Hi Marcel,

I do not care what they say about you, you are amazing. I was re-reading the script several million times, and did not notice the problem. Thank you.

I was re-reading the script several million times, and did not notice the problem. Thank you.

I know that the syntax is not checked, your guide is clear about it.

Yes, I do have the physical device. And yes, I am trying to re-create the shape as best as I can to compare the simulation with measurement. However, with my already demonstrated incompetence, it will be a while.

The reason for creating the STL file is two-fold. I am learning the different features of Ath and I want to generate a profile in a CAD to compare it with the physical device as noted above, so I can have as good a model for the simulation. Since Ath does not support the universal *.dxf format, and I do not use Fusion, I am trying to figure out the best manner of doing it.

Kindest regards,

M

I do not care what they say about you, you are amazing.

I know that the syntax is not checked, your guide is clear about it.

Yes, I do have the physical device. And yes, I am trying to re-create the shape as best as I can to compare the simulation with measurement. However, with my already demonstrated incompetence, it will be a while.

The reason for creating the STL file is two-fold. I am learning the different features of Ath and I want to generate a profile in a CAD to compare it with the physical device as noted above, so I can have as good a model for the simulation. Since Ath does not support the universal *.dxf format, and I do not use Fusion, I am trying to figure out the best manner of doing it.

Kindest regards,

M

Last edited:

In CAD programs there's typically a possibility to import X,Y[,Z] data form the text files Ath creates. You would have to experiment. I know it's possible with LibreCAD (free), I used that myself. Then it's easy to save that as DXF.Since Ath does not support the universal *.dxf format, and I do not use Fusion, I am trying to figure out the best manner of doing it.

I have just printed a small syngery horn with PLA 20% infill (squares) and it seems that the horn itself with it´s thin PLA is causing high distortion because of resonating. When measring the drivers without horn it´s not there.

Any suggestion which fillament to use?

I have read somethinkg like TPU65D.

Is there a link available where I can buy it?

Any suggestion how much infill (in percent) and what kind of infill to use?

You can try PLA and make very thick wall like 2cm and low infill 10-15%.

e.g. two perimeters and 150% width for infill. It will be stiff (high resonance low decay)

What programs do you have or can use? Maybe I can tell you how to do it with them.Since Ath does not support the universal *.dxf format, and I do not use Fusion, I am trying to figure out the best manner of doing it.

Another thing is that it's probably a lot easier to damp the waveguide when clamped along the mouth (i.e. in a baffle) than the free standing one with its open end.

This has been my experience. I made some smaller prototype waveguides using the same construction as the ones my speakers (Plaster over MDF), but with an unconstrained edge (i.e. not built into a cabinet). The prototypes ring quite a bit more than the final product. It makes intuitive sense—A bell rings much less if you constrain the lip.

How much do the sand prints ring? Like an actual bell? A ceramic vase? It'd be interesting to see if the ringing can be seen in the measurements.

I don't know, perhaps. You can define almost anything as an independent function of the angle around the axis, I guess it should not be a problem but I of course don't know anything about this particular shape.Marcel, can ATH generate below shape?

Last edited:

Hi Fluid,

thank you for the offer. I am using AutoCAD R14 and Solidworks.

Kindest regards,

M

What programs do you have or can use? Maybe I can tell you how to do it with them.

thank you for the offer. I am using AutoCAD R14 and Solidworks.

Kindest regards,

M

Not bell but more like pottery. I'd like to perform some measurements where it would show up. Apparently these will be quite high Q resonances.... How much do the sand prints ring? Like an actual bell? A ceramic vase? It'd be interesting to see if the ringing can be seen in the measurements.

Perhaps it won't be so easy to excite them by the radiating sound from the waveguide itself, I don't know. That would be good news, I suppose.

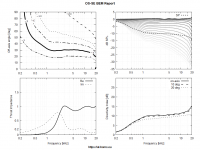

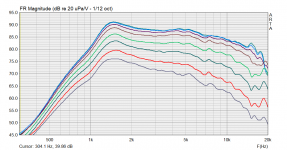

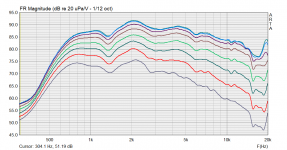

Otherwise I'm pretty satisfied with the results so far.

Last edited:

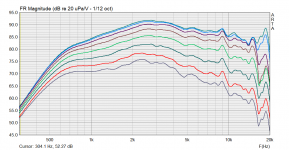

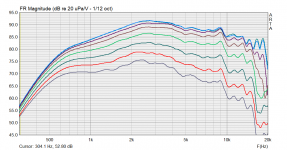

... B&C DE250TN:

Happen to have any BMS drivers at hand?

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)