dice45 said:... something better than a Teres or Redpoint to way lower costs.

I do not want something slightly bettering a Rega. At same costs.

That is a good goal. I've had enuff regas already, and something in the league of the Teres or Redpoint would be just fine -- a step up from my Linn (then i can move it downstairs and call it my beater Linn ;^)

What i have seen so far is very encoraging, if not completely digested. Dice & Variac have some momentum from years of turntables dancing in their heads. Methinks there is something elegant, and effective just within grasp here. Some "blending at the edges", a little catalyst, and some sloshing around of ideas...

dave

Mark,

So:

mass <-> spring <-> mass <-> spring <-> ground.

Either mass triggers oscillations of the other one and the the springs in between store and feed the energry needed for that. As amplitude and phase of said oscillations are practically unpredictable, we have a chaotic system.

I have quite some skills in formulating and solving differential equations, but for solving this mass-spring sytem's differential equation my abilities are not sufficient. Maybe you can do this, then atleast you are knowing what you are doing with this airbearing, frequency-, amplitude- and phase-wise.

If the air gap of the axial platter bearing is determined by the balance of bearing force and platter weight force only, then this assembly can oscillate enthusiastically. Remember, platter weight force is only constant if the platter is in NO vertical movement. So if you choose this simple air bearing, my recommendation, do not let it get excited by a plinth suspension.

It will work somehow, maybe create fancy sonic artifacts, maybe just never achieving the minimum of sonic calm you need to enjoy your music. Be aware you are gambling, combining your single surface airbearing with a plinth suspension.

I know the Brakemeier Apolyth from own auditioning. It is a $20.000.- behemoth with a 54kg platter and a single surface airbearing and air suspension for the plinth. and a total weight of 135kg. Although having spectacular sonics, the sucker never gave me near the sonic calm i demand to have. I always felt jumpy and uneasy and tense, listening to it.

Thom Mackris from Redpoint had a MapleNoll before he got his Teres and he reported it was so much more relaxing and PRaT was sooo much better with the Teres. TMK, the MapleNoll has a single surface airbearing.

The German distributor of the Platine Verdier (which als has a repellent-force axail bearing, a magnet bearing in this case) uses his demo Verdier with an additional trustplate&ball bearing to impeded vertical oscillations of the platter against the spring-suspended plinth and reported drmaitic improvement concerning both bass reproduction ans sonic calm.

Just three snippets ...

Anyone out there having listened to a Forsell Air Reference TT? It also has a single surface airbearing.

Nozzles:

I would presume we need 4 for the spherical surface and something between 7 and 16 for the axial bearing. But i have to draw touching circles into the bearing surface to find out how many are needed.

But methinks, i have adressed your points and not brushed them aside. And if i think i have not made my points understood enough, i invest another hour i don't have to illustrate them from a (hopefully) different point of view. As far as the chaotic system talk above is concerned, methinks you have preferred not to consider the issue so far (elaborate term for "brushing aside"). AFAIR, one of my earlier posts described it already and there should have been no need to do it again.

Re Announcing to retract participation (yeah, i read it, you intend to come back, okok). Last time i did this to others was in kindergarden. Then my mother explained to me that a menace is a promise is a promise is a promise ... and promises have to be kept.. Since then, i just did leave when i felt so, but i did never menace again. And i could come back whenever i felt it. No broken promise.

And, sorry for yet another lecturing 🙂

I would regret it very much if you feel sore and leave.

Mark, you may call me a merciless monster if it pleases you. You may do so in public 🙂 .

But i want to remind you that i have no interest to build the TT we are discussing myself (i have stated so before). So i have no stock options in this project. Can be i change my mind someday, say, i find it so sexy, so exciting that i want to try it out myself. Could be.

Besides that, i really have no time for it and regret the time i have spent posting everyday as it costs time i need for founding my own audio business. So, why am i doing it then? Because it is fun to me to see such a TT project grow and succeed. I want you all to succeed with it.

In this respect the merciless monster demands proper design conduct and this does also include that technical situations are thought thru properly and vague and/or wishful thinking is eliminated.

All,

I am happy with every simplification one of us comes up with and we as design group find the simplification benefitting and not getting in conflict with the technical requirements written into the specification.

I am very happy if one of us finds a way to avoid expensive machining. But we should not limit ourselves to scissors and cardboard, to kitchen table workshop. A workbench with a vice, a drillpress, a circular saw, keyhole saw, a surface milling cutter should be within reach for all of us. Some may have access to a metal workshop and maybe even to to precision maching and may help others with parts needed. So do i and, if desired, i can obtain CNC-turned parts for instance.

diyAudio TT design result may come out completely different to my ideas but as far as our consensual spec is concerned, i am happy with it.

And ... please apologize for me being such a monster, cannot jump out of my skin 🙂 ... don't get intimidated, the monster is not biting and most of the time cute and friendly.

See the platter as a weight, see the flat air gap as a (very progressive) spring, see the plinth/subchassis as another mass, see the supsension as another (more or less damped) spring and the base plate /outer plinth as the gound.I think making the plinth suspended or unsuspended can be decided by the maker. also the platter material other than maybe the lower layer being glass.

So:

mass <-> spring <-> mass <-> spring <-> ground.

Either mass triggers oscillations of the other one and the the springs in between store and feed the energry needed for that. As amplitude and phase of said oscillations are practically unpredictable, we have a chaotic system.

I have quite some skills in formulating and solving differential equations, but for solving this mass-spring sytem's differential equation my abilities are not sufficient. Maybe you can do this, then atleast you are knowing what you are doing with this airbearing, frequency-, amplitude- and phase-wise.

If the air gap of the axial platter bearing is determined by the balance of bearing force and platter weight force only, then this assembly can oscillate enthusiastically. Remember, platter weight force is only constant if the platter is in NO vertical movement. So if you choose this simple air bearing, my recommendation, do not let it get excited by a plinth suspension.

It will work somehow, maybe create fancy sonic artifacts, maybe just never achieving the minimum of sonic calm you need to enjoy your music. Be aware you are gambling, combining your single surface airbearing with a plinth suspension.

I know the Brakemeier Apolyth from own auditioning. It is a $20.000.- behemoth with a 54kg platter and a single surface airbearing and air suspension for the plinth. and a total weight of 135kg. Although having spectacular sonics, the sucker never gave me near the sonic calm i demand to have. I always felt jumpy and uneasy and tense, listening to it.

Thom Mackris from Redpoint had a MapleNoll before he got his Teres and he reported it was so much more relaxing and PRaT was sooo much better with the Teres. TMK, the MapleNoll has a single surface airbearing.

The German distributor of the Platine Verdier (which als has a repellent-force axail bearing, a magnet bearing in this case) uses his demo Verdier with an additional trustplate&ball bearing to impeded vertical oscillations of the platter against the spring-suspended plinth and reported drmaitic improvement concerning both bass reproduction ans sonic calm.

Just three snippets ...

Anyone out there having listened to a Forsell Air Reference TT? It also has a single surface airbearing.

Nozzles:

I would presume we need 4 for the spherical surface and something between 7 and 16 for the axial bearing. But i have to draw touching circles into the bearing surface to find out how many are needed.

Oops, sorry for having offended you.I found your lecture not to be profoundly constructive so am going to retract my participation for the time being Perhaps your statements are triggered by the subconscious and show your intentions, differing from the conscious.

But methinks, i have adressed your points and not brushed them aside. And if i think i have not made my points understood enough, i invest another hour i don't have to illustrate them from a (hopefully) different point of view. As far as the chaotic system talk above is concerned, methinks you have preferred not to consider the issue so far (elaborate term for "brushing aside"). AFAIR, one of my earlier posts described it already and there should have been no need to do it again.

Re Announcing to retract participation (yeah, i read it, you intend to come back, okok). Last time i did this to others was in kindergarden. Then my mother explained to me that a menace is a promise is a promise is a promise ... and promises have to be kept.. Since then, i just did leave when i felt so, but i did never menace again. And i could come back whenever i felt it. No broken promise.

And, sorry for yet another lecturing 🙂

I would regret it very much if you feel sore and leave.

Mark, you may call me a merciless monster if it pleases you. You may do so in public 🙂 .

But i want to remind you that i have no interest to build the TT we are discussing myself (i have stated so before). So i have no stock options in this project. Can be i change my mind someday, say, i find it so sexy, so exciting that i want to try it out myself. Could be.

Besides that, i really have no time for it and regret the time i have spent posting everyday as it costs time i need for founding my own audio business. So, why am i doing it then? Because it is fun to me to see such a TT project grow and succeed. I want you all to succeed with it.

In this respect the merciless monster demands proper design conduct and this does also include that technical situations are thought thru properly and vague and/or wishful thinking is eliminated.

All,

I am happy with every simplification one of us comes up with and we as design group find the simplification benefitting and not getting in conflict with the technical requirements written into the specification.

I am very happy if one of us finds a way to avoid expensive machining. But we should not limit ourselves to scissors and cardboard, to kitchen table workshop. A workbench with a vice, a drillpress, a circular saw, keyhole saw, a surface milling cutter should be within reach for all of us. Some may have access to a metal workshop and maybe even to to precision maching and may help others with parts needed. So do i and, if desired, i can obtain CNC-turned parts for instance.

diyAudio TT design result may come out completely different to my ideas but as far as our consensual spec is concerned, i am happy with it.

And ... please apologize for me being such a monster, cannot jump out of my skin 🙂 ... don't get intimidated, the monster is not biting and most of the time cute and friendly.

dice45[/i] [B]... something better than a Teres or Redpoint to way lower costs. I do not want something slightly bettering a Rega. At same costs. [/B][/QUOTE] [QUOTE][i]Originally posted by planet10 said:

That is a good goal. I've had enuff regas already, and something in the league of the Teres or Redpoint would be just fine -- a step up from my Linn (then i can move it downstairs and call it my beater Linn ;^)

What i have seen so far is very encoraging, if not completely digested. Dice & Variac have some momentum from years of turntables dancing in their heads. Methinks there is something elegant, and effective just within grasp here. Some "blending at the edges", a little catalyst, and some sloshing around of ideas...

dave

Gentlemen,

I am very interested in this project, but other committments have kept me from giving this idea much more than a cursory glance. Breifly looking over it now, I must say I'm extremely impressed by what I've seen and the level of detail and knowledge shown. I hope to be able to offer some constructive input soon.

My only comment at the moment is to echo Bernhard and Dave above. I would only be interested in something that betters my modified Gyro by a decent margin.

Thanks Bernhard and Mark for sharing your knowledge and experience.

Regards

Brett

boy this is serious stuff!

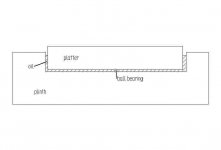

I've just returned from my hollidays and suddenly this thread has emerged. I think it is great and would love to be part of it all. I am an industial designer by trade and by no means an engineer and therefore cannot really understand the technical bits of what you lot are saying. But i do have some expertise in manufacturing techniques. Reading all this got me wondering if you couldn't simply let the platter be the bearing (see picture). Let the platter sit in an oil(?)bath (and if neccessary use one ball bearing to support the platter).

As I said it is just an idea, but why wouldn't it work?

Peter

I try to attach a drawing, bur I am not sure it will work😡

I've just returned from my hollidays and suddenly this thread has emerged. I think it is great and would love to be part of it all. I am an industial designer by trade and by no means an engineer and therefore cannot really understand the technical bits of what you lot are saying. But i do have some expertise in manufacturing techniques. Reading all this got me wondering if you couldn't simply let the platter be the bearing (see picture). Let the platter sit in an oil(?)bath (and if neccessary use one ball bearing to support the platter).

As I said it is just an idea, but why wouldn't it work?

Peter

I try to attach a drawing, bur I am not sure it will work😡

Attachments

Lots of good ideas, but...

Sorry, I didn't bother to read all of the posts on this topic, but one thing comes clear, Teres is already there in a relatively affordable package. I corresponded briefly with one of the principle of RedPoint and his take was that Teres had topped out, choosing to remain a solid, and relatively economical product.

But, has anyone LISTENED to the Teres? I keep putting this question out and am floored by the total LACK of responses. This 'table has been highly touted, but few have actually heard it, and even fewer have taken the time to review it in comparison to the marques such as the Gyrodec, the Oracle, Linns, etc. While it may seem cost effective, if it doesn't hold up in comparison, especially on the used market, then what's the point?

I realize that this is a DIY forum and many of you have the time/access/materials to pull something like this off. Me personally, if I built a 'table, I would want something that would significantly better the established standards at a given price point, in concurrence with Brett's remarks.

Greetings, Bernhard! Long time.

LS

Sorry, I didn't bother to read all of the posts on this topic, but one thing comes clear, Teres is already there in a relatively affordable package. I corresponded briefly with one of the principle of RedPoint and his take was that Teres had topped out, choosing to remain a solid, and relatively economical product.

But, has anyone LISTENED to the Teres? I keep putting this question out and am floored by the total LACK of responses. This 'table has been highly touted, but few have actually heard it, and even fewer have taken the time to review it in comparison to the marques such as the Gyrodec, the Oracle, Linns, etc. While it may seem cost effective, if it doesn't hold up in comparison, especially on the used market, then what's the point?

I realize that this is a DIY forum and many of you have the time/access/materials to pull something like this off. Me personally, if I built a 'table, I would want something that would significantly better the established standards at a given price point, in concurrence with Brett's remarks.

Greetings, Bernhard! Long time.

LS

I hope this image works. I’m not good at getting stuff out of Autocad.

I can post an acad file too

My approach is to keep the design simple at first, then add complexity as EXPERIMENTATION shows the need. Perhaps 4 nozzles aren't enough. If it doesn't work, we drill more!

At the moment I'm sure your suggestions will improve it (or make it functional!) It is not proposed as a finished product. In fact it might be a horrible turntable or the finest ever made I sure don't know!!

Gilad's idea of grinding, which would allow those with extra energy to tighten the tolorences is an example of this. I think that what could make it great is the eperimentation and effort by many people to the basic design.

As it stands, the platter and plinth should be able to be made by any glass fabricators that makes thick tabletops. The bearing can be make by anyone. Keep in mind that I have seen a working example this bearing concept albeit without a heavy platter! This example used the actual ball to form the socket, but I can only agree that if a slightly oversized ball is available to make the socket that would be better. I guess it is quite possible that ball bearings are available in very tiny increments of size. Even though the air film must have varied-it worked fine.

Of course plinth and platter size and layers of additional material can be experimented with by all. Even suspension if Dice doesn't break down your door! Eeeek turntable police!!!

Another thought: The Teres was a great deal for the original participants, but because of the special machining, any DIY person has to order the parts from Teres at a cost that is still pretty steep (perhaps still a bargain) or pay a fortune at a local precision machine shop for a one off part. At least the Teres parts are still available, otherwise the design would just be an interesting footnote for those that didn't get one in the beginning.

If we use complicated special parts, then we are at the mercy of the fabricator, and future builders will not be able to replicate the design and improve on it at reasonable cost- especially if the fabricator loses interest.

!!!!! If we keep it easy to fabricate, it will gain a life of it's own. !!!!

Perhaps this can be combined with other proposed ideas to make a better design. I am open to that of course.

At the moment, I see a few steps that people could do to help analyze this design:

1. Check your local cost for a 12” dia piece of glass 25mm thick with a hole about 50mm, and a rectangular plate with a similar hole for the plinth.

2. Check the availability of ball bearings in about the 50mm size and a thousanth oversize (Dice-what is the air thickness we are looking for?

3. Don’t do anything because this design doesn’t catch your interest.

Enjoy,

Mark

I can post an acad file too

My approach is to keep the design simple at first, then add complexity as EXPERIMENTATION shows the need. Perhaps 4 nozzles aren't enough. If it doesn't work, we drill more!

At the moment I'm sure your suggestions will improve it (or make it functional!) It is not proposed as a finished product. In fact it might be a horrible turntable or the finest ever made I sure don't know!!

Gilad's idea of grinding, which would allow those with extra energy to tighten the tolorences is an example of this. I think that what could make it great is the eperimentation and effort by many people to the basic design.

As it stands, the platter and plinth should be able to be made by any glass fabricators that makes thick tabletops. The bearing can be make by anyone. Keep in mind that I have seen a working example this bearing concept albeit without a heavy platter! This example used the actual ball to form the socket, but I can only agree that if a slightly oversized ball is available to make the socket that would be better. I guess it is quite possible that ball bearings are available in very tiny increments of size. Even though the air film must have varied-it worked fine.

Of course plinth and platter size and layers of additional material can be experimented with by all. Even suspension if Dice doesn't break down your door! Eeeek turntable police!!!

Another thought: The Teres was a great deal for the original participants, but because of the special machining, any DIY person has to order the parts from Teres at a cost that is still pretty steep (perhaps still a bargain) or pay a fortune at a local precision machine shop for a one off part. At least the Teres parts are still available, otherwise the design would just be an interesting footnote for those that didn't get one in the beginning.

If we use complicated special parts, then we are at the mercy of the fabricator, and future builders will not be able to replicate the design and improve on it at reasonable cost- especially if the fabricator loses interest.

!!!!! If we keep it easy to fabricate, it will gain a life of it's own. !!!!

Perhaps this can be combined with other proposed ideas to make a better design. I am open to that of course.

At the moment, I see a few steps that people could do to help analyze this design:

1. Check your local cost for a 12” dia piece of glass 25mm thick with a hole about 50mm, and a rectangular plate with a similar hole for the plinth.

2. Check the availability of ball bearings in about the 50mm size and a thousanth oversize (Dice-what is the air thickness we are looking for?

3. Don’t do anything because this design doesn’t catch your interest.

Enjoy,

Mark

Attachments

Variac said:I'll try again later......sorry

If you want to mail me the autocad file, i can get it out in a web-friendly form.

dave

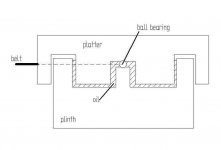

A larger pic of Variac's drawing... i used colors to replace the hatches that got lost in the translation (and i still haven't figured out why the board SW sometimes shows the graphic as a link instead of a pic (Jason?).

dave

An externally hosted image should be here but it was not working when we last tested it.

dave

Mark,

good job with AutoCAD! no need to humble yourself 🙂. Maybe you get in to 3D soon and stop hassling around with 2D drawings 🙂

I have asked a friend to make my LISP routines understandable for English people and to clean up the icon salad a bit. My routines help very much for 3D drafting and will be downloadable from my website soon.

no, TT police won't come, has to brush the own porcupine 🙂 . But you know my concerns, no need to repeat them.

I agree, dependance from a manufacturer could be a limiting factor for a DIY project. I had something other in mind when i suggested that. And i know what happened to the Teres thing, in fact one member of the original group maaged to occupy it and make his own business out of it.

To your drawing:

1) please muse about differnt materials. massing too much glass together and letting it be a major part of platter and plinth might cause glasses nasty sonic footprint to dominate and spoil sonics.

2) the edge of the lower epoxy cup should not touch the balls equator. Consider, vertical movements do not cause much gap variation at the equator but considerable gap variations at the south pole. Maybe it is better to have no south pole at all, maybe a band between Alaska and Florida would be best. No pressure belly then and almost uniform gap variations. Consider, the flat surface does the axial bearing job, no need for a well-meaning spherical bearing to help (and disturb). Make geometrical worstcase investigations, AutoCAD helps a lot; if you have drawn proplerly, you can measure down to 1/infinity. Try out how bearing gap varies on height variations.

3) 4 nozzles in the sphere and 8 in the flat surface, my suggestion.

4) please look that the air can leave the bearing gap on both sides. The flat surface needs air release holes at the inner radius.

So does the spherical surface. Imagine the bearings as circular elelmnatary bearings. The air has to be able to escape around the circle.

5) MicroSeiki had 25µm bearing gap. But provided surfaces are precise enough, on can go down to 10µm, maybe even 5.

Dave,

good job in making Mark's pix readable, now we have a Mac person having to help to post CAD drawings ... what a disgrace 🙂

Mark,

you won't believe it, but my pixes are resized screenshots. No other way to get shaded/rendered 3D pixes out of plain AutoCAD ... if you have bought the expensive add-ons however then plotting/printing 3D is no problem 🙁 no, not intending to start an anti AutoCAD flame here 🙂

good job with AutoCAD! no need to humble yourself 🙂. Maybe you get in to 3D soon and stop hassling around with 2D drawings 🙂

I have asked a friend to make my LISP routines understandable for English people and to clean up the icon salad a bit. My routines help very much for 3D drafting and will be downloadable from my website soon.

no, TT police won't come, has to brush the own porcupine 🙂 . But you know my concerns, no need to repeat them.

I agree, dependance from a manufacturer could be a limiting factor for a DIY project. I had something other in mind when i suggested that. And i know what happened to the Teres thing, in fact one member of the original group maaged to occupy it and make his own business out of it.

To your drawing:

1) please muse about differnt materials. massing too much glass together and letting it be a major part of platter and plinth might cause glasses nasty sonic footprint to dominate and spoil sonics.

2) the edge of the lower epoxy cup should not touch the balls equator. Consider, vertical movements do not cause much gap variation at the equator but considerable gap variations at the south pole. Maybe it is better to have no south pole at all, maybe a band between Alaska and Florida would be best. No pressure belly then and almost uniform gap variations. Consider, the flat surface does the axial bearing job, no need for a well-meaning spherical bearing to help (and disturb). Make geometrical worstcase investigations, AutoCAD helps a lot; if you have drawn proplerly, you can measure down to 1/infinity. Try out how bearing gap varies on height variations.

3) 4 nozzles in the sphere and 8 in the flat surface, my suggestion.

4) please look that the air can leave the bearing gap on both sides. The flat surface needs air release holes at the inner radius.

So does the spherical surface. Imagine the bearings as circular elelmnatary bearings. The air has to be able to escape around the circle.

5) MicroSeiki had 25µm bearing gap. But provided surfaces are precise enough, on can go down to 10µm, maybe even 5.

Dave,

good job in making Mark's pix readable, now we have a Mac person having to help to post CAD drawings ... what a disgrace 🙂

Mark,

you won't believe it, but my pixes are resized screenshots. No other way to get shaded/rendered 3D pixes out of plain AutoCAD ... if you have bought the expensive add-ons however then plotting/printing 3D is no problem 🙁 no, not intending to start an anti AutoCAD flame here 🙂

dice45 said:good job in making Mark's pix readable, now we have a Mac person having to help to post CAD drawings ... what a disgrace 🙂

One of my joys is taking things that are a problem on the PC, moving it over to the Mac where it is no problem, fixing it and moving it back. People even pay me to do it :^)

you won't believe it, but my pixes are resized screenshots. No other way to get shaded/rendered 3D pixes out of plain AutoCAD ...

The pic i did of Variacs is a colorized screen-snap... the PostScript imaging model in OS X does a lovely job, the screen snap is built-in to the OS, and with the 22" screen i just have to be careful i don't make it too big.

dave

dice45 said:Mark,

good job with AutoCAD! no need to humble yourself 🙂

This is the kind of jolly comment I made to you at first.

The one you responded to with an admonition to keep things positive, while titleing your screed with "What the @#$$@%!^"

There's a positive comment!!!!

All this based on your analysis of my SUBCONSIOUS INTENT!!

I thought only police states were allowed to judge people based of thoughts or even better Subconsious thoughts! Maybe you should get a job with one of these states, you could develop nifty gizmos to help with your work. I assure you that my message was only meant to encourage, and to be positive which makes me feel thast you owe me an apology.

Then I respond with a post that USED YOUR OWN WORDS about

offending others and people dropping out, with adding text to make it clear that I was not leaving, but to try and show you that you are the problem-you are the one bullying others. BUT YOU DIDN"T GET IT! Instead you respond with a self rightious self centered, condescending response about your Mommy.

Too bad your mommy didn't teach you better manners! It is not clear to me why you appointed yourself uber-monitor of correct behavior on this thread, but YOU AREN"T GOOD AT IT!!

I have spent a lot of time on this forum helping others, mainly newbies, because my knowlege is pretty limited. This takes some of the load off the heavy hitters. I also try to drum up interest in projects I find interesting and add positive,encouraging remarks. Sometimes I think I might have a clever idea and post it for response. Because of this involvement I consider myself friends with many on this site and have even invited a few to visit me (I don't do this lightly- I live in San Francisco and the people DO show up!!) That is why your comments are so offnsive to me.

In the future please look at the subject of the thread and make your comments relevent to the issue.

Otherwise to paraphrase you: Shut the @%$ up!

Thank You,

Mark

I have no interest in persuing this further, and will not post anything of this sort in the future on this thread here no matter how provoked, I has said what I needed to say and will drop it at this point.

My next message will address the issues at hand

🙂. Maybe you get in to 3D soon and stop hassling around with 2D drawings 🙂

--Yup, I'm a bit intimidated about 3D, but spend about 4 hours a day using Autocad 2D in my Architectural profession.

I have asked a friend to make my LISP routines understandable for English people and to clean up the icon salad a bit. My routines help very much for 3D drafting and will be downloadable from my website soon.

--This is just what I need!

no, TT police won't come, has to brush the own porcupine 🙂 . But you know my concerns, no need to repeat them.

---I want to make it clear that I have never proposed any sort of suspension - I just want to emphasize to people that they are free to experiment. I'm sure you are right, They would probably end up regreting it!!

I agree, dependance from a manufacturer could be a limiting factor for a DIY project. I had something other in mind when i suggested that. And i know what happened to the Teres thing, in fact one member of the original group maaged to occupy it and make his own business out of it.

---And I don't think that is a bad thing necessarily. At least the Teres lives on. Otherwise it would probably never be built again, because of the cost of one-off machining, and all the work they did designing it wouldn't continue to be used.

To your drawing:

1) please muse about differnt materials. massing too much glass together and letting it be a major part of platter and plinth might cause glasses nasty sonic footprint to dominate and spoil sonics.

---Of course this is true, but we had come to the conclusion that glass would work well for the bearing. Again-keep in mind that I'm not trying to prescribe an exact design. I assure you that the people on this forum will do things such as make the platter out of 10mm glass and glue a 50 mm disk of acrylic on top, or laminate various materials in the plinth. As it stands, the plinth glass is glued to another material such as wood or MDF or metal wich makes it very different than a piesce of glass by itself. This is constrained layer damping, and people could take it to ridiculous extents it they want. Also I'm sure someone will try stone for the plinth bearing even though I spec glass!! That's how DIY folks are!!!

2) the edge of the lower epoxy cup should not touch the balls equator. Consider, vertical movements do not cause much gap variation at the equator but considerable gap variations at the south pole.

--I would say that is why it is very important to have contact almost to the equator- that is the best part of the bearing (most consistant) and is required to take the lateral load of the motor and belt. Of course, any higher than the equator and it won't work!!

Maybe it is better to have no south pole at all,

---Maybe since the south pole is thicker and relatively springier, it will have NO effect vs. the platter bearing. the air will just compress.

maybe a band between Alaska and Florida would be best. No pressure belly then and almost uniform gap variations.

---Probably, but very difficult to make in my design

Consider, the flat surface does the axial bearing job, no need for a well-meaning spherical bearing to help (and disturb).

--As I mention above, perhaps the much thicker gap characteristic of the south polar region 🙂 make it affect the platter bearing very little. Perhaps just wishful thinking

Make geometrical worstcase investigations, AutoCAD helps a lot; if you have drawn proplerly, you can measure down to 1/infinity. Try out how bearing gap varies on height variations.

3) 4 nozzles in the sphere and 8 in the flat surface, my suggestion.

-This is a lot less than initially mentioned, and could be done at a reasonable price I think. But keep in mind that I have seen the ball bearing in a working configuration with the socket made by the ball itself AND only one nozzle. It was very stable and worked very well. I suspect that you are right and more nozzles will work better, but because I have seen it work, I would be tempted to try one. I also like your suggestion to find a ball i tiny bit bigger to make the socket. I just don't know if they are available. Also, as I mentioned above, maybe the thicker air film on the souuth actually is good?

4) please look that the air can leave the bearing gap on both sides. The flat surface needs air release holes at the inner radius.

So does the spherical surface. Imagine the bearings as circular elelmnatary bearings. The air has to be able to escape around the circle.

--Here is how I was originally envisioning it: ONE circular elementary bearing (the platter.) The air enters from the center and exits from the perimeter. I added the extra nozzles under the platter at your suggestion. This is probably necessary, You appear to knowabout this stuff and I don't, but as you point out, that creates more problems.

MAYBE if we had about 6 nozzles around the the ball socket

the air would flow into the gap between the platter and plinth evenly? Probably more wishful thinking. Damn 🙁

5) MicroSeiki had 25µm bearing gap. But provided surfaces are precise enough, on can go down to 10µm, maybe even 5.

good info

Mark,

you won't believe it, but my pixes are resized screenshots. No other way to get shaded/rendered 3D pixes out of plain AutoCAD ... if you have bought the expensive add-ons however then plotting/printing 3D is no problem 🙁 no, not intending to start an anti AutoCAD flame here 🙂 [/B][/QUOTE]

OOooooo! but I love to flame Autocad !!!!!

Let's say I have a love/hate relatioship with it!

regards, MArk

--Yup, I'm a bit intimidated about 3D, but spend about 4 hours a day using Autocad 2D in my Architectural profession.

I have asked a friend to make my LISP routines understandable for English people and to clean up the icon salad a bit. My routines help very much for 3D drafting and will be downloadable from my website soon.

--This is just what I need!

no, TT police won't come, has to brush the own porcupine 🙂 . But you know my concerns, no need to repeat them.

---I want to make it clear that I have never proposed any sort of suspension - I just want to emphasize to people that they are free to experiment. I'm sure you are right, They would probably end up regreting it!!

I agree, dependance from a manufacturer could be a limiting factor for a DIY project. I had something other in mind when i suggested that. And i know what happened to the Teres thing, in fact one member of the original group maaged to occupy it and make his own business out of it.

---And I don't think that is a bad thing necessarily. At least the Teres lives on. Otherwise it would probably never be built again, because of the cost of one-off machining, and all the work they did designing it wouldn't continue to be used.

To your drawing:

1) please muse about differnt materials. massing too much glass together and letting it be a major part of platter and plinth might cause glasses nasty sonic footprint to dominate and spoil sonics.

---Of course this is true, but we had come to the conclusion that glass would work well for the bearing. Again-keep in mind that I'm not trying to prescribe an exact design. I assure you that the people on this forum will do things such as make the platter out of 10mm glass and glue a 50 mm disk of acrylic on top, or laminate various materials in the plinth. As it stands, the plinth glass is glued to another material such as wood or MDF or metal wich makes it very different than a piesce of glass by itself. This is constrained layer damping, and people could take it to ridiculous extents it they want. Also I'm sure someone will try stone for the plinth bearing even though I spec glass!! That's how DIY folks are!!!

2) the edge of the lower epoxy cup should not touch the balls equator. Consider, vertical movements do not cause much gap variation at the equator but considerable gap variations at the south pole.

--I would say that is why it is very important to have contact almost to the equator- that is the best part of the bearing (most consistant) and is required to take the lateral load of the motor and belt. Of course, any higher than the equator and it won't work!!

Maybe it is better to have no south pole at all,

---Maybe since the south pole is thicker and relatively springier, it will have NO effect vs. the platter bearing. the air will just compress.

maybe a band between Alaska and Florida would be best. No pressure belly then and almost uniform gap variations.

---Probably, but very difficult to make in my design

Consider, the flat surface does the axial bearing job, no need for a well-meaning spherical bearing to help (and disturb).

--As I mention above, perhaps the much thicker gap characteristic of the south polar region 🙂 make it affect the platter bearing very little. Perhaps just wishful thinking

Make geometrical worstcase investigations, AutoCAD helps a lot; if you have drawn proplerly, you can measure down to 1/infinity. Try out how bearing gap varies on height variations.

3) 4 nozzles in the sphere and 8 in the flat surface, my suggestion.

-This is a lot less than initially mentioned, and could be done at a reasonable price I think. But keep in mind that I have seen the ball bearing in a working configuration with the socket made by the ball itself AND only one nozzle. It was very stable and worked very well. I suspect that you are right and more nozzles will work better, but because I have seen it work, I would be tempted to try one. I also like your suggestion to find a ball i tiny bit bigger to make the socket. I just don't know if they are available. Also, as I mentioned above, maybe the thicker air film on the souuth actually is good?

4) please look that the air can leave the bearing gap on both sides. The flat surface needs air release holes at the inner radius.

So does the spherical surface. Imagine the bearings as circular elelmnatary bearings. The air has to be able to escape around the circle.

--Here is how I was originally envisioning it: ONE circular elementary bearing (the platter.) The air enters from the center and exits from the perimeter. I added the extra nozzles under the platter at your suggestion. This is probably necessary, You appear to knowabout this stuff and I don't, but as you point out, that creates more problems.

MAYBE if we had about 6 nozzles around the the ball socket

the air would flow into the gap between the platter and plinth evenly? Probably more wishful thinking. Damn 🙁

5) MicroSeiki had 25µm bearing gap. But provided surfaces are precise enough, on can go down to 10µm, maybe even 5.

good info

Mark,

you won't believe it, but my pixes are resized screenshots. No other way to get shaded/rendered 3D pixes out of plain AutoCAD ... if you have bought the expensive add-ons however then plotting/printing 3D is no problem 🙁 no, not intending to start an anti AutoCAD flame here 🙂 [/B][/QUOTE]

OOooooo! but I love to flame Autocad !!!!!

Let's say I have a love/hate relatioship with it!

regards, MArk

Variac said:--Yup, I'm a bit intimidated about 3D, but spend about 4 hours a day using Autocad 2D in my Architectural profession.

OOooooo! but I love to flame Autocad !!!!!

Let's say I have a love/hate relatioship with it!

In our city some 60% of the Architects use VectorWorks on the Mac (and another 10% use ArchiCad or Archetrion). Not only because of the love/hate thing, but because of the vastly reduced costs involved, generally better software, particularily for Architecture. The lower entry cost (a single seat of ACAD can buy Vectorworks & an entry level Mac to run it on), the dramatically lower support costs, the fact that the Macs have at least twice the useful life of a PC, and the improved productivity all add up to less $$$ spent -- and almost all the architects i have met are quite stingy with their computing dollars. Even the IBM building was designed on Macs (as was Bill Gates house).

dave

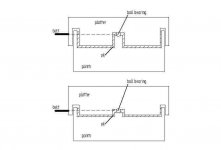

About 10 posts before this one I posted an idea to let the platter sit on a single ball bearing and stabilize the platter in an oil bath. Something like a unipivot arm.

Nobody has replied on it, so I assume it is a very stupid idea. But could anybody please explain why that is so? The drawing was there just to explain the principle of the bearing, the actual thing may have to be very different in order to solve other problems. But still, what is wrong with the basic idea?

Peter

Nobody has replied on it, so I assume it is a very stupid idea. But could anybody please explain why that is so? The drawing was there just to explain the principle of the bearing, the actual thing may have to be very different in order to solve other problems. But still, what is wrong with the basic idea?

Peter

Peter,

sorry to have not responded.

to be honest, I am not quite sure if your idea works. That is because the axial bearing is over-determined: either the ball or the flat bottom surface carries the platter. Reason: you cannot predict actually happening oil gap that precise and you probably cannot machine the ball surfaces that precise then. And there will be wear-off, adding to the problem.

Moreover the platter's center of inertia is above the ball so the platter will tend to tilt around.

If you omit the ball, this would help. But then the platter's outer diameter and the plinth hole has to be machined to a high precision.

Then i see an additional challenge: the oil will heavily dampen any platter motion.

Partial oscillation. That is good. Rotation. That is not so good. But, her lays the challenge, if you manage to find a motor able to drive this "oil-breaked" platter to a constant speed, you will have the most constant platter speed in the world. Because your motor/platter/platter-bearing assembly generates 99.9% static base load and 0.1% load variation by the record played.

sorry to have not responded.

to be honest, I am not quite sure if your idea works. That is because the axial bearing is over-determined: either the ball or the flat bottom surface carries the platter. Reason: you cannot predict actually happening oil gap that precise and you probably cannot machine the ball surfaces that precise then. And there will be wear-off, adding to the problem.

Moreover the platter's center of inertia is above the ball so the platter will tend to tilt around.

If you omit the ball, this would help. But then the platter's outer diameter and the plinth hole has to be machined to a high precision.

Then i see an additional challenge: the oil will heavily dampen any platter motion.

Partial oscillation. That is good. Rotation. That is not so good. But, her lays the challenge, if you manage to find a motor able to drive this "oil-breaked" platter to a constant speed, you will have the most constant platter speed in the world. Because your motor/platter/platter-bearing assembly generates 99.9% static base load and 0.1% load variation by the record played.

thanks for your reply Bernhard,

you cannot predict actually happening oil gap that precise and you probably cannot machine the ball surfaces that precise then.

*this seems to me to be a question of how much of the platter as actually supported by the oil. And also maybe about viscosity?

Moreover the platter's center of inertia is above the ball so the platter will tend to tilt around.

*see picture

Then i see an additional challenge: the oil will heavily dampen any platter motion.

*Isn't this also about viscosity and/or the width of the oil film?

Peter

you cannot predict actually happening oil gap that precise and you probably cannot machine the ball surfaces that precise then.

*this seems to me to be a question of how much of the platter as actually supported by the oil. And also maybe about viscosity?

Moreover the platter's center of inertia is above the ball so the platter will tend to tilt around.

*see picture

Then i see an additional challenge: the oil will heavily dampen any platter motion.

*Isn't this also about viscosity and/or the width of the oil film?

Peter

Attachments

Stop yelling around here!

Mark,

apologies if i have bullied someone around here. This would have been my last intention.

One word to my private email to you. I wrote you an apology for the case i have overdone with my remarks. I felt i overdid. I expected a private answer to it. I would have taken any set of lumps by you and apologized for it.

That you preferred to ignore it and write such a post instead contributes to my considerable disappointment about your person. And makes me feel you deserve a public answer.

Nor can you. You have a tendency to bully, too, just my opinion and let's call it not a strong one, and i had a similar impression on other threads where i did just lurk. Your snappy and vitriolic answers to my acknowldeging your AutoCAD backups that opinion. Call me biased if you wish. I wanted to soften your impact here a bit and of course, i also wanted to bring in my own ideas, would be stupid to deny it.

(Again, apologies for my strong impact)

Honestly, i felt bullied by you. I felt my ideas downtalked. Now that we have established i am moderator and biased, it is better for me and you and the project and the whole diyAudio show that i step back and out of the way. I let you all guys have fun, without spec, without my lectures, ok?

But Mark,

(very softly speaking now) i stay observing ... should i or one of the other moderators find you bully other members the way you bullied me, or should you be spotted yelling around here like you did in the post quoted above, i promise that will have consequences.

I use to keep my promises.

Yours faithfully

Bernhard

(diyAudio moderator)

..and so onVariac said:This is the kind of jolly comment I made to you at first.[/B]

Mark,

apologies if i have bullied someone around here. This would have been my last intention.

One word to my private email to you. I wrote you an apology for the case i have overdone with my remarks. I felt i overdid. I expected a private answer to it. I would have taken any set of lumps by you and apologized for it.

That you preferred to ignore it and write such a post instead contributes to my considerable disappointment about your person. And makes me feel you deserve a public answer.

that is because legally i am; i just tried to keep a low profile. You are right, i am not good in keeping low profile. I am a strong person and cannot jump out of my skin....uber-monitor of correct behavior...

Nor can you. You have a tendency to bully, too, just my opinion and let's call it not a strong one, and i had a similar impression on other threads where i did just lurk. Your snappy and vitriolic answers to my acknowldeging your AutoCAD backups that opinion. Call me biased if you wish. I wanted to soften your impact here a bit and of course, i also wanted to bring in my own ideas, would be stupid to deny it.

(Again, apologies for my strong impact)

Honestly, i felt bullied by you. I felt my ideas downtalked. Now that we have established i am moderator and biased, it is better for me and you and the project and the whole diyAudio show that i step back and out of the way. I let you all guys have fun, without spec, without my lectures, ok?

But Mark,

(very softly speaking now) i stay observing ... should i or one of the other moderators find you bully other members the way you bullied me, or should you be spotted yelling around here like you did in the post quoted above, i promise that will have consequences.

I use to keep my promises.

Yours faithfully

Bernhard

(diyAudio moderator)

yes. if the gap is thin, a bearing gap, then the oil film's coherenece carries the platter. With a wide gap, the oil only dampens. the wider the gap, the less the damping.peterr said:*this seems to me to be a question of how much of the platter as actually supported by the oil. And also maybe about viscosity?

way better! but please avoid the platter's Xsectional bell shape. make the platter massive as before. The circular fin hanging in the oil need not to be that thick.*see picture

you could use the shaft on which the ball is resting as radial bearing shaft.

Another weird idea once realized y some French guys: a stainless steel platter swimming in mercury. They used shaft and bushing for radial bearing. The rest of their platter looked like your draft, just that a thin layer of silicone oil prevented the mercury from evaporating slowly. Mercury (Hg) is quite poisonous.

Having the belt pulling along the axial bearing point height is a good idea. But your platter is a gyro: it tends to keep it's rotational plane. If this plane is tilted, it remains tilted. If the belt pulls not horizontally ..

What do you do to prevent that? Remember, tonearm vertical tracking angle is utterly sensitive for changes.

Yes. The wider the gap, the less the damping and breaking.*Isn't this also about viscosity and/or the width of the oil film?

The circular fin hanging in the oil need not to be that thick

Bernhard,

I'm afraid I don't quite understand what you mean. I assume that the fin you speak of is the part of the PLATTER that hangs in the oil.But by thickness do you mean its height or its width?

If you mean width: shouldn't actually be even wider (see picture)

If you mean height: wouldn't the stability of the platter suffer as the point of gravity will lie above the ball. (see picture) I am supposing the ball should be in the oil (?)

. But your platter is a gyro: it tends to keep it's rotational plane. If this plane is tilted, it remains tilted.

Is this really an issue at 33rpm?

Thank you for your wisdom,

Peter

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Let's make a DIYAUDIO TT