There is some art to tuning the port length and diameter to get a sharp acoustic low pass filter right at the notch frequency and then crossing there. I think T. Danley would say that is optimal. With a more gradual roll off to the notch one can cross below it, but then you don't get the full benefit of that acoustic LPF. You could also provide some boost along that slope to move the XO further up and closer to the notch (watching power consumption carefully).

As Mark says, so long as the notch isn't in the passband, with DSP it can be made to work.

As Mark says, so long as the notch isn't in the passband, with DSP it can be made to work.

There is some art to tuning the port length and diameter to get a sharp acoustic low pass filter right at the notch frequency and then crossing there. I think T. Danley would say that is optimal. With a more gradual roll off to the notch one can cross below it, but then you don't get the full benefit of that acoustic LPF. You could also provide some boost along that slope to move the XO further up and closer to the notch (watching power consumption carefully).

Very much agree with this, and it is the fine art of synergies,... acoustic filtering,..... and something i haven't come close to mastering.

I think this acoustic filtering is probably easier to manage using 4-5" mid ranges in between the CD and bottom drivers, than trying to go straight from CD to 12 or 10". Someday I'd like to try the mid-ranges route.

My guess is Danley keeps the mid-range drivers, either for the acoustic filtering advantage and hence sound quality, or to achieve max SPL by taking lower end load off the CD, or to be able to use passive xovers in his designs.

Hmmm...maybe/probably all three..

I think you are right Mark. When you scale mid ports up from those suitable for 4" mids in home to those for 12" or 15" woofers in PA, the port length might get out of practical range.

Although Danley seems to have moved from 1" CDs to 1.4", I think to allow XO down to 800 Hz or so, one would expect a nicer top end from the 1" CD originally used with small mids

Although Danley seems to have moved from 1" CDs to 1.4", I think to allow XO down to 800 Hz or so, one would expect a nicer top end from the 1" CD originally used with small mids

You'll find that the ability to cross in a certain manner is an indicator of the success of the acoustic design, according to Tom.xovers

You'll find that the ability to cross in a certain manner is an indicator of the success of the acoustic design, according to Tom.

AllenB, enough of your cryptic 'wisdom' please....

give me some specifics, some posts to illustrate what you mean....

i dare say i've studied Tom's posts and patents far more than you,

as I've been working on this synergy project for almost a year,

after having discussed discussed it with Tom in person.

This can't be news to you but all I'm saying, is when you design it according to the methods laid out, the crossover works like Toms. This has been said before. If it doesn't work that way there's an inconsistency. For this reason, in a conventional design, the same simple crossover could be seen as a virtual goal. Neat.

Suitable midrange cone, for bandpass mid in Unity horn.

Suitable midrange cone, for bandpass mid in Unity horn.

This can't be news to you but all I'm saying, is when you design it according to the methods laid out, the crossover works like Toms. This has been said before. If it doesn't work that way there's an inconsistency. For this reason, in a conventional design, the same simple crossover could be seen as a virtual goal. Neat.

Suitable midrange cone, for bandpass mid in Unity horn.

If you read posts about this syn7 build, you know it is not a typical synergy that uses the normal method of incorporating mid-range drivers between the CD and woofer.

When i had the opportunity to describe to Tom what I wanted to do, use a bms coax CD down to 500-600Hz....he nodded and immediately interjected, you go probably go straight to a 12 inch.

I said that was what i was hoping, and I planned to crossover pretty steep to maintain protection for the CD and keep SPL high.

He asked what software i use, and i said rephase and FirDesigner.

He nodded again, and said he was going to suggest LspCad, but with rephase you can do anything....and continued by saying he had used rephase to refine the tuning of his personal SH-50's.

Btw, are you aware the SH-50 has about 720 degrees of phase rotation over its specified -3dB bandwidth from 50Hz to 18kHz?

And a little over 360 degrees rotation if you throw out the tails and just look at response from about 100Hz to 8kHz?

Look at the phase scale....https://www.danleysoundlabs.com/wp-content/uploads/2012/04/SH-50-spec-sheet11.pdf

Not exactly first/very-low order by any means....

Imo, there's more going on in synergy xovers than just simple and neat, which fall into place if acoustic design goals are met....

There are always particular goals chosen to optimize.......and tradeoffs to consider......goals and tradeoffs that more advanced tools make possible ime/imo.

Very smart using the horn wall as the cabinet. I didn't care about cabinet weight before but after hitting 50, it's becoming an increasing issue.

Thanks for the idea, I'll use it for my synergy build....

Thanks for the idea, I'll use it for my synergy build....

Getting ready to start on this. Is there an advantage to a 90x90 square mouth compared to the popular 90x60, while keeping the cutoff freq the same?

Thx !

One 'maybe' advantage of 90x90 vs 90x60, could be better polars as both horiz and vert react the same...maybe less need for a secondary flare ....kinda spitballing here...dunno for sure

For the same cutoff freq, I figure the 90x90 will be bigger and weigh more, simply being a bit taller. Also, it will throw more energy onto floor and ceiling.

Easier to build though.

I've thought about using 8" drivers to be able to maybe shrink the pattern to 75x50, or 75x75. Not sure 8"s would be small enough though, to still be able to use horn wall as cabinet.

It definitely took the 90 deg horiz width to do that with 10"s.

One 'maybe' advantage of 90x90 vs 90x60, could be better polars as both horiz and vert react the same...maybe less need for a secondary flare ....kinda spitballing here...dunno for sure

For the same cutoff freq, I figure the 90x90 will be bigger and weigh more, simply being a bit taller. Also, it will throw more energy onto floor and ceiling.

Easier to build though.

I've thought about using 8" drivers to be able to maybe shrink the pattern to 75x50, or 75x75. Not sure 8"s would be small enough though, to still be able to use horn wall as cabinet.

It definitely took the 90 deg horiz width to do that with 10"s.

But the 90 degree vertical could (likely to) be problematic from floor and ceiling bounce perspective, depending on listening geometry

But the 90 degree vertical could (likely to) be problematic from floor and ceiling bounce perspective, depending on listening geometry

Yes, that's what I meant to be saying....kinda assuming folks naturally don't want energy on floors and ceiling, and would see it as a negative.. ..like they would see extra size and weight as a negative. Sorry for any lack of clarity.

90x90 Pros:

*Wider dispersion has some evidence of listener preference, JBL M2 targets wide dispersion based on Harmen listener preference research (120° H x 100° V. claimed nominal). However I'm a bit skeptical on this as it may just be the listeners prefer the sound of conventional Hi-Fi speakers and want something that confirms their existing expectations.

*No pattern flip phenomenon where the vertical dispersion becomes wider than the horizontal as the frequency goes down and the mouth size becomes insufficient in the vertical plane.

Cons:

*midrange drivers are pushed out further from the throat in wider angle synergy horns which can reduce the crossover frequency achievable.

*Increased symmetry in the horn causing greater on axis variation

*horn is physically larger

*horn loading not as good

*Wider dispersion has some evidence of listener preference, JBL M2 targets wide dispersion based on Harmen listener preference research (120° H x 100° V. claimed nominal). However I'm a bit skeptical on this as it may just be the listeners prefer the sound of conventional Hi-Fi speakers and want something that confirms their existing expectations.

*No pattern flip phenomenon where the vertical dispersion becomes wider than the horizontal as the frequency goes down and the mouth size becomes insufficient in the vertical plane.

Cons:

*midrange drivers are pushed out further from the throat in wider angle synergy horns which can reduce the crossover frequency achievable.

*Increased symmetry in the horn causing greater on axis variation

*horn is physically larger

*horn loading not as good

Ok thanks guys for the answers.

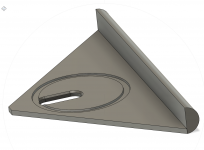

Yes, I was hoping with the squarish horn I could get away without the secondary flare and just go with a simple round over. Thinking of just cutting a 4" ABS pipe in half (image)

Point taken about the floor/ceiling issue. I will go with a 60 vertical.

My plan is to stick this in a corner, use walls as the horizontal horn extension. I really like when I had my synergy flush to the side walls. Eliminated the side wall reflections, which was a big bonus.

Corner placement will let me go big, possibly up to 48" wide with no issues and let me use a 15" woofer, hoping to 400Hz XO with BMS 4592ND. Just planning stage for now, looking for ideas or somebody pointing the obvious mistakes...

Yes, I was hoping with the squarish horn I could get away without the secondary flare and just go with a simple round over. Thinking of just cutting a 4" ABS pipe in half (image)

Point taken about the floor/ceiling issue. I will go with a 60 vertical.

My plan is to stick this in a corner, use walls as the horizontal horn extension. I really like when I had my synergy flush to the side walls. Eliminated the side wall reflections, which was a big bonus.

Corner placement will let me go big, possibly up to 48" wide with no issues and let me use a 15" woofer, hoping to 400Hz XO with BMS 4592ND. Just planning stage for now, looking for ideas or somebody pointing the obvious mistakes...

Attachments

Right now it's single flare 41" wide to fit a 15" driver. It's actually not that big if placed in the corner, virtually disappears, almost 🙂

Gotta thank Mark for his work, I would not have thought about this without his excellent work. Thank you

Gotta thank Mark for his work, I would not have thought about this without his excellent work. Thank you

Ok thanks guys for the answers.

Yes, I was hoping with the squarish horn I could get away without the secondary flare and just go with a simple round over. Thinking of just cutting a 4" ABS pipe in half (image)

Point taken about the floor/ceiling issue. I will go with a 60 vertical.

My plan is to stick this in a corner, use walls as the horizontal horn extension. I really like when I had my synergy flush to the side walls. Eliminated the side wall reflections, which was a big bonus.

Corner placement will let me go big, possibly up to 48" wide with no issues and let me use a 15" woofer, hoping to 400Hz XO with BMS 4592ND. Just planning stage for now, looking for ideas or somebody pointing the obvious mistakes...

Oh, be incredibly careful if you attempt to slice pvc pipe longways. It's a long story, but it's why I had to retire early. Injury due to a tablesaw kickback from hell! Also don't underestimate the difficulty of gluing pvc to wood. Most things that adhere to pvc don't adhere to wood and viceversa. I'd look into ply or maybe even foamboard if I were you!

Ouch sorry to hear that. Thanks for the warning Bill. I was going to try it with a band saw or a tracksaw. I'll play it safe and follow your suggestion.

I'll be measuring it first before adding round overs to see if it makes a significant difference.

I read here that the bigger the horn the less the second flare or round over helps?

At least for home use purposes

I'll be measuring it first before adding round overs to see if it makes a significant difference.

I read here that the bigger the horn the less the second flare or round over helps?

At least for home use purposes

Last edited:

Ok thanks guys for the answers.

Yes, I was hoping with the squarish horn I could get away without the secondary flare and just go with a simple round over. Thinking of just cutting a 4" ABS pipe in half (image)

Point taken about the floor/ceiling issue. I will go with a 60 vertical.

My plan is to stick this in a corner, use walls as the horizontal horn extension. I really like when I had my synergy flush to the side walls. Eliminated the side wall reflections, which was a big bonus.

Corner placement will let me go big, possibly up to 48" wide with no issues and let me use a 15" woofer, hoping to 400Hz XO with BMS 4592ND. Just planning stage for now, looking for ideas or somebody pointing the obvious mistakes...

Take this from me and the thread in my signature:

You will get a good response in the sweet spot but the waistbanding will constrain the sweet spot. As will the fixed toe-in, if you indeed fit it tightly into the corner - but if the geometry works out, go for it! It doesn't need to be wide because of the corner walls but it needs to be tall for vertical directivity down low enough to preclude a floor bounce null at the LP - which will make it wide.

If I had to do it again, I would implement some form of mouth termination.

I agree with having mouth termination.

Both for preventing waistbanding and the extended pattern control.

The added flares on my 90x60 and 60x40, both made sound imaging extend lower in freq.

fwiw, i would not make foamboard flares again. Too much work and expense. And hard to get right.

Just making a hot wire cutter that could handle a 4 ft span was enough work, then there was learning how to use epoxy and glass cloth.

Was a hell of a bigger project than the dang synergy itself.

I'd go with wood for either a straight or curved secondary. I'd use bendy board with ribs if curved.

Bill, I always cringe picturing that kickback...yikes, sorry, glad it wasn't even worse.

Nice you keep warning folks when PVC comes up...

Both for preventing waistbanding and the extended pattern control.

The added flares on my 90x60 and 60x40, both made sound imaging extend lower in freq.

fwiw, i would not make foamboard flares again. Too much work and expense. And hard to get right.

Just making a hot wire cutter that could handle a 4 ft span was enough work, then there was learning how to use epoxy and glass cloth.

Was a hell of a bigger project than the dang synergy itself.

I'd go with wood for either a straight or curved secondary. I'd use bendy board with ribs if curved.

Bill, I always cringe picturing that kickback...yikes, sorry, glad it wasn't even worse.

Nice you keep warning folks when PVC comes up...

- Home

- Loudspeakers

- Multi-Way

- synergy.....Take #7