Same fullrange driver in a bigger wooden enclosure with concrete inside making the box stable.

https://www.diyaudio.com/community/threads/are-cardboard-enclosures-any-good.394837/post-7719815

https://www.diyaudio.com/community/threads/are-cardboard-enclosures-any-good.394837/post-7719815

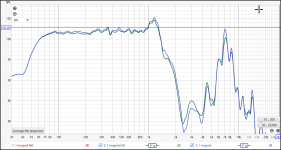

Measurements of 15cm fullrange driver with one sided aluminium foil (to be seen too in post one in this thread)

https://www.diyaudio.com/community/...ed-to-off-the-shelf-stuff.414702/post-7730931

https://www.diyaudio.com/community/...ed-to-off-the-shelf-stuff.414702/post-7730931

Reminiscence to KEF sandwich loudspeaker Celeste:

aluminium foil - polystyrol - aluminium foil

with B139 in 1962

aluminium foil - polystyrol - aluminium foil

with B139 in 1962

Attachments

Dr. Kurt Müller on the availability of sandwich cones for loudspeaker production, downloaded 14 08 2024

@Freedom666: Thanks for sharing all this information.

I get why other mention they like to see more before/after measurements. Me too.

I don’t like the general trend of untreated cone. Yes they may sound more lively, but not my taste. On every driver I have tried with paper cone, I have heard improvement with felt dots on the cone.

I think maybe this water based glue is OK alternative to the one you use:

https://www.casco.dk/da/reparations-hobbylim/toj-og-sko/casco-universal-aqua.html

I will try for myself.

Subjectively how much stiffer would you say the cone get with your mod?

I get why other mention they like to see more before/after measurements. Me too.

I don’t like the general trend of untreated cone. Yes they may sound more lively, but not my taste. On every driver I have tried with paper cone, I have heard improvement with felt dots on the cone.

I think maybe this water based glue is OK alternative to the one you use:

https://www.casco.dk/da/reparations-hobbylim/toj-og-sko/casco-universal-aqua.html

I will try for myself.

Subjectively how much stiffer would you say the cone get with your mod?

@Rokytheman

Nice to hear you want to try for yourself.

If you have equipment to measure, do it.

So there would be second opinion and independent testing, even more respectable if I add another measurement to the ones I did already.

I gave some measurements here mainly burst decay before after what I find most interesting.

If you want you can do distortion measurements, before and after.

Can you tell me more exactly how your modification works?

Or do you have foto(s)?

Aluminum tweak adds a lot of stability to the cone, D.A. Barlow stated a 200x improvement with a thick polystyrol core and duraluminium sheets.

In my eyes thinner household aluminium foil on paper cones works better for fullrange drivers.

Paper adds damping - giving a less stiff but better damped core. And mellow aluminium is less prone to resonances.

I would be lucky if my alu paper alu sandwich gives 20x more stiffness.

I can tell from a listening test that a one sided covered with aluminium foil fullrange paper cone sounded better to me than the Mini Leak sandwich loudspeakers I own. But this was a subjective test.

So I am looking forward to your test.

You can do one driver first and make an A / B listening test with the second untuned driver.

You can also record music played on the loudspeakers one after the other for a comparison everyone can DIY listen to at home with a good headphone.

Nice to hear you want to try for yourself.

If you have equipment to measure, do it.

So there would be second opinion and independent testing, even more respectable if I add another measurement to the ones I did already.

I gave some measurements here mainly burst decay before after what I find most interesting.

If you want you can do distortion measurements, before and after.

Can you tell me more exactly how your modification works?

Or do you have foto(s)?

Aluminum tweak adds a lot of stability to the cone, D.A. Barlow stated a 200x improvement with a thick polystyrol core and duraluminium sheets.

In my eyes thinner household aluminium foil on paper cones works better for fullrange drivers.

Paper adds damping - giving a less stiff but better damped core. And mellow aluminium is less prone to resonances.

I would be lucky if my alu paper alu sandwich gives 20x more stiffness.

I can tell from a listening test that a one sided covered with aluminium foil fullrange paper cone sounded better to me than the Mini Leak sandwich loudspeakers I own. But this was a subjective test.

So I am looking forward to your test.

You can do one driver first and make an A / B listening test with the second untuned driver.

You can also record music played on the loudspeakers one after the other for a comparison everyone can DIY listen to at home with a good headphone.

I have wide rolls of self-adhesive 0.1mm Al and 0.06mm Cu as well as automotive stretchy plast. Will set up four 4" so-called drum-paper drivers for a test.

Even with small drivers there is a sonic difference.

Its not subtle.

With the thin quality from the goldsmith I have covered tweeter domes made of mylar and textile.

Its not subtle.

With the thin quality from the goldsmith I have covered tweeter domes made of mylar and textile.

Im waiting for glue to arrive. First I will check how good it sticks to Alu foil. My guess it will work fine. And maybe dry so fast I could even test the day after.

By felts I mean the ‘dots’ you can have for almost free in 100 pack meant to protect shelf’s and floor. Put under furniture. The weight of them is next to nothing. Generally they can be removed without any tear (Satori paper driver is exception. I found it ripped a bit).

To have it stick a bit less, you could place them on different material before you put them on driver.

Here is some testing with 5” midrange. Definitely remove some of the peak above 5 KHz. My guess is then applying glue + alu would improve it much more.

Next is Dayton RS225 Alu. I installed 4 felt dots on the backside. It definitely removed some ringing. Not night and day, but enough I installed felt on all 4 drivers. In 1-2 year they may fall off. Then I could apply fresh glue to the felt, and it would stick till they drivers give up.

Also added bucking magnet with double sided tape and then enough painters tape to adhere further and remove some of the sharp edges. And some hot glue because gut feeling told so (properly too hard to add any damping)

By felts I mean the ‘dots’ you can have for almost free in 100 pack meant to protect shelf’s and floor. Put under furniture. The weight of them is next to nothing. Generally they can be removed without any tear (Satori paper driver is exception. I found it ripped a bit).

To have it stick a bit less, you could place them on different material before you put them on driver.

Here is some testing with 5” midrange. Definitely remove some of the peak above 5 KHz. My guess is then applying glue + alu would improve it much more.

Next is Dayton RS225 Alu. I installed 4 felt dots on the backside. It definitely removed some ringing. Not night and day, but enough I installed felt on all 4 drivers. In 1-2 year they may fall off. Then I could apply fresh glue to the felt, and it would stick till they drivers give up.

Also added bucking magnet with double sided tape and then enough painters tape to adhere further and remove some of the sharp edges. And some hot glue because gut feeling told so (properly too hard to add any damping)

@Rokytheman

feel free to post.

Your tweak became known in germany by Bastani with fullrange drivers. Never tried it. Reminds me of whizzer cone tweaks with damping material.

If you try metal foil tweak don't forget to post, too.

feel free to post.

Your tweak became known in germany by Bastani with fullrange drivers. Never tried it. Reminds me of whizzer cone tweaks with damping material.

If you try metal foil tweak don't forget to post, too.

The glue have arrived: https://www.casco.dk/da/reparations-hobbylim/toj-og-sko/casco-universal-aqua.html

I guess this may be the same glue that Troels is using. Only he knows, and he decided to keep it a secret. I would say sharing is caring.

I sacrified a driver to check how the glue is to work with and how it behaves.

I feels about the same as PVA glue. I think less tendency to run. No nasty smell at all!

I admit it look like crap, but for testing is fine.

It is older driver and rather dirty. I tried if I could peel it of after 24H. I could (left side). After 48H it sticks MUCH better on the surround. And it is still soft and flexible. I guess not so soft that dust would adhere.

Plenty adhering to the alu-foil.

I guess this may be the same glue that Troels is using. Only he knows, and he decided to keep it a secret. I would say sharing is caring.

I sacrified a driver to check how the glue is to work with and how it behaves.

I feels about the same as PVA glue. I think less tendency to run. No nasty smell at all!

I admit it look like crap, but for testing is fine.

It is older driver and rather dirty. I tried if I could peel it of after 24H. I could (left side). After 48H it sticks MUCH better on the surround. And it is still soft and flexible. I guess not so soft that dust would adhere.

Plenty adhering to the alu-foil.

Attachments

Last edited:

Then some measurements of Drivers

Dayton RS225 Alu

0 magnet

1 magnet

3 magnet

O magnet

2 magnet

Then With and without felt:

I quess we could say resonances is just shifted, but on the other side I would say we have decent improvement from the cost of less than a dime.

Not sure if we can trust burst decay. I took it with standard measurement sweep. In all measurement it show reduction at marker:

1 magnet No felt:

1 magnet with felt:

I tested back and forth with magnet and with and without felt many times. Driver not bad as is, but I definetely prefer with added magnet and felt.

Then we have the midrange with felts on the dustcap. It is with felt like on picture above. For sure it would not stick for months before falling of.

Nearfield:

Mid Mic distance 20 cm no gating

Dayton RS225 Alu

0 magnet

1 magnet

3 magnet

O magnet

2 magnet

Then With and without felt:

I quess we could say resonances is just shifted, but on the other side I would say we have decent improvement from the cost of less than a dime.

Not sure if we can trust burst decay. I took it with standard measurement sweep. In all measurement it show reduction at marker:

1 magnet No felt:

1 magnet with felt:

I tested back and forth with magnet and with and without felt many times. Driver not bad as is, but I definetely prefer with added magnet and felt.

Then we have the midrange with felts on the dustcap. It is with felt like on picture above. For sure it would not stick for months before falling of.

Nearfield:

Mid Mic distance 20 cm no gating

Attachments

Last edited:

Then I thought what would happen if I add Tesa painters tape. 30 seconds later and a mindblowing result on the graph is to be seen.

Mod:

Change was so big that I did measurement backward. Ie new measurement. Then remove tape. Then measure again.

Change in frequency:

No tape impulse (impulse inverted. You could reverse your device 180 degree if it is better to the eye):

Iimpulse with tape:

Waterfall decay no tape:

With tape:

Mod:

Change was so big that I did measurement backward. Ie new measurement. Then remove tape. Then measure again.

Change in frequency:

No tape impulse (impulse inverted. You could reverse your device 180 degree if it is better to the eye):

Iimpulse with tape:

Waterfall decay no tape:

With tape:

Last edited:

isn't it that pieces of damping (here felt) depends on positioning for taming resonances and needs therefore lots of experimenting with it? So fotos of positioning would help.

Out of band changes in resonances of non fullrange drivers - where is the benefit?

Paper tape is just a quick try but would be theoretically interesting for taming resonances of full metal cones. However this tapes self adhesive glue dries and paper falls off after some time.

Once tried to dampen full metal cones with adding a thin film of elastic adhesive on the back side - but with not sufficient result.

So I sticked to good available paper cone fullranges tweaked with alu foil.

Anyone ever found out how to tame the bell like resonances of full metal cones effectively?

Ted Jordan et al were researching this for sure. But I have to admit I never tried listening to any of the descendants.

Out of band changes in resonances of non fullrange drivers - where is the benefit?

Paper tape is just a quick try but would be theoretically interesting for taming resonances of full metal cones. However this tapes self adhesive glue dries and paper falls off after some time.

Once tried to dampen full metal cones with adding a thin film of elastic adhesive on the back side - but with not sufficient result.

So I sticked to good available paper cone fullranges tweaked with alu foil.

Anyone ever found out how to tame the bell like resonances of full metal cones effectively?

Ted Jordan et al were researching this for sure. But I have to admit I never tried listening to any of the descendants.

I've read through your modifications for a while but I wanted to ask two critical questions.

1. What negative aspects have you encountered? I know, the spl is dropping a bit and so is the fs. I mean, that's to be expected. Did you measure any decay delay?

2. On which drivers you wouldn't recommend that treatment?

A (most likely) non critical question: Might it be we've met once in Möhrendorf? My name is Frank btw.

1. What negative aspects have you encountered? I know, the spl is dropping a bit and so is the fs. I mean, that's to be expected. Did you measure any decay delay?

2. On which drivers you wouldn't recommend that treatment?

A (most likely) non critical question: Might it be we've met once in Möhrendorf? My name is Frank btw.

1. Thin foil tweak is not critical at all concerning weight and negative influence on frequency response (loss of highs). Burst decay mostly shows at last slight advance. BUT the sound changes dramatically due to better impulse response, transients profit a lot.

Thick foil tweak can cause classic one resonance peak of hard(er) cones at a higher break up point (decay delay) what disappeared after linearization with dsp or analogue EQ.

2. I do not recommend foil tweak on modern cones like glass fiber, polypropylen, kevlar et al.

Tried only on polyprop thin foil tweak but it does not change much.

Moehrendorf does not tell me anything now. Was there a hifi event?

Thick foil tweak can cause classic one resonance peak of hard(er) cones at a higher break up point (decay delay) what disappeared after linearization with dsp or analogue EQ.

2. I do not recommend foil tweak on modern cones like glass fiber, polypropylen, kevlar et al.

Tried only on polyprop thin foil tweak but it does not change much.

Moehrendorf does not tell me anything now. Was there a hifi event?

If it doesn't ring a bell for you, then you were probably not the one who I've met there. You would have remembered me after the IRC chats. A Night at the Roxbury 😉 It was about a measurement seminar. Doesn't matter, I just thought you might be one of the guys I've met there. Nidda isn't THAT far away, so I thought you might have been there.

Polyproplen is very difficult to glue, you essentially have to dissolve the surface for it. so that's not a good or likely option anyway and hard cone materials will probably not profit from it much anyway. Thank you for the reply, I'll probably try it out soon but I have other plans before that. I have drivers that I can try this on, so even if I'm not satisfied with the result, I've not sacrifyced much. Thank you again for the reply.

Polyproplen is very difficult to glue, you essentially have to dissolve the surface for it. so that's not a good or likely option anyway and hard cone materials will probably not profit from it much anyway. Thank you for the reply, I'll probably try it out soon but I have other plans before that. I have drivers that I can try this on, so even if I'm not satisfied with the result, I've not sacrifyced much. Thank you again for the reply.

- Home

- Loudspeakers

- Full Range

- How to make a loudspeaker sandwich cone