I suspect, the mass reduction by alu, CCA wires (related to copper) well masked by mass of necessary membrane coating (glue, for example). Did you ever measure the mass of glue on membrane? At the Magnepans seems dominating part the glue and the Milloxan. Furthermore this layer make better mechanical coupling between wire and undriven foil sections, gives a better high-frequency response (paradoxically). Perhaps the copper can be enough good (against its higher specific mass)?

Maybe your driven mass is too heavy for the magnets .Lack of control.

Have you tried to measure thiele small values .Too high Q value.

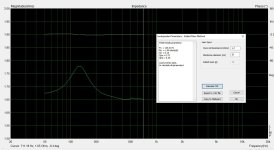

Underneeth here some measurements of my AMT´s . One with soft film PVDC Saran and one with mylar.

Might be different aluminium thickness too

Bernt Båndsei

Have you tried to measure thiele small values .Too high Q value.

Underneeth here some measurements of my AMT´s . One with soft film PVDC Saran and one with mylar.

Might be different aluminium thickness too

Bernt Båndsei

Attachments

Here’s an interesting dual sided diaphragm and most likely have a symmetrical magnet arrangement on both sides of the screen

When running double membranes you also have higher force factor pushing the air. So if you extend the baffle the bass response below 250Hz will increase.

So almost no adding cost you will get a huge bass boost with a wider and higher baffle.

I have tried it on ESL 63, important to NOT make a H frame rather a v shape where the baffle is pointing back wards.

So almost no adding cost you will get a huge bass boost with a wider and higher baffle.

I have tried it on ESL 63, important to NOT make a H frame rather a v shape where the baffle is pointing back wards.

Are you sure? At another side of magneted plate isn't useable induction, because the fluxlines close via steel plate. Perhaps the manufacturer takes one more magnet assembly to the plate. Or is this a prototype, and contains one membran behind the magnets (as at early Magnepans)?Here’s an interesting dual sided diaphragm and most likely have a symmetrical magnet arrangement on both sides of the screen

Joppe. What i mean is that you have good force factor and the membranes can handle higher load that you will get with a larger baffle. It is easy to try out...

When running double membranes you also have higher force factor pushing the air. So if you extend the baffle the bass response below 250Hz will increase.

So almost no adding cost you will get a huge bass boost with a wider and higher baffle.

I have tried it on ESL 63, important to NOT make a H frame rather a v shape where the baffle is pointing back wards.

So almost no adding cost you will get a huge bass boost with a wider and higher baffle.

I have tried it on ESL 63, important to NOT make a H frame rather a v shape where the baffle is pointing back wards.

It’s a .7 ohm series resistance right after the 240uf cap since the mid foil is only .1 ohmIt's not a sound emitting membrane. It's an alu-foil resistor to raise the impedance (Apogee Scintilla)

BR

Olaf

Better heat dissipation (surface area) than a typical high voltage resistor

What's this massive planar? I bet it’s somewhat pricey...🤑Here’s an interesting dual sided diaphragm and most likely have a symmetrical magnet arrangement on both sides of the screen View attachment 1308727

Oh it's their cheaper Model 😛

Nice craftmanship. The frame seems stable like a rock.

I like (except the horizontal bars at the front, they look somehow deplaced)

Nice craftmanship. The frame seems stable like a rock.

I like (except the horizontal bars at the front, they look somehow deplaced)

Last edited:

Im not sure but havent they just showed clarisys with out the magnets ?.

https://pbs.twimg.com/media/GLXFLKPb0AAZilT?format=jpg&name=large

https://pbs.twimg.com/media/GLXFLKPb0AAZilT?format=jpg&name=large

copper is a no go for top end , and i use alu tape. so there is no extra glue over everything. just the traces with glue underneithI suspect, the mass reduction by alu, CCA wires (related to copper) well masked by mass of necessary membrane coating (glue, for example). Did you ever measure the mass of glue on membrane? At the Magnepans seems dominating part the glue and the Milloxan. Furthermore this layer make better mechanical coupling between wire and undriven foil sections, gives a better high-frequency response (paradoxically). Perhaps the copper can be enough good (against its higher specific mass)?

nope i did not 🙁 but i am sure Q went up, well the whole thing was interesting but i think ill make a push pull as next panel. more expensive though but see how it plays when compared. it makes having lower res more easy and damping more easy and lower Q and more output, and l;ast but not least less coil making and stretching, downside.... priceMaybe your driven mass is too heavy for the magnets .Lack of control.

Have you tried to measure thiele small values .Too high Q value.

Underneeth here some measurements of my AMT´s . One with soft film PVDC Saran and one with mylar.

Might be different aluminium thickness too

Bernt Båndsei

Last edited:

true (thought about it ) but that beats the purpose a little bit 🙁 i would make it normal push pull if i need to use twice the magnets.If you would increase magnet strength you could do like this.

Bernt

- Home

- Loudspeakers

- Planars & Exotics

- Dual membrane planar magnetic (both active driven)