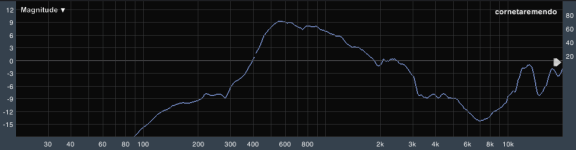

Measurement that close to the horn mouth will be a bit "off", but the general -12dB per octave rolloff is to expected.I took the measurement on the central axis of the horn, positioning the microphone right after the end of it. 1/12 magnitude smooth.

Corporatemisfit's measurement looks closer to bushmeister's than yours:From what I could see in corporatemisfit's measurement, this same pattern that I could observe in my measurements was repeated. Is this normal or is there something that could've been done wrong?

Throat details, driver differences, measurement distance and mics, smoothing, and room surroundings all play a part in what you will see.

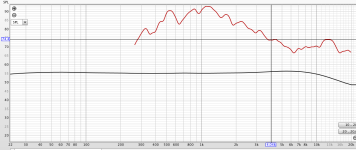

The phase wraps in your screen shot (lost count after 5760 degrees 😉 ) show the delay found (or applied) is wrong.

That shouldn't affect the frequency response portion of the graph, but you will want to sort that issue out before working on the crossover 👍

Art

Attachments

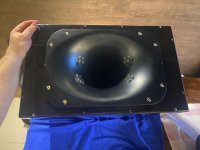

There has been some effort around mating the 2.5" driver to the horn mouth, in order to smooth a notch. There was some success here, with felt + epoxy putty for bushmeister and a 3d printed adapter for xrk971 (on different horns). Part of what is going on is the horns are 1.4" which is a standard size for compression drivers. The 2.5" drivers are too large to fit directly to the horn opening.

So if you could magic up a horn (print / make / modify / etc) with whatever properties you wanted, is it better to have the mouth a bit small and implement some transition to narrow it before it opens up again? Or would it be better to have a horn that was wide enough to start just exactly around the outside of the driver's surround?

I've read a bunch of this thread, there's quite a lot here. I do recall seeing some discussion of this geometry.

options that I'm considering, but haven't seen discussed

Finally, one option is "we don't know, it just ended up this way"...

Can anyone say it's one of these things, or I have misunderstood and it's something else?

So if you could magic up a horn (print / make / modify / etc) with whatever properties you wanted, is it better to have the mouth a bit small and implement some transition to narrow it before it opens up again? Or would it be better to have a horn that was wide enough to start just exactly around the outside of the driver's surround?

I've read a bunch of this thread, there's quite a lot here. I do recall seeing some discussion of this geometry.

- there are phase plugs and compression, these small FR drivers are not compression drivers and probably that is not best for them (this would be extreme narrowing)

- substantial narrowing but with no phase plug, this would make a band pass, I think, and is probably not desirable here

- some narrowing (maybe a slot, so it's narrow but maintains cross sectional area) can be used to create diffraction to spread HF coverage, but this might sound bad. Some horns do this in stock form, but I think not the two prime examples in this thread.

- just a bit of narrowing, with a smooth non-diffracting profile (and or damping material) to prevent a discontinuity and internal reflections. Just an interface between these two shapes, if the horn and the driver were the same diameter this would be unnecessary.

options that I'm considering, but haven't seen discussed

- the driver surround makes a noise we don't like, so we block it a bit. But the diaphragm output sounds good and it escapes. So the narrowing is a useful acoustic feature.

- Driver Sd only includes a portion of the surround. The narrowing helps the horn mate to exactly the Sd of the transducer. So the narrowing is a useful acoustic feature.

Finally, one option is "we don't know, it just ended up this way"...

Can anyone say it's one of these things, or I have misunderstood and it's something else?

Thanks for the answers.

Forgive me, I forgot to mention that I haven't connected the speakers yet, so this measurement is only from the sb65wbac25 in full range connected to the horn, so I haven't applied delay, crossover or anything yet.

Art, knowing that, should I still worry about the phase before proceeding?

Forgive me, I forgot to mention that I haven't connected the speakers yet, so this measurement is only from the sb65wbac25 in full range connected to the horn, so I haven't applied delay, crossover or anything yet.

Art, knowing that, should I still worry about the phase before proceeding?

Right, filtering is needed to flatten the part below 2 khz. shelfing filter or so. Multi point horns use that also.Wow! Nice work! I think the falloff above 3k5 is normal and EQ is needed. It’s a shame to attenuate that else it would be very high sensitivity. But works well to match the bass level.

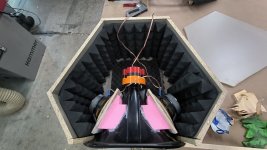

Some progress...

Attachments

-

WhatsApp Image 2024-06-21 at 17.43.42.jpeg120.4 KB · Views: 219

WhatsApp Image 2024-06-21 at 17.43.42.jpeg120.4 KB · Views: 219 -

WhatsApp Image 2024-06-21 at 17.43.41 (4).jpeg145.7 KB · Views: 223

WhatsApp Image 2024-06-21 at 17.43.41 (4).jpeg145.7 KB · Views: 223 -

WhatsApp Image 2024-06-21 at 17.43.41 (3).jpeg110.6 KB · Views: 221

WhatsApp Image 2024-06-21 at 17.43.41 (3).jpeg110.6 KB · Views: 221 -

WhatsApp Image 2024-06-21 at 17.43.41 (2).jpeg107.1 KB · Views: 210

WhatsApp Image 2024-06-21 at 17.43.41 (2).jpeg107.1 KB · Views: 210 -

WhatsApp Image 2024-06-21 at 17.43.41 (1).jpeg159.5 KB · Views: 206

WhatsApp Image 2024-06-21 at 17.43.41 (1).jpeg159.5 KB · Views: 206 -

WhatsApp Image 2024-06-21 at 17.43.41.jpeg130.6 KB · Views: 223

WhatsApp Image 2024-06-21 at 17.43.41.jpeg130.6 KB · Views: 223

Adam,Part of what is going on is the horns are 1.4" which is a standard size for compression drivers. The 2.5" drivers are too large to fit directly to the horn opening.

So if you could magic up a horn (print / make / modify / etc) with whatever properties you wanted, is it better to have the mouth a bit small and implement some transition to narrow it before it opens up again?

The mouth of a horn is the large end, the throat is where the driver is attached.

Small horn throats are desirable for extended smooth high frequency response, large driver Sd and excursion is required for low frequency output. Compression drivers use phase plugs to solve that problem, but the greater excursion and lower motor strength of a full range driver eliminate that option.

A driver to throat reduction adapter is required for the compromise.

A throat reduction creates an acoustical bandpass filter, reducing high frequency response.

The SB65 throat reduction adapter with the felt ring as bushmeister or Corporatemisfit use in post # 1833 appear to work well.

A larger throat would compromise the upper frequency response. A driver with only 1.4" diameter would not have enough output capability to keep up with the 2 woofers.Or would it be better to have a horn that was wide enough to start just exactly around the outside of the driver's surround?

Art

It was apparent the measurement was the SB65 only.Forgive me, I forgot to mention that I haven't connected the speakers yet, so this measurement is only from the sb65wbac25 in full range connected to the horn, so I haven't applied delay, crossover or anything yet.

Art, knowing that, should I still worry about the phase before proceeding?

No need to worry about the phase before proceeding, but you will have to figure out how to properly set the measurement system to eliminate the excessive phase wraps before proceeding with EQ and crossover settings.

Art

@viniciusv well done!. You project is looking good!

Looking at the pictures it appears that the felt lining around the edge of SB65 is thicker than 2mm. The reason I settled on the 2mm thickness was to ensure that the felt did not touch the roll surround of the SB65.

The felt touching the roll surround may have an impact on the distortion levels and frequency response.

Regarding the frequency response, this is normal when horn loading a speaker. You do need some form of DSP to equalise the response.

With my combination of SB65/XT1464 I get approx. 20db of acoustic gain between 460hz and 1100hz. Then a 10db and octave roll off to 4400hz. It is relatively easy to equalise this back to flat.

The benefit of this approach is that I use 20db less amplifier power and associated speaker excursion in the critical lower octave of the driver.

Looking forward to watching your progress!!

Looking at the pictures it appears that the felt lining around the edge of SB65 is thicker than 2mm. The reason I settled on the 2mm thickness was to ensure that the felt did not touch the roll surround of the SB65.

The felt touching the roll surround may have an impact on the distortion levels and frequency response.

Regarding the frequency response, this is normal when horn loading a speaker. You do need some form of DSP to equalise the response.

With my combination of SB65/XT1464 I get approx. 20db of acoustic gain between 460hz and 1100hz. Then a 10db and octave roll off to 4400hz. It is relatively easy to equalise this back to flat.

The benefit of this approach is that I use 20db less amplifier power and associated speaker excursion in the critical lower octave of the driver.

Looking forward to watching your progress!!

Hello everyone, I hope everyone is well.

I appreciate all the responses after my posts, I continued the assembly process and I was able to practically finish it and get the first responses from the box.

I made a few changes to the SB65 chamber and got better results in the response, just like you said, I added a little equalization in the DSP and got a result beyond what I expected.

I treated myself to some time listening to the box and I was amazed, I thought the result was incredible.

I had to speed up the painting process before even finishing the assembly because I realized that after assembling the horn on the front panel and consequently connecting the speakers, it would no longer be possible to remove just the horn from the front panel, so I had to do the process before assembling the horn on the front panel and I decided to paint it all.

Now with a little more care because of the painting, I will be making the final adjustments, which will be the bracing and internal damping, which I decided to follow the same way as Bushmeister did.

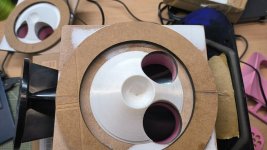

As you can see up to the 3rd image I shared, I had to develop a new cone filling, because the one I was able to print based on the XRK files I believe was made for the 8-inch Dayton and not for the one used at the end of the RS180P project. So with the help of a friend we developed the new part and printed it, it worked perfectly, for those who want to use the part I will be sharing the file soon, but remember to use a 6mm gasket to raise the speaker a little and not have the problem of the cone hitting the cone filling.

Also i noticed that ehen I don't use an HP for the RS180 I am hearing air turbulence in the holes, my intention is to use an HP to cross with a subwoofer I have, but if by chance someone knows how I could perhaps solve this air turbulence in the holes I would appreciate it if you could share it.

I also accept suggestions for improvements in the equalization process to improve the response.

One note, I noticed that the frequency response line was missing in the image at high frequencies, I don't know what happened, but as soon as I finish the damping and bracing process I will put the frequency response back here again.

That's it for now. I'll now be importing another pair of Daytons and an SB Acoustics to build the second speaker and have a stereo home theater. Thanks to everyone who contributed so far.

Art, it's time to give your creation in the last image a more appropriate destination. My living room doesn't really fit a speaker of this size, haha.

The RS180 has 6mm Xmax. Without a HP, the pair would exceed that at 40Hz at ~ 99dB at one meter.Also i noticed that ehen I don't use an HP for the RS180 I am hearing air turbulence in the holes, my intention is to use an HP to cross with a subwoofer I have, but if by chance someone knows how I could perhaps solve this air turbulence in the holes I would appreciate it if you could share it.

As the cone gets closer to the plug, air velocity will increase even before contact is made.

You could also be hearing the cone surround hitting the plug at high excursion, which could go considerably more than 6mm.

On the SynTripP, I made sure no part of the surround or cone could hit even when driven to Xlim.

Never noticed any air noise with it.

I don't know what process you used, but equalization done with the measurement mic positioned at the horn mouth won't be valid in other positions.I also accept suggestions for improvements in the equalization process to improve the response.

One note, I noticed that the frequency response line was missing in the image at high frequencies, I don't know what happened, but as soon as I finish the damping and bracing process I will put the frequency response back here again.

You still have not addressed the problem mentioned in post 1842, the delay found (or applied) is wrong.

The applied delay is so far off in this measurement that there is no coherency above ~10kHz, so the magnitude screen dims out the response to let you know, in case you weren't seeing the obvious problem on the phase screen 😳

Using a 4th order (4x90 degrees of phase shift) mid/high crossover, there should only be around 360 degrees phase rotation total between ~200 and 10kHz if the drivers are time aligned to each other.

Your screen is showing about 100x360 💩

Your living room just needs a bigger bookshelf 😉Art, it's time to give your creation in the last image a more appropriate destination. My living room doesn't really fit a speaker of this size, haha.

Art

I've read this thread twice before i started building prototypes of these speakers.

WOW! Thank you!!

I'm coming from upgraded SH50 Multiple-Entry horns and could not believe that small unity-horns could perform anywhere near that design.

Scott Hinson's DIYRM MEH was already great for the size, so i was not expecting any game-changing surprise.

Man I was wrong!

What you guys squeeze out of these budget drivers is truely impressive.

I'm using the combination

Tested with the DCX464 replacing the SB65 - the setup gains a bit more "airiness" in the highs, but nothing anywhere near to justify the +600€ more expenses for the DCX+crossover.

Still dialing in the settings.

Current challenges:

I had to design a volume filler for the rs180p and modified the horn-adaptors to fit the xt1464 (not 100% exact, as i used a measured-shape of the horn to modify the adapter)

If anyone is interested in listening to them - they're now available in berlin - let me know when you're in the area!

WOW! Thank you!!

I'm coming from upgraded SH50 Multiple-Entry horns and could not believe that small unity-horns could perform anywhere near that design.

Scott Hinson's DIYRM MEH was already great for the size, so i was not expecting any game-changing surprise.

Man I was wrong!

What you guys squeeze out of these budget drivers is truely impressive.

I'm using the combination

- SB65WBAC25-4

- rs180p-8

- XT1464

Tested with the DCX464 replacing the SB65 - the setup gains a bit more "airiness" in the highs, but nothing anywhere near to justify the +600€ more expenses for the DCX+crossover.

Still dialing in the settings.

Current challenges:

- Port chuffing (air noise) from about 100db with a 50hz BW24 HP (completely goes away if i cross over at 100hz)

- polishing the EQ

I had to design a volume filler for the rs180p and modified the horn-adaptors to fit the xt1464 (not 100% exact, as i used a measured-shape of the horn to modify the adapter)

If anyone is interested in listening to them - they're now available in berlin - let me know when you're in the area!

Attachments

-

IMG_20241102_163756.jpg78 KB · Views: 182

IMG_20241102_163756.jpg78 KB · Views: 182 -

rs180p-8- coneplug-1st try.stl5.8 MB · Views: 62

-

xt1464-adapter-v4.stl1.2 MB · Views: 53

-

IMG_20241017_175010.jpg72.3 KB · Views: 170

IMG_20241017_175010.jpg72.3 KB · Views: 170 -

IMG_20241028_215434.jpg195.5 KB · Views: 145

IMG_20241028_215434.jpg195.5 KB · Views: 145 -

IMG_20241028_232210.jpg85.4 KB · Views: 170

IMG_20241028_232210.jpg85.4 KB · Views: 170 -

IMG_20241102_154625.jpg188.4 KB · Views: 186

IMG_20241102_154625.jpg188.4 KB · Views: 186

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn