The liability if there is a fire or even lift failure after any modifications can be huge. So I suggest you make no major changes.

Apparently there is no schematic, so suggesting a major change, like converting the control circuit to DC, is a sure fire recipe for disaster.

How can anyone possibly work on it, if they don't really know what it is??

Making a schematic of that control box isn't all that hard, once you understand the components.

The 4 pole relays & sockets always look confusing at first, but once you learn the NO - NC - COM & Coil screw connection pattern it's just repetition.

I speak from experience, having done this at my job several times on much larger panels with hundreds of components.

Yeah, it's not fun, but that what it takes to do it right.

How can anyone possibly work on it, if they don't really know what it is??

Making a schematic of that control box isn't all that hard, once you understand the components.

The 4 pole relays & sockets always look confusing at first, but once you learn the NO - NC - COM & Coil screw connection pattern it's just repetition.

I speak from experience, having done this at my job several times on much larger panels with hundreds of components.

Yeah, it's not fun, but that what it takes to do it right.

Believe me, that has gone through my head a few times. This will be used by my mother and when the day comes, it will be scraped.The liability if there is a fire or even lift failure after any modifications can be huge. So I suggest you make no major changes.

Again, this is where we are with troubleshooting: Line voltage (wall plug, 120 vac) to primary of transformer, secondary not connected, transformer overheating and going into protection mode. It doesn't matter what's on the other side of that switch on the secondary, it's having as much affect on the circuit as the box of loose resistors under my work bench.Apparently there is no schematic,

When this first happened, before I got to isolating the transformer for troubleshooting, I replaced every part and still had the issue. 3 relays, the timer, replaced one relay socket and tested all the switches.

I think the original transformer is poorly made and speced incorrectly for continuous work (regardless of what the manufacturer claims). This is supported by the fact that lift sales person says this is a common issue with this type of lift.

I purchased the 250 va transformer before posting here. It's incased in epoxy in a 16 gauge metal box and that box is getting pretty hot. Again, plugged in with nothing hooked to the secondary, it gets hot. The manufacturer says this is normal (although I'm not sure how much I trust the tech I talked too). I'll keep running it to see if it shuts down.

If that fails, I'll come back here to see if anyone can recommend a better made, continuous duty transformer. Toroidal has been mentioned.

I won't be redesigning this to run on DC. I won't be changing out the relays, timers and sockets again just to see if that has any affect on the transformer while disconnected from the secondary circuit. Trust me, I have tested the switch between the secondary and the rest of the circuitry many times. When that switch is on, it activates the first relay and the light in that relay goes on. With switch off, no secondary power goes to the relay and the light will be off. I am always watching for that light just to make sure the switch doesn't "Turn on by itself". Between taking a meter to it and watching for the light, I can guarantee, there is nothing connected after the secondary switch. And if that's not enough, I have physically disconnected the secondary wires on both transformers, wire capped them, plugged them in and both still get just as hot.

Only in civilized countries! Here I suspect one is certified by each state. So in some places probably not needed. However the liability can be pursued by many different folks from regulatory authorities to insurance companies. I would expect the insurance company to deny coverage for a fire resulting from any changes.Working on it while being uncertified results in the same liability blame game.

Again I would see if the transformer end bells are acting as a shorted turn.

Isn't this only if it's a toroidal design?Again I would see if the transformer end bells are acting as a shorted turn.

Look at a NEW Class 2 Transformer,40VA,24VAC,Foot WHITE-RODGERS 90-T40F3 from amazon, it covered with plastic end caps and made in USA. Perhaps your existing one is poor quality that made in China?

Last edited:

I don't know about getting the same model # from the same manufacturer. That one looks identical to the one I have EXCEPT the sticker says made in USA. Mine is new, purchased from Supply House a few months back.

I'm up for trying something different but that isn't different enough!

I'm up for trying something different but that isn't different enough!

First, please clarify that you connected the transformer primary in the circuit, or out of it during testing on an unloaded secondary.

Second, do you have a thermometer or temperature indicator of any sort to measure and quantify 'pretty hot'?

(As in so many degrees above ambient, under steady conditions).

Second, do you have a thermometer or temperature indicator of any sort to measure and quantify 'pretty hot'?

(As in so many degrees above ambient, under steady conditions).

Last edited:

Yes the typical asker is not good at answering questions that are asked to solve her/his problem.

The transformers are probably designed to work where there is adequate ventilation, not in a small sealed box.

Simon (...7000) is citing some legal requirements, this could be another, that nobody should be able to stick a finger, or similar object inside. So closed box.

It is easy to make a suitable opening in the housing, and cover it with mesh, to allow circulation, and prevent accidents.

It is easy to make a suitable opening in the housing, and cover it with mesh, to allow circulation, and prevent accidents.

Slowly realizing that for instance asking how to drive to the airport will result in tips for best food, what airplanes can be found, what temperature it is and how beautiful the local girls are.

This device has been produced and sold in the USA and probably in numbers, it should simply function "as is" whether the US brand that made the transformers had them wound in China or not. First finding the defect (root cause analysis) and a solution to make it in nominal state. Please. Then we can add water cooling, fans and whatnot.

This device has been produced and sold in the USA and probably in numbers, it should simply function "as is" whether the US brand that made the transformers had them wound in China or not. First finding the defect (root cause analysis) and a solution to make it in nominal state. Please. Then we can add water cooling, fans and whatnot.

Last edited:

The type of transformer is known to run hot. It is recommended for use in HVAC and or industrial type applications. The application is this case seems more like its in sealed consumer equipment located inside human occupied living space. Doesn't seem like that is what it was intended for.

Therefore, I would vote for trying a louvered metal case or something with at least some safe airflow.

Other than that, haven't we already established that load current is in the range from low to zero? Also that line voltage is stable and within specifications?

What else is there to check? Anyone care to make a list?

Therefore, I would vote for trying a louvered metal case or something with at least some safe airflow.

Other than that, haven't we already established that load current is in the range from low to zero? Also that line voltage is stable and within specifications?

What else is there to check? Anyone care to make a list?

How about the Hammond Manufacturing energy limiting, 24V 40VA plug-in style transformer BPE2G, made installation quick and easy! It can plug into a outlet nearby and no ventilation issue.

https://www.digikey.com/en/htmldatasheets/production/69419/0/0/1/bpd2g.html

https://www.digikey.com/en/htmldatasheets/production/69419/0/0/1/bpd2g.html

Last edited:

A licensed engineer would be required to report to the manufacturer any design defects found. This is called “Discharge of Duty.”

If the end bells are plastic as has been shown by someone else then if I had first hand knowledge I would be sending a registered letter including a description of the problem, meter readings and photographs.

Next I would expect someone showing up to confirm and repair things.

In the USA I would expect any gear to work with AC line voltages from 110 to 135 VAC RMS.

If the end bells are plastic as has been shown by someone else then if I had first hand knowledge I would be sending a registered letter including a description of the problem, meter readings and photographs.

Next I would expect someone showing up to confirm and repair things.

In the USA I would expect any gear to work with AC line voltages from 110 to 135 VAC RMS.

Having worked for a US company I suggest rewiring the home by certified and licensed technicians. New breakers too. A new utility transformer might be worthwhile together with a diesel generator as brownouts and blackouts are an everyday risk. Of course as built drawings and discrimation studies are required. Lightning protection with UL approved equipment would be mandatory just as a LMRA before every step in the reversible process. All with preapproved method statement. And … safety first!

Last edited:

jean-paul,

In the USA it is common for an inspection of the electrical system to be done when the property is being sold. However it is not mandatory.

Lightning protection is still optional. Where I live a lightning surge on the AC power wiring did occur. It actually damaged two of my Ground Fault Interrupter outlets. I then added an incoming service surge suppressor, never having had such a problem before that. I don’t think you can even find a surge suppressor sold without UL approval.

The utility company changed the feed to my entire neighborhood after that happened. Also the utility transformer is owned by the utility not the residential user.

Around where I live backup generators are powered by natural gas. It is available even when the electricity service has failed. This is preferred as liquid fuel can go bad in storage, requires additional storage safety and should have regular safety inspections.

The issue with a backup generator is that when the main AC power has failed, your darkened neighbors for some reason seem to be quite irritated by the noise! I think I have mentioned I use lead acid batteries and a power inverter to keep vital power available without my neighbors hearing anything.

But I think you have raised quite reasonable issues.

In the USA it is common for an inspection of the electrical system to be done when the property is being sold. However it is not mandatory.

Lightning protection is still optional. Where I live a lightning surge on the AC power wiring did occur. It actually damaged two of my Ground Fault Interrupter outlets. I then added an incoming service surge suppressor, never having had such a problem before that. I don’t think you can even find a surge suppressor sold without UL approval.

The utility company changed the feed to my entire neighborhood after that happened. Also the utility transformer is owned by the utility not the residential user.

Around where I live backup generators are powered by natural gas. It is available even when the electricity service has failed. This is preferred as liquid fuel can go bad in storage, requires additional storage safety and should have regular safety inspections.

The issue with a backup generator is that when the main AC power has failed, your darkened neighbors for some reason seem to be quite irritated by the noise! I think I have mentioned I use lead acid batteries and a power inverter to keep vital power available without my neighbors hearing anything.

But I think you have raised quite reasonable issues.

I would suggest you give these people a call WRT this device or similar / smaller: https://www.functionaldevices.com/product/tr100va001/

The data sheet states operation in -30 to 140F environment. It is fully specced for 50/60Hz operation and what this means is that at 60Hz (US) the core will be running

around 0.85 less magnetization than 50 = at least some assurance of reliability. Circuit breaker + all approvals and metal end bells.

They may be able to advise someone to do the very easy installation.

The data sheet states operation in -30 to 140F environment. It is fully specced for 50/60Hz operation and what this means is that at 60Hz (US) the core will be running

around 0.85 less magnetization than 50 = at least some assurance of reliability. Circuit breaker + all approvals and metal end bells.

They may be able to advise someone to do the very easy installation.

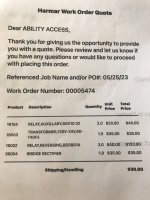

You guys suggestion conversion to DC may not have been too far off. Attached are pictures of the control panel of a newer version of the same lift, the one I'm thinking of getting for out backyard. I also attached a pictures of the part list for that unit:

2 - auxiliary relays (I think for gate controls or lights, I can't identify them in the pictures)

1 - transformer (Identical to the one in my lift)

3 - relays (Just like mine, UP, DOWN, POWER RELAY)

1 - Bridge Rectifier (!?!) I'm assuming it's part of the unit in the upper right side of the control box, has red trim piece and high voltage warning. Although, if you look closely at the picture, you can see another transformer in that unit.

I'm going to try and get more info. on this unit. I'm a little worried about the amount of oxidation on the control panel, I'm assuming this was used outside or stored outside for a while. It works. If I can work a deal with one set of spare parts I may be good after a thorough cleaning.

I found a version of this on e-Bay, it looks like new but it's in New York and I'm in CA.

Thanks,

Eric

2 - auxiliary relays (I think for gate controls or lights, I can't identify them in the pictures)

1 - transformer (Identical to the one in my lift)

3 - relays (Just like mine, UP, DOWN, POWER RELAY)

1 - Bridge Rectifier (!?!) I'm assuming it's part of the unit in the upper right side of the control box, has red trim piece and high voltage warning. Although, if you look closely at the picture, you can see another transformer in that unit.

I'm going to try and get more info. on this unit. I'm a little worried about the amount of oxidation on the control panel, I'm assuming this was used outside or stored outside for a while. It works. If I can work a deal with one set of spare parts I may be good after a thorough cleaning.

I found a version of this on e-Bay, it looks like new but it's in New York and I'm in CA.

Thanks,

Eric

Attachments

- Home

- General Interest

- Everything Else

- Need Some Advice Regarding a Handicap Lift, Odd Transformer Issue