Finished Beyma 8 ag/n with aluminium sandwich cone.

Aluminized double / whizzer cone with thin foil from the gold smith.

Tinfoil on both sides of the cone

See also posts

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7443460

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7443479

The paper surround was treated with "Anlegemilch dick" (from the goldsmith) to make the paper less susceptible to humidity.

It adds also damping.

Aluminized double / whizzer cone with thin foil from the gold smith.

Tinfoil on both sides of the cone

See also posts

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7443460

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7443479

The paper surround was treated with "Anlegemilch dick" (from the goldsmith) to make the paper less susceptible to humidity.

It adds also damping.

Attachments

Been following with interest and just purchased a big 2" roll of 0.06mm copper-foil one-sided tape. I guess I just have to try it on enough different drivers (that I wouldn't cry over) to form conclusions. Earlier I used "plast" automotive stretchy tape quite successfully on fiberglass honeycomb and resin-coated carbon fiber (very) hard cones. But on a "coated drum paper" cone the plast (applied only to the back) failed to eliminate high-frequency peak(s)/unevenness. These "hard" drum-paper drivers already have superlative clarity and dynamic articulation/realism.

Is metal foil better suited to softer cones like wool or PP?

Is metal foil better suited to softer cones like wool or PP?

Yes, definitely.

Paper and household aluminium foil together minimize resonances.

Its documented here in the thread with waterfall (burst decay) measurements.

One sided covering securely minimizes resonances.

Just make an A / B test with one speaker modified and the other unmodified. The balance knob on the preamp helps to switch fast left to right and back.

However better use glue like Pattex or Uhu and aluminium foil. I do not know if self adhesive foil glues well enough.

Paper and household aluminium foil together minimize resonances.

Its documented here in the thread with waterfall (burst decay) measurements.

One sided covering securely minimizes resonances.

Just make an A / B test with one speaker modified and the other unmodified. The balance knob on the preamp helps to switch fast left to right and back.

However better use glue like Pattex or Uhu and aluminium foil. I do not know if self adhesive foil glues well enough.

The glue is only adding damping.

It does nothing for stability and velocity in the meterial.

At least the foil always has to be glued upon forming a constrained layer construction.

The metal foil is applied overlapping by some millimeters.

It does nothing for stability and velocity in the meterial.

At least the foil always has to be glued upon forming a constrained layer construction.

The metal foil is applied overlapping by some millimeters.

@wchang

I used the thin aluminum foil on pp (polypropylene) cones, too.

The "Anlegemilch" from Noris Blattgold Germany is on basis of Nitrocellulose, someone told me.

And it works well for PP cones, paper and wool cones, alike.

Copper foil will do like aluminum foil, technically there are only little differences.

It will have an alternative look.

I used the thin aluminum foil on pp (polypropylene) cones, too.

The "Anlegemilch" from Noris Blattgold Germany is on basis of Nitrocellulose, someone told me.

And it works well for PP cones, paper and wool cones, alike.

Copper foil will do like aluminum foil, technically there are only little differences.

It will have an alternative look.

Appreciate the info. When I landed in Beijing oh seventeen years ago I immediately concluded, China's #1 technology weakness was not chips etc but glue -- witness every tile-faced apartment or office building had (missing) patches. So I'd have to try ordering abroad and brave customs....

Concerning "Anlegemilch". (thin foil bonding)

For treating a whizzer cone like from Beyma 8 agn:

You first put one layer glue with the brush on the paper.

After short time you glue the thin aluminum from the gold smith with a fresh second layer of Anlegemilch glue.

This technique can be necessary on untreated paper absorbing fluids.

For treating a whizzer cone like from Beyma 8 agn:

You first put one layer glue with the brush on the paper.

After short time you glue the thin aluminum from the gold smith with a fresh second layer of Anlegemilch glue.

This technique can be necessary on untreated paper absorbing fluids.

Different than with working with thick(er) household aluminium foils with Uhu and Pattex on loudspeaker paper cones you apply the Anlegemilch glue only on the paper cone.

No glue is put on the thin foil from the gold smith - this foil is too fragile for applying glue on it.

One closer look at the treated paper surround of the cone. Two coats of Anlegemilch.

No glue is put on the thin foil from the gold smith - this foil is too fragile for applying glue on it.

One closer look at the treated paper surround of the cone. Two coats of Anlegemilch.

Attachments

Last edited:

Here an example for a quicker solution to putting household alufoil on a speaker cone. It's an eight inch driver with inverted dustcap.

You can cut the foil as one part. To reduce wrinkles you cut out 1/16 out of the circle.

The Fotos speak for themselves.

You can cut the foil as one part. To reduce wrinkles you cut out 1/16 out of the circle.

The Fotos speak for themselves.

Attachments

Some Fotos with better light.

Already one sided with alu tinfoil there is a great stiffening effect. Will be added as bass for the Beyma 8agn speakers. Used for an outdoor Bluetooth speaker.

Current driven amp with Lm1875 will be used as amplification.

Already one sided with alu tinfoil there is a great stiffening effect. Will be added as bass for the Beyma 8agn speakers. Used for an outdoor Bluetooth speaker.

Current driven amp with Lm1875 will be used as amplification.

Attachments

Please show before and after measurements for FR and distortion of your modifications.

@5th element

There are measurements to be found in this thread.

I did a lot of measurements. But have it archived somewhere. So not at hand.

Everyone can reproduce and test this foil tweak with own measurements with known conditions and equipment.

I have some measurements of already tweaked Fane Sovereign 15 300tc:

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7468487

There are plenty measurements with waterfall of the big Fane in another thread of the original driver.

Saba Greencones before and after:

https://www.diyaudio.com/community/threads/acoustic-research-ar-7.156828/post-7177968

Measurements of a 10 inch fullrange after DSP

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7464433

On what is to be expected from measurements

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7443469

There are measurements to be found in this thread.

I did a lot of measurements. But have it archived somewhere. So not at hand.

Everyone can reproduce and test this foil tweak with own measurements with known conditions and equipment.

I have some measurements of already tweaked Fane Sovereign 15 300tc:

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7468487

There are plenty measurements with waterfall of the big Fane in another thread of the original driver.

Saba Greencones before and after:

https://www.diyaudio.com/community/threads/acoustic-research-ar-7.156828/post-7177968

Measurements of a 10 inch fullrange after DSP

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7464433

On what is to be expected from measurements

https://www.diyaudio.com/community/...loudspeaker-sandwich-cone.402917/post-7443469

Third Bluetooth marble box about to be finished.

Alu-paper-alu sandwich cone.

Front of the cone is with aluminium household foil treated. Backside with thin foil from the gold smith.

Working with the thin foil is faster as the beaten aluminum delivered in books makes it easier to cut the foil in shapes.

Alu-paper-alu sandwich cone.

Front of the cone is with aluminium household foil treated. Backside with thin foil from the gold smith.

Working with the thin foil is faster as the beaten aluminum delivered in books makes it easier to cut the foil in shapes.

Attachments

None of those measurements are what I'm after. Detailed before and after frequency response plus harmonic distortion.

Public Adress loudspeaker with diy aluminium foil on piezo tweeters and alu foil sandwich on 15 inch fullrange driver

https://www.diyaudio.com/community/...ials-with-ragged-response.408887/post-7594037

https://www.diyaudio.com/community/...ials-with-ragged-response.408887/post-7594037

Restoring, tuning / tweaking of Leak Sandwich 600 loudspeaker:

https://www.diyaudio.com/community/...rebuild-and-th-parameters.408753/post-7598035

https://www.diyaudio.com/community/...rebuild-and-th-parameters.408753/post-7598035

A good book in german on loudspeakers is Götz Schwamkrug "Lautsprecher - Dichtung und Wahrheit", its from 1986.

PDF download here

http://www.einklang-audio.com/buch/dichtung_und_wahrheit.pdf

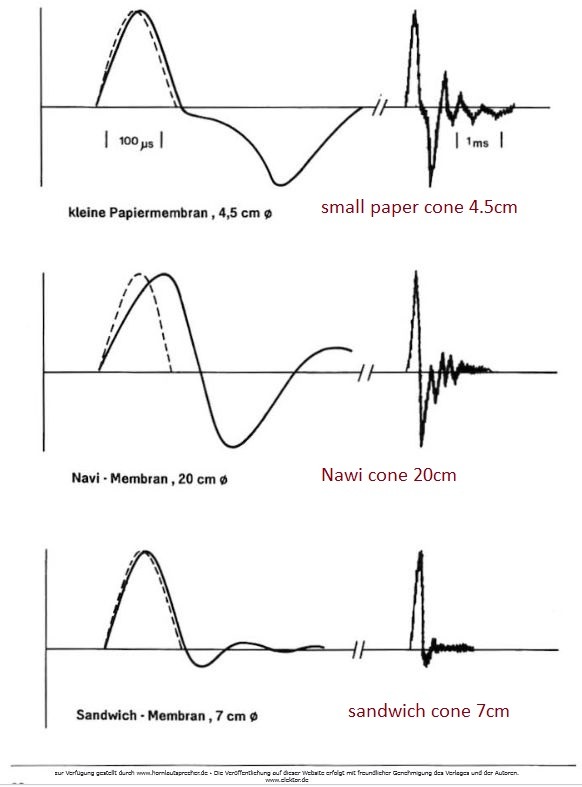

Concerning sandwich loudspeakers here some information, page 92 in the book, showing impulse responses in comparison:

small paper cone 4,5 cm, 20cm navi paper cone and 7 cm sandwich cone.

The 7cm sandwich cone has a better impulse response than the smaller 4.5 cm paper cone

Schwamkrugs second book "Lautsprecher Aufbau Nachbau Umbau" is very good, too.

PDF download here

http://www.einklang-audio.com/buch/dichtung_und_wahrheit.pdf

Concerning sandwich loudspeakers here some information, page 92 in the book, showing impulse responses in comparison:

small paper cone 4,5 cm, 20cm navi paper cone and 7 cm sandwich cone.

The 7cm sandwich cone has a better impulse response than the smaller 4.5 cm paper cone

Schwamkrugs second book "Lautsprecher Aufbau Nachbau Umbau" is very good, too.

- Home

- Loudspeakers

- Full Range

- How to make a loudspeaker sandwich cone