Peter,

Fin: you assume right.

oil thickness: i mean the dimension of the oil gap perpendicular to surfaces.

Platter's center of gravity/inertia should be above the ball or in its center, not below. If it is above, it will help the platter stay horizontally oriented. It will suppress the gyro's tendency for nutation. Be the platter guided by a conventional shaft/bushing friction bearing or not.

Gyro @ 33 rpm: take your bicycle's front wheel, unmount it, hold te axle horizontally oriented and make the wheel turn. About 33 rpm. Then try to tilt the axle. But be careful, the reponse forces maybe be quite a surprise. Then consider your platter has not the same diameter but a huge multiple of the wheel's mass. If you feel you have to repeat the Q then, come back and ask it again 🙂 then we both have to crawl thru the math. (Oh, i hope not 🙂 )

I'm afraid I don't quite understand what you mean. I assume that the fin you speak of is the part of the PLATTER that hangs in the oil.But by thickness do you mean its height or its width?

Fin: you assume right.

oil thickness: i mean the dimension of the oil gap perpendicular to surfaces.

Platter's center of gravity/inertia should be above the ball or in its center, not below. If it is above, it will help the platter stay horizontally oriented. It will suppress the gyro's tendency for nutation. Be the platter guided by a conventional shaft/bushing friction bearing or not.

Gyro @ 33 rpm: take your bicycle's front wheel, unmount it, hold te axle horizontally oriented and make the wheel turn. About 33 rpm. Then try to tilt the axle. But be careful, the reponse forces maybe be quite a surprise. Then consider your platter has not the same diameter but a huge multiple of the wheel's mass. If you feel you have to repeat the Q then, come back and ask it again 🙂 then we both have to crawl thru the math. (Oh, i hope not 🙂 )

Platter's center of gravity/inertia should be above the ball or in its center, not below. If it is above, it will help the platter stay horizontally oriented. It will suppress the gyro's tendency for nutation. Be the platter guided by a conventional shaft/bushing friction bearing or not.

??

Surely, if the platter's centre of gravity is above the ball the platter will be not be stable, but instead tend to tilt.

If, however, the CofG is beneath the ball the platter will always remain horizontal. It does seem important though to keep the drive belt in the plane of the ball.

My reasoning is analogue to what is often done in unipivot tone arms. Am I wrong?

Peter

Peter,

you are not wrong, you are right.

Terrible goof by me! Of course the center of inertia should be lower than the bearing point! the platter shall "hang", not "stand"! my goof, must have had something else in my mind.

if the center of inertia would be above (as i said) this would cause the nutation!

Hanging platter does not self-excite nutation.

Belt plane: if you realize your unipivot bearing, it is important IMO. But if you settle on a shaft/bushing configuration, i consider belt plane location as a minor influence. Hint: Choose a reasonable location and be happy with it.

you are not wrong, you are right.

Terrible goof by me! Of course the center of inertia should be lower than the bearing point! the platter shall "hang", not "stand"! my goof, must have had something else in my mind.

if the center of inertia would be above (as i said) this would cause the nutation!

Hanging platter does not self-excite nutation.

Belt plane: if you realize your unipivot bearing, it is important IMO. But if you settle on a shaft/bushing configuration, i consider belt plane location as a minor influence. Hint: Choose a reasonable location and be happy with it.

Thankyou, Variac!

Mark,

i am very thankful for the private apology you have sent me. Completely satisfactory. 🙂

All,

Now it is my turn to apologize:

I have used wildcard characters "concealing" naughty thougts, curses, slippery language to describe on of my thoughts. So far I have always used those in a funny context and it was clearly obvious i was speaking to myself or meaning it serious. Moreover, i use the wildcards not to curse even in a funny context. Using those wildcards was meant like: i would like to curse but i never curse.

It came never to my mind someone could take them as offense. Not even in this case, as i was speaking to myself, i was referring to my thought. I was intending to point out what effect Mark's remark could have had.

I see now it could be misunderstood as an offense. For that i deeply apologize.

It was never meant that way. I have to be more careful with that in the future.

Whoever was lurking and feeling offended, again i apologize.

Different topic: being biased.

Please put a big IMO on aynthing what i write below:

Mark is biased, i am biased, anyone of us human beings is biased. Internet communication does not help to make that better it makes it worse: body language is missing and body language contributes to 95% of the communication. Anyone of more or less reads what he wants to read: So it happens easy that statements go down the wrong way and make the reader cough it up again. And be angry about it.

Please, all, Mark, Bernhard included, let some mutual benevolence happen for the case something goes down the wrong way and makes cough.

Look at it how it could have been meant in a positive way 🙂 and give the benefit of the doubt.

Mark,

i am very thankful for the private apology you have sent me. Completely satisfactory. 🙂

All,

Now it is my turn to apologize:

I have used wildcard characters "concealing" naughty thougts, curses, slippery language to describe on of my thoughts. So far I have always used those in a funny context and it was clearly obvious i was speaking to myself or meaning it serious. Moreover, i use the wildcards not to curse even in a funny context. Using those wildcards was meant like: i would like to curse but i never curse.

It came never to my mind someone could take them as offense. Not even in this case, as i was speaking to myself, i was referring to my thought. I was intending to point out what effect Mark's remark could have had.

I see now it could be misunderstood as an offense. For that i deeply apologize.

It was never meant that way. I have to be more careful with that in the future.

Whoever was lurking and feeling offended, again i apologize.

Different topic: being biased.

Please put a big IMO on aynthing what i write below:

Mark is biased, i am biased, anyone of us human beings is biased. Internet communication does not help to make that better it makes it worse: body language is missing and body language contributes to 95% of the communication. Anyone of more or less reads what he wants to read: So it happens easy that statements go down the wrong way and make the reader cough it up again. And be angry about it.

Please, all, Mark, Bernhard included, let some mutual benevolence happen for the case something goes down the wrong way and makes cough.

Look at it how it could have been meant in a positive way 🙂 and give the benefit of the doubt.

Whew! Sorry to waste even more bandwidth, but I need to bask in the new DIY world of positivity!

I think Bernhard hits the nail right on the head with his comments about body language. In "real life" I am a rather outgoing person, but I bend over backwards (perhaps too much) to show that I love people, and interacting with them. I am almost never misinterpreted because it is so clear that I mean no offense. So on the net I might be overbearing sometimes, because I haven't had to deal with this issue in real life, so haven't learned to censor myself. I will strive to do better.

To clarify my position, writing $%$@^^%^ is fine, no problem, but does mean cursing, which even as a joke can be misinterpreted, but is generally harmless.

The thing that caused the offense to me was the sentence it was used it in which I felt made it a specific attack with only one word that fit. In the city I live in those are "fightin' words" I hope you see the distinction. I did overeact though, perhaps because I felt slapped down while trying to make what I thought was a positive statement. I generally am not offended by a little cursing....might even do a little myself....

😉

The forum has taken a bit of a downturn lately in attitude and we really need to get on with returning it to it's previous state. We have gotten some good new people to contribute, but if the rancor continues, people like Grey are just gonna fade away more, and even Lord Nelson might think to himself " this forum reflects negatively on my business" and retire to his own web site!!

I think Bernhard hits the nail right on the head with his comments about body language. In "real life" I am a rather outgoing person, but I bend over backwards (perhaps too much) to show that I love people, and interacting with them. I am almost never misinterpreted because it is so clear that I mean no offense. So on the net I might be overbearing sometimes, because I haven't had to deal with this issue in real life, so haven't learned to censor myself. I will strive to do better.

To clarify my position, writing $%$@^^%^ is fine, no problem, but does mean cursing, which even as a joke can be misinterpreted, but is generally harmless.

The thing that caused the offense to me was the sentence it was used it in which I felt made it a specific attack with only one word that fit. In the city I live in those are "fightin' words" I hope you see the distinction. I did overeact though, perhaps because I felt slapped down while trying to make what I thought was a positive statement. I generally am not offended by a little cursing....might even do a little myself....

😉

The forum has taken a bit of a downturn lately in attitude and we really need to get on with returning it to it's previous state. We have gotten some good new people to contribute, but if the rancor continues, people like Grey are just gonna fade away more, and even Lord Nelson might think to himself " this forum reflects negatively on my business" and retire to his own web site!!

Hi all - I've just read whole thread!! Intriuging stuff indeed. Have also had similar thoughts over the past years - panning out similarly to peterr's and focusing on platter resonance control. Sadly little time to try out. You may remember me posting a while ago re an old Mayware (JHL) unipivot arm I have - (still) begging for a deck...

What follows is based on school 'A' level physics circa 1976, the dynamics module of my electronics course, native cunning (my old maths lecturer use to swear by it!) and a little misguided intuition!! You are forgiven for skipping to the next post. But heck, isn't it a great way to while away the time?

So here goes - hope it stimulates the grey matter... Jeepers - its got a little long - sorry.

I go with peterr's thoughts on an oil suspended unibearing based platter, belt driven level with the uni-ball-bearing to prevent tilting. CofG below uniball for natural stability.

I see also the need to have a =slightly= concave belt 'groove' to make the platter naturally self levelling but important also to neutralise any tendancy to tilt by driving at the correct level.

I believe the platter should be (mostly) =floating= in the oil bath such that maybe 80-90% of its weight is supported by the oil. Leave enough to locate properly on the ball bearing resisting belt forces. Floating it will also cause natural self levelling. Not sure how sensitive it would still be to tilting due to stylus pressure - probably not very (it would be proportional to radius too). If significant, then arm mounting could be tilted to compensate for average tilt? It would also be required to limit max tilt when loading the vinyl or platter would wobble everywhere.

Perhaps a proof of concept experiment could be done with an easily turned wooden mock-up to help answer these queries? Some other liquid used also to compensate for different density of wood Vs our chosen platter material?

Re platter material, first off, perhaps it cannot be too dense with this design if floating is to be the predominant support mechanism? I have not looked at material statistics. I saw an interesting reference to floating a platter on Mercury earlier.

Secondly, this design appeals to me (as a complete non expert in vibration physics I should add) as I think the oil bath will cause significant damping of the platter, across most of it's diameter too.

One could imagine doing it all in wood I suppose (some are very dense and dimensially stable too) - not sure what effect an oil bath would have on the wood over time...

Ok, so to the platter <> vinyl interface... getting really whacky... maybe breaks KISS rules?

AFAIK, general opinion says the platter should be lovingly intimate with the the disc to damp resonance and couple it really well. (Best glue it on - but obviously costly in new vinyl and platters, low WAF too). Maybe the felt or velvet mat does this with it's little sticky-up fibres? Going beyond this, what about liquid coupling the disc to the platter? Crazy? I'm not so sure. Plainly floating disc on puddle of liquid is silly, but what if liquid <> disc interface was actually a thin membrane (and liquid only a few mm deep in a recess in top of platter)?? Kitchen cling-film springs to mind sitting on something like oil again. I think this arrangement would 'take-up' the shape of the disc - warps and all, and make for a good coupling to the platter main structure. Still use disc clamp? Perhaps some bowing of disc could result but would it matter?

Hmm, (quick) thinking how to make it... film across whole platter - spindle thru middle - epoxy around adjacent to spindle. same at rim (slightly bigger diam than biggest vinyl) - leave small gap - load oil thru gap (enuf to make it 'bloat' up a bit proud) - (don't contaminate gap surfaces where to be glued) - glue seal it up. Film need be stronger than kitchen stuff?

Along similar lines I can also imagine some sort of very compliant rubber mat - not dunno if such a material exists...

Of course driving this gizzmo could be interesting as has already been pointed out in this thread.... Any (proper) fluid dynamics experts out there please who could comment on drive requirements, viscosity and other such stuff?

Re air bearing discussions - while it would make a great bearing, I'm also not sure on what happens with the various spring components in the dynamics equation. Although different to in free air (due to compressed air cushion platter sits on), I believe the platter damping would be minimal, still requiring careful platter design. If platter damping is not important (to be honest I don't really know, but it feels like it should be) then all the better and an oil damped route is not necessary etc. etc.

Another thought has been to make platter from old vinyl for impedance coupling reasons - also seen in this post. Could itself be quite challenging. Now - how to make that vinyl paste to put under the membrane.....

OK, that's my tuppence worth - I look forward to your collective thoughts. Am quite happy to be shot down in a cloud of thick black oily smoke, but I'm sure we'll all learn from it either way 😉

Cheers to all

Pete

What follows is based on school 'A' level physics circa 1976, the dynamics module of my electronics course, native cunning (my old maths lecturer use to swear by it!) and a little misguided intuition!! You are forgiven for skipping to the next post. But heck, isn't it a great way to while away the time?

So here goes - hope it stimulates the grey matter... Jeepers - its got a little long - sorry.

I go with peterr's thoughts on an oil suspended unibearing based platter, belt driven level with the uni-ball-bearing to prevent tilting. CofG below uniball for natural stability.

I see also the need to have a =slightly= concave belt 'groove' to make the platter naturally self levelling but important also to neutralise any tendancy to tilt by driving at the correct level.

I believe the platter should be (mostly) =floating= in the oil bath such that maybe 80-90% of its weight is supported by the oil. Leave enough to locate properly on the ball bearing resisting belt forces. Floating it will also cause natural self levelling. Not sure how sensitive it would still be to tilting due to stylus pressure - probably not very (it would be proportional to radius too). If significant, then arm mounting could be tilted to compensate for average tilt? It would also be required to limit max tilt when loading the vinyl or platter would wobble everywhere.

Perhaps a proof of concept experiment could be done with an easily turned wooden mock-up to help answer these queries? Some other liquid used also to compensate for different density of wood Vs our chosen platter material?

Re platter material, first off, perhaps it cannot be too dense with this design if floating is to be the predominant support mechanism? I have not looked at material statistics. I saw an interesting reference to floating a platter on Mercury earlier.

Secondly, this design appeals to me (as a complete non expert in vibration physics I should add) as I think the oil bath will cause significant damping of the platter, across most of it's diameter too.

One could imagine doing it all in wood I suppose (some are very dense and dimensially stable too) - not sure what effect an oil bath would have on the wood over time...

Ok, so to the platter <> vinyl interface... getting really whacky... maybe breaks KISS rules?

AFAIK, general opinion says the platter should be lovingly intimate with the the disc to damp resonance and couple it really well. (Best glue it on - but obviously costly in new vinyl and platters, low WAF too). Maybe the felt or velvet mat does this with it's little sticky-up fibres? Going beyond this, what about liquid coupling the disc to the platter? Crazy? I'm not so sure. Plainly floating disc on puddle of liquid is silly, but what if liquid <> disc interface was actually a thin membrane (and liquid only a few mm deep in a recess in top of platter)?? Kitchen cling-film springs to mind sitting on something like oil again. I think this arrangement would 'take-up' the shape of the disc - warps and all, and make for a good coupling to the platter main structure. Still use disc clamp? Perhaps some bowing of disc could result but would it matter?

Hmm, (quick) thinking how to make it... film across whole platter - spindle thru middle - epoxy around adjacent to spindle. same at rim (slightly bigger diam than biggest vinyl) - leave small gap - load oil thru gap (enuf to make it 'bloat' up a bit proud) - (don't contaminate gap surfaces where to be glued) - glue seal it up. Film need be stronger than kitchen stuff?

Along similar lines I can also imagine some sort of very compliant rubber mat - not dunno if such a material exists...

Of course driving this gizzmo could be interesting as has already been pointed out in this thread.... Any (proper) fluid dynamics experts out there please who could comment on drive requirements, viscosity and other such stuff?

Re air bearing discussions - while it would make a great bearing, I'm also not sure on what happens with the various spring components in the dynamics equation. Although different to in free air (due to compressed air cushion platter sits on), I believe the platter damping would be minimal, still requiring careful platter design. If platter damping is not important (to be honest I don't really know, but it feels like it should be) then all the better and an oil damped route is not necessary etc. etc.

Another thought has been to make platter from old vinyl for impedance coupling reasons - also seen in this post. Could itself be quite challenging. Now - how to make that vinyl paste to put under the membrane.....

OK, that's my tuppence worth - I look forward to your collective thoughts. Am quite happy to be shot down in a cloud of thick black oily smoke, but I'm sure we'll all learn from it either way 😉

Cheers to all

Pete

I really don't know what percentage of the platter weight should be supported by the oil. I am afraid only tests can show this. Or somebody who knows how to do the math??I believe the platter should be (mostly) =floating= in the oil bath such that maybe 80-90% of its weight is supported by the oil. Leave enough to locate properly on the ball bearing resisting belt forces. Floating it will also cause natural self levelling.

My personal feeling is that there should be (much) more weight on the ball. The main reason being simplicity. The way I see it the principle is much the same as a unipivot arm. You just hang the platter on the ball. The oil is there to dampen, but in theory you could leave it out completely. (Like adding damping to an arm).

If you let the gaps where the oil sits be fairly wide the only tight tolerance is the place where the ball touches the platter. It should be exactly in the center.

This should make it a great concept for home cooking...

I don't think so either. I also think Bernhard's gyroscopic effect will help. Haven't had time to try his bicycle wheel test yet, though.Not sure how sensitive it would still be to tilting due to stylus pressure - probably not very

If the oil is fairly thin and you accept that it is neccessary to help it along at startup would it really be such a problem?Of course driving this gizzmo could be interesting as has already been pointed out in this thread

As I said before I am not an engineer so what I say may very well be complete nonsense. All I am doing here is thinking out loud. But then again it may be brilliant.....

Just let me know.

Peter

I think Peterr's comments are a good analysis of how to make this design more practical. Traditionally the platter is made heavy to act as a flywheel. Anything that is heavy enough for this is going to be hard to float on any fluids I can think of. The mercury would work, but the side effects are probably excessive- "Mad as a hatter", etc. But the oil bath as damping is good.

Without being constrained, there might well be precession issues if the table is vibrated, or the platter touched in any way Dice seems to have a handle on this so it would be interesting to hear his opinion. My suspicion is that it would act pretty screwy in the real world but I just don't know. The oil bath would lube the bearing, which is good🙂

An air bearing is actually pretty stiff although techically springy, because the air layer is soooooo thin and the surface area so great. To pump oil through the radial air bearing as a thin film would really create a lot of drag I agree. I think that would take a big motor!! As you have discussed, a thicker gap has less drag.

Multiple plates of metal are used in an oil bath to create clutches because the drag is so high.

The Platter Waterbed could be studied as a separate device.

and tested on an existing turntable.

Feel free to use the name!

Without being constrained, there might well be precession issues if the table is vibrated, or the platter touched in any way Dice seems to have a handle on this so it would be interesting to hear his opinion. My suspicion is that it would act pretty screwy in the real world but I just don't know. The oil bath would lube the bearing, which is good🙂

An air bearing is actually pretty stiff although techically springy, because the air layer is soooooo thin and the surface area so great. To pump oil through the radial air bearing as a thin film would really create a lot of drag I agree. I think that would take a big motor!! As you have discussed, a thicker gap has less drag.

Multiple plates of metal are used in an oil bath to create clutches because the drag is so high.

The Platter Waterbed could be studied as a separate device.

and tested on an existing turntable.

Feel free to use the name!

Thanks guys!

On gaps and tolerances with an oil bath: I'd not envisaged any such narrow tolerances - platter simply (partially) floats on oil, constrained by uniball. Actually I suspect all gaps involving a a differential movement across their width will need a =minimum= size to help keep viscous drag down. Experiment or degree in fluid dynamics required...

Quote:

To pump oil through the radial air bearing as a thin film would really create a lot of drag I agree..

Not the intention here - oil (or whatever/) just supports and damps. No pumping required. Oil forms a bath not a bearing film.

Quote: oil bath would lube the bearing, which is good

Yes! I'd overlooked that one!

On material: yup - floating obviously brings material density contraints - (hence use of Mercury - agreed - a dicey strategy). Experiments and data books required here... Does anyone have time to play around with this?

Quote: An air bearing is actually pretty stiff although techically springy...

Like a very stiff but short spring? - what does this do for platter damping?

Indeed how important IS platter damping?

Like I said, I'm no expert here - just chucking a few ideas around. Hope it stimulates someone with some time to experimenting and report back...

Cheers

Pete

PS How do you insert these nice embedded quotes I see here with lines etc.?

On gaps and tolerances with an oil bath: I'd not envisaged any such narrow tolerances - platter simply (partially) floats on oil, constrained by uniball. Actually I suspect all gaps involving a a differential movement across their width will need a =minimum= size to help keep viscous drag down. Experiment or degree in fluid dynamics required...

Quote:

To pump oil through the radial air bearing as a thin film would really create a lot of drag I agree..

Not the intention here - oil (or whatever/) just supports and damps. No pumping required. Oil forms a bath not a bearing film.

Quote: oil bath would lube the bearing, which is good

Yes! I'd overlooked that one!

On material: yup - floating obviously brings material density contraints - (hence use of Mercury - agreed - a dicey strategy). Experiments and data books required here... Does anyone have time to play around with this?

Quote: An air bearing is actually pretty stiff although techically springy...

Like a very stiff but short spring? - what does this do for platter damping?

Indeed how important IS platter damping?

Like I said, I'm no expert here - just chucking a few ideas around. Hope it stimulates someone with some time to experimenting and report back...

Cheers

Pete

PS How do you insert these nice embedded quotes I see here with lines etc.?

I have been wondering about the problem of drag between platter and oil and it seems to me that it really should not be that much of a problem.

drag is a big issue if you try to move a padle through a fluid in a direction perpendicular to its biggest area (like the padle of a canoe), but if you try to move it in a direction tangential to this it will be easy. (like on a boat where te keel or the rudder will cause very little drag, because they are oriented in the direction the boat is going)

And the way I understand it what we have is more like a rudder than a padle.

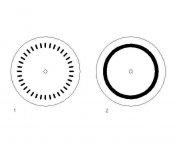

version 1 is the unwanted padle variety and version 2 is the rudder model

Peter

drag is a big issue if you try to move a padle through a fluid in a direction perpendicular to its biggest area (like the padle of a canoe), but if you try to move it in a direction tangential to this it will be easy. (like on a boat where te keel or the rudder will cause very little drag, because they are oriented in the direction the boat is going)

And the way I understand it what we have is more like a rudder than a padle.

version 1 is the unwanted padle variety and version 2 is the rudder model

Peter

Attachments

Folks,

sorry, too absorbed with other unpleasant duties at the moment. Will catch up and try to answer QQ ASAP.

peted,

just click on the quote button above the editing window. Box pops up, you can fill in what you want to be quoted, then correct syntax is attached to the end of the text you wrote. You can then cut and paste it where needed and also have an example for correct syntax. Directly typing syntax also works. Syntax is not case-sensitive TME.

sorry, too absorbed with other unpleasant duties at the moment. Will catch up and try to answer QQ ASAP.

peted,

just click on the quote button above the editing window. Box pops up, you can fill in what you want to be quoted, then correct syntax is attached to the end of the text you wrote. You can then cut and paste it where needed and also have an example for correct syntax. Directly typing syntax also works. Syntax is not case-sensitive TME.

Thanks Bernhard!! I await your further comment...just click on the quote button above the editing window ...

Agreed but still not qualified - experiment/fluid dyn degree required again🙁 If there are only smooth (note smooth) surfaces slipping tangentially/linearly thru damping fluid - like the hull of a boat, then drag will be minimal though I think not zero, due to good ol' surface tension effects. And that's as deep as I'm prepared to go in public!!🙁 (Though native cunning also says it can't be a big problem). Now if drag were to =vary= as the platter rotated due to a) turbulance in the damping fluid (could this happen if those clearences were too small?), or b) differences in gap as platter rotated, it would be a different matter. Turbulance in oil will have a much greater effect than in air. So, I think what this means is we need no turbulance (doesn't this then dictate minimum gap for a given speed differential?), and quite carefully dimensioned gaps around the periphery of the platter surfaces to avoid ecentricity - in that limiting (ridiculous!) case one can imagine a cam arrangement where the fluid is squashed out of the system by ecentricity, gradually loading the motor... more and more we need that fluid dynamicist or a set of experiments to prove or kill this concept...I have been wondering about the problem of drag between platter and oil and it seems to me that it really should not be that much of a problem.

Agreed - though I'd like an initial reaction to these thoughts for future reference if you please.The Platter Waterbed could be studied as a separate device.

Not sure what you mean by "precession issues" Mark? did you mean the whole thing gradually tilting over? No, that's =procession= - dunno - plse explain. Constraint is there in form of uniball (apex is constrained) + belt groove + floating platter (naturally self levelling i.e. stable).Without being constrained, there might well be precession issues if the table is vibrated

Wood still appeals to me - especially as experimental material - I like the idea of the natural material and relative ease of working using wood turning techniques. Would have to be nicely stable timber. (Or persex?) Using such could be good for playing around with (say) loading a rim groove with lead shot loaded epoxy/plaster for better inertia where it really matters, without going too heavy overall (i.e. sinking it in the oil bath!!).

OK - Enuf of this madness...

Cheers

Pete

Hello Pete

Yup thats procession. I took a chance and got it wrong!

Shows how little I know about this!! My mentioning that I don't know about gyro stuff is not modesty- I really don't know! 😛

Until very recently, my design was the air bearing big ball and a platter with a rim hanging down for stability-no radial bearing between flat plates. I think my earliest post mentions this. So, I am also interested in unipivot designs , only mine was the air bearing with metal plater, yours oil bearing , maybe a lot smaller ball, with oil damping, and the floating platter.

I see what you are thinking with the wooden platter- even though it is light and won't have much flywheel effect, the oil will help keep the speed constant. It's beginning to sound like it might work! Of course oil is less dense than even water, so the materials are limited. I think Perspex sinks in water. First you will have to do some experiments like Archimedes!

When I heard about Dice's radial air bearing I added it to my design. I think he added the big ball to his, so we ended up with very similar approaches, but I would be very interested in how well the unipivot works-it might be a very good alternative.

My impression is that few people on this thread have the time (or interest?) to take the chance on some experiments. It would be wonderful if you could make a unipivot turntable and see what happens. Maybe using the motor and belt out of a cheap turntable. If it works, I can visualize lots of different designs coming out of this thread.

MArk

Yup thats procession. I took a chance and got it wrong!

Shows how little I know about this!! My mentioning that I don't know about gyro stuff is not modesty- I really don't know! 😛

Until very recently, my design was the air bearing big ball and a platter with a rim hanging down for stability-no radial bearing between flat plates. I think my earliest post mentions this. So, I am also interested in unipivot designs , only mine was the air bearing with metal plater, yours oil bearing , maybe a lot smaller ball, with oil damping, and the floating platter.

I see what you are thinking with the wooden platter- even though it is light and won't have much flywheel effect, the oil will help keep the speed constant. It's beginning to sound like it might work! Of course oil is less dense than even water, so the materials are limited. I think Perspex sinks in water. First you will have to do some experiments like Archimedes!

When I heard about Dice's radial air bearing I added it to my design. I think he added the big ball to his, so we ended up with very similar approaches, but I would be very interested in how well the unipivot works-it might be a very good alternative.

My impression is that few people on this thread have the time (or interest?) to take the chance on some experiments. It would be wonderful if you could make a unipivot turntable and see what happens. Maybe using the motor and belt out of a cheap turntable. If it works, I can visualize lots of different designs coming out of this thread.

MArk

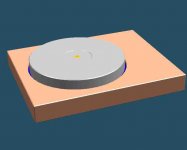

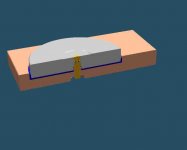

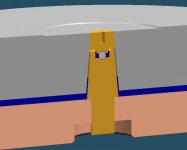

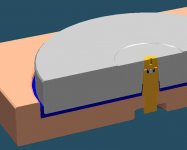

I have made a quick design for a simple oilbath tt.

basically its a translation of my previous pictures. The only real change is the separation of the damping oil and the bearing oil. This way you can keep the platter much simpler. Also can use different fluids optimised for damping vs lubrication.

Peter

basically its a translation of my previous pictures. The only real change is the separation of the damping oil and the bearing oil. This way you can keep the platter much simpler. Also can use different fluids optimised for damping vs lubrication.

Peter

Attachments

Hey - cool pics Peter 😀 That looks about the size of it without going real-world. However chances are (backed up by history 🙁 ) that I too cannot find time to play with this - I'm in throws of trying roll my own IT business and generally stay afloat. This stuff will have a somewhat rock-bottom WAF just now!! Needs someone to take up the challenge (Peter - just hook your CAD up to the molecular replicator in the kitchen - preload with worn-out vinyl first??).

Mull it all over a bit...

Yes - to me it seems like a way to go - pending a lot of playing about and also sitting down and working out densities, loads and stuff like that.

I'll need to step away for a while - look in towards the weekend...

Cheers

Pete

Mark - attraction of the oil for me is for damping as well as flotation. I think it more effectively couples the platter down into the plinth which can be as massive as is practical etc.So, I am also interested in unipivot designs , only mine was the air bearing with metal plater, yours oil bearing , maybe a lot smaller ball, with oil damping, and the floating platter.

Wood density ranges from the very low (balsa) to the very high which will even sink in water as far as I'm aware - so choice is wide open and the rim can be loaded for more inertia. But you're right - book of material densities (or an oil bath and wood samples) is required. I'd go for a hardwood anyway for dimensional stability (it also looks real cool if finished well), but above all wood is relatively easy to turn. As you say there are probably other choices re fluid.wooden platter- even though it is light and won't have much flywheel effect, the oil will help keep the speed constant

That seems a reasonable idea - at least while playing with the concept. and if it makes it easier to produce too. May actually be necesary due to uniball being physically above than the oil bath, so it needs its own little bath to sit in. There may be dry alternatives too - ptfe/teflon/nylon etc.only real change is the separation of the damping oil and the bearing oil.

I feel the opposite may be true - better speed reg without oil (no turbulance (variable drag) & dimensional variation around the platter - per my previous post) but it's about controlling the size of such effects if present or swamping them by rotational inertia. Back to the experimenting...the oil will help keep the speed constant

Mull it all over a bit...

Yes - to me it seems like a way to go - pending a lot of playing about and also sitting down and working out densities, loads and stuff like that.

I'll need to step away for a while - look in towards the weekend...

Cheers

Pete

🙂 To me these pictures are not about WAF. The only reason I did them was to explore possible problems and solutions. Of course, once we can be sure there is a future for this concept I might think of something more sexy (even though my wife's AF is very high 😀).This stuff will have a somewhat rock-bottom WAF just now!!

I will see what I can do, but it is the same thing here. More ideas than time I fear. 😡Need someone to take up the challenge (Peter - just hook your CAD up to the molecular replicator in the kitchen - preload with worn-out vinyl first??).

Peter

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Let's make a DIYAUDIO TT