That's sort of why I made my woofer mounting plate an extended rectangle of the same internal width as the box - it will brace the horn and driver to the side of enclosure. The tricky thing is to make the thing disassemble-friendly. I think then baffle and horn will slip into the box and the side braces screwed on to allow diassambly later. Alternatively, access panels on top and bottom for drivers can be made but that is a pain. There is no way a single access panel from back alone will work - so the easiest is a removable front horn that pulls the entire innards out seems to be the way to go for me. (no box).

That is exactly the thought processes I have gone through.

I am going to have a completely removable front baffle and horn. The baffle will have a sorbothane gasket to the rest of the cabinet and the 'damping cradle' will be screwed/glued to the cabinet and only connect to the horn via sorbothane pads. That way the horn/baffle unit will only be connected to the main cabinet via sorbothane. The mounting screws will also use rubber grommets to isolate them.

I have made the boxes slightly oversized to allow, damping layer, rubber layer, wool 15mm layer, extensive bracing and finally rock wool stuffing.

All the above materials are left over from previous builds and have worked well in the past so I will be using the same techniques again.

I have to say, at 18" wide, 20" high, and 16" deep, these are no longer 'book-shelf' speakers!

I will likely be placing them on top a 15 " sub cabinet. But first need to see how well the SB23s behave in a sealed cab.

I don't have sorbothane but have lots of 2mm EVA craft foam sheets for dampening/sealing. That sorbothane is pricey. The box will turn out to be almost as big a project as the horn, no?

Hah ha... Bookshelf size. It seems standard books do not get any taller than 17in per some library shelving standard! So you are officially relegated to a "Stand Mount"! 🙂

That gives me impetus to chop off 0.5in where possible and make it 17in tall max external height !

Hah ha... Bookshelf size. It seems standard books do not get any taller than 17in per some library shelving standard! So you are officially relegated to a "Stand Mount"! 🙂

That gives me impetus to chop off 0.5in where possible and make it 17in tall max external height !

Not a huge amount in it - as the woofers highest points are almost the same as the widest diameter of the horn.

X you say put woofer more to throat give a horn load for it, and the peak (that is because of hornload) and dsp it away is not a good idea, because it will possible also modulate the HF, and when you need dsp it then efficienty is also dsp away.

The frequenties below horn cut off is the problem, making it normal efficienty not more then sensitivity of used speaker, so no dsp but put woofer more to mouth giving a nice output when use a analog low pass filer and dsp the hf alone.

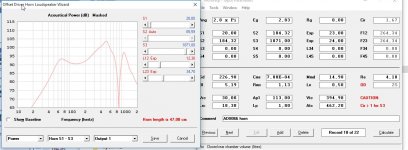

What happens when put woofer close to throat you can see here, a uge peak where hornloading occurs, but below it loos everything, so dsp this is useless.

Maybe I am wrong, I am not so educated what speaker systems concerns but learn fast I think. Yes calculations still is a problem, I am never be good in this, and use help from internet and calculator.

regards

The frequenties below horn cut off is the problem, making it normal efficienty not more then sensitivity of used speaker, so no dsp but put woofer more to mouth giving a nice output when use a analog low pass filer and dsp the hf alone.

What happens when put woofer close to throat you can see here, a uge peak where hornloading occurs, but below it loos everything, so dsp this is useless.

Maybe I am wrong, I am not so educated what speaker systems concerns but learn fast I think. Yes calculations still is a problem, I am never be good in this, and use help from internet and calculator.

regards

Attachments

That was the main advantage of putting woofers on the small sides of the horns, the downside is my horiz (60 deg) polars would probably not look as good as yours. I was intent on trying to keep to the title of the thread though 🙂

I am sure it will sound fine and as a "squarish" box it gives you flexibility of placement int either orientation. Do you have a horn loaded sub to round out the "all 3-way horn" system? I have a 98dB folded bass horn for the bottom that covers 30Hz to 250Hz if needed, so it will work out nicely.

I am sure it will sound fine and as a "squarish" box it gives you flexibility of placement int either orientation. Do you have a horn loaded sub to round out the "all 3-way horn" system? I have a 98dB folded bass horn for the bottom that covers 30Hz to 250Hz if needed, so it will work out nicely.

X you say put woofer more to throat give a horn load for it, and the peak (that is because of hornload) and dsp it away is not a good idea, because it will possible also modulate the HF, and when you need dsp it then efficienty is also dsp away.

The frequenties below horn cut off is the problem, making it normal efficienty not more then sensitivity of used speaker, so no dsp but put woofer more to mouth giving a nice output when use a analog low pass filer and dsp the hf alone.

What happens when put woofer close to throat you can see here, a uge peak where hornloading occurs, but below it loos everything, so dsp this is useless.

Maybe I am wrong, I am not so educated what speaker systems concerns but learn fast I think. Yes calculations still is a problem, I am never be good in this, and use help from internet and calculator.

regards

Maybe you are right about the HF modulation - probably bad. But lots of builds are putting big woofers right at throat. Look at Legis' horn and also the Jubilee with a pair of sizable woofers in Cask05's thread:

Something to be said for horns with a flat wall that allows easy and closeup woofer mounting with a simple plywood board.

Kees, the "big" bandpass overshoot peak is no big deal for DSP to flatten out with a single -peak cut PEQ.

Last edited:

Maybe you are right about the HF modulation - probably bad. But lots of builds are putting big woofers right at throat. Look at Legis' horn and also the Jubilee with a pair of sizable woofers in Cask05's thread:

Something to be said for horns with a flat wall that allows easy and closeup woofer mounting with a simple plywood board.

Kees, the "big" bandpass overshoot peak is no big deal for DSP to flatten out with a single -peak cut PEQ.

X you are right however we are deal with a wide band speaker and not a compression driver, there is differents, and with the synergy there are threat's about the speaker modulations also, yes I now it are all compromisses and I like the idea to do all analog, with a simple coil I can make a 12 dB because if natural fall off, and peak is 6 db also, so the coil flatten it out easely as you did see in previous posts with pictures.

This threats are the most exciting ones I did see, such a fun.

kees

wow lots has happened in this thread.

interesting fix with the distributed port/plug/hot melt/electrical tape fix X!!

i wish i had the measurement tools to confirm if using mesh screening can give the same results as your distributed injection port fix.

interesting fix with the distributed port/plug/hot melt/electrical tape fix X!!

i wish i had the measurement tools to confirm if using mesh screening can give the same results as your distributed injection port fix.

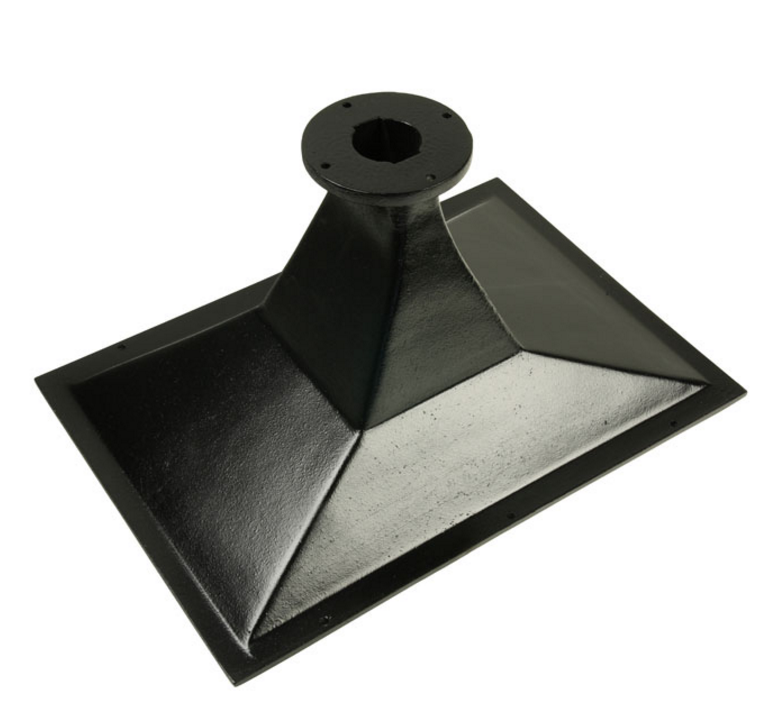

Speaking of bigger horns I came across the BMS 2236 Fibreglass horn designed for the 2" throat 4590 compression drivers. It is an interesting shape with a few flat sides that woofers might be mounted to.

At nearly 500mm wide it's not really suitable for a bookshelf

View attachment 528764 View attachment 528765 View attachment 528766 View attachment 528767

There are a lot of flat walls to attach woofers/mids to with this thing. Fully-loaded you can add 4 mids and 4 woofers! A beast for sure. The 2in throat may be perfect for a SS 10F though.

Thread title of "Bookshelf" notwithstanding, a great find and thanks for pointing it out.

wow lots has happened in this thread.

interesting fix with the distributed port/plug/hot melt/electrical tape fix X!!

i wish i had the measurement tools to confirm if using mesh screening can give the same results as your distributed injection port fix.

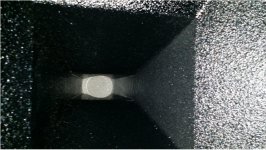

In my case, the "2 in dia hole" was drilled at an oblique angle on a part of the horn where the expansion was happening rapidly so maybe equivalent to a 4in dia hole in CSA. The drill wandered a bit so hole was even bigger! The patch closed up much of the slop and excess hole size so I think it improved the response a lot. Not sure screening would have helped in my case.

wow lots has happened in this thread.

interesting fix with the distributed port/plug/hot melt/electrical tape fix X!!

i wish i had the measurement tools to confirm if using mesh screening can give the same results as your distributed injection port fix.

How can anyone DIY without a mic???

Do yourself a big favor and call it a new year's present to yourself and get one. Download REW and away you go.

I like the UMIK-1. Even better, get one that is independently calibrated for $20 more from Cross Spectrum Labs.

One of the most important tools you can have as a DIY'er. The DATS v2 is the other tool.

yeah i know it's not much money but a mic comes after a long list of other needs...

i was more interested in trying to confirm my previous observations with respect to mesh screen layers and horn/drivers as a tool/method of smoothing response.

i was more interested in trying to confirm my previous observations with respect to mesh screen layers and horn/drivers as a tool/method of smoothing response.

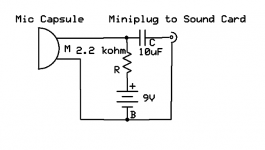

Is that the Siegfried Linkwitz special based on Panasonic WM-61A capsule for $2? I made one of those too but the USB interface of the UMIK is oh so nice. 🙂

... especially considering that most common laptops sold today don't have a dedicated linear sound-in jack (the mic-in is usually overly sensitive).Is that the Siegfried Linkwitz special based on Panasonic WM-61A capsule for $2? I made one of those too but the USB interface of the UMIK is oh so nice. 🙂

Is that the Siegfried Linkwitz special based on Panasonic WM-61A capsule for $2? I made one of those too but the USB interface of the UMIK is oh so nice. 🙂

Yes it is, I am use a other microphone amp with very high quality opamps, and cap is modified, it works fine, can go high spl if i want... But UMIK has also just a capsule and a calibration who works the same. But it have a usb and works without al that stuff connected like here is indeed very easy, WM-61 is not made anymore so maybe I go to the UMIK because it is not so expensive. But I like making things, that is why we are on diy here. I have to build the amp and mike in a case so I have one box and one cable connected to.

regards

Last edited:

Yes it is, I am use a other microphone amp with very high quality opamps, and cap is modified, it works fine, can go high spl if i want... But UMIK has also just a capsule and a calibration who works the same. But it have a usb and works without al that stuff connected like here is indeed very easy, WM-61 is not made anymore so maybe I go to the UMIK because it is not so expensive. But I like making things, that is why we are on diy here. I have to build the amp and mike in a case so I have one box and one cable connected to.

regards

Yes, I used a WM-61 capsule for many years with ARTA. Here's my schematic

Attachments

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn