Didn't know this was possible! One of my frustrations with DIY (of various kinds) has been the constant glasses on/glasses off ballet. I'll ask my guy at this year's appointment.I also have a new pair of glasses that focus about 10 inches in front of my nose. You know watchmaker kind of distances. My eye doctor ask why 10 inches? I said, "I solder"

@mhenshcel -- those caps are surface mount, and as I found to my slight chagrin, once the electrolytics are fitted it's a bit difficult (but not impossible ) to solder them in.

I second the issue WRT glasses. I strongly recommend you put them back on when you are snipping leads from resistors etc.

I second the issue WRT glasses. I strongly recommend you put them back on when you are snipping leads from resistors etc.

This phono stage is such a truth machine, it really puts the spotlight on the rest of a system. I made one change this morning, I pulled my current favorite power amp, a Sony VFET OS2 variant, replaced it with a DIY Aleph 20, and spun some records with decent bass. That amp immediately highlighted the boomy, flubby deep bass of my speakers. The midrange and treble sound more distorted and recordy as well than with the VFET and highlights to me how well paired that other amp and my speakers were, something I'd instinctively suspected anyway before the swap. This is a lot of fun, first being able to hear differences and then to describe them. Thanks Wayne for this stage, and Papa for these amps.

So next step will be to get some new decent speakers that have tighter bas response?

If it is a Rembrandt painting you have at the wall you can sell it and get some new speakers instead?

If it is a Rembrandt painting you have at the wall you can sell it and get some new speakers instead?

I wouldn't need to sell anything to get new speakers. 🙂 I'm quite fond of these, bass notwithstanding, and the only ones I've heard and like better are large full-ranges like the DIY ceiling speaker Tannoys that were at Burning Amp last year.So next step will be to get some new decent speakers that have tighter bas response?

If it is a Rembrandt painting you have at the wall you can sell it and get some new speakers instead?

The painting is by Russian Artist Vladimir Pentjuh.

Looks good.Boards after a bit of "flux-cleaning"!

Yes, I also soldered the small smd 1uF capacitors first!

Impressing such a small size can be 1uF.

Solvent? and a toothbrush?

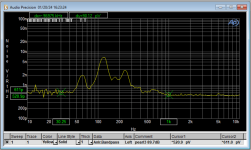

The input noise of this phono preamp is remarkable. This is unbridled by the RIAA compensation capacitors, gain is 89.7dB. Instead of the 7815/7915 reg scheme I used the Jung-Didden SR set to +/-15V, not 13.7V. Edit -- I also used 4 closely matched 2sk170BL.

Attachments

Last edited:

Looks good.

Solvent? and a toothbrush?

I use a method for removing flux I learned from a YouTube video. I can't find it now. It would be the best way to explain. I don't use toothbrush anymore.

Think I spent 10 min. to clean the two PCB's.

I use isopropanol and paper and at last step a fine paint brush to dust off "paper dust".

The paper used is the paper you use in the kitchen which can suck a lot of fluid.

I take a sheet and fold it many times and soak it in isopropanol. Then I clean PCB by grinding the solder side and the trick is that the solder side of PCB will rasp off the paper so new clean paper which is still soaked in propanol will clean off the flux. It has to be done over a bucket (or something to take the paper dust) else you will have paper dust all over the place. Folded paper piece will be smaller and smaller. Think I used 4-5 folded sheets for one PCB (two pr. half PCB and then one to finish off). And then at last the brush to dust off any paper dust.

Hard to explain......but maybe you got some of it.......or the method 🙂

You have to take care not to scratch your fingers. To protect against the alcohol I used "one time" gloves on both hands.

There will be a nice smell of alcohol in the room after cleaning (as a value added service).

Call me Can, but I think you Boyz are overthinking that cleaning drek

well, it is MC amp, but far from HF circuit for which you need hot bath and ultrasonic bath and help of pretty neighbor girl

use no-clean flux, then leave it as is or clean with wad of cotton and isopropanol

don't forget decent moonshine, good to have and use, gift to Gods of Sound

well, it is MC amp, but far from HF circuit for which you need hot bath and ultrasonic bath and help of pretty neighbor girl

use no-clean flux, then leave it as is or clean with wad of cotton and isopropanol

don't forget decent moonshine, good to have and use, gift to Gods of Sound

@MEPER

well, I have no objection that anyone cleans pcbs thoroughly after soldering ........ I'm just objecting when it becomes an issue per se

just saying that I found it absolutely unnecessary when using proper solder and solder-helping stuff

now, if someone actually gives me example of his own troubles, solved with thorough cleaning of solder-flux residues, I'll have full trust in different experience than mine - one learns something new everyday

well, I have no objection that anyone cleans pcbs thoroughly after soldering ........ I'm just objecting when it becomes an issue per se

just saying that I found it absolutely unnecessary when using proper solder and solder-helping stuff

now, if someone actually gives me example of his own troubles, solved with thorough cleaning of solder-flux residues, I'll have full trust in different experience than mine - one learns something new everyday

One of the quadraphonic formats used a 30kHz carrier signal embedded in the LP groove: https://en.wikipedia.org/wiki/Compatible_Discrete_4Some MC-cartridges go to 50 kHz?

A kind of HF?

It could be fun to hear a quadraphonic setup. I guess not many recordings exists.

No-Clean-Solder: does it look 100% clean after soldering or does it just mean that it is not necessary to remove "anything"?

I have only "heard" rumors that the flux can attract some dirt / moisture over time and cause some problems.

No-Clean-Solder: does it look 100% clean after soldering or does it just mean that it is not necessary to remove "anything"?

I have only "heard" rumors that the flux can attract some dirt / moisture over time and cause some problems.

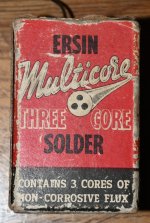

I still have a lot of vintage solder left from a past time......

I guess most quality solder.......it is probably claimed that it is not necessary to remove it.

Here they tell it "indirect" by writing "non-corrosive".

I also have some of the very modern "Fire-metall"......with Mar-core I think they call it.......no need to remove......I am sure?

I guess most quality solder.......it is probably claimed that it is not necessary to remove it.

Here they tell it "indirect" by writing "non-corrosive".

I also have some of the very modern "Fire-metall"......with Mar-core I think they call it.......no need to remove......I am sure?

Attachments

- Home

- Amplifiers

- Pass Labs

- Pearl 3 Burning Amp 2023