What a clever idea, Btsd, of DIY'ing the sinks! To get the back surface plain, I'd take them to an engine overhaul shop and ask them to put them at their cylinder head milling machine.

Best regards!

Thanks, I would like to take the credit for the idea but that came from the net. These are small enough 100x120mm to fit in my lathe and face the back of them. The next ones approx. 400x250mm will need to be taken out for machining the backs flat.

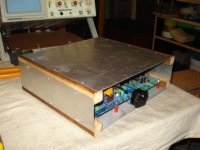

Another box. This one like the little ACA box is more a proof of building style type thing. All shed scraps. Not wasting what good timber and ally I have on an experiment.

Tony

Attachments

Last edited:

Hi Toni,

do they also sell in low numbers?

Best regards!

Small amounts seem to be no problem.

A few weeks ago I have ordered 21 pieces of small heatsinks for below Project - they needed to cut them to 60mm length (about EUR 135 total incl. taxes and shipping Europe):

raspberry pi4 passive cooler - heatpipe based

But not sure if they directly sell to consumers.

BR, Toni

Another box. This one like the little ACA box is more a proof of building style type thing. All shed scraps. Not wasting what good timber and ally I have on an experiment.

Tony[/QUOTE]

Nice work. From where do you get the circular mesh grilles?

Tony[/QUOTE]

Nice work. From where do you get the circular mesh grilles?

Excellent stuff everyone. I'm about to start work on an enclosure which will house a little 2.1 class D amp and a 24v power supply that i use to power a pair of Dayton RS100-4 Cyburg Needle Speakers I recently built. I'll likely upgrade the amp board sometime once i find a suitable one.

I'm going to be going with the sides of the enclosure made from Walnut, with an inset top that will be perforated aluminum. Probably the same for the bottom of it. And offset to one side in the front an inset aluminum panel which will have the knobs, etc. Should be a fun build. I love working with walnut. Has a great smell to it. lol.

Here's one of the speakers i built. Figured i'd stick with the wood theme.

I'm going to be going with the sides of the enclosure made from Walnut, with an inset top that will be perforated aluminum. Probably the same for the bottom of it. And offset to one side in the front an inset aluminum panel which will have the knobs, etc. Should be a fun build. I love working with walnut. Has a great smell to it. lol.

Here's one of the speakers i built. Figured i'd stick with the wood theme.

Attachments

Nice work. From where do you get the circular mesh grilles?

They look similar to these PC fan grills, only not black.

Hi Toni, this time i will built the house at the first. 😎You are welcome! Looks really good. 40 years ago I have brushed my aluminium front panels by hand using sand paper, water and only in one direction. Afterwards single adhesive letters. Finish using clear acryl paint.

Have fun, Toni

Then i will find the<< tenant>>.

Thanks again!

Regards.

Last edited:

Another box. This one like the little ACA box is more a proof of building style type thing. All shed scraps. Not wasting what good timber and ally I have on an experiment.

Tony

Nice work. From where do you get the circular mesh grilles?[/QUOTE]

I made them out of some fine stainless steel mesh I had sitting around for years.

I machined up a crude die for the hydraulic press to get the right shape and depth for the hole.

Tony

They do look very nice, although I prefer hardwoods for my tastes, try doing those shapes in metal.

I know many like the blank finish, offer both finishes 🙂 Not BPC 🙂

MDF?, wood? in close proximity (~1cm) to very hot glass tube envelopes? Over time? Smell?

I know many like the blank finish, offer both finishes 🙂 Not BPC 🙂

MDF?, wood? in close proximity (~1cm) to very hot glass tube envelopes? Over time? Smell?

Last edited:

Cases are open at the bottom with some mesh protection. With preamp tubes(low power) no heat problems or smell.

I have now in the same mdf enclosure with open bottom 2 x 400W class D amp and linear power supply . No problem with heat at all.

I have now in the same mdf enclosure with open bottom 2 x 400W class D amp and linear power supply . No problem with heat at all.

Sorry, I meant consumer..., private ...Hi Toni,

may I politely ask you, what makes you more than just a »customer« 😉?

Best regards!

I made them out of some fine stainless steel mesh I had sitting around for years.

I machined up a crude die for the hydraulic press to get the right shape and depth for the hole.

Tony[/QUOTE]

Thanks Tony

I machined up a crude die for the hydraulic press to get the right shape and depth for the hole.

Tony[/QUOTE]

Thanks Tony

Before the clear acryl paint do you apply any primer?You are welcome! Looks really good. 40 years ago I have brushed my aluminium front panels by hand using sand paper, water and only in one direction. Afterwards single adhesive letters. Finish using clear acryl paint.

Have fun, Toni

AFAIR I used a transparent matte acryl spray directly after lettering. The brushed aluminum has been made oil an grease free before lettering using soap and isopropyl alcohol.

I like the MDF enclosures as well. Would there be any advantage to lining a wood or MDF enclosure with aluminum foil tape or light aluminum sheets?

- Home

- Amplifiers

- Solid State

- Building your own amplifier enclosure