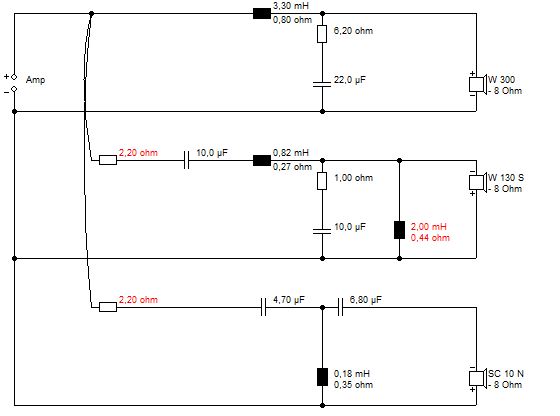

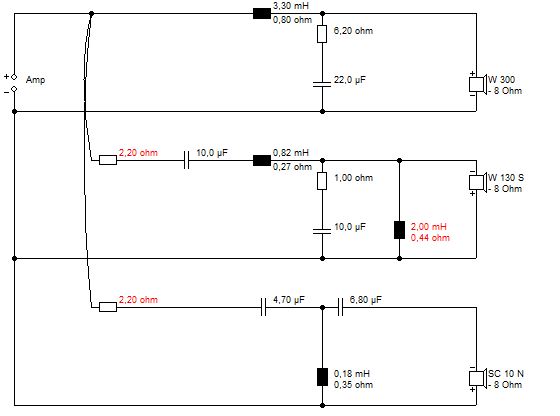

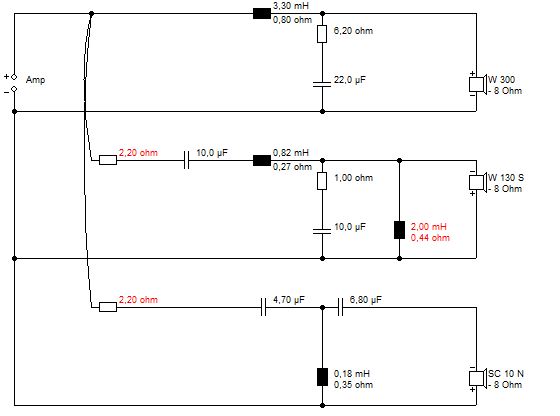

I was quite shocked at the price of large aircoils these days. £15? 😱

We might do better...

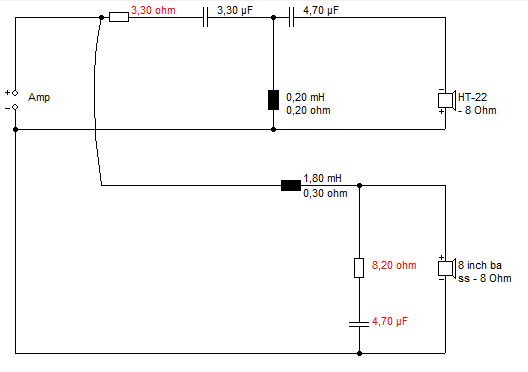

That 3.3mH and 2mH (1.8mH or 2.2mH will do, not critical) might be ferrites. FWIW ferrite increases inductance about fourfold, so easy enough to get under an ohm resistance:

Ferrite Cored Inductors

I would use electrolytics on the bass and mid sections.

Mundorf Electrolytic ECap Capacitors

Film capacitors for the tweeter, nothing fancy:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Capacitors

Good choice of resistors here:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Resistors

20W for the bass circuit, 5-10W elsewhere. The 1 ohm in the mid shunt could probably go with an electrolytic capacitor. They have a small resistance anyway.

Quite feasable to build your own coils with 1mm enamelled copper wire and a bobbin, as some do. You then wrap tape round the outside. Our friend Lojzek might advise on this. But you need an inductance meter.

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Inductor Bobbins

When placing coils it is good to keep them far apart, or at right angles when close. Reduces crosstalk. The main field strength and sensitivity is in the line of the axis it is wound round.

We might do better...

That 3.3mH and 2mH (1.8mH or 2.2mH will do, not critical) might be ferrites. FWIW ferrite increases inductance about fourfold, so easy enough to get under an ohm resistance:

Ferrite Cored Inductors

I would use electrolytics on the bass and mid sections.

Mundorf Electrolytic ECap Capacitors

Film capacitors for the tweeter, nothing fancy:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Capacitors

Good choice of resistors here:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Resistors

20W for the bass circuit, 5-10W elsewhere. The 1 ohm in the mid shunt could probably go with an electrolytic capacitor. They have a small resistance anyway.

Quite feasable to build your own coils with 1mm enamelled copper wire and a bobbin, as some do. You then wrap tape round the outside. Our friend Lojzek might advise on this. But you need an inductance meter.

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Inductor Bobbins

When placing coils it is good to keep them far apart, or at right angles when close. Reduces crosstalk. The main field strength and sensitivity is in the line of the axis it is wound round.

Last edited:

Sigh....gone are the days back when I could buy surplus magnet winding wire in bulk for 'pennies on the dollar' and unwind as required.

There is a well known seller on Ali Express that sells coils:

Ferrite: 0.8mm Speaker Crossover Inductance Copper 0.5mh 1.0mh 2.0mh 3.0mh Oxygen free Copper Frequency Divider Coil 1PC|Speaker Accessories| - AliExpress

It says they’ll adjust to order if you need a different / specific measurement.

For a 3.3mH (assuming you buy the nearest to the desired value) it looks to be about £10 after VAT.

They also have stock values of 2.0mH and 1.0mH, which would come to £14.39 after VAT for both.

Air coils: GHXAMP 1PCS 0.5mm LoudSpeaker Crossover Inductor 4N Oxygen free Copper Coil Hollow Circle Skeleton 0.3mH 0.5mH 1.0mH 2.0mH|Portable Speakers| - AliExpress

They adjust to order again. These look huge. Not sure if I would be able to fit components this size on the approx 9cm x 10cm space where the existing crossover is.

I could always relocate the crossover to the space behind the tweeter ie on the top right wall. This would give me more than enough space for larger components.

Ferrite: 0.8mm Speaker Crossover Inductance Copper 0.5mh 1.0mh 2.0mh 3.0mh Oxygen free Copper Frequency Divider Coil 1PC|Speaker Accessories| - AliExpress

It says they’ll adjust to order if you need a different / specific measurement.

For a 3.3mH (assuming you buy the nearest to the desired value) it looks to be about £10 after VAT.

They also have stock values of 2.0mH and 1.0mH, which would come to £14.39 after VAT for both.

Air coils: GHXAMP 1PCS 0.5mm LoudSpeaker Crossover Inductor 4N Oxygen free Copper Coil Hollow Circle Skeleton 0.3mH 0.5mH 1.0mH 2.0mH|Portable Speakers| - AliExpress

They adjust to order again. These look huge. Not sure if I would be able to fit components this size on the approx 9cm x 10cm space where the existing crossover is.

I could always relocate the crossover to the space behind the tweeter ie on the top right wall. This would give me more than enough space for larger components.

I didn't find anything in those AliExpress links that excited me... 😀

Surely Wilmslow ferrite coils are much the same price?

Ferrite Cored Inductors

Wilmslow will unwind to exact values for you, and after-sales sevice is assured.

I found Wilmslow extremely helpful over the phone with a query about whether a soft dome was cloth or plastic. The guy went into the stock room and checked for me. Thus settling an argument at DIYAudio...

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Inductors

Aircoil prices depend largely on the guage of wire employed. Blue Aran have three guages. The 0.5mm are significantly cheap, but you must expect highish resistance with such things. Maybe 3 ohms with 3.3mH. This would lead to heating in a bass circuit. The 0.8mm guage looks a bit of an all-rounder to me. Blue Aran are nice people too. I have visited them.

Surely Wilmslow ferrite coils are much the same price?

Ferrite Cored Inductors

Wilmslow will unwind to exact values for you, and after-sales sevice is assured.

I found Wilmslow extremely helpful over the phone with a query about whether a soft dome was cloth or plastic. The guy went into the stock room and checked for me. Thus settling an argument at DIYAudio...

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Inductors

Aircoil prices depend largely on the guage of wire employed. Blue Aran have three guages. The 0.5mm are significantly cheap, but you must expect highish resistance with such things. Maybe 3 ohms with 3.3mH. This would lead to heating in a bass circuit. The 0.8mm guage looks a bit of an all-rounder to me. Blue Aran are nice people too. I have visited them.

Apologies for the long silence. It’s been very busy this end since the summer holidays started!

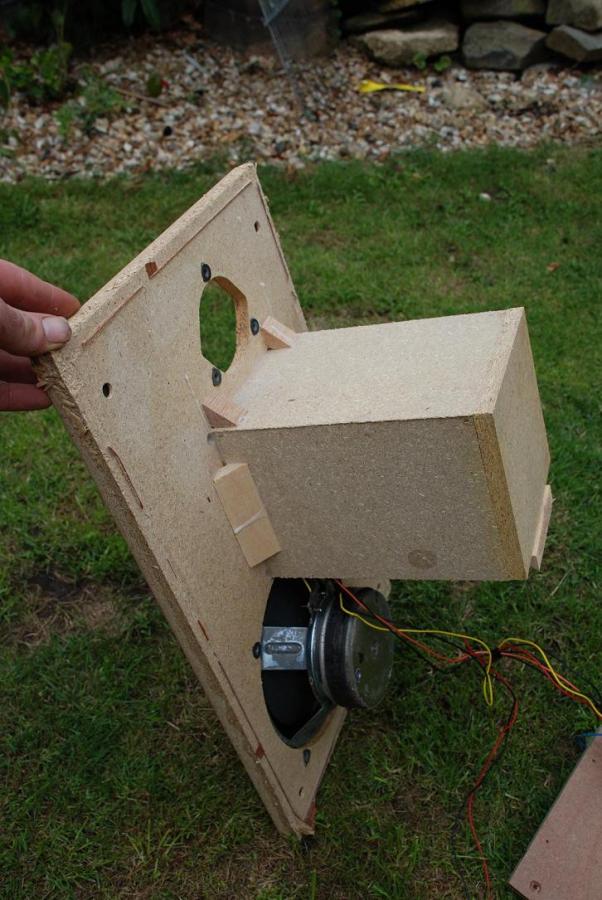

I have started ordering components for the crossover. Until they get here, I have been building the mid housing and increasing the cut out size in the baffles and grilles.

The mid housings are cut from MDF I had in the shed and are cut with my trusty old jigsaw cutter. They aren’t as straight as B&Q cuts so I’ve sealed them with copious amounts of hot glue and liquid nails the latter of which was applied by [nitrile gloved] hand to ensure a good seal. I’m quite confident they’re air tight and fit for purpose. The final volume ended up being about 6L. Due to the size of the enclosures, they were assembled once inside the cabinets (including screws) which was lots of fun 😛

I have also gutted the original crossover on the small plywood boards and replaced the posts in preparation for the new crossovers.

Finally, it occurred to me that the way the bass drivers are secured is no longer suitable. The nuts/bolts are basically inverse, with a Phillips M bolt facing inwards and a nut on the outside. This requires a hand with stubby screwdriver inserted through the mid cutout (or tweeter if you have insanely small hands) to hold/tighten which is no longer possible with the mid enclosure. To solve this, I have changed the way the bass drivers are secured by fixing a small piece of MDF behind the baffle so that a screw may secure the bass driver from the front.

Increasing the mid cutout:

Increasing the grille cutout:

The mid enclosure:

View from cutout:

Posts pre crossover removal:

New posts fitted:

MDF fixed with liquid nails behind the baffle so that bass can be secured from front:

More soon 🙂

I have started ordering components for the crossover. Until they get here, I have been building the mid housing and increasing the cut out size in the baffles and grilles.

The mid housings are cut from MDF I had in the shed and are cut with my trusty old jigsaw cutter. They aren’t as straight as B&Q cuts so I’ve sealed them with copious amounts of hot glue and liquid nails the latter of which was applied by [nitrile gloved] hand to ensure a good seal. I’m quite confident they’re air tight and fit for purpose. The final volume ended up being about 6L. Due to the size of the enclosures, they were assembled once inside the cabinets (including screws) which was lots of fun 😛

I have also gutted the original crossover on the small plywood boards and replaced the posts in preparation for the new crossovers.

Finally, it occurred to me that the way the bass drivers are secured is no longer suitable. The nuts/bolts are basically inverse, with a Phillips M bolt facing inwards and a nut on the outside. This requires a hand with stubby screwdriver inserted through the mid cutout (or tweeter if you have insanely small hands) to hold/tighten which is no longer possible with the mid enclosure. To solve this, I have changed the way the bass drivers are secured by fixing a small piece of MDF behind the baffle so that a screw may secure the bass driver from the front.

Increasing the mid cutout:

Increasing the grille cutout:

The mid enclosure:

View from cutout:

Posts pre crossover removal:

New posts fitted:

MDF fixed with liquid nails behind the baffle so that bass can be secured from front:

More soon 🙂

Last edited:

I might have some time later today to recover the grilles. I was initially a bit concerned about the weave of the fabric being too loose as the foam that will be behind it is a light grey colour. I would have preferred black, but I got this off cut free of charge so in the theme of keeping costs down it’s what will be used. The fabric was also free and looks like the stuff from vintage floor standing units.

Here’s the posts and original yellow board against the newly stained dark walnut back:

I’ll keep and reconnect the DIN socket just because it adds character 😎

The original back was a chocolate mousse brown, pretty ugly in my opinion. The veneer was something like oak or similar. It was scratched, dented and peeling in the corners.. instead of spending hours repairing veneer (which I know nothing about) I decided a lot of wood filler and stain would be a better idea. Thanks to some garage door left overs from a neighbour, the cabinet will go dark walnut which will look much better with the grille fabric.

Here’s the posts and original yellow board against the newly stained dark walnut back:

I’ll keep and reconnect the DIN socket just because it adds character 😎

The original back was a chocolate mousse brown, pretty ugly in my opinion. The veneer was something like oak or similar. It was scratched, dented and peeling in the corners.. instead of spending hours repairing veneer (which I know nothing about) I decided a lot of wood filler and stain would be a better idea. Thanks to some garage door left overs from a neighbour, the cabinet will go dark walnut which will look much better with the grille fabric.

@system7 one thing I haven’t ordered yet is air coils, and I was considering making them as you suggested. I’ve been using an inductor calculator and cross checking various prebuilt coils with a copper wire diameter of 1mm as you suggested, and it looks like the resistance value is about 0.4ohms for the 0.82mH… such as this: https://cpc.farnell.com/visaton/5013/inductor-air-core-0-82mh-0-4r/dp/FT01421?st=air core inductors

how critical is it that the 2 air coils remain close to the values of 0.27 ohms and 0.35 ohms? Will that extra 0.05 ohms on the 0.82mH matter too much? Or do I need to look at ferrites for these too?

@Lojzek I’ve found some suitable 1mm enamelled copper wire here: https://cpc.farnell.com/unbranded/ecw1-0/19swg-enamelled-copper-wire/dp/CB01222

Could you advise on the most suitable bobbins for 0.82mH and 0.18mH? Will the 70M spool be sufficient for two of each?

how critical is it that the 2 air coils remain close to the values of 0.27 ohms and 0.35 ohms? Will that extra 0.05 ohms on the 0.82mH matter too much? Or do I need to look at ferrites for these too?

@Lojzek I’ve found some suitable 1mm enamelled copper wire here: https://cpc.farnell.com/unbranded/ecw1-0/19swg-enamelled-copper-wire/dp/CB01222

Could you advise on the most suitable bobbins for 0.82mH and 0.18mH? Will the 70M spool be sufficient for two of each?

Looking at the data sheet for that wire: https://www.farnell.com/datasheets/2021941.pdf It says that’s the max resistance per meter is 0.0224R.

Warning, some possible very erroneous calculations ahead 😀

Using this calculator here: Air Cored Inductor Calculator – M0UKD – Amateur Radio Blog and assuming a bobbin size of 38mm from Blue Aran, which is 22.25mm diameter and 16.25mm length, it would take:

1. 0.824mH > 211 turns > 14.72M. 14.72 * 0.0224R = 0.329R

2. 0.181mH > 99 turns > 6.90M. 6.90 * 0.0224R = 0.154R

So I can get under for the 0.18mH, but slightly over for the 0.82mH.

Looks like a very rough calculation for how many turns that bobbin could accommodate would be about 112 turns, so fine for the 0.18mH but would need to increase for the 0.82mH. The next size up is the 54mm, which might be able to hold ~375 turns. But then 24mm diameter and 28mm length in the calf gives:

0.824mH > 228 turns > 17.19M. 17.19 * 0.0024R = 0.385mH… 😱

The one thing missing from that calculator is wire gauge… But I think it’s likely that the 0.82mH needs the 1.25mm wire, it’s 0.01435R per meter, which would make 17.19M = 0.246R so spot on.

However, the 1.25mm comes in 47M spools so there would not be enough on that roll for all 4 coils, as ~48.18M would be needed. 2 spools at about £32 plus meter for £10 plus bobbins for £3 it’s working out more than most places sell prebuilt. Unless I buy ferrite core bobbins and make those too? Any recommendations for ferrite bobbins? Looks like Wilmslow just use a small rod.

Edit: actually, it looks just like this: https://uk.rs-online.com/web/p/ferrite-rods/1730001

Wondering if it would actually be feasible to make the lot!

Warning, some possible very erroneous calculations ahead 😀

Using this calculator here: Air Cored Inductor Calculator – M0UKD – Amateur Radio Blog and assuming a bobbin size of 38mm from Blue Aran, which is 22.25mm diameter and 16.25mm length, it would take:

1. 0.824mH > 211 turns > 14.72M. 14.72 * 0.0224R = 0.329R

2. 0.181mH > 99 turns > 6.90M. 6.90 * 0.0224R = 0.154R

So I can get under for the 0.18mH, but slightly over for the 0.82mH.

Looks like a very rough calculation for how many turns that bobbin could accommodate would be about 112 turns, so fine for the 0.18mH but would need to increase for the 0.82mH. The next size up is the 54mm, which might be able to hold ~375 turns. But then 24mm diameter and 28mm length in the calf gives:

0.824mH > 228 turns > 17.19M. 17.19 * 0.0024R = 0.385mH… 😱

The one thing missing from that calculator is wire gauge… But I think it’s likely that the 0.82mH needs the 1.25mm wire, it’s 0.01435R per meter, which would make 17.19M = 0.246R so spot on.

However, the 1.25mm comes in 47M spools so there would not be enough on that roll for all 4 coils, as ~48.18M would be needed. 2 spools at about £32 plus meter for £10 plus bobbins for £3 it’s working out more than most places sell prebuilt. Unless I buy ferrite core bobbins and make those too? Any recommendations for ferrite bobbins? Looks like Wilmslow just use a small rod.

Edit: actually, it looks just like this: https://uk.rs-online.com/web/p/ferrite-rods/1730001

Wondering if it would actually be feasible to make the lot!

Last edited:

David, these values only have to be within 10%. If you want to be fussy, you keep the product of capacitance and inductance constant, and most of the error cancels out.

I bought a lot of my stuff from Wilmslow Audio.

Their PCBs are useful too, but the very devil to figure out for tidy wiring... 😕

Bit more diy. Using tagstrip, available form RS. Troels likes tagstrip.

I'd have thought 1mm or 19 swg wire will be OK for most things.

I bought a lot of my stuff from Wilmslow Audio.

Their PCBs are useful too, but the very devil to figure out for tidy wiring... 😕

Bit more diy. Using tagstrip, available form RS. Troels likes tagstrip.

I'd have thought 1mm or 19 swg wire will be OK for most things.

Last edited:

I messed up an image in the previous post and lost it...

But here's a nice way to strengthen a midrange enclosure against heavy handling courtesy of the Celestion 33:

Still a good speaker even by today's standards. The classic 3 way.

But here's a nice way to strengthen a midrange enclosure against heavy handling courtesy of the Celestion 33:

Still a good speaker even by today's standards. The classic 3 way.

Nice one thanks Steve. I can certainly try and do something like that to the rear of the mid enclosure. It might not be all the way round, but I’ll see what I can manage.

I’ve ordered some prototype boards to add the components to, and am thinking of separating them out just due to space constraints. This way I can place the coils far apart easily. Ie. Have a board for each circuit. There’s certainly enough space in the cabinet.

I’ll grab the 1mm wire and I’ve grabbed some ferrite rods and a meter. I’m going to have a go at making the lot and I will fall back on prebuilt if I stumble. I’m kinda enjoying the challenge. 😉

I’ve ordered cement resistors of 5R and 1.2R rated at 20W for the bass, and 1R and 2.2R cements rated at 10W for elsewhere.

Are those mostly film capacitors in your kit? I have the electrolytics, but I’m seriously considering just putting film in instead. Can you recommend a film capacitor? The clarity caps seem to be a good all rounder…. Would bump the price of the crossover considerably, but if it’s worth it and they don’t need replacing….

I’ve ordered some prototype boards to add the components to, and am thinking of separating them out just due to space constraints. This way I can place the coils far apart easily. Ie. Have a board for each circuit. There’s certainly enough space in the cabinet.

I’ll grab the 1mm wire and I’ve grabbed some ferrite rods and a meter. I’m going to have a go at making the lot and I will fall back on prebuilt if I stumble. I’m kinda enjoying the challenge. 😉

I’ve ordered cement resistors of 5R and 1.2R rated at 20W for the bass, and 1R and 2.2R cements rated at 10W for elsewhere.

Are those mostly film capacitors in your kit? I have the electrolytics, but I’m seriously considering just putting film in instead. Can you recommend a film capacitor? The clarity caps seem to be a good all rounder…. Would bump the price of the crossover considerably, but if it’s worth it and they don’t need replacing….

I was quite shocked at the price of large aircoils these days. £15? 😱

We might do better...

That 3.3mH and 2mH (1.8mH or 2.2mH will do, not critical) might be ferrites. FWIW ferrite increases inductance about fourfold, so easy enough to get under an ohm resistance:

Ferrite Cored Inductors

I would use electrolytics on the bass and mid sections.

Mundorf Electrolytic ECap Capacitors

Film capacitors for the tweeter, nothing fancy:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Capacitors

Good choice of resistors here:

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Resistors

20W for the bass circuit, 5-10W elsewhere. The 1 ohm in the mid shunt could probably go with an electrolytic capacitor. They have a small resistance anyway.

Quite feasable to build your own coils with 1mm enamelled copper wire and a bobbin, as some do. You then wrap tape round the outside. Our friend Lojzek might advise on this. But you need an inductance meter.

Blue Aran - The UK's no.1 Loudspeaker Component Stockist > Speaker Components > Crossovers & Components > Inductor Bobbins

When placing coils it is good to keep them far apart, or at right angles when close. Reduces crosstalk. The main field strength and sensitivity is in the line of the axis it is wound round.

20W for a 1.2R resistor is overkill, especially in series with a 5R 20W.

Ohms Law. Power is W = I^2 R.

or W = V^2 / R.

Therefore the 5R is going to get 4X more power than the 1.2R. So 5W will do if you can't get exact value.

And 10% accuracy will do here. It's only impedance correction which is an inexact science at the best of times...

That I didn't post a picture of electrolytics doesn't mean I haven't used them for large values. Just couldn't dig up an image. A film 22uF is huge. NPEs are small. I mentioned if you use NPEs on the mid shunt you don't need the 1R resistor.

Way to think about power ratings for resistors is a tweeter never goes above 10W, and a mid rarely above 20W. It's the bass where all the power goes.

So a 2.2R in series with a 6R tweeter will consume about 3W at parties and loud. Often used as a fuse, in fact. Saves the tweeter.

20W for a 1.2R resistor is overkill, especially in series with a 5R 20W.

Ohms Law. Power is W = I^2 R.

or W = V^2 / R.

Therefore the 5R is going to get 4X more power than the 1.2R. So 5W will do if you can't get exact value.

This is where my lack of electronics knowledge really shows 😱 Even though they are overkill, will they work? I can check and see if they have already been dispatched. They were only a couple of quid so if they’re suitable but just hideously overkill I’m happy to use them.

That I didn't post a picture of electrolytics doesn't mean I haven't used them for large values. Just couldn't dig up an image. A film 22uF is huge. NPEs are small. I mentioned if you use NPEs on the mid shunt you don't need the 1R resistor.

I realise this but I was thinking more about having to not open them up in x years to recap them. The 22uF being big doesn’t seem to be too much of an issue? It’s about 40mm x 45mm, whilst massive compared to NPEs, this shouldn’t be an issue to fit within the cabinets, especially if the crossover is separated into sections for the 3 drivers.

However: if you’re basically saying this is going to explode in my face and I’m being stupid, I’ll change course. 😀

Nothing will break with higher rated components! 😀

These Harbeth crossovers don't overdo the glam on components... just all gets bigger and possibly awkward. Lot of 3W resistors there and maybe MKT (Polypropylene dielectric) less glamourous brothers MKP (Polyester dielectric). And largely ferrite coils.

An older version:

Alan Shaw charges about £5000 for these Bass, Tweeter, Supertweeter jobbies. Designed to last. But admits that NPE capacitors don't last forever.

Crossover Upgrade Advice

These Harbeth crossovers don't overdo the glam on components... just all gets bigger and possibly awkward. Lot of 3W resistors there and maybe MKT (Polypropylene dielectric) less glamourous brothers MKP (Polyester dielectric). And largely ferrite coils.

An older version:

Alan Shaw charges about £5000 for these Bass, Tweeter, Supertweeter jobbies. Designed to last. But admits that NPE capacitors don't last forever.

Crossover Upgrade Advice

Wow that’s a busy and chunky looking board 😀 I’m imagining what I’ll end up with. I’m expecting chunky, but not as busy if my idea works out. I enjoy stuff that is built to last. I put minimal in my landfill bin and recycle lots (some of which we pay extra for, like some plastics). I suppose that’s one of the reasons I like these K2’s… they’re from a non-throwaway era. The Mrs said her Dad used to have a pair of big old speakers similar to these and they used to stand on them to put the Christmas decorations up 😱 they never fell apart though and apparently were in full working order when he put them on freecycle. Doubt you could say that for 90% of stuff today.

I’ve had a shout out and have been offered some tweeters for peanuts. I don’t know much about them yet except they might be 6ohm and they’re unused because they didn’t fit in whatever they were meant to be fixing. Before I bother going any further, will 6ohm tweeters be suitable or is that a no go? I know you said the mids being 4ohm were an issue, but not sure how it sits with the tweeters.

I’ve had a shout out and have been offered some tweeters for peanuts. I don’t know much about them yet except they might be 6ohm and they’re unused because they didn’t fit in whatever they were meant to be fixing. Before I bother going any further, will 6ohm tweeters be suitable or is that a no go? I know you said the mids being 4ohm were an issue, but not sure how it sits with the tweeters.

I don't find any measurement of tweeter DC resistance in this thread, but would assume it's around 6 ohms.

If it is 3 ohms, things change on ideal component values. Capacitors get bigger, coils smaller. But in this case, the filter likely will cope going overdamped.

We must wait and see what the replacement tweeters are. Probably an upgrade. Likely ferrofluid these days with less impedance problems. But that circuit should be OK with most stuff. 1" tweeters tend to 91dB. 3/4" to 88dB.

Personally I usually remove ferrofluid. Modern tweeters don't need it IMO. Better glues.

If it is 3 ohms, things change on ideal component values. Capacitors get bigger, coils smaller. But in this case, the filter likely will cope going overdamped.

We must wait and see what the replacement tweeters are. Probably an upgrade. Likely ferrofluid these days with less impedance problems. But that circuit should be OK with most stuff. 1" tweeters tend to 91dB. 3/4" to 88dB.

Personally I usually remove ferrofluid. Modern tweeters don't need it IMO. Better glues.

Ok, more information on them. Good news and bad.

Bad news is they are these: HIFIDIY LIVE X1II 4 inch 4.5 Tweeter Speaker Unit aluminum panel transparent Silk membrane 6OHM30W Treble Loudspeaker 94~120mm|Speaker Accessories| - AliExpress so nothing mainstream. I should have guessed really, the guy who offered them is the one who got me into AliExpress.

With that said, here is some info from the listing:

They’re being offered for £15. So the question is, are they junk or worth a shot? They were purchased to replace two damaged tweeters in some Yamaha speakers but they were the wrong size. Apparently the correct size was ordered and they sound better than the originals.

Good news is: the reviews seem fairly good and they seem to be 6ohm, 90db, 30W max and one guy says their range is pretty good:

I don’t have actual resistance measurements yet as they’re in a loft. Waiting to actually see them.

I can’t find any Monacor, Visaton etc tweeters that are anywhere near £7.50 each. Thinking it might be worth taking a risk.

Bad news is they are these: HIFIDIY LIVE X1II 4 inch 4.5 Tweeter Speaker Unit aluminum panel transparent Silk membrane 6OHM30W Treble Loudspeaker 94~120mm|Speaker Accessories| - AliExpress so nothing mainstream. I should have guessed really, the guy who offered them is the one who got me into AliExpress.

With that said, here is some info from the listing:

They’re being offered for £15. So the question is, are they junk or worth a shot? They were purchased to replace two damaged tweeters in some Yamaha speakers but they were the wrong size. Apparently the correct size was ordered and they sound better than the originals.

Good news is: the reviews seem fairly good and they seem to be 6ohm, 90db, 30W max and one guy says their range is pretty good:

I don’t have actual resistance measurements yet as they’re in a loft. Waiting to actually see them.

I can’t find any Monacor, Visaton etc tweeters that are anywhere near £7.50 each. Thinking it might be worth taking a risk.

I’ve said yes to the tweets, if they’re junk I’ll pass em on. I get a lot on freecycle and I give a lot back. What goes around comes around.

The caps arrived today.

Here is a pic of the 22uF in the bottom of the cabinet just for size reference:

I think if I place the board containing the bass crossover components where the original crossover was, it should be ok. The mid crossover could be placed within the mid housing, and the tweeter crossover on the top right back wall behind the tweeter.

The caps arrived today.

Here is a pic of the 22uF in the bottom of the cabinet just for size reference:

I think if I place the board containing the bass crossover components where the original crossover was, it should be ok. The mid crossover could be placed within the mid housing, and the tweeter crossover on the top right back wall behind the tweeter.

It's hard to see what can go wrong with a tweeter apart from voice-coil rubbing due to poor quality control...

There IS a tweeter for about £7.50, the Monacor HT22/8:

But an acquired taste, and 90mm front plate and 80mm screws can be problematic.

Anyway, all good. I told you a 22uF MKP (polypropylene) was a big jobbie! 😀

I'd mount the crossover on the bottom of the cabinet on a piece of timber. Just sits in place.

There IS a tweeter for about £7.50, the Monacor HT22/8:

But an acquired taste, and 90mm front plate and 80mm screws can be problematic.

Anyway, all good. I told you a 22uF MKP (polypropylene) was a big jobbie! 😀

I'd mount the crossover on the bottom of the cabinet on a piece of timber. Just sits in place.

Last edited:

It's hard to see what can go wrong with a tweeter apart from voice-coil rubbing due to poor quality control...

Fingers crossed then, the only negative reviews are from orders that didn’t get delivered so I am hoping they aren’t half bad QC wise.

There IS a tweeter for about £7.50, the Monacor HT22/8:

But an acquired taste

Out of interest, why an acquired taste?

I'd mount the crossover on the bottom of the cabinet on a piece of timber. Just sits in place.

Yeah I think that’s a good idea, thanks.

Crossover wise I am still waiting for ferrite rods, LCR meter and resistors. I also need to find something like dowel or similar to insert the ferrite rods into. After that I’m fairly good to go with assembly. 🙂

- Home

- Loudspeakers

- Multi-Way

- Restoring / Modifying Goodmans Magnum K2s Advice Needed