A bit more fettling, coaxing and gentle persuasion - I think the retaining clip will now go back in?

As for the azimuth issue, the cartridge wasn't correctly clipped into place - LOL 😳

Last step (?) is to reunite the Garrard 210 auto-changer with the stereo amp module and replace everything back in the PYE Stereo Black Box G63 cabinet.

As for the azimuth issue, the cartridge wasn't correctly clipped into place - LOL 😳

Last step (?) is to reunite the Garrard 210 auto-changer with the stereo amp module and replace everything back in the PYE Stereo Black Box G63 cabinet.

Thought I'd finished but the auto-changer is playing up again! 😡

When in Manual the motor and turntable spin correctly - speeds checked again.

When I switch to Automatic the turntable stops spinning and the tonearm doesn't lift? If I manually rotate the turntable several times it seems to re-engage with the auto-changer cycle, a record drops and the tonearm swings into position and plays the record. At the end, however, the same thing seems to happen and the turntable stops spinning, the tonearm lifts but doesn't move back. Manual intervention finishes off the auto-changer cycle, the tonearm returns to the rest position and it turns off.

When in Manual the motor and turntable spin correctly - speeds checked again.

When I switch to Automatic the turntable stops spinning and the tonearm doesn't lift? If I manually rotate the turntable several times it seems to re-engage with the auto-changer cycle, a record drops and the tonearm swings into position and plays the record. At the end, however, the same thing seems to happen and the turntable stops spinning, the tonearm lifts but doesn't move back. Manual intervention finishes off the auto-changer cycle, the tonearm returns to the rest position and it turns off.

Perhaps the motor is transferring insufficient torque to the platter when the extra load of the autochange mechanism is engaged.

Have you checked the condition of the idler wheel? Over time the rubber hardens and slippage occurs. This may be cured by lightly roughening the driving surface of the idler wheel with fine emery paper.

Have you checked the condition of the idler wheel? Over time the rubber hardens and slippage occurs. This may be cured by lightly roughening the driving surface of the idler wheel with fine emery paper.

Sounds like a possibility.

My only reservation is that is was working but started playing up again today so I'm still thinking it's part of the auto-changer mechanism, but which part?

I'll find some fine emery paper in the morning!

My only reservation is that is was working but started playing up again today so I'm still thinking it's part of the auto-changer mechanism, but which part?

I'll find some fine emery paper in the morning!

I roughened the surface of the idler wheel with fine emery paper but that made no difference?

I understand that the motor could be 'transferring insufficient torque when the extra load of the autochange mechanism is engaged' but as the auto-changer mechanism sticks at both ends of the cycle, start and finish, then I'm at a loss to understand what is happening, or not!

I understand that the motor could be 'transferring insufficient torque when the extra load of the autochange mechanism is engaged' but as the auto-changer mechanism sticks at both ends of the cycle, start and finish, then I'm at a loss to understand what is happening, or not!

I'm stuck too!

I know that on my deck there is a sliding lever, moved by the tonearm, that operates the trip mechanism. This lever must be free of oil and grease to work properly.

Have you have serviced the motor itself? The bottom bearing may require lubrication which would necessitate disassembly of the motor.

I know that on my deck there is a sliding lever, moved by the tonearm, that operates the trip mechanism. This lever must be free of oil and grease to work properly.

Have you have serviced the motor itself? The bottom bearing may require lubrication which would necessitate disassembly of the motor.

As I'm really struggling could you highlight or point to the sliding arm you refer to - thanks.

Wouldn't ask normally but this Garrard 210 may have an early appointment at our local Recycling Centre!

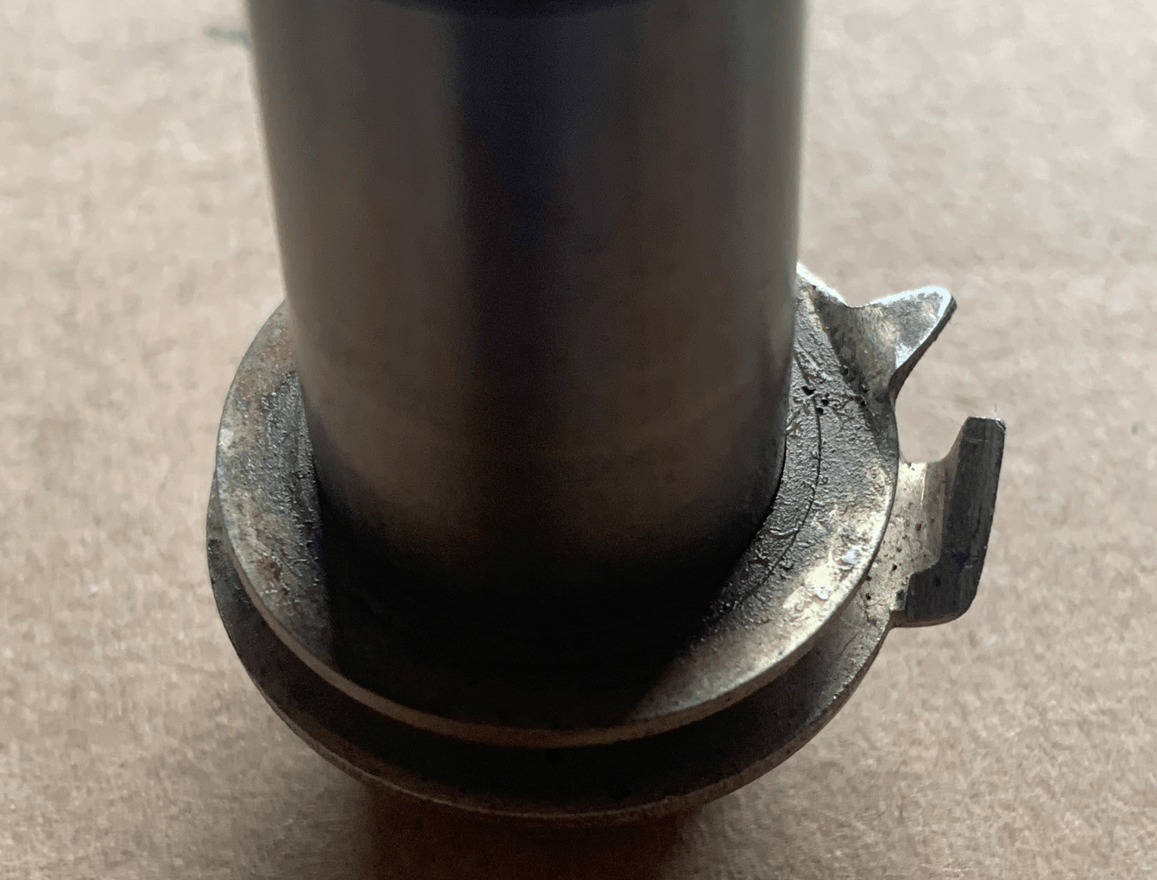

The two nuts either side of the motor bearing are easily removed and this should allow access for some lubrication.

Wouldn't ask normally but this Garrard 210 may have an early appointment at our local Recycling Centre!

The two nuts either side of the motor bearing are easily removed and this should allow access for some lubrication.

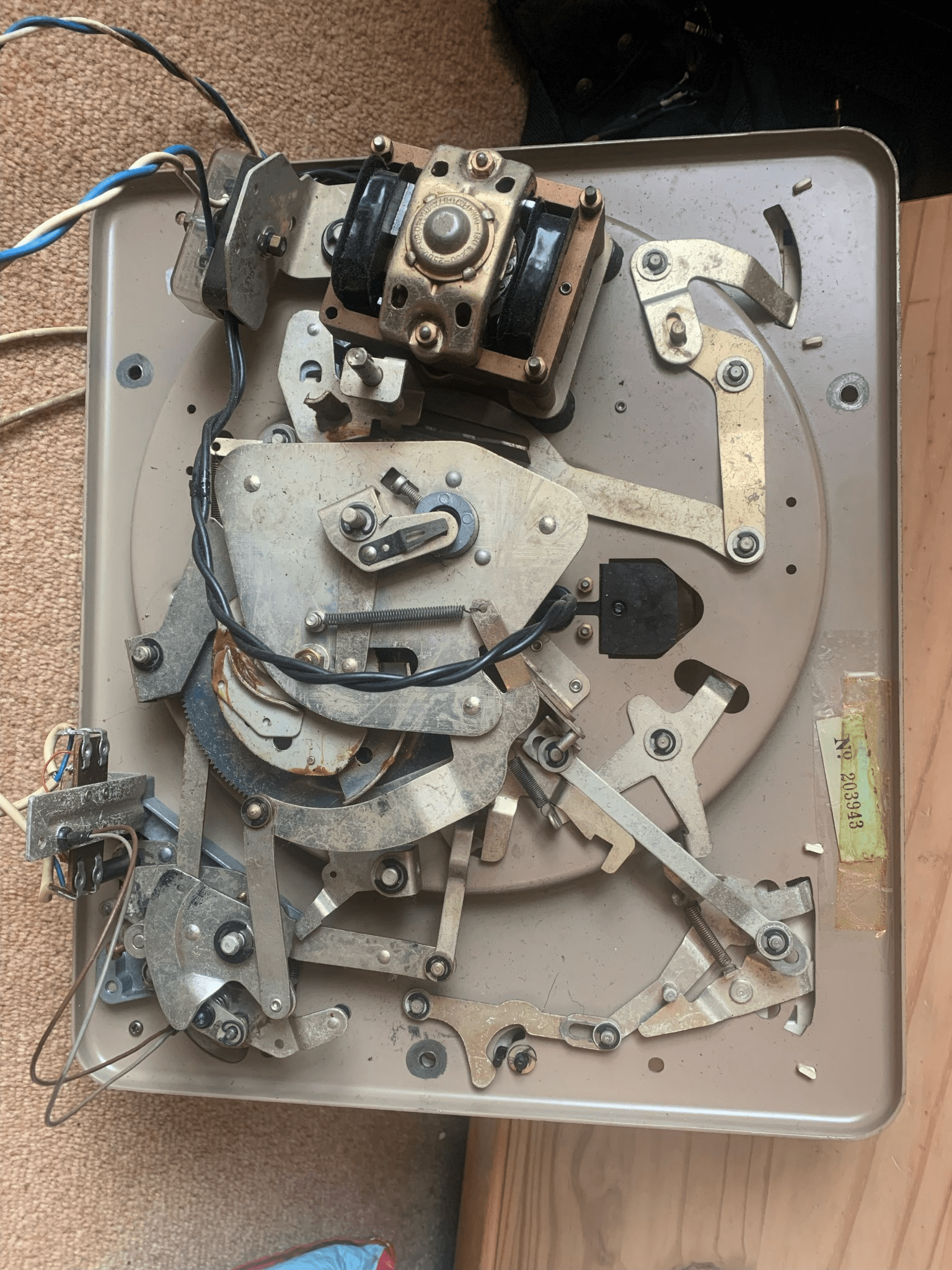

I'm further confused by the role of these two 'tags' shown here on the right hand side of the turntable (platter) unit?

What are these for as they don't appear to engage with anything?

What are these for as they don't appear to engage with anything?

I'm not familiar with this particular vintage mechanism and can't identify a sliding lever like the more modern one of which I speak.

However the operation is similar to more modern mechanisms in that the cam gear must engage with the turntable hub gear in order to drive the auto cycle. This should be instigated by the movement of the auto select lever or the movement of the pickup arm.

Does the problem occur at all speed settings?

Re 'tags': Where are these located precisely? Zoom out for me.

However the operation is similar to more modern mechanisms in that the cam gear must engage with the turntable hub gear in order to drive the auto cycle. This should be instigated by the movement of the auto select lever or the movement of the pickup arm.

Does the problem occur at all speed settings?

Re 'tags': Where are these located precisely? Zoom out for me.

As you know it's extremely challenging to view the operation of the auto-changer mechanism from beneath!

Narrowing down the source of this annoying problem as the auto-changer mechanism works ok at 78 RPM which points to a torque problem as Galu suggested above.

I've lubricated the motor bearing, roughened the surface of the idler wheel with fine emery paper and cleaned the inside rim of the platter with IPA?

Narrowing down the source of this annoying problem as the auto-changer mechanism works ok at 78 RPM which points to a torque problem as Galu suggested above.

I've lubricated the motor bearing, roughened the surface of the idler wheel with fine emery paper and cleaned the inside rim of the platter with IPA?

Also check that the idler wheel is correctly riding in the centre of the 33 rpm and 45 rpm sections of the motor pulley and not rubbing on the shoulders of the stepped pulley.

When you give the motor spindle a quick turn by hand it does about 2-3 revolutions before coming to a stop?

The idler wheel wasn't correctly positioned so I moved the pulley up a fraction so that it now runs exactly in the centre of the 33 rpm and 45 rpm sections of the motor pulley.

Of course it was working so what happened and the platter spins at the correct speeds when on Manual?

The idler wheel wasn't correctly positioned so I moved the pulley up a fraction so that it now runs exactly in the centre of the 33 rpm and 45 rpm sections of the motor pulley.

Of course it was working so what happened and the platter spins at the correct speeds when on Manual?

The fact that you did have the auto mechanism working for a time is the killer!

The fact that the mechanism works when you operate it by hand and at 78 rpm does seem to indicate a lack of motor torque at low speeds.

The idler wheel rubber may have become too hard for the job. It's possible to have new rubber fitted, but this service may not be available in the UK.

The fact that the mechanism works when you operate it by hand and at 78 rpm does seem to indicate a lack of motor torque at low speeds.

The idler wheel rubber may have become too hard for the job. It's possible to have new rubber fitted, but this service may not be available in the UK.

Thanks Galu for staying the course - much appreciated.

Let's do a detailed breakdown of events after it was working: -

1. Repositioned the idler wheel pully.

2. Cleaned the idler wheel and platter inside rim with IPA.

3. Roughened the surface of the idler wheel with fine emery paper.

4. Lubricated motor bottom bearing.

Auto-changer engages and sticks almost immediately (at 16, 33 and 45 rpm - 78 rpm is ok) but continues after some manual assistance. Record plays normally until end and then tonearm lifts but sticks but continues after some manual assistance. So we have two sticky periods at the beginning and near the end of the auto-changer cycle?

All records play at correct speeds when on Manual but auto-changer doesn't complete at end of record.

It does look and feel as if it's a motor torque problem getting it started and finished?

Three possible causes:-

1. Idler wheel rubber too hard/shiny?

2. Motor bearings sticky?

3. Sticky/bent lever somewhere in or around the main cam assembly?

I'd maybe at a fourth (4.) and that is the idler wheel tension spring which seems a bit 'loose' ?

Let's do a detailed breakdown of events after it was working: -

1. Repositioned the idler wheel pully.

2. Cleaned the idler wheel and platter inside rim with IPA.

3. Roughened the surface of the idler wheel with fine emery paper.

4. Lubricated motor bottom bearing.

Auto-changer engages and sticks almost immediately (at 16, 33 and 45 rpm - 78 rpm is ok) but continues after some manual assistance. Record plays normally until end and then tonearm lifts but sticks but continues after some manual assistance. So we have two sticky periods at the beginning and near the end of the auto-changer cycle?

All records play at correct speeds when on Manual but auto-changer doesn't complete at end of record.

It does look and feel as if it's a motor torque problem getting it started and finished?

Three possible causes:-

1. Idler wheel rubber too hard/shiny?

2. Motor bearings sticky?

3. Sticky/bent lever somewhere in or around the main cam assembly?

I'd maybe at a fourth (4.) and that is the idler wheel tension spring which seems a bit 'loose' ?

Do not mess with that spring. Shortening it will not fix the problem.

Check that the idler wheel swing arm is moving smoothly.

Check that the idler wheel swing arm is moving smoothly.

You really have to assume that all of these little sleeve bearings are gummed up - it's been more than half a century and those old greases are more wax now than grease. It's painful to contemplate, but they all need to be washed out and new light grease applied. A good choice today would be some of the white molys, not really wheel bearing strength but heavier than an oil (which would run with gravity).

A good test of the lack of drive is whether or not you can "encourage" things to cycle with a little hands on push to the platter. If so, the platter isn't being driven strongly enough, meaning motor, idler surface, idler lateral tension, etc. If not, say your prayers, cam sleeve bearing, lotsa linkages, wailing and gnashing of teeth, etc.

All good fortune,

Chris

A good test of the lack of drive is whether or not you can "encourage" things to cycle with a little hands on push to the platter. If so, the platter isn't being driven strongly enough, meaning motor, idler surface, idler lateral tension, etc. If not, say your prayers, cam sleeve bearing, lotsa linkages, wailing and gnashing of teeth, etc.

All good fortune,

Chris

Thanks Chris for mentioning the sleeve bearings.

They must be free to spin while running in guide channels in the mechanism.

They must be free to spin while running in guide channels in the mechanism.

Thanks Chris and Galu.

Almost there ... !

I'm satisfied that sleeve bearings, levers and cam shaft components have been thoroughly cleaned and re-greased with moly. Although I'm willing to admit that there may be an issue with one particular bearing, lever or component involved in that initial 'push' on the platter, but which one?

I readjusted the height of the idler wheel pully and put it back to where it was near the top of each section i.e. not in the middle! Auto-changer now functioning much better at 45 rpm and only slightly sticky at the start/finish of the cycle. Doesn't stop as previously just runs a little slower but once the platter gets going the speed is ok. 33 rpm still a bit more sticky?

I'm now also satisfied with the idler surface, idler lateral tension etc which leaves the motor which has had it's bottom bearing re-lubricated with a few drops of sewing machine oil.

Almost there ... !

I'm satisfied that sleeve bearings, levers and cam shaft components have been thoroughly cleaned and re-greased with moly. Although I'm willing to admit that there may be an issue with one particular bearing, lever or component involved in that initial 'push' on the platter, but which one?

I readjusted the height of the idler wheel pully and put it back to where it was near the top of each section i.e. not in the middle! Auto-changer now functioning much better at 45 rpm and only slightly sticky at the start/finish of the cycle. Doesn't stop as previously just runs a little slower but once the platter gets going the speed is ok. 33 rpm still a bit more sticky?

I'm now also satisfied with the idler surface, idler lateral tension etc which leaves the motor which has had it's bottom bearing re-lubricated with a few drops of sewing machine oil.

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- PYE Stereo Black Box G63