Good morning Freddy,

nope....i have no building experiences with the X15-cabinets. I've heared a couple of them and they sounded OK but i like the dry/instantanious/direct way of an open baffle better (has it's own problems.....i know).

Choices....choices...

Regards, Reinout

nope....i have no building experiences with the X15-cabinets. I've heared a couple of them and they sounded OK but i like the dry/instantanious/direct way of an open baffle better (has it's own problems.....i know).

Choices....choices...

Regards, Reinout

Hi Reinout

Here's something I wish to try for my 6PEV13 as a midrange module, There may be enough on-axis rise to use an aperture like in my rough sketch. Whether it would play smooth without undue resonances = ? 🙂. A K-tube would sit on top.

https://i.imgur.com/upA7ZEB.jpg

Best wishes,

Freddy

Here's something I wish to try for my 6PEV13 as a midrange module, There may be enough on-axis rise to use an aperture like in my rough sketch. Whether it would play smooth without undue resonances = ? 🙂. A K-tube would sit on top.

https://i.imgur.com/upA7ZEB.jpg

Best wishes,

Freddy

Good morning Freddy,

only the actual build will tell/hear if this is a smooth solution.....

In the meantime i'm working through my speakersystem cleaning up the details. Next little project: to exchange the binding posts + internal wires inside the compression drivers. I know both drivers stuck to the original Altec-description that field replacement of the diaphragm had to be done immediately and without specialised tools (so they use crappy Faston connectors) but currently the precious audio-signal is through mediocre binding posts - awful internal cable - sheetmetal Fastons ? AAAARRGGHH

Noted in serious other brand drivers like TAD and JBL they do the same ?! Of course this works but it is not audio acceptable.

Currently gathering nice parts and the correct tap because i have to drill/tap into the driver units (better do this when my kid is not playing in the house which is a problem currently with the COVID19 lockdown and schools formally closed; i have to find the correct time to do this as i don't want to be disturbed when those units are internally exposed).

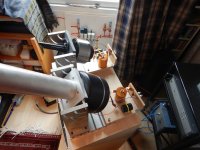

Look at the current situation (pictures): options for improvement....= audio hobby.

Regards, Reinout

only the actual build will tell/hear if this is a smooth solution.....

In the meantime i'm working through my speakersystem cleaning up the details. Next little project: to exchange the binding posts + internal wires inside the compression drivers. I know both drivers stuck to the original Altec-description that field replacement of the diaphragm had to be done immediately and without specialised tools (so they use crappy Faston connectors) but currently the precious audio-signal is through mediocre binding posts - awful internal cable - sheetmetal Fastons ? AAAARRGGHH

Noted in serious other brand drivers like TAD and JBL they do the same ?! Of course this works but it is not audio acceptable.

Currently gathering nice parts and the correct tap because i have to drill/tap into the driver units (better do this when my kid is not playing in the house which is a problem currently with the COVID19 lockdown and schools formally closed; i have to find the correct time to do this as i don't want to be disturbed when those units are internally exposed).

Look at the current situation (pictures): options for improvement....= audio hobby.

Regards, Reinout

Attachments

Good afternoon DIYAudio-forum,

with the help of a drill and tap now the Von Langa backcovers have populated with quality ETi binding posts and Audiaz silver wire instead of those horrible original binding posts, the to-be-avoided Faston-connectors and dreadful wire. Much better !

Luckily that i had an extra set of back covers so i could do this "procedure" while the system is playing. With that drilling/thread-making i have certainly metal dust/parts on my clothes and i will NOT open a compression driver with metal particles flying around....

So the actual fixing of the new backcovers + proper will be done later on.

In the meantime: Merry Christmas and a Wonderfull (healthy !) 2021 to you all.

Regards,

Reinout

(pictures of the original Von Langa innards and the new situation that avoids all the non-audio metal/connectors)

with the help of a drill and tap now the Von Langa backcovers have populated with quality ETi binding posts and Audiaz silver wire instead of those horrible original binding posts, the to-be-avoided Faston-connectors and dreadful wire. Much better !

Luckily that i had an extra set of back covers so i could do this "procedure" while the system is playing. With that drilling/thread-making i have certainly metal dust/parts on my clothes and i will NOT open a compression driver with metal particles flying around....

So the actual fixing of the new backcovers + proper will be done later on.

In the meantime: Merry Christmas and a Wonderfull (healthy !) 2021 to you all.

Regards,

Reinout

(pictures of the original Von Langa innards and the new situation that avoids all the non-audio metal/connectors)

Attachments

Hi Reinout,

you seem to know no mercy with original manufacturer design 😀😀😀

Will the two wires be soldered to the diaphragm?

Congrats to this mod, it looks very good! Do you think it will have a major impact on sound?

Bernd

you seem to know no mercy with original manufacturer design 😀😀😀

Will the two wires be soldered to the diaphragm?

Congrats to this mod, it looks very good! Do you think it will have a major impact on sound?

Bernd

Good evening Bernd,

i simply love these drivers but don't understand these horrible audio-constraints like Faston-connectors.

Probably the manufacturers like to stick to Altec-guidelines which stated that diaphragm-replacement had to be done "in field without specialised tools". Those Fastons are great in following that guideline but audio-wise it is a nightmare.

This is not a specific Von Langa issue ! Look at those fantastic Fostex D200a i have; they have the same crappy connection-solution. Or Google the TAD-4001 (fantastic driver !!!!!!!!!!!!!); even that icon uses those crappy sh@# connections. Why ?

Currently there are numerous really serious binding posts (your choice....) and perfect "cable/wire" suited to your liking. If i'm willing to spend serious money on loudspeaker cabling, like many audio affecionados do, this 5 cm replacement of sh@# is an easy upgrade.

With the money involved in all the above serious drivers i would like to see that manufacturers would at least start with a proper audio-acceptable solution. Currently they are just limiting their fantastic products .....which a shame.

In a couple of days (after Christmas) i will install these freshly fitted back-covers and find out the differences. I do not expect a landslide difference but only the thought that my precious audio signal currently passes brass binding posts - tin covered connectors - pvc covered copper wire will be a mental improvement on its own.

I'll keep you posted.

Merry Christmas and a Wonderful (and healthy) 2021.

Regards,

Reinout

i simply love these drivers but don't understand these horrible audio-constraints like Faston-connectors.

Probably the manufacturers like to stick to Altec-guidelines which stated that diaphragm-replacement had to be done "in field without specialised tools". Those Fastons are great in following that guideline but audio-wise it is a nightmare.

This is not a specific Von Langa issue ! Look at those fantastic Fostex D200a i have; they have the same crappy connection-solution. Or Google the TAD-4001 (fantastic driver !!!!!!!!!!!!!); even that icon uses those crappy sh@# connections. Why ?

Currently there are numerous really serious binding posts (your choice....) and perfect "cable/wire" suited to your liking. If i'm willing to spend serious money on loudspeaker cabling, like many audio affecionados do, this 5 cm replacement of sh@# is an easy upgrade.

With the money involved in all the above serious drivers i would like to see that manufacturers would at least start with a proper audio-acceptable solution. Currently they are just limiting their fantastic products .....which a shame.

In a couple of days (after Christmas) i will install these freshly fitted back-covers and find out the differences. I do not expect a landslide difference but only the thought that my precious audio signal currently passes brass binding posts - tin covered connectors - pvc covered copper wire will be a mental improvement on its own.

I'll keep you posted.

Merry Christmas and a Wonderful (and healthy) 2021.

Regards,

Reinout

Hi Reinout,

Your efforts to get the last few centimeters right are IMO very correct. If you hear a difference or not, at least it will provide peace of mind for a relatively cheap investment in comparison to the cost of the drivers. A thought I have here is that I personally like to stay with a single material, so as long as my voicecoil is from copper, I like to use copper a s well in all signal conductors (I use silver for small-signal conductors a s well) after the amps. With a silver voicecoil things would change, but a silver voicecoil has its own set of advantages and disadvantages (especially in low Mms drivers).

Another thing: Are you aware of BT´s article and measurements of the K-tube? If not, PM me and I´ll send it to you, avoiding copyright issues.

All the best

Mattes

Your efforts to get the last few centimeters right are IMO very correct. If you hear a difference or not, at least it will provide peace of mind for a relatively cheap investment in comparison to the cost of the drivers. A thought I have here is that I personally like to stay with a single material, so as long as my voicecoil is from copper, I like to use copper a s well in all signal conductors (I use silver for small-signal conductors a s well) after the amps. With a silver voicecoil things would change, but a silver voicecoil has its own set of advantages and disadvantages (especially in low Mms drivers).

Another thing: Are you aware of BT´s article and measurements of the K-tube? If not, PM me and I´ll send it to you, avoiding copyright issues.

All the best

Mattes

Good afternoon Mattes,

thanks for the support.

Same as your idea/insight: i like to stick to a single material but the details/improvement of silver in the audio-path can not be denied. This is a strictly personal opinion (before i'm crucified by the "copper-clan"). Of much more importance is the quality of the material. I would ALWAYS choose serious quality copper (in a correct insulator) above a mediocre silver conductor ! But if both copper and silver are of correct quality i prefer silver and like to do the whole audiopath with that material.

Wiring is easy, connectors can be made possible, transformers are worth it (but so expensive i simply can not afford it on all places, capacitors no problem, etc etc.....

Again the execution of the material is important. I love the really old Siltech FT12 G3 as that loudspeaker wire (combination of 4 parallel flatwire cables) could be seperated. Those individual inductors are great for internal crossover-wiring. It's the same i do/use with the Neotech NS-02525 currently used for the midrange: the left over pieces are donors for internal wiring.

But currently i'm almost empty of those donor-cables so i had to look for other quality stuff: found it at Duelund (the real silver version and not the WE-replica's) and Audiaz.

The crossovers of the current system will be built with these cables.

You'll get an PB for the info....thanks in advance.

Regards, Reinout

thanks for the support.

Same as your idea/insight: i like to stick to a single material but the details/improvement of silver in the audio-path can not be denied. This is a strictly personal opinion (before i'm crucified by the "copper-clan"). Of much more importance is the quality of the material. I would ALWAYS choose serious quality copper (in a correct insulator) above a mediocre silver conductor ! But if both copper and silver are of correct quality i prefer silver and like to do the whole audiopath with that material.

Wiring is easy, connectors can be made possible, transformers are worth it (but so expensive i simply can not afford it on all places, capacitors no problem, etc etc.....

Again the execution of the material is important. I love the really old Siltech FT12 G3 as that loudspeaker wire (combination of 4 parallel flatwire cables) could be seperated. Those individual inductors are great for internal crossover-wiring. It's the same i do/use with the Neotech NS-02525 currently used for the midrange: the left over pieces are donors for internal wiring.

But currently i'm almost empty of those donor-cables so i had to look for other quality stuff: found it at Duelund (the real silver version and not the WE-replica's) and Audiaz.

The crossovers of the current system will be built with these cables.

You'll get an PB for the info....thanks in advance.

Regards, Reinout

Good morning diyAudio-forum,

yesterday i had the opportunity to swap the inner cables of the Von Langa drivers. My 10 years old son stayed over at his grandparents which is a must before i open up compression drivers ......

The swap itself was easy and straightforward. I dropped 0,1 ohm in resistance (always nice to see that my own contraption is functioning). Happily surprised with the result: more crisp (not hard/edgy !) and detailed.

Although it is only 5 cm of Audiaz wire the absence of the former crappy wire was easy to notice. It was like swapping an interlink or loudspeaker cable.

What a simple and effective upgrade.

A healthy and wonderful 2021 for everyone.

Regards, Reinout

yesterday i had the opportunity to swap the inner cables of the Von Langa drivers. My 10 years old son stayed over at his grandparents which is a must before i open up compression drivers ......

The swap itself was easy and straightforward. I dropped 0,1 ohm in resistance (always nice to see that my own contraption is functioning). Happily surprised with the result: more crisp (not hard/edgy !) and detailed.

Although it is only 5 cm of Audiaz wire the absence of the former crappy wire was easy to notice. It was like swapping an interlink or loudspeaker cable.

What a simple and effective upgrade.

A healthy and wonderful 2021 for everyone.

Regards, Reinout

Attachments

K-tubes

Any news on the 2 inch Transylvania tubes?

I used 1 inch K-tubes for a while with a pair of transmission line midrange drivers, Karlson boxes and subwoofers when my Lowther drivers I used in front waveguides went down. The 1 inch K tubes sounded great. I tried aiming the K-tubes directly at the listening position to extend the high frequencies at the listening position. In the end, I did not like it and aimed the K-tubes upward, but the high frequencies rolled off at about 8 khz. I added a pair of ribbon tweeters to bring up the high frequencies.

I replaced the failed Lowthers (were DX4s, now DX65s) and I am now using them from 500 hz to 8 khz in the front waveguides in lieu of the transmission line midrange and 1 inch K-tubes. At some point I will likely try the 1 inch K-tubes in lieu of the Lowther high frequencies which can be troublesome.

I am using a pair of K15 boxes and put EVM15L drivers in them. I find them quite excellent, with lower distortion and better dynamics than open baffle variants I have tried.

What did you not like about the K15s that you heard? I need to build a new pair of K15s though, because these are very old and the plywood is delaminating causing obnoxious buzzing sounds in the midrange at certain frequencies.

Retsel

Any news on the 2 inch Transylvania tubes?

I used 1 inch K-tubes for a while with a pair of transmission line midrange drivers, Karlson boxes and subwoofers when my Lowther drivers I used in front waveguides went down. The 1 inch K tubes sounded great. I tried aiming the K-tubes directly at the listening position to extend the high frequencies at the listening position. In the end, I did not like it and aimed the K-tubes upward, but the high frequencies rolled off at about 8 khz. I added a pair of ribbon tweeters to bring up the high frequencies.

I replaced the failed Lowthers (were DX4s, now DX65s) and I am now using them from 500 hz to 8 khz in the front waveguides in lieu of the transmission line midrange and 1 inch K-tubes. At some point I will likely try the 1 inch K-tubes in lieu of the Lowther high frequencies which can be troublesome.

I am using a pair of K15 boxes and put EVM15L drivers in them. I find them quite excellent, with lower distortion and better dynamics than open baffle variants I have tried.

What did you not like about the K15s that you heard? I need to build a new pair of K15s though, because these are very old and the plywood is delaminating causing obnoxious buzzing sounds in the midrange at certain frequencies.

Retsel

have you tried using a double cutaway K- tube. I like them much better than a single cutaway version. I set mine up centred upon my seated ear height, the tube is parallel to the floor with the cutaway in the vertical position. I start with the tube firing directly at each ear then adjust toe in or out as required to suit my taste. I keep k- tubes on the short side at 1/4 wave of the compression drivers impedance peak or the cone drivers Fs. Longer k- tubes can be easily damped with open cell foam (25 PPI).

Please note that I borrowed the photo of the single and double cutaway k- tubes off line it is not my own, I make mine from single or double wall layer rolls of standard weight graph paper the kind in school note books. These have zero energy storage can be made or modified in a few minutes each and sound wonderful.

Please note that I borrowed the photo of the single and double cutaway k- tubes off line it is not my own, I make mine from single or double wall layer rolls of standard weight graph paper the kind in school note books. These have zero energy storage can be made or modified in a few minutes each and sound wonderful.

Attachments

How do you compare efficiency and directivity of both versions ?

I can not imagine that thin paper tubes have any effect as wave

guides. Dense tubular cardboard could probably be used. Thanks

I can not imagine that thin paper tubes have any effect as wave

guides. Dense tubular cardboard could probably be used. Thanks

I never measured efficiency or directivity of either version I simply listened to each and played with positioning of each and I chose the one I liked best it was not a difficult choice to make. I did not notice any difference in efficiency so far as I could tell. You would be very wrong about using paper as a tube material but if you want to make protoyping and your build more expensive and time consuming build what ever type you like. Having some hands on experience would give weight to your comment on the suitability of using paper as a tube material.

Here is a simple paper tube on one of my compression drivers this is a EV DH1A fitted with a single cutaway paper K-tube. With paper you can experiment with as many different profiles as you like to find which you like best in a single session you never have to leave the room all you need is a pencil paper scissors and a form to roll on (you don't have to have a form it just makes the process faster). Every paper tube you make will be a perfect fit for your driver exit.

Here is a simple paper tube on one of my compression drivers this is a EV DH1A fitted with a single cutaway paper K-tube. With paper you can experiment with as many different profiles as you like to find which you like best in a single session you never have to leave the room all you need is a pencil paper scissors and a form to roll on (you don't have to have a form it just makes the process faster). Every paper tube you make will be a perfect fit for your driver exit.

Attachments

Double cut K-tube model for 3D printing is here: 3D printed K-Tube for 1" compression drivers and some measurements here: 3D printed K-Tube for 1" compression drivers

Moray, how long is that single slot 1.4" format K-tube ? I like "The Tube" and clones - on axis (straight down the tube) they go to about 17K with a DE250, but should be elevated or pointed down for best sound.

The double slot tube by Pelanj has excellent sound. It freaks me a bit that I like it best with the slots facing the ceiling and floor.

For K-midrange I hope to try a strong 6 or 8 in a regular and shallow K -"wedge". Softening the hard/sharp inside corners with auto putty might be helpful (?)

@Retsel - what compression driver do you run with the K-tube? If a crossover was high enough the Tymphany Ti with polyimide surround might be a good budget choice.

Test Bench: Peerless by Tymphany DFM-2544R00-08 Compression Driver | audioXpress

The double slot tube by Pelanj has excellent sound. It freaks me a bit that I like it best with the slots facing the ceiling and floor.

For K-midrange I hope to try a strong 6 or 8 in a regular and shallow K -"wedge". Softening the hard/sharp inside corners with auto putty might be helpful (?)

@Retsel - what compression driver do you run with the K-tube? If a crossover was high enough the Tymphany Ti with polyimide surround might be a good budget choice.

Test Bench: Peerless by Tymphany DFM-2544R00-08 Compression Driver | audioXpress

Last edited:

the tube was set at 1/4 wavelength at the impedance peak of the driver (around 475 Hz), so the tube was about 5 3/4" - 6" long. I had my tubes (double cutaway) set up so the vents were facing up and down with the solid sections of the tubes to the left and right, tubes parallel to the floor at seated ear height gave best results for me after a lot of different orientations. Hope this helps.

the K-Tube set up mentioned above was used for near field listening. Other orientations of the K-Tube might suit other listening goals more effectively, Omni directional reproduction comes to mind.

Good evening all,

till now i used the speakersystem with an active XO in order to find the most optimal crossover-frequencies and slopes for the respective drivers.

I had 2 active XO's available:

- a Bryston 10B; an older trusty workhorse. 100% analog, few XO-possibilities but with highly appreciated 6/12/18 dB-slope options.

- A Behringer CX3400; ultra modern device. 100% digital, multiple XO-possibilities, slopes fixed at 24dB.

Soundwise the Bryston won hands down; but that was not the essence of this procedure. With these 2 (different !) active XO's i could found out the correct crossover-frequencies.

The Fertin woofer is happy with anything below 1000 Hz but sounded better with "below 500 Hz".

The split between mid and high was around 4250 Hz (2nd order).

That means huge coils for the bass. I prefer air coils....they exist but they are "interestingly" priced. From earlier projects i have enough experiences with ZeroOhm coils which are acceptable but not preferred here. So i decided to do the bass somewhat different and use the PAP-C1 (Pass XO) to actively divide low and mid/high.

That PAP-C1 is an analog XO (fistfull of FETs) with some tweaking possibilities. The crossover can be set tot 120 Hz - 550 Hz which is spot on for my set up.

So from that PAP-C1 (with a ridicilous minute external feather weight power supply....rest assured....this will be different in near future !!!!!!) the bass amplifier is fed directly.

The other output of the PAP-C1 is split to seperate mid and high amplifiers to be followed by the passive XO-filters near the drivers/K-tubes. With a single capacitor + coil at each seperate crossover-board it made sense to invest in quality.

The coil is the quite new Mundorf VLCU10; the capacitor is Mundorf Supreme SilverOil (prefer this one above the SilverGoldOil).

And after some running in i can state that this is way better then the Behringer-Bryston combination. Bass is deep and the mids/highs are more crisp.

The combination of actively dividing low and mid/high certainly keeps the partnumber of the passive XO down as you only are building a 2-way XO whereas the bass-power is channelled away by that Pass PAP-C1 (which works very nice).

Next project is my own tweeteramp. Currently i'm running my set with an on loan 1,1 Watt E2C SPUD which works flawlesly and proves that 1 Watt should be more than sufficient.

Regards,

Reinout

till now i used the speakersystem with an active XO in order to find the most optimal crossover-frequencies and slopes for the respective drivers.

I had 2 active XO's available:

- a Bryston 10B; an older trusty workhorse. 100% analog, few XO-possibilities but with highly appreciated 6/12/18 dB-slope options.

- A Behringer CX3400; ultra modern device. 100% digital, multiple XO-possibilities, slopes fixed at 24dB.

Soundwise the Bryston won hands down; but that was not the essence of this procedure. With these 2 (different !) active XO's i could found out the correct crossover-frequencies.

The Fertin woofer is happy with anything below 1000 Hz but sounded better with "below 500 Hz".

The split between mid and high was around 4250 Hz (2nd order).

That means huge coils for the bass. I prefer air coils....they exist but they are "interestingly" priced. From earlier projects i have enough experiences with ZeroOhm coils which are acceptable but not preferred here. So i decided to do the bass somewhat different and use the PAP-C1 (Pass XO) to actively divide low and mid/high.

That PAP-C1 is an analog XO (fistfull of FETs) with some tweaking possibilities. The crossover can be set tot 120 Hz - 550 Hz which is spot on for my set up.

So from that PAP-C1 (with a ridicilous minute external feather weight power supply....rest assured....this will be different in near future !!!!!!) the bass amplifier is fed directly.

The other output of the PAP-C1 is split to seperate mid and high amplifiers to be followed by the passive XO-filters near the drivers/K-tubes. With a single capacitor + coil at each seperate crossover-board it made sense to invest in quality.

The coil is the quite new Mundorf VLCU10; the capacitor is Mundorf Supreme SilverOil (prefer this one above the SilverGoldOil).

And after some running in i can state that this is way better then the Behringer-Bryston combination. Bass is deep and the mids/highs are more crisp.

The combination of actively dividing low and mid/high certainly keeps the partnumber of the passive XO down as you only are building a 2-way XO whereas the bass-power is channelled away by that Pass PAP-C1 (which works very nice).

Next project is my own tweeteramp. Currently i'm running my set with an on loan 1,1 Watt E2C SPUD which works flawlesly and proves that 1 Watt should be more than sufficient.

Regards,

Reinout

Attachments

-

DSCN2565.JPG596.2 KB · Views: 155

DSCN2565.JPG596.2 KB · Views: 155 -

DSCN2567.JPG525.8 KB · Views: 149

DSCN2567.JPG525.8 KB · Views: 149 -

DSCN2545.JPG690.3 KB · Views: 141

DSCN2545.JPG690.3 KB · Views: 141 -

DSCN2540.JPG456 KB · Views: 144

DSCN2540.JPG456 KB · Views: 144 -

DSCN2564.JPG568.1 KB · Views: 136

DSCN2564.JPG568.1 KB · Views: 136 -

DSCN2302.JPG531.3 KB · Views: 143

DSCN2302.JPG531.3 KB · Views: 143 -

DSCN2558.JPG582.5 KB · Views: 139

DSCN2558.JPG582.5 KB · Views: 139 -

DSCN2301.JPG279.2 KB · Views: 237

DSCN2301.JPG279.2 KB · Views: 237 -

DSCN2151.JPG441.5 KB · Views: 242

DSCN2151.JPG441.5 KB · Views: 242 -

DSCN2150.JPG472 KB · Views: 232

DSCN2150.JPG472 KB · Views: 232

- Home

- Loudspeakers

- Multi-Way

- Fieldcoil + K-tube