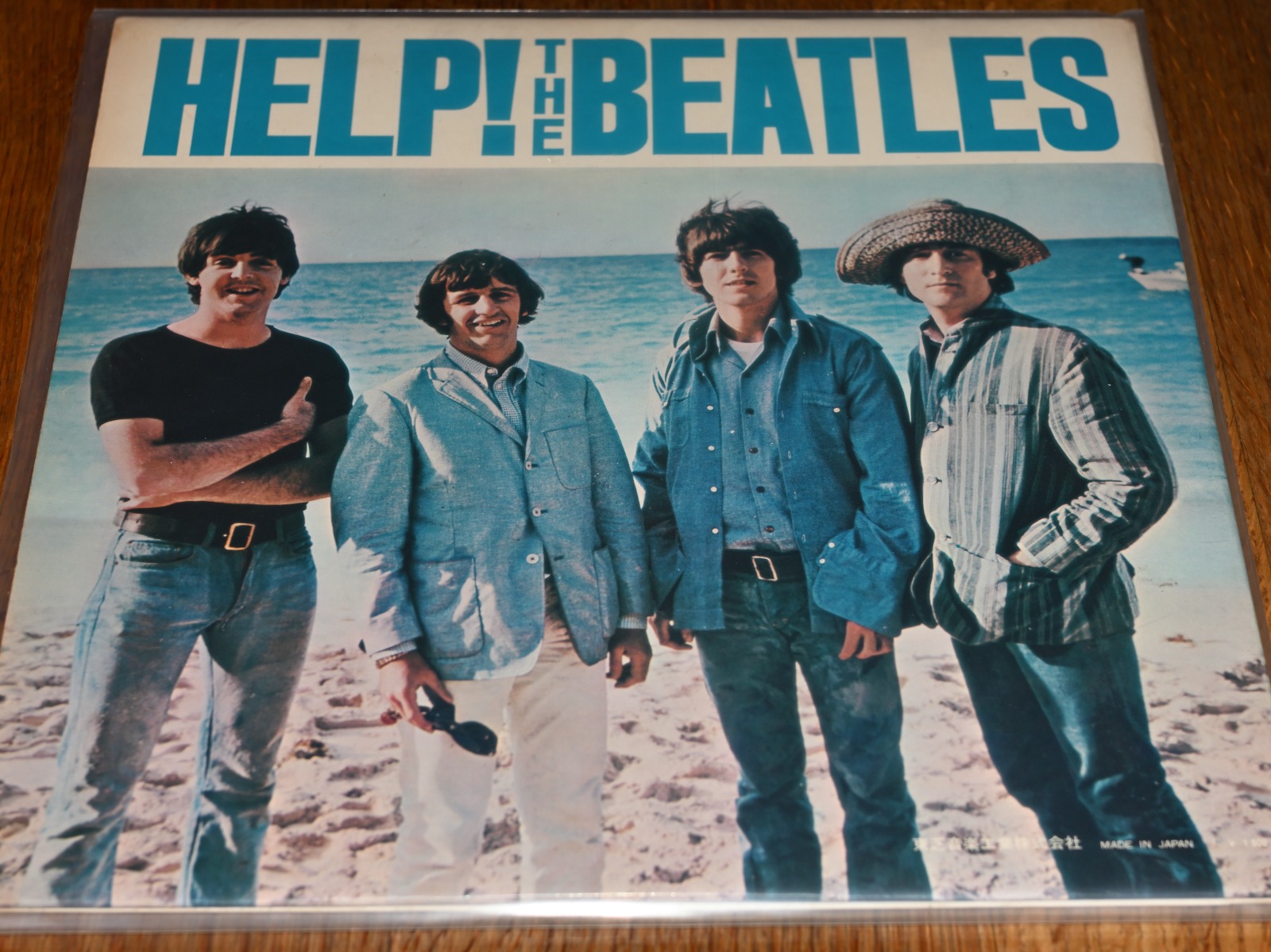

One of the records I have ultrasonic cleaned (Japanese pressing on red vinyl). It sounded awful before. Now sound is surprisingly good (it also got LAST! treatment). Anybody heard of the band?

I remember them from the old days but was never a fan but now it is quite fun to listen to........but I must say not close to Led Zeppelin.

I remember them from the old days but was never a fan but now it is quite fun to listen to........but I must say not close to Led Zeppelin.

Hi Meper,

JR = Jochen Räke... nowadays the company is called JR Transrotor and most products just Transrotor.

You can call Transrotor a specific brand: they build high end TT since decades, google is your friend.

Regarding the cleaning arm, yes kind of, but the JR I own is much better built.

I realise it cost meanwhile a small fortune for what it is. Here you go

https://www.auditorium.de/fr/vinyle...retien/transrotor-broom-for-turntables-chrome

The one you found may work, who knows...

Good luck

Claude

JR = Jochen Räke... nowadays the company is called JR Transrotor and most products just Transrotor.

You can call Transrotor a specific brand: they build high end TT since decades, google is your friend.

Regarding the cleaning arm, yes kind of, but the JR I own is much better built.

I realise it cost meanwhile a small fortune for what it is. Here you go

https://www.auditorium.de/fr/vinyle...retien/transrotor-broom-for-turntables-chrome

The one you found may work, who knows...

Good luck

Claude

Thank you!

Nice one!

They write it works for platter heights from 25 - 40mm.

When I measure from the TT base to the platter top when a record is mounted I measure about 45mm.

In this case I should set the Transrotor on "something".

About 100 Euro for something nice that works is not expensive 🙂

Nice one!

They write it works for platter heights from 25 - 40mm.

When I measure from the TT base to the platter top when a record is mounted I measure about 45mm.

In this case I should set the Transrotor on "something".

About 100 Euro for something nice that works is not expensive 🙂

- Home

- Amplifiers

- Pass Labs

- Pearl 3 Burning Amp 2023