When not required for sealing, metal plumbing threads get a single layer of PTFE tape from me. Works on compression nuts to allow for easy disassembly even years later without twisting the pipework.

Oh yes! I hate it when that happens!!! 🙂

Happens every time. A good thing that Diy stores in my country are open 7 days a week, and to quite late.

Last time I installed a new zink, I just had to remove two bolts and mount two new ones. First bolt did not fit, because of different size to original. Bought the correct tubes to replace. First one easy, next one did not fit. Issue - the two original bolts were different size from each other, and one was non standard. So I had to cut the copper tube, and mount standard size threads. A 20 minute job turned into a 4 hours job.

LOL. That's for sure! It does help relieve some of the stress.....along with uncontrolled cursing.

I felt like Old Man Parker fixing the furnace in A Christmas Story.

I felt like Old Man Parker fixing the furnace in A Christmas Story.FWIW, the kitchen spigot I replaced was only 3.5 years old - and I was the fool who installed the damn thing. Fingers crossed that the Super Lube grease will keep the threads from seizing on this one.

Next big repair project is audio related. A tweeter rewire and woofer repair on a set of Magenpan MG-1b panels. I don't expect that to go quickly, but there's no hurry.

I use that teflon tape for the shower head... For the drain threads, I'd use anti-seize, but I dunno if that's advisable for the water supply lines...

Today was more of an upgrade / mod than a repair, but I changed the output transformers and output tubes in my IA from 6P36S on 2k2 to 6P45S 1k.

Also upgraded the power supply with 50,000uF on the 12V and another 2000uF on the 320V, and made the time delay longer to accommodate the extra capacitance avoiding OCP. Lowered some 5R to 3R3, and changed the 10R in the amp to 5R. They gets about 5 volts less drop on the B+ at high power.

Also changed the bias supply from -110V to -200V and added an RC dropper to allow for 75 / 90 / 105 VR tube for the bias regulation.

And then I added a voltmeter and an ammeter to the PSU. All while my lover sleeps 5 feet away (I dunno how they slept through the drilling of the 44mm holes in the face plate...

All in all, an eventful morning!

Today was more of an upgrade / mod than a repair, but I changed the output transformers and output tubes in my IA from 6P36S on 2k2 to 6P45S 1k.

Also upgraded the power supply with 50,000uF on the 12V and another 2000uF on the 320V, and made the time delay longer to accommodate the extra capacitance avoiding OCP. Lowered some 5R to 3R3, and changed the 10R in the amp to 5R. They gets about 5 volts less drop on the B+ at high power.

Also changed the bias supply from -110V to -200V and added an RC dropper to allow for 75 / 90 / 105 VR tube for the bias regulation.

And then I added a voltmeter and an ammeter to the PSU. All while my lover sleeps 5 feet away (I dunno how they slept through the drilling of the 44mm holes in the face plate...

All in all, an eventful morning!

Attachments

Yup...

It powers this like in the middle picture in my last post...

It has a phono stage (only get power when you set it to phono (0) though.

Also a headphone amp/line amp based that will drive 32R (even if only at a few mW - I use 470R ATH-R70x).

~80W 6P45S trioded output stage...

6E2 Level meters

6 input board for 5 +phono input. 2 pre out, 2 line out.

The empty sockets housed a HP filter for the phono, but I thought it was trash, so I left them there as a place holder for if i try and add balance and tone control...

It powers this like in the middle picture in my last post...

It has a phono stage (only get power when you set it to phono (0) though.

Also a headphone amp/line amp based that will drive 32R (even if only at a few mW - I use 470R ATH-R70x).

~80W 6P45S trioded output stage...

6E2 Level meters

6 input board for 5 +phono input. 2 pre out, 2 line out.

The empty sockets housed a HP filter for the phono, but I thought it was trash, so I left them there as a place holder for if i try and add balance and tone control...

Attachments

Last edited:

I'm currently overhauling a Technics RS-1500US reel to reel.

While it's in pristine cosmetic condition, she needs some work both mechanically and in the electronics.

While it's in pristine cosmetic condition, she needs some work both mechanically and in the electronics.

USB scope I designed that didn't work once built up.

I had set a2d upper reference voltage to 4.6 but then realised my front end op amps only go to 3.3 volts.

So reduced 4.6v ref to 3.3v and reduced gain on front end to work with new limited a2d range. Works great now.

I had set a2d upper reference voltage to 4.6 but then realised my front end op amps only go to 3.3 volts.

So reduced 4.6v ref to 3.3v and reduced gain on front end to work with new limited a2d range. Works great now.

Tandberg 6000X 4 track reel to reel machine. My first foray into R2R, and it was a blast. Incredible sound quality, playing 60 year old recordings. Classical music never sounded so good in my house! Now it's acting up again, right channel not working anymore. Need a love session on the bench..

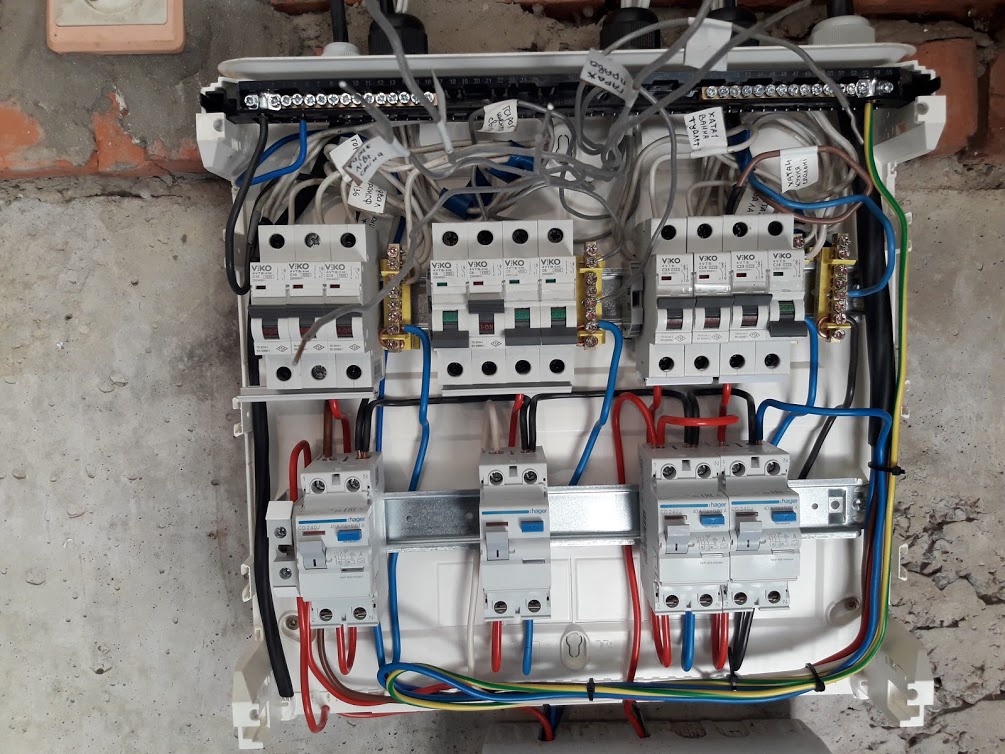

I made not repair but rather an upgrade for my parent's house old mains input cabinet and distribution cabinet. It was only equipped with old soviet circuit breakers but now it has RCDs too.

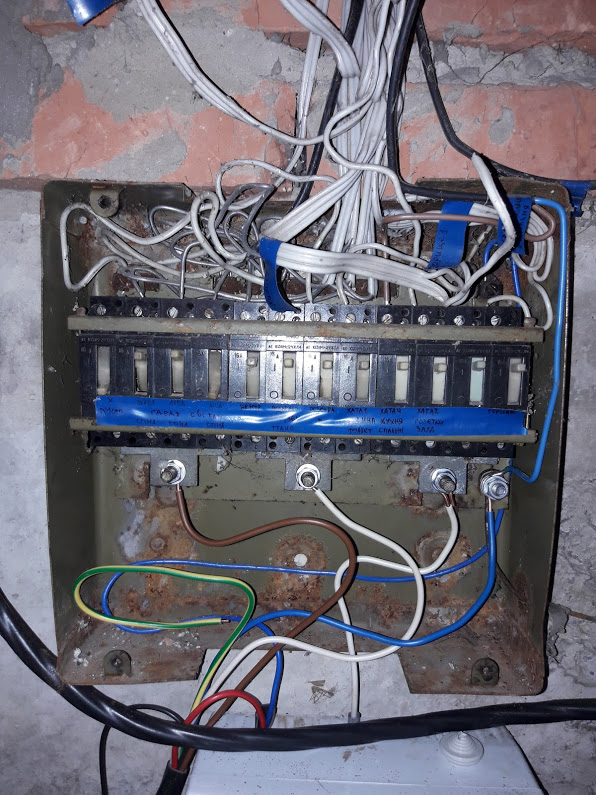

The main cabinet moved from this:

to this:

And distribution changed from this:

to this:

I believe it is much safer now.

The main cabinet moved from this:

to this:

And distribution changed from this:

to this:

I believe it is much safer now.

Attachments

Last edited:

Well it's not an audio device. Last year my employer was E-Wasting an Avcom PSA-65a spectrum analyzer.

I pulled it out and it sat for a year but 3 weeks back I opened it up and found the EHT module for the CRT

had some burned parts. I compared it with the other working unit and bought some parts from DigiKey.

When I installed them I got some smoke. Bad. I disconnected the drain lead of the driver to reduce the power

and looked for the drive pulse to the gate. No pulse, just +11 Volt drive coming from a lowly 555 timer. New

555 restored the drive pulse and when the drain was reconnected it all worked again. I now have a spectrum

analyzer for about $5 in parts.

G²

I pulled it out and it sat for a year but 3 weeks back I opened it up and found the EHT module for the CRT

had some burned parts. I compared it with the other working unit and bought some parts from DigiKey.

When I installed them I got some smoke. Bad. I disconnected the drain lead of the driver to reduce the power

and looked for the drive pulse to the gate. No pulse, just +11 Volt drive coming from a lowly 555 timer. New

555 restored the drive pulse and when the drain was reconnected it all worked again. I now have a spectrum

analyzer for about $5 in parts.

G²

I am working on an old Telefunken Magnetophon 203 De_luxe.

It was my fathers.

He passed away 10 years ago and I finally got the belts I needed to get it going. I have been replacing caps in the PS section and got most of the hum out. I'm debating replacing the coupling caps as well.

It is good enough now to start digitizing the 37 tapes I got with it.

I had to breadboard a buffer amp as the output from the line out was too low to drive the audio card in my computer.

It was my fathers.

He passed away 10 years ago and I finally got the belts I needed to get it going. I have been replacing caps in the PS section and got most of the hum out. I'm debating replacing the coupling caps as well.

It is good enough now to start digitizing the 37 tapes I got with it.

I had to breadboard a buffer amp as the output from the line out was too low to drive the audio card in my computer.

Attachments

Last edited:

A lovely cool day to do some more servicing to that Technics reel to reel.

Some dirty switches, relubing the mechs, and alignment are on the list.

Biggest damn flywheel I ever seen in a tape deck!

Whoa - nice Iso-Loop porn there. And that flywheel looks like it could knock off a fingernail. 😱

Actually, this brings to mind a question (to which I feel I should know the answer by now, but I don't) about dual-capstan systems like this, also the many cassette drives of the day: What mechanism is it exactly that maintains the exact proper tape tension across the heads in this setup?

The only thing I can guess is that the leading capstan is attempting to "push" the tape at a slightly slower speed than the trailing capstan is pulling it. Is that how it works? If this is correct, how is it achieved? I suppose the leading capstan could be machined to an ever-so-slightly smaller diameter, but I guess it would be easier to make its drive pulley slightly larger? Or is there something else altogether going on here?

Last edited:

Very simple repair for me today. The bulb that tells that the solar hot water needs boosting. I only replaced it a few months back, I guess 12V bulbs aint what they used to be, so today I made up a new connecting wire with a 24 ohm 1/2 W resistor in line, which should drop the voltage about 2.4V. Hoping that it running a little less hot will extend the life time 🙂

Tony.

Tony.

Whoa - nice Iso-Loop porn there. And that flywheel looks like it could knock off a fingernail. 😱

Actually, this brings to mind a question (to which I feel I should know the answer by now, but I don't) about dual-capstan systems like this, also the many cassette drives of the day: What mechanism is it exactly that maintains the exact proper tape tension across the heads in this setup?

The only thing I can guess is that the leading capstan is attempting to "push" the tape at a slightly slower speed than the trailing capstan is pulling it. Is that how it works? If this is correct, how is it achieved? I suppose the leading capstan could be machined to an ever-so-slightly smaller diameter, but I guess it would be easier to make its drive pulley slightly larger? Or is there something else altogether going on here?

Well Jim, this Technics rs-1500 doesn't have "dual" capstans, just one.

What you see is..... the top large drum IS the capstan, (on the same shaft as that huge flywheel inside - Direct Drive) flanked by twin pressure rollers, the lower large drum is merely an idler that basically drives the tape counter, and acts as a secondary smaller flywheel.

Above the capstan are a pair of tension rollers that control tape tension across all 4 heads and 6 tape guides.

The reel motors are controlled by a complex logic system with several IC's - and they also control tension as needed.

Very sophisticated machine this is - but then again, it's a Technics.

In dual capstan cassette machines, the belt/flywheels are designed to slip so that tension is always applied to the head block.

The "driven" flywheel does the "pulling" and the other flywheel does some slipping.

Last edited:

Wow, that's a huge diameter for a capstan. That would put the RPM down around 300 or so @ 15 ips, eh? That explains the massive flywheel!

Thanks for the info.

Thanks for the info.

I'm sure you've all had simple jobs like this that turn into a nightmare. 🙁

It's a given that simple jobs on a 60 year old house like mine turn into a nightmare.

Some years back my old kitchen sink was leaking. I decided to upgrade everything. New sink, new faucet, new traps. It was a nightmare to get apart; I had to heat everything up with a torch to get it apart while my buddy stood by with a fire extinguisher. Got it all together and it still leaked. One of the big cast iron pipes coming out of the wall had a small hole from corrosion. I managed (miraculously) to get it out without breaking anything. I got some new pipes and managed to get them installed and nothing leaked. It was a "Y" pipe (I'm no plumber) so I was able to turn it with a big bar (one of my "cheater bars" I use to work on cars) stuck in one of the legs. The pipe broke while disassembling but still came out.

I hate plumbing. I've always avoided it but when you own a house it's either DIY or $$$$$$. I had a plumber in here once when I broke a pipe off inside the wall of one of my bathrooms. I told him to do what he had to do, including breaking the wall open. My walls are gypsum lath plaster and I had tiled the bathroom wall some years back. Anyway, he got the pipe out without even making hole any bigger, and installed a new pipe. I think that was money well spent. 🙂

- Home

- Member Areas

- The Lounge

- What did you last repair?