Hello,

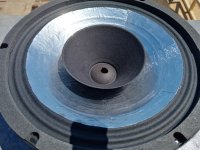

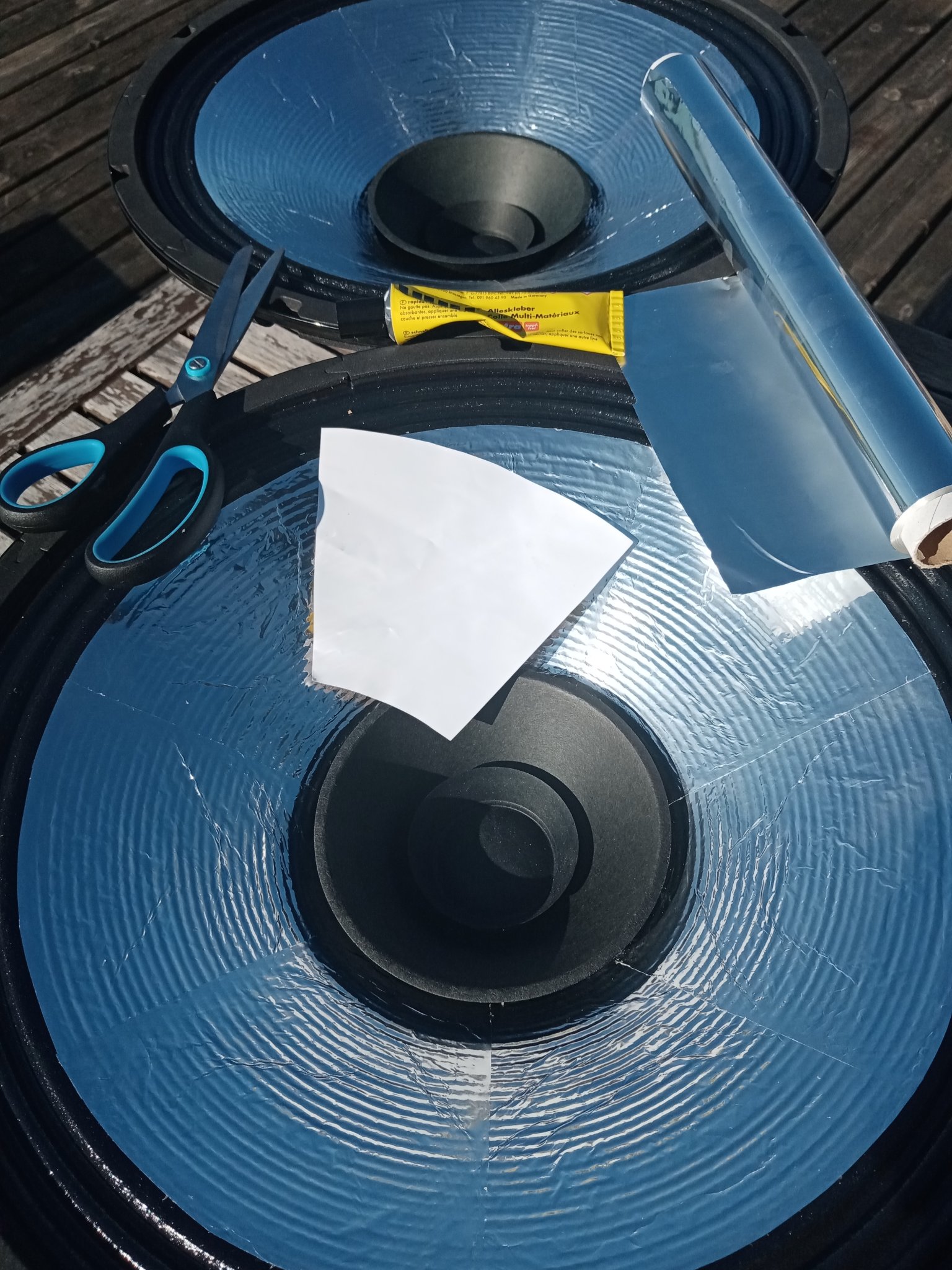

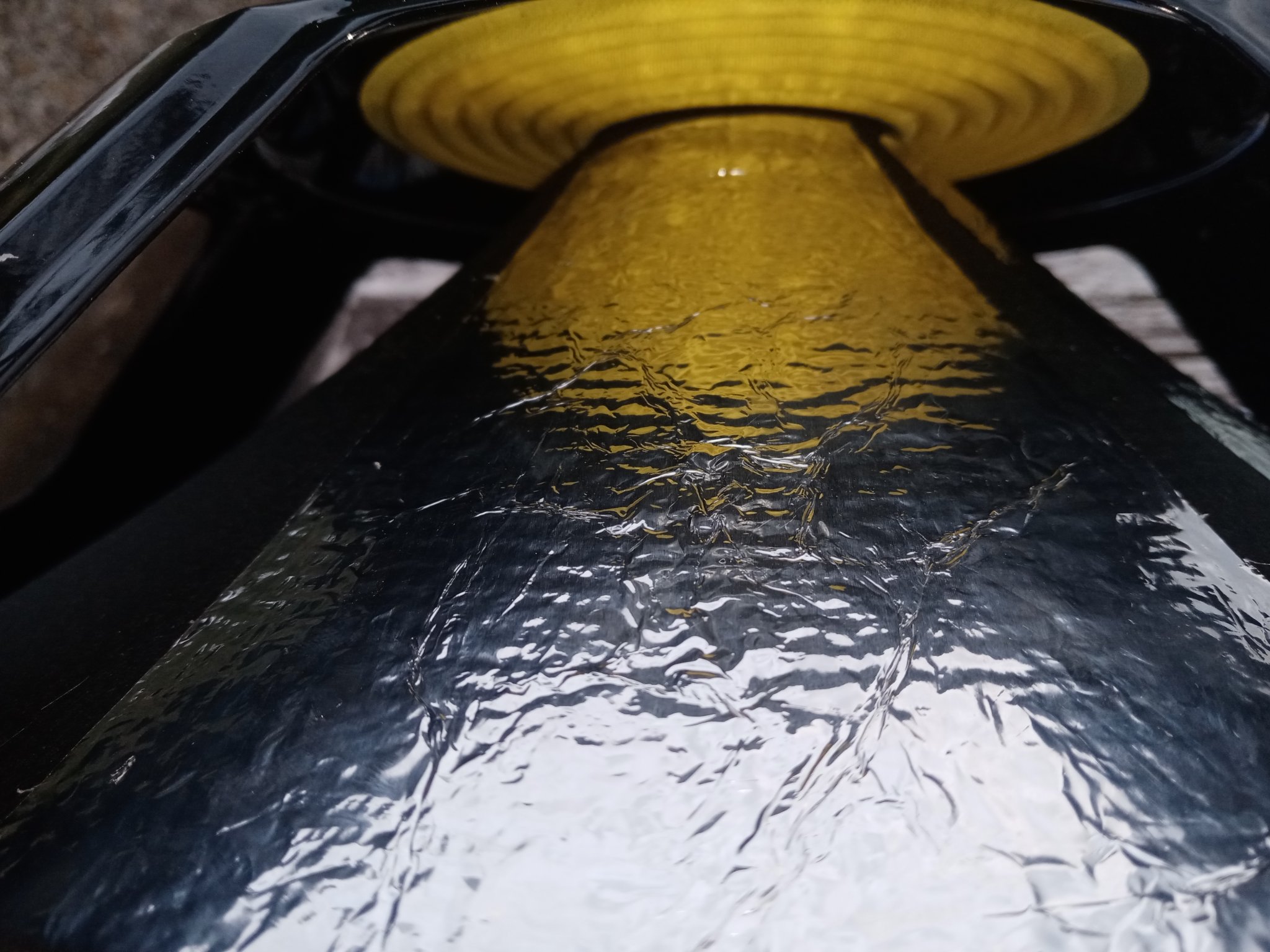

here I want to describe how I do make a sandwich cone with aluminium foil.

This can be done with normal household aluminium foil and normal glue you can buy everywhere as "universal glue".

You need a scissor and the materials like aluminium foil, glue and the loudspeaker.

The foil can be applied easily to paper cones / diaphragms.

You can use thin aluminium foil from the gold smith and the glue they sell (in german "Anlegemilch") for making sandwich cones with polypropylene loudspeaker cones as here normal glue will not work. Also for delicate whizzer cones the thin aluminium foil from the goldsmith will be a better choice.

More information on this concerning loudspeaker history and theory in this thread and my post:

https://www.diyaudio.com/community/...cone-speaker-cone-profile.402470/post-7432593

here I want to describe how I do make a sandwich cone with aluminium foil.

This can be done with normal household aluminium foil and normal glue you can buy everywhere as "universal glue".

You need a scissor and the materials like aluminium foil, glue and the loudspeaker.

The foil can be applied easily to paper cones / diaphragms.

You can use thin aluminium foil from the gold smith and the glue they sell (in german "Anlegemilch") for making sandwich cones with polypropylene loudspeaker cones as here normal glue will not work. Also for delicate whizzer cones the thin aluminium foil from the goldsmith will be a better choice.

More information on this concerning loudspeaker history and theory in this thread and my post:

https://www.diyaudio.com/community/...cone-speaker-cone-profile.402470/post-7432593

Attachments

-

IMG_20221227_224125.jpg425.8 KB · Views: 623

IMG_20221227_224125.jpg425.8 KB · Views: 623 -

IMG_20221227_230836.jpg553.7 KB · Views: 484

IMG_20221227_230836.jpg553.7 KB · Views: 484 -

IMG_20221227_230629.jpg498.6 KB · Views: 493

IMG_20221227_230629.jpg498.6 KB · Views: 493 -

IMG_20221227_225115.jpg631.5 KB · Views: 485

IMG_20221227_225115.jpg631.5 KB · Views: 485 -

IMG_20221227_224731.jpg633.3 KB · Views: 479

IMG_20221227_224731.jpg633.3 KB · Views: 479 -

IMG_20221227_224420.jpg672.7 KB · Views: 487

IMG_20221227_224420.jpg672.7 KB · Views: 487 -

IMG_20221227_224255.jpg623.3 KB · Views: 478

IMG_20221227_224255.jpg623.3 KB · Views: 478 -

IMG_20221227_224058.jpg578.2 KB · Views: 480

IMG_20221227_224058.jpg578.2 KB · Views: 480 -

IMG_20221227_224506.jpg527.1 KB · Views: 515

IMG_20221227_224506.jpg527.1 KB · Views: 515 -

IMG_20221227_225057.jpg621.4 KB · Views: 491

IMG_20221227_225057.jpg621.4 KB · Views: 491 -

IMG_20221227_233925.jpg685.8 KB · Views: 501

IMG_20221227_233925.jpg685.8 KB · Views: 501 -

IMG_20221227_225457.jpg616.1 KB · Views: 492

IMG_20221227_225457.jpg616.1 KB · Views: 492 -

IMG_20221227_225543.jpg390.1 KB · Views: 502

IMG_20221227_225543.jpg390.1 KB · Views: 502

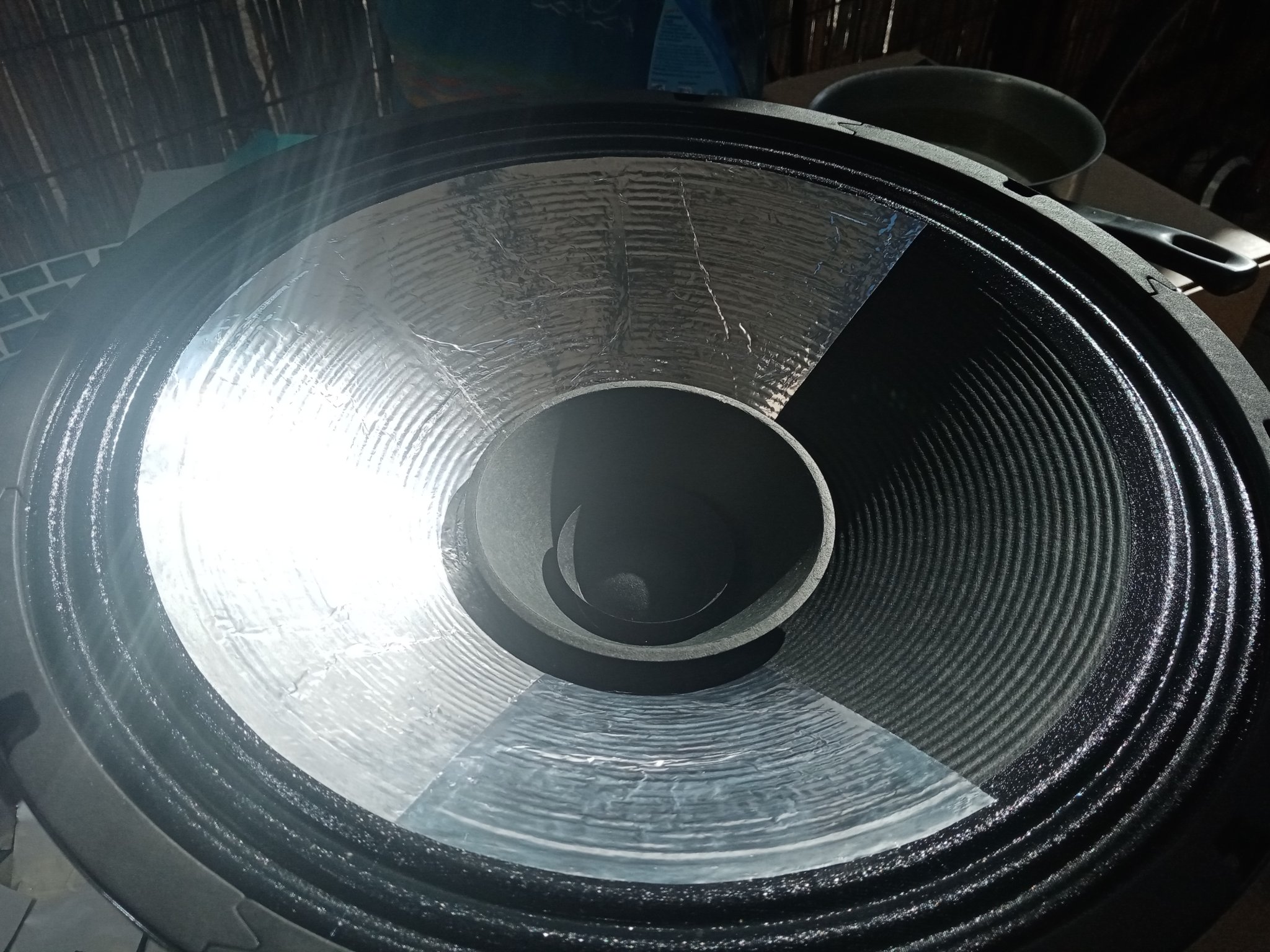

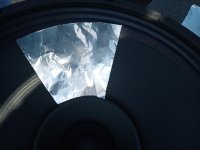

The backside of the cone is more difficult to access - but you can do it DIY.

You can cover the complete backside or only the area you are able to access.

With more experience you can reach all places - also on the back side but it needs some practice.

Here you see a Beyma 8 ag/n driver.

You can cover the complete backside or only the area you are able to access.

With more experience you can reach all places - also on the back side but it needs some practice.

Here you see a Beyma 8 ag/n driver.

Attachments

Here you can see a more delicate work with thin foil from the goldsmith.

In german this metal foil is call "Schlagmetall" - means "beaten metal".

Correctly they call it "beaten aluminium" - in german "Schlagaluminium".

The driver has been tweaked / tuned with a double magnet and a little paper box filled with dry sand on its back working against resonances of the driver.

The dustcap was ventilated with a hot soldering iron.

Here you can see the work with this thin aluminium foil on a tweeter in a PA loudspeaker - its worth to watch the complete thread written by me to see how I did the sandwich Diy work on a big driver.

https://www.diyaudio.com/community/threads/tuning-tweaking-of-bp-115-a.375464/page-2#post-7403173

In german this metal foil is call "Schlagmetall" - means "beaten metal".

Correctly they call it "beaten aluminium" - in german "Schlagaluminium".

The driver has been tweaked / tuned with a double magnet and a little paper box filled with dry sand on its back working against resonances of the driver.

The dustcap was ventilated with a hot soldering iron.

Here you can see the work with this thin aluminium foil on a tweeter in a PA loudspeaker - its worth to watch the complete thread written by me to see how I did the sandwich Diy work on a big driver.

https://www.diyaudio.com/community/threads/tuning-tweaking-of-bp-115-a.375464/page-2#post-7403173

Attachments

Here some loudspeakers I did this aluminium tweaking - tuning which can be done by yourself.

You see: 18 inch bass driver with aluminium foil for sauna construction - approximately 3x thicker than household aluminium foil.

10cm car hifi driver

Saba Greencones with aluminized cones

A round loudspeaker sphere with alu foiled drivers.

You see: 18 inch bass driver with aluminium foil for sauna construction - approximately 3x thicker than household aluminium foil.

10cm car hifi driver

Saba Greencones with aluminized cones

A round loudspeaker sphere with alu foiled drivers.

Attachments

Measurements show that the frequency response does change but not so much as expected.

The biggest change concerns stability of the cone and therefore impulse response becomes better and resonances are tamed.

This can be easily tested in an A / B listening test tweaking first only one driver and then make a comparison with the balance knob on your amplifier and a mono recording changing fastly from A to B and back.

In my eyes aluminizing a cone is the most effective single tweak you can do DIY on a simple paper cone driver.

As the paper cone gives you damping this aluminium reduces resonances and makes the driver sound like much more expensive sandwich cones.

Here you see Fostex FE 208 sigma with aluminiumized dustcap

You can see on a small fullrange driver a copper / faraday ring on the pole piece - this reduces distortion and makes the high frequencies louder.

The biggest change concerns stability of the cone and therefore impulse response becomes better and resonances are tamed.

This can be easily tested in an A / B listening test tweaking first only one driver and then make a comparison with the balance knob on your amplifier and a mono recording changing fastly from A to B and back.

In my eyes aluminizing a cone is the most effective single tweak you can do DIY on a simple paper cone driver.

As the paper cone gives you damping this aluminium reduces resonances and makes the driver sound like much more expensive sandwich cones.

Here you see Fostex FE 208 sigma with aluminiumized dustcap

You can see on a small fullrange driver a copper / faraday ring on the pole piece - this reduces distortion and makes the high frequencies louder.

Attachments

-

beschichtete lautsprechermembran 2.jpg134.3 KB · Views: 294

beschichtete lautsprechermembran 2.jpg134.3 KB · Views: 294 -

schallzeile1ypjwg.jpg267.1 KB · Views: 280

schallzeile1ypjwg.jpg267.1 KB · Views: 280 -

schallzeile2i3kr2.jpg276.2 KB · Views: 274

schallzeile2i3kr2.jpg276.2 KB · Views: 274 -

schallzeile64lkkz.jpg236.3 KB · Views: 285

schallzeile64lkkz.jpg236.3 KB · Views: 285 -

schallzeile4tbjx3.jpg143.9 KB · Views: 303

schallzeile4tbjx3.jpg143.9 KB · Views: 303 -

schallzeile5objpb.jpg192.2 KB · Views: 295

schallzeile5objpb.jpg192.2 KB · Views: 295 -

schallzeile64lkkz.jpg236.3 KB · Views: 302

schallzeile64lkkz.jpg236.3 KB · Views: 302 -

beschichtete breitbänder.jpg115.4 KB · Views: 293

beschichtete breitbänder.jpg115.4 KB · Views: 293 -

beschichtete breitbänder 2.jpg124.5 KB · Views: 281

beschichtete breitbänder 2.jpg124.5 KB · Views: 281 -

beschichtete dustcap.jpg86.9 KB · Views: 270

beschichtete dustcap.jpg86.9 KB · Views: 270 -

beschichtete dustcap 2.jpg63.2 KB · Views: 284

beschichtete dustcap 2.jpg63.2 KB · Views: 284 -

beschichtet neu 1.jpg202.3 KB · Views: 291

beschichtet neu 1.jpg202.3 KB · Views: 291 -

beschichtet neu 2.jpg139.2 KB · Views: 279

beschichtet neu 2.jpg139.2 KB · Views: 279 -

beschichtet neu 3.jpg141.9 KB · Views: 279

beschichtet neu 3.jpg141.9 KB · Views: 279 -

beschichtet neu 4.jpg230.6 KB · Views: 291

beschichtet neu 4.jpg230.6 KB · Views: 291

18 inch bass project with one sided alu foil for more stability of big cones

Here you see more fotos and description - and the use of EQ for making a good suboofer

https://www.diyaudio.com/community/...ow-off-my-new-18in-build.365764/#post-6711139

Here you see more fotos and description - and the use of EQ for making a good suboofer

https://www.diyaudio.com/community/...ow-off-my-new-18in-build.365764/#post-6711139

Using full aluminim foil for a DIY whizzer cone

https://www.diyaudio.com/community/threads/how-to-make-a-whizzer-cone.398063/

Here the no name driver I was tweaking.

https://www.diyaudio.com/community/threads/how-to-make-a-whizzer-cone.398063/

Here the no name driver I was tweaking.

Attachments

Where to get thin aluminium foil as an example (=Noris Blattgold company, germany):

https://www.diyaudio.com/community/threads/full-range-pics.87174/post-7262291

Some measurements before / after putting foil:

https://www.diyaudio.com/community/threads/acoustic-research-ar-7.156828/post-7177968

Thin aluminium foil as a sandwich for a 12cm fullrange driver with later added faraday ring on pole piece - DIY - I call it "50 cent trick":

https://www.diyaudio.com/community/...fication-to-current-drive.389985/post-7197710

Sonab type loudspeaker "up firing" against a wall with aluminium paper aluminium DIY sandwich cone:

https://www.diyaudio.com/community/...-firing-speakers.121385/page-175#post-6707993

Some more fotos of sandwich cones:

https://www.diyaudio.com/community/threads/full-range-pics.87174/post-6711011

Dsp corrected fullrange driver sandwiched with aluminium foil of thick quality - with measurements:

https://www.diyaudio.com/community/...w-distortion-with-a-2-way.334757/post-6711184

A thread I started - How to remove a Dustcap here on DIY Audio Forum:

https://www.diyaudio.com/community/threads/how-to-remove-a-dustcap.397165/#post-7300018

https://www.diyaudio.com/community/threads/full-range-pics.87174/post-7262291

Some measurements before / after putting foil:

https://www.diyaudio.com/community/threads/acoustic-research-ar-7.156828/post-7177968

Thin aluminium foil as a sandwich for a 12cm fullrange driver with later added faraday ring on pole piece - DIY - I call it "50 cent trick":

https://www.diyaudio.com/community/...fication-to-current-drive.389985/post-7197710

Sonab type loudspeaker "up firing" against a wall with aluminium paper aluminium DIY sandwich cone:

https://www.diyaudio.com/community/...-firing-speakers.121385/page-175#post-6707993

Some more fotos of sandwich cones:

https://www.diyaudio.com/community/threads/full-range-pics.87174/post-6711011

Dsp corrected fullrange driver sandwiched with aluminium foil of thick quality - with measurements:

https://www.diyaudio.com/community/...w-distortion-with-a-2-way.334757/post-6711184

A thread I started - How to remove a Dustcap here on DIY Audio Forum:

https://www.diyaudio.com/community/threads/how-to-remove-a-dustcap.397165/#post-7300018

Sometimes there was the question if a sandwich cone is really necessary.

If you cover only one side - the front side - of a loudspeaker cone the sound becomes much better. I would guess you get already 80% of the possible sound.

With the second layer on the back side - as sandwich technology - the loudspeaker gets the maximum profit out of this tweak. This second layer is mostly audible in the bass.

Example of a classical fullrange for tube radios. Got an extra double magnet.

If you cover only one side - the front side - of a loudspeaker cone the sound becomes much better. I would guess you get already 80% of the possible sound.

With the second layer on the back side - as sandwich technology - the loudspeaker gets the maximum profit out of this tweak. This second layer is mostly audible in the bass.

Example of a classical fullrange for tube radios. Got an extra double magnet.

Attachments

Last edited:

I am a big fan of the Leak Sandwich loudspeakers

Some information on its construction:

https://www.hifi-wiki.de/index.php/Leak_Sandwich_600

https://www.hifisystemcomponents.com/forum/leak-sandwich_topic1121.html

https://44bx.com/leak/sandwich.html

Here from the forum - nice to find it!

https://www.diyaudio.com/community/threads/leak-sandwich-600-project.212632/

Some information on its construction:

https://www.hifi-wiki.de/index.php/Leak_Sandwich_600

https://www.hifisystemcomponents.com/forum/leak-sandwich_topic1121.html

https://44bx.com/leak/sandwich.html

Here from the forum - nice to find it!

https://www.diyaudio.com/community/threads/leak-sandwich-600-project.212632/

Attachments

Last edited:

I like this one

In the other photo, the immense stiffness of the Sandwich cone material is demonstrated by placing 100 half-pennies on it, and comparing it to paper cone material of the same weight with just one half-penny.

In the other photo, the immense stiffness of the Sandwich cone material is demonstrated by placing 100 half-pennies on it, and comparing it to paper cone material of the same weight with just one half-penny.

Putting household aluminium foil on Fane Sovereign 15-300tc aka FC-152F01-TC

Attachments

-

IMG_20230916_160904.jpg360.8 KB · Views: 233

IMG_20230916_160904.jpg360.8 KB · Views: 233 -

IMG_20230916_161426.jpg445 KB · Views: 256

IMG_20230916_161426.jpg445 KB · Views: 256 -

IMG_20230916_175111.jpg447.8 KB · Views: 241

IMG_20230916_175111.jpg447.8 KB · Views: 241 -

IMG_20230917_094256.jpg467.4 KB · Views: 244

IMG_20230917_094256.jpg467.4 KB · Views: 244 -

IMG_20230917_094846.jpg605.1 KB · Views: 237

IMG_20230917_094846.jpg605.1 KB · Views: 237 -

IMG_20230917_095032.jpg389.3 KB · Views: 245

IMG_20230917_095032.jpg389.3 KB · Views: 245 -

IMG_20230917_095043.jpg306 KB · Views: 235

IMG_20230917_095043.jpg306 KB · Views: 235 -

IMG_20230917_100143.jpg567.4 KB · Views: 239

IMG_20230917_100143.jpg567.4 KB · Views: 239 -

IMG_20230917_100155.jpg534.7 KB · Views: 240

IMG_20230917_100155.jpg534.7 KB · Views: 240

Last edited:

Now two Fane fullrange drivers are covered with metal foil. Whizzer cones will be done, too.

And the backside.

And the backside.

Attachments

First pics from the back side.

Ordered same size magnet for compensating efficiency loss due to more mass.

Ordered same size magnet for compensating efficiency loss due to more mass.

Attachments

Fostex FE208sigma old generation drivers (year 2000).

Cone with thin aluminium foil sandwich.

https://www.diyaudio.com/community/threads/full-range-speaker-photo-gallery.65061/post-7380591

Cone with thin aluminium foil sandwich.

https://www.diyaudio.com/community/threads/full-range-speaker-photo-gallery.65061/post-7380591

Some asked me if gold foil works.

Never tried it as it is technically worse than alu.

Bronze foil could be the choice and I tried it. Similar look to gold.

Never tried titan foil. Did not find thin enough quality and it is more difficult to work with.

Barlow used duraluminium sheets of thick quality. Works only for straight comes. Not for Navi ones.

I like the space age look of aluminum.

Never tried it as it is technically worse than alu.

Bronze foil could be the choice and I tried it. Similar look to gold.

Never tried titan foil. Did not find thin enough quality and it is more difficult to work with.

Barlow used duraluminium sheets of thick quality. Works only for straight comes. Not for Navi ones.

I like the space age look of aluminum.

- Home

- Loudspeakers

- Full Range

- How to make a loudspeaker sandwich cone