comparison of sled vs reality vs nanook

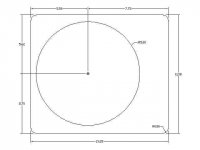

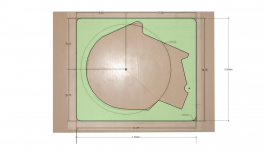

Guys: Attached is a png image comparing reality to sled's quick sketch and my sketchup of the required cut-out for the Garrard "AT6" (or "60" or "Lab60")

I overlaid sled's image and scaled it correctly (well actually scaled the photo and then scaled the photo to sled's image). Then ensured my cut-out diagram was in good dimensional agreement with both the photo and sled's image (dwg ?).

The reasoning for the difference in the circular cut-out is that the radius of my cut-out is smaller than sled's. sled (as far as I can tell) drew the platter, I drew the cut-out required to clear the underside of the metal top plate. It has a recessed area with a R=110mm. The platter has a radius of 132mm (as measured on my platter). So there are some minor discrepancies. Just remember everything underneath the Garrard's metal top plate will not be seen.

The manner in which the main bearing is supported is pretty shoddy. That must be addressed by any that are using changers as the basis of their project, if they use the caged "bicycle" style ball bearings. Either that or come up with an alternative solid bearing...

Guys: Attached is a png image comparing reality to sled's quick sketch and my sketchup of the required cut-out for the Garrard "AT6" (or "60" or "Lab60")

I overlaid sled's image and scaled it correctly (well actually scaled the photo and then scaled the photo to sled's image). Then ensured my cut-out diagram was in good dimensional agreement with both the photo and sled's image (dwg ?).

The reasoning for the difference in the circular cut-out is that the radius of my cut-out is smaller than sled's. sled (as far as I can tell) drew the platter, I drew the cut-out required to clear the underside of the metal top plate. It has a recessed area with a R=110mm. The platter has a radius of 132mm (as measured on my platter). So there are some minor discrepancies. Just remember everything underneath the Garrard's metal top plate will not be seen.

The manner in which the main bearing is supported is pretty shoddy. That must be addressed by any that are using changers as the basis of their project, if they use the caged "bicycle" style ball bearings. Either that or come up with an alternative solid bearing...

Attachments

Hi,

In my younger days I rebuild quite a few turntables, most turned

out very well but I did realise that real effort is wasted on cheap

stuff and rewarded with a decently engineered starting point.

Consequently I gravitated towards maximum effect / least effort.

You wouldn't believe how much better this deck gets with some

sympathetic mods and fitted with a decent tonearm, as the stock

arm is quite frankly very cheap and just very wrong, I fitted :

An easy arm to shorten, using a pipe cutter. Cheap used at the time, not anymore.

rgds, sreten.

In my younger days I rebuild quite a few turntables, most turned

out very well but I did realise that real effort is wasted on cheap

stuff and rewarded with a decently engineered starting point.

Consequently I gravitated towards maximum effect / least effort.

You wouldn't believe how much better this deck gets with some

sympathetic mods and fitted with a decent tonearm, as the stock

arm is quite frankly very cheap and just very wrong, I fitted :

An easy arm to shorten, using a pipe cutter. Cheap used at the time, not anymore.

rgds, sreten.

Last edited:

Hi,

In my younger days I rebuild quite a few turntables, most turned

out very well but I did realise that real effort is wasted on cheap

stuff and rewarded with a decently engineered starting point.

Consequently I gravitated towards maximum effect / least effort.

You wouldn't believe how much better this deck gets with some

sympathetic mods and fitted with a decent tonearm, as the stock

arm is quite frankly very cheap and just very wrong, I fitted :

An easy arm to shorten, using a pipe cutter. Cheap used at the time, not anymore.

rgds, sreten.

sreten: Yes, the Mayware Formula 4 is no longer available "cheap". I don't doubt that you massaged the Phillips into something better. I suppose better power regulation, chassis damping, etc? Remove the bottom plate and either leave it off or replace it with something better. And that is after ensuring that the basic table was in good order after cleaning and servicing it.

Everyone here should recognize that prior to rebuilding or making a new plinth for any turntable, a basic service must be done.

Now don't let any Linnies suggest that only a Linn warrants upgrades or improvements.

Sorry Stew...That JPeg was just a Quick Shot from the top, showing the 10" Platter...

sled: I assumed as much, but your jpeg was to scale pretty much. I suspect ACAD? My attached image was for illustrative purposes, that's it. But the differences between a drawing, and reality is interesting.

Seems like I'm going to be getting a Strathclyde "STD 305S" for a Christmas present. I know I enjoyed working on a Roksan Xerxes and with mods was very good. I'm going to do the same sort of thing. I know I shouldn't have got rid of my Heybrook TT2 as well.

all:

Some thoughts and a Christmas project.

sreten: Yes, the Mayware Formula 4 is no longer available "cheap". I don't doubt that you massaged the Phillips into something better. I suppose better power regulation, chassis damping, etc? Remove the bottom plate and either leave it off or replace it with something better. And that is after ensuring that the basic table was in good order after cleaning and servicing it.

Everyone here should recognize that prior to rebuilding or making a new plinth for any turntable, a basic service must be done.

Now don't let any Linnies suggest that only a Linn warrants upgrades or improvements.

sled: I assumed as much, but your jpeg was to scale pretty much. I suspect ACAD? My attached image was for illustrative purposes, that's it. But the differences between a drawing, and reality is interesting.

Seems like I'm going to be getting a Strathclyde "STD 305S" for a Christmas present. I know I enjoyed working on a Roksan Xerxes and with mods was very good. I'm going to do the same sort of thing. I know I shouldn't have got rid of my Heybrook TT2 as well.

all:

Hi,

In my younger days I rebuild quite a few turntables, most turned

out very well but I did realise that real effort is wasted on cheap

stuff and rewarded with a decently engineered starting point.

Consequently I gravitated towards maximum effect / least effort.

You wouldn't believe how much better this deck gets with some

sympathetic mods and fitted with a decent tonearm, as the stock

arm is quite frankly very cheap and just very wrong, I fitted :

An easy arm to shorten, using a pipe cutter. Cheap used at the time, not anymore.

rgds, sreten.

sreten: Yes, the Mayware Formula 4 is no longer available "cheap". I don't doubt that you massaged the Phillips into something better. I suppose better power regulation, chassis damping, etc? Remove the bottom plate and either leave it off or replace it with something better. And that is after ensuring that the basic table was in good order after cleaning and servicing it.

Everyone here should recognize that prior to rebuilding or making a new plinth for any turntable, a basic service must be done.

Now don't let any Linnies suggest that only a Linn warrants upgrades or improvements.

Sorry Stew...That JPeg was just a Quick Shot from the top, showing the 10" Platter...

sled: I assumed as much, but your jpeg was to scale pretty much. I suspect ACAD? My attached image was for illustrative purposes, that's it. But the differences between a drawing, and reality is interesting.

Seems like I'm going to be getting a Strathclyde "STD 305S" for a Christmas present. I know I enjoyed working on a Roksan Xerxes and with mods was very good. I'm going to do the same sort of thing. I know I shouldn't have got rid of my Heybrook TT2 as well.

all:

Last edited:

Yes, it's ACAD...And, JPEGs are only for Display Purposes..A PDF or PLT would have been More Accurate...sreten: Yes, the Mayware Formula 4 is no longer available "cheap". I don't doubt that you massaged the Phillips into something better. I suppose better power regulation, chassis damping, etc? Remove the bottom plate and either leave it off or replace it with something better. And that is after ensuring that the basic table was in good order after cleaning and servicing it.

Everyone here should recognize that prior to rebuilding or making a new plinth for any turntable, a basic service must be done.

Now don't let any Linnies suggest that only a Linn warrants upgrades or improvements.

sled: I assumed as much, but your jpeg was to scale pretty much. I suspect ACAD? My attached image was for illustrative purposes, that's it. But the differences between a drawing, and reality is interesting.

Seems like I'm going to be getting a Strathclyde "STD 305S" for a Christmas present. I know I enjoyed working on a Roksan Xerxes and with mods was very good. I'm going to do the same sort of thing. I know I shouldn't have got rid of my Heybrook TT2 as well.

all:

Last edited:

Seems like I'm going to be getting a Strathclyde "STD 305S" for a Christmas present.

Hi,

That is basically AFAICT the standard plinth without the stainless steel

inserts and a simpler typical motor supply. Never had one to play with.

4 point suspension I recall, and a damped subchassis I recall.

Have to see photos for the details, but the sort of thing you can take from

good to very good for peanuts with simple mods fitted with a good arm.

rgds, sreten.

STD 305S

sreten: I believe that once tweaked the STD should be pretty reasonable. If I want to add mass, I can add a steel bottom plate. The stainless top plate looks good (on the 305M and 305D), but may require a rework to fit to the 305S. I don't think I'd bother.

I have a Linn Akito II arm here that might be a suitable match. AFAIK all of the STD tables used 115VAC motors. They just used a drop resistor from 230V to 115V. If that is the case, I'll just remove the drop resistor. Then have a friend cut the existing pulley down on a lathe (50Hz vs 60Hz mains frequency). I may have to make an arm board. I wonder if a DIY 'geddon would be suitable...and of course if the Akito II doesn't work out, I'll build another 219 for it.

This particular tt is cosmetically a little rough, but for CAD $50 (under £30), even if only the platter and bearing are intact still a lot of fun. Not as good a deal as a Roksan Xerxes that I bought for CAD $150 (about £88), that ended up with a Michell hot-rodded Rega on it.

This is the beauty of making your own tonearms. Tables can be had inexpensively, and often with (as you correctly state) not too much effort can be improved. Even very good tables.

sled: why not just ask any to view the image with a dwg viewer?

sreten: I believe that once tweaked the STD should be pretty reasonable. If I want to add mass, I can add a steel bottom plate. The stainless top plate looks good (on the 305M and 305D), but may require a rework to fit to the 305S. I don't think I'd bother.

I have a Linn Akito II arm here that might be a suitable match. AFAIK all of the STD tables used 115VAC motors. They just used a drop resistor from 230V to 115V. If that is the case, I'll just remove the drop resistor. Then have a friend cut the existing pulley down on a lathe (50Hz vs 60Hz mains frequency). I may have to make an arm board. I wonder if a DIY 'geddon would be suitable...and of course if the Akito II doesn't work out, I'll build another 219 for it.

This particular tt is cosmetically a little rough, but for CAD $50 (under £30), even if only the platter and bearing are intact still a lot of fun. Not as good a deal as a Roksan Xerxes that I bought for CAD $150 (about £88), that ended up with a Michell hot-rodded Rega on it.

This is the beauty of making your own tonearms. Tables can be had inexpensively, and often with (as you correctly state) not too much effort can be improved. Even very good tables.

sled: why not just ask any to view the image with a dwg viewer?

Stew: I wonder if a DIY 'geddon would be suitable..!

Ive not long fitted a Geddon to my Linn & I can whole heartedly recommend this mod, to anyone that still has a Valhalla powering their Linn, Get a Geddon !

This link to Nigel Person's Geddon, the one in the picture is the one I now have.

http://www.diyaudio.com/forums/analogue-source/97740-two-speed-valhalla-13.html

Ive not long fitted a Geddon to my Linn & I can whole heartedly recommend this mod, to anyone that still has a Valhalla powering their Linn, Get a Geddon !

This link to Nigel Person's Geddon, the one in the picture is the one I now have.

http://www.diyaudio.com/forums/analogue-source/97740-two-speed-valhalla-13.html

a little Off Topic...

sled:I just wanted to highlight the differences between my drawing, the outline of the AT6 (as you kindly posted) and the reality of what I ended up with for the first layer. I have modelled the Lab60 in sketchup as well, which I'll post for any interested.

Jay:er those look like speed controllers....not PSU. The Armageddon was/is a dedicated "stiff" power supply for the motor. AFAIR, it is basically a big transformer and phasing cpas for the motor. The Valhalla is then removed. Now if a 'geddon and some sort of speed controller is used, then I could see it all working out. Maybe I just don't understand...

sled:I just wanted to highlight the differences between my drawing, the outline of the AT6 (as you kindly posted) and the reality of what I ended up with for the first layer. I have modelled the Lab60 in sketchup as well, which I'll post for any interested.

Jay:er those look like speed controllers....not PSU. The Armageddon was/is a dedicated "stiff" power supply for the motor. AFAIR, it is basically a big transformer and phasing cpas for the motor. The Valhalla is then removed. Now if a 'geddon and some sort of speed controller is used, then I could see it all working out. Maybe I just don't understand...

Yep big old toroidal transformer & a few caps + a resistor. No speed controller just 33.

The thread started out as converting a Valhalla to a two speed unit.

The thread started out as converting a Valhalla to a two speed unit.

Hi,

The geddon replaces the step down resistor with a dirty great toroid,

pretty much specced AFAICT to make the supply seem very heavy.

There is nothing much "stiff" about it given it drives a 3.3K resistor

is series with both motor windings, one winding additionally has

2.0uF (2 x 1.0uF) in series with it, rocket science it is not.

(For direct 240V operation you just increase the resistor value,

If its not obvious you do not remove the drop resistor

for 115V operation, that is downright very dangerous.)

It will add nothing to a decent 60Hz oscillator type supply,

which is an option instead of reducing the pulley size.

Each winding is about 4K to give some idea of currents and power.

rgds, sreten.

The geddon replaces the step down resistor with a dirty great toroid,

pretty much specced AFAICT to make the supply seem very heavy.

There is nothing much "stiff" about it given it drives a 3.3K resistor

is series with both motor windings, one winding additionally has

2.0uF (2 x 1.0uF) in series with it, rocket science it is not.

(For direct 240V operation you just increase the resistor value,

If its not obvious you do not remove the drop resistor

for 115V operation, that is downright very dangerous.)

It will add nothing to a decent 60Hz oscillator type supply,

which is an option instead of reducing the pulley size.

Each winding is about 4K to give some idea of currents and power.

rgds, sreten.

Last edited:

Also how can the cartridge be cleaned of what looks like magnetic debris.

Try a small piece of blutack on a toothpick and carefully touch it lightly on the places you want to clean. Careful with coils of course 🙂

dropping the voltage...and back on topic, a turntable

On the fly I suggested just removing the voltage dropping resistor. This was if a 220 VAC input voltage machine being used in a 115 VAC market, if the original motor is a 115 VAC motor. The only other compensation would be a different sized pulley, 20% smaller in diameter (apply 60Hz to a 50Hz motor and the motor spins 20% faster, so the linear speed at the pulley must be dropped the same percentage). Then the only difference are the phasing capacitors needed to supply the second pair of coils with the required amount of phase shift.

To make my point more directly:

This is certainly not limited to turntables, as it seems more 220 VAC market stuff sneaks into N.A.

Back on topic:

Last night I screwed together a plinth, making the required cut-outs as I went along, layer by layer. I'll do a double check on the BB ply thickness, but IIRC it is 12 mm. It seems that 4 layers should enclose most everything. Once the complete mechanicals are covered, I will add a final 3/4" layer. Once I am satisfied I'll then take it someplace to get the full thickness cut , take it apart and then take some photographs. Once photographed I will attempt sketches of each layer. and post them. The only "hard points" used for location of all the others are the 2 drilled holes for the transport screws.

On the fly I suggested just removing the voltage dropping resistor. This was if a 220 VAC input voltage machine being used in a 115 VAC market, if the original motor is a 115 VAC motor. The only other compensation would be a different sized pulley, 20% smaller in diameter (apply 60Hz to a 50Hz motor and the motor spins 20% faster, so the linear speed at the pulley must be dropped the same percentage). Then the only difference are the phasing capacitors needed to supply the second pair of coils with the required amount of phase shift.

To make my point more directly:

- other than the voltage, the only thing electrically that may be required to change 220 VAC/50HZ motor to a 115 VAC/60Hz motor is the use of the phasing capacitors for 50Hz vs 60Hz operation. For voltage a simple 2:1 step down transformer could drop the voltage sufficiently (but something more like a 2.75:1 would get the originally Premotec motor down into its quietest range of about 80 VAC, as I understand it).

- if the Valhalla is essentially a frequency generator, then using a 50Hz motor in N.A, should not be a problem, it should do it electronically.

- The differences in the drivetrain of the motor/platter system are essentially just the pulley diameter

This is certainly not limited to turntables, as it seems more 220 VAC market stuff sneaks into N.A.

Back on topic:

Last night I screwed together a plinth, making the required cut-outs as I went along, layer by layer. I'll do a double check on the BB ply thickness, but IIRC it is 12 mm. It seems that 4 layers should enclose most everything. Once the complete mechanicals are covered, I will add a final 3/4" layer. Once I am satisfied I'll then take it someplace to get the full thickness cut , take it apart and then take some photographs. Once photographed I will attempt sketches of each layer. and post them. The only "hard points" used for location of all the others are the 2 drilled holes for the transport screws.

On the fly I suggested just removing the voltage dropping resistor.

Hi, Yes and its just clueless, rgds, sreten.

Halving the resistor or a bit more is sensible, no

resistor will cause start up belt stretch issues,

as well as in all respects being dangerous.

FWIW in simple terms you can use bigger caps

to approach the ideal 90 degree phase shift.

50/60Hz doesn't matter in any real sense.

Proper biphase drive can be done by a supply.

Last edited:

well I guess I must be...

sreten: thanks for the compliment. Not so clueless if the motor is a 115 VAC one, and my domestic mains are 115 VAC, and apparently the Valhalla drops voltage to 115VAC for the motor on LP12s and similar, so clueless? Only by not continuing along with the proper cap and possible change to the pulley diameter might it be suggested that it was clueless.

Off Topic:

Stuey: Hinton, AB is very near the same distance from me as Montrose, Scotland is from London. As an example, Alberta is the 4th largest Canadian province and has an area of 255,500 sq mi. The complete British Isles has an area of 121,673.9 sq mi so slightly less than 1/2 (about 47.6% of the area of the province of Alberta). We are a large country, and driving 800 kms for a visit is not uncommonly done for a 2 or 3 day trip (including a full day stay). Folks that live in congested cities here have no clue about what is "driving distance" as referred to the prairie provinces. Essentially a great, relatively flat, plain that dominates the 3 prairie provinces (Alberta, Saskatchewan, and Manitoba).SO relatively straight flat roads that are easy to drive. But the downside is the occurrence of falling asleep behind the wheel, which I have done a couple of times. Thankfully I hadn't crashed. Friends have rolled their cars at 100km when nodding off, but thankfully most survive. It is a real and potentially fatal peril.

Although a "western province", British Columbia is geographically dominated by mountains, and thus not a "prairie province". So next time you're emailing or talking with your aunt and uncle in Hinton, ask them to drop on by...for coffee or tea, their choice🙂.

sreten: thanks for the compliment. Not so clueless if the motor is a 115 VAC one, and my domestic mains are 115 VAC, and apparently the Valhalla drops voltage to 115VAC for the motor on LP12s and similar, so clueless? Only by not continuing along with the proper cap and possible change to the pulley diameter might it be suggested that it was clueless.

Off Topic:

Stuey: Hinton, AB is very near the same distance from me as Montrose, Scotland is from London. As an example, Alberta is the 4th largest Canadian province and has an area of 255,500 sq mi. The complete British Isles has an area of 121,673.9 sq mi so slightly less than 1/2 (about 47.6% of the area of the province of Alberta). We are a large country, and driving 800 kms for a visit is not uncommonly done for a 2 or 3 day trip (including a full day stay). Folks that live in congested cities here have no clue about what is "driving distance" as referred to the prairie provinces. Essentially a great, relatively flat, plain that dominates the 3 prairie provinces (Alberta, Saskatchewan, and Manitoba).SO relatively straight flat roads that are easy to drive. But the downside is the occurrence of falling asleep behind the wheel, which I have done a couple of times. Thankfully I hadn't crashed. Friends have rolled their cars at 100km when nodding off, but thankfully most survive. It is a real and potentially fatal peril.

Although a "western province", British Columbia is geographically dominated by mountains, and thus not a "prairie province". So next time you're emailing or talking with your aunt and uncle in Hinton, ask them to drop on by...for coffee or tea, their choice🙂.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- The Nanook turntable thread