@L.rivera92172

The piezo drivers really sound good. With high resolution.

Next time I do this modification I will make a waterfall measurement.

Makes me curious

The piezo drivers really sound good. With high resolution.

Next time I do this modification I will make a waterfall measurement.

Makes me curious

Feedback on the use of a new type for glue for the thin foil from the goldsmith.

Easier work with methylcellulose - its the glue used for wallpapers.

It has less damping properties than the "Anlegemilch" usually used for thin foil metals but its easier to work with and tidier work is possible.

It has stiffening properties.

Here I tried it on piezo drivers. Will measure if there is a benefit using sandwich technology on piezo paper cones.

Easier work with methylcellulose - its the glue used for wallpapers.

It has less damping properties than the "Anlegemilch" usually used for thin foil metals but its easier to work with and tidier work is possible.

It has stiffening properties.

Here I tried it on piezo drivers. Will measure if there is a benefit using sandwich technology on piezo paper cones.

Attachments

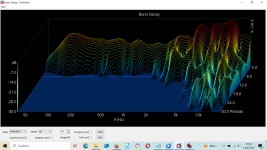

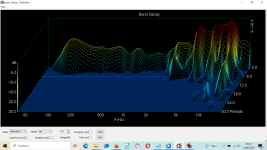

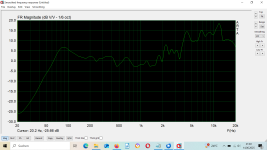

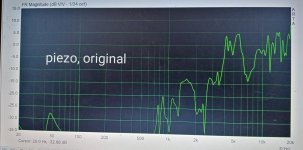

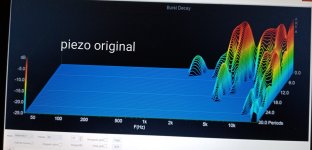

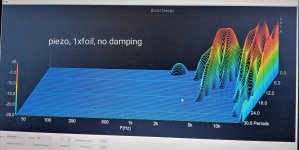

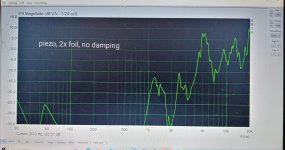

made a series of measurements

Arta f response and waterfall

4 no name piezos and one

Monacor MPT-142

all have filter:

12 ohm in line 1uF in line, 91 ohm across plus and minus on the driver

no name piezos

1 driver original

2nd driver 1x alu foil

3rd driver 2x alu foil - sandwich

4th driver 2x alu foil + damped cavity with medical cotton

5th driver Monacor MPT142

2x foil plus damped cavity

Arta f response and waterfall

4 no name piezos and one

Monacor MPT-142

all have filter:

12 ohm in line 1uF in line, 91 ohm across plus and minus on the driver

no name piezos

1 driver original

2nd driver 1x alu foil

3rd driver 2x alu foil - sandwich

4th driver 2x alu foil + damped cavity with medical cotton

5th driver Monacor MPT142

2x foil plus damped cavity

Attachments

-

IMG_20250423_211449.jpg273.2 KB · Views: 107

IMG_20250423_211449.jpg273.2 KB · Views: 107 -

IMG_20250423_211647.jpg226.3 KB · Views: 106

IMG_20250423_211647.jpg226.3 KB · Views: 106 -

IMG_20250423_211002.jpg286.9 KB · Views: 102

IMG_20250423_211002.jpg286.9 KB · Views: 102 -

IMG_20250423_211102.jpg364.4 KB · Views: 106

IMG_20250423_211102.jpg364.4 KB · Views: 106 -

IMG_20250423_212427.jpg285.7 KB · Views: 104

IMG_20250423_212427.jpg285.7 KB · Views: 104 -

IMG_20250423_213018.jpg221.6 KB · Views: 112

IMG_20250423_213018.jpg221.6 KB · Views: 112 -

IMG_20250423_212609.jpg287.3 KB · Views: 112

IMG_20250423_212609.jpg287.3 KB · Views: 112 -

IMG_20250423_213147.jpg314.6 KB · Views: 110

IMG_20250423_213147.jpg314.6 KB · Views: 110 -

IMG_20250423_213501.jpg212.2 KB · Views: 109

IMG_20250423_213501.jpg212.2 KB · Views: 109 -

IMG_20250423_213648.jpg390.1 KB · Views: 105

IMG_20250423_213648.jpg390.1 KB · Views: 105

especially on piezo cones the cone stiffening foil raises resonance frequency. Due to the lack of a real suspension.

The suspension was not covered with foil.

The quality piezo MPT142 shows better linearity.

Very effective is the damping of the cavity with medical cotton

The suspension was not covered with foil.

The quality piezo MPT142 shows better linearity.

Very effective is the damping of the cavity with medical cotton

Attachments

if bandwidth is important in a piezo project I would damp it only thinly with silicone sealant (no cone stiffening).

This should not raise the resonance frequency.

This should not raise the resonance frequency.

now the drivers from post 3 came to use in the doors of a VW Touran car

thin foil from the goldsmith.

Defect driver replaced

thin foil from the goldsmith.

Defect driver replaced

Attachments

loudspeaker from post 150 got protection grill.

Will make a RCL filter for the +15db peak at 1.8khz.

Simulation shows for a test 15uF, 0.37mh and 10 to 20 ohms for taming that unpleasant peak

Will make a RCL filter for the +15db peak at 1.8khz.

Simulation shows for a test 15uF, 0.37mh and 10 to 20 ohms for taming that unpleasant peak

Attachments

in a previous design I put the tweeter concentric in front of the driver. Always sounds good like this.

This time I put it above the fullrange driver.

Turning the box shows the highs sound better integrated with the tweeter at the side, so distance to the ear changes for better.

This time I put it above the fullrange driver.

Turning the box shows the highs sound better integrated with the tweeter at the side, so distance to the ear changes for better.

Attachments

made a listening test with metal instruments and cymbals.

The aluminized piezo tweeters show with well damped back cavity and proper 6db filtering an attack and "speed" rarely heard. I am quite impressed how well they can sound if used correctly.

The aluminized piezo tweeters show with well damped back cavity and proper 6db filtering an attack and "speed" rarely heard. I am quite impressed how well they can sound if used correctly.

just because someone on the internets says a piano prelude sounds buzzy like a piano should. Op, you had.....You do exactly the same thing regarding listening experience

@ruba1

completely true.

But giving a hint makes me not worse than the others?

If you recommend something without a proof (like measurements) is it by force worthless?

You must know I made in this thread a series of measurements of the modified piezo drivers. Now I just give a feedback on how they perform.

Anything wrong here?

completely true.

But giving a hint makes me not worse than the others?

If you recommend something without a proof (like measurements) is it by force worthless?

You must know I made in this thread a series of measurements of the modified piezo drivers. Now I just give a feedback on how they perform.

Anything wrong here?

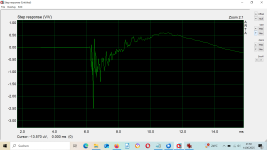

promised to make some measurement of the Fane 15 300tc.

It is sandwich aluminized, double cones are one sided.

damped 70 liter polypropylen box.

But I think I will house them one day in nice wooden boxes.

measured in near field 20cm on axis outside, so no walls only on the floor.

no tweeter active here!

First listening test - its needs with this F response close walls maybe even corner placement and a FBQ 1502 from Behringer won't hurt.

Burst decay is in 25 db but because of the rising response I show 35 db too, to see the mids.

Nice clean mids up to 2khz.

Then the double cones are contributing a bit resonant.

It is sandwich aluminized, double cones are one sided.

damped 70 liter polypropylen box.

But I think I will house them one day in nice wooden boxes.

measured in near field 20cm on axis outside, so no walls only on the floor.

no tweeter active here!

First listening test - its needs with this F response close walls maybe even corner placement and a FBQ 1502 from Behringer won't hurt.

Burst decay is in 25 db but because of the rising response I show 35 db too, to see the mids.

Nice clean mids up to 2khz.

Then the double cones are contributing a bit resonant.

Attachments

Are the burst measurement pre and after the treatment? Difficult to compare - vertical spans are different. Are there any pre-and-after frequency response measurements (with the same smoothing applied)?promised to make some measurement of the Fane 15 300tc.

It is sandwich aluminized, double cones are one sided.

Last edited:

@Sonce

here not until now. but i have a pair of untreated cones and will measure them one day too.

If I find out how steps from arta works will try distortion measurements

from other cones there are pre and post measurements. From piezo tweeters, too. Burst decay shows that alu foil treatment can reduce resonances. Just search the thread. Because people ask without looking for it I reposted it already.

here not until now. but i have a pair of untreated cones and will measure them one day too.

If I find out how steps from arta works will try distortion measurements

from other cones there are pre and post measurements. From piezo tweeters, too. Burst decay shows that alu foil treatment can reduce resonances. Just search the thread. Because people ask without looking for it I reposted it already.

Yes, I am aware of your previous measurements of other drivers, including piezo. I was asking only about Fane 15 300TC.from other cones there are pre and post measurements. From piezo tweeters, too. Burst decay shows that alu foil treatment can reduce resonances. Just search the thread.

- Home

- Loudspeakers

- Full Range

- How to make a loudspeaker sandwich cone