Many thanks Joe, your reply crossed with mine, many thanks for your advice and info, i shall study it all.Hi, Mike56

Came across these computer fan bearings on ebay--ABEC-9 grade. This may help you and others looking for high precision bearings.

Computer Fan Ball Bearings For PC Cooling Case Fan Repair 3*8*4 mm | eBay

Get yourself a pair of 12" tungsten carbide rods. These are rigid, hard (92 Rockwell), precision ground, and have an approximate 600 grit finish. You can gain about 10% less friction. They are also cheap, These are the rods Niffy and I use. You can get a cheap set of diamond polishing compounds ( ebay ) and further polish the rods if you wish.

Carbide Rod – Centennial Carbide: Carbide Blanks, Rod and End Mills

Hope this helps you and others out. Jewel V, pin bearings are the best but Clearaudio makes some very nice linear tonearms using ball bearings, so it can be done. Good luck

Joe

I really don't know how straight and consistent my glass rods are, i shall check some, but polishing has helped a lot.

What style of arm are you using please? - if that's already on the thread maybe point me to it?

Many thanks

Mike

Mike56.

I have many projects to complete but nearly done on most. Glass rod are mostly extruded, so they look straight and feel smooth till close inspection reveals otherwise. Carbide is FAR superior. There are 2 YouTube, Steve Guttenberg videos ( fellow audio club member) that explain most of what I have done.

Joe's mind blowing DIY audio workshop - YouTube

Meet Joe, and his amazing DIY horn speakers - YouTube

Joe

I have many projects to complete but nearly done on most. Glass rod are mostly extruded, so they look straight and feel smooth till close inspection reveals otherwise. Carbide is FAR superior. There are 2 YouTube, Steve Guttenberg videos ( fellow audio club member) that explain most of what I have done.

Joe's mind blowing DIY audio workshop - YouTube

Meet Joe, and his amazing DIY horn speakers - YouTube

Joe

Thanks Joe, its amazing what you and others do! - congratulations!

My little efforts are very insignificant in comparison, however lots of fun.

They are also limited to hand tool execution.

I shall keep going to a small extent and enjoy this hobby alongside the virtual good company of you and the serious guys!

mike

My little efforts are very insignificant in comparison, however lots of fun.

They are also limited to hand tool execution.

I shall keep going to a small extent and enjoy this hobby alongside the virtual good company of you and the serious guys!

mike

Mike56,

You have to start somewhere, just like everyone else. You learn from your efforts with the help and suggestions from your friends here. What you see in the videos took me 45+ yrs. of trying different audio components, etc. so don't minimize your accomplishments. I still have much to learn. Depending on your desire, space, finances, small lathes and drill / mills can be had for not too much money. When I think I am so smart, I look at mechanical marvels like this, it's a very humbling experience !!!

Remarkable 240-Year-Old Doll Automaton Can Write Actual Programmable Text

Joe

You have to start somewhere, just like everyone else. You learn from your efforts with the help and suggestions from your friends here. What you see in the videos took me 45+ yrs. of trying different audio components, etc. so don't minimize your accomplishments. I still have much to learn. Depending on your desire, space, finances, small lathes and drill / mills can be had for not too much money. When I think I am so smart, I look at mechanical marvels like this, it's a very humbling experience !!!

Remarkable 240-Year-Old Doll Automaton Can Write Actual Programmable Text

Joe

Get yourself a pair of 12" tungsten carbide rods. These are rigid, hard (92 Rockwell), precision ground, and have an approximate 600 grit finish. You can gain about 10% less friction. They are also cheap, These are the rods Niffy and I use. You can get a cheap set of diamond polishing compounds ( ebay ) and further polish the rods if you wish.

Carbide Rod – Centennial Carbide: Carbide Blanks, Rod and End Mills

Joe

Hi Joe,

I tried them but they wouldn't ship to Australia, so I bought supposedly ground carbide rods off eBay and none of them were completely straight, the worst wouldn't roll on the surface plate. I also bought 4mm hardened linear shaft which were straight within 0.01mm over 250mm.

Thanks All,

Mainland suppliers here for ground carbide the price is (to me) quite high, 4mmx330 is £59.22, which doubles my material budget..............

At the moment i am satisfied with my hand polished glass, but i know they aren't really straight and could be bettered and are only inside the acceptable after polishing. I don't really like the vulnerability to derail either.

Its a strange emphasis but it appeals to me to focus on simplicity and inexpensive as well as good performance.

I might try next some balls on profile like Carlo's, but i am still puzzled if they are temperamental/vulnerable to get out of position over time?

Mike

Mainland suppliers here for ground carbide the price is (to me) quite high, 4mmx330 is £59.22, which doubles my material budget..............

At the moment i am satisfied with my hand polished glass, but i know they aren't really straight and could be bettered and are only inside the acceptable after polishing. I don't really like the vulnerability to derail either.

Its a strange emphasis but it appeals to me to focus on simplicity and inexpensive as well as good performance.

I might try next some balls on profile like Carlo's, but i am still puzzled if they are temperamental/vulnerable to get out of position over time?

Mike

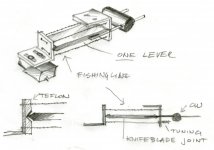

Or just a bit of mousetrap tech, Mike.

if it works (if...) separating upper ropes tension from that of under, could spare even the CW.

carlo

a sphere is not a wandering drunk, it goes just were it could; every time you put the carriage at the beginning of the disc you realign them exactly were they must

if it works (if...) separating upper ropes tension from that of under, could spare even the CW.

carlo

a sphere is not a wandering drunk, it goes just were it could; every time you put the carriage at the beginning of the disc you realign them exactly were they must

Attachments

Last edited:

Or just a bit of mousetrap tech, Mike.

if it works (if...) separating upper ropes tension from that of under, could spare even the CW.

carlo

a sphere is not a wandering drunk, it goes just were it could; every time you put the carriage at the beginning of the disc you realign them exactly were they must

I like this a lot Carlo, the counterweight gives constant VTF in warp but the tensioned line would not?

This and similar are nice and tight in the perpendicular plane as well.

Is 3.5mm BB your best from experience please?

thanks

Mike

I don't know Mike. is a solution considered for the first LC, but the loads were excessive.

With the CW, the VTF should not depend on the fishing lines, that just folds, without usually springs behave linearly, but who knows.

That sketch is not enough even for a mock up, to start you must prevent the cartridge from going down more than necessary.

carlo.

Is 3.5 mm BB your best from experience please?

what are you referring?

With the CW, the VTF should not depend on the fishing lines, that just folds, without usually springs behave linearly, but who knows.

That sketch is not enough even for a mock up, to start you must prevent the cartridge from going down more than necessary.

carlo.

Is 3.5 mm BB your best from experience please?

what are you referring?

Or just a bit of mousetrap tech...

You could (I'd rather say should) go with only one fishing-line for the upper / lower sides, because the blade makes the parallel alignment of the "headshell"—less fuss with adjustments, proper/even horizontal distribution of the tension …

doesn't a fishing line wear out? It's quite elastic after all... Did you consider silk or plant fibre like bamboo?

another 2c

d.)

Nylon, dacron, spectra, dyneema, etc.* in order of stiffness. But would be better an elastic or a totally rigid? totally rigid, tensioned by screws o springs? Continuos or separate? and how to deal with?

Tons of problems (and failures) laying around: that's fun. But before looking for titanium isotopes maybe better scavenging inside old toys for solutions, that's what i meant

carlo

* all lasting much more than me

Tons of problems (and failures) laying around: that's fun. But before looking for titanium isotopes maybe better scavenging inside old toys for solutions, that's what i meant

carlo

* all lasting much more than me

Nylon, dacron, spectra, dyneema, etc.* in order of stiffness. But would be better an elastic or a totally rigid? totally rigid, tensioned by screws o springs? Continuos or separate? and how to deal with?

May I?

Tensioned by springs, adjusted with screws: a spring doesn‘t wear out (or slower at least) so that the tension of whatever you use is neglectable...

Is 3.5 mm BB your best from experience please?

what are you referring?

For the motion of the carriage, whether prism or flat or as drawn in your recent corkscrew proposal, thanks, mike

I like the basic concept a lot, no rattling cans of nails, excellent lateral stiffness/lack of play but i see all the difficulties in assembling it with the correct geometry, equal lengths, tensions etc and its all in the effective weight if one adds complexity as well......Dental floss?

I perceive Carlo has the bit between his teeth at the moment and look forward to more!

I like the idea of the top and bottom lengths being preset accurately on a jig and exactly equal as they need to be and putting tension into both equally by adjustment of the lever length buy a simple and clever mechanism that someone else can think of!Or just a bit of mousetrap tech, Mike.

if it works (if...) separating upper ropes tension from that of under, could spare even the CW.

carlo

Tapers or something?

Last edited:

Wouldn't this just tilt the cartridge ?Or just a bit of mousetrap tech, Mike.

if it works (if...) separating upper ropes tension from that of under, could spare even the CW.

carlo

I perceive Carlo has the bit between his teeth at the moment and look forward to more! -- Mike

Unfortunately no, Mike. Imo there's no need of a parallelogram with a fixed rail, and therefore I'm looking for solutions starting from "corkscrew carriage": for now I'm just realizing the problems and making some calcs.

I posted this solution, that we all already know, but that can be lost in sight while chasing details only secondary for now. Why look for the best bearing in the world, if you can do without it?

However, I know two things: if the line is single and continuous (and rigid as the dyneema) you give the tension (with a screw?) and then set the two plates perfectly parallel. At that point lock the line into its holes with a drop of loctite - That's all; spectra or dyneema will no longer move.

If instead we want to remove the counterweight (how complicated are simple things) we must use something a bit elatic

(nylon monofilament or, better, the dacron - dental floss) in two sections, to be tightened separately.

Wouldn't this just tilt the cartridge? Karsten

Sure, but now we have to design two fine tuning, that allows us to have them perfectly parallel at the right VTF.

Hoping that 1-2 mm of warp won't change things too much (i can't bet on this)

carlo

new sketch

May work really fine Karsten, and it'much simpler too; but 2 levers again (without ball bearings, though 🙂)

Unfortunately no, Mike. Imo there's no need of a parallelogram with a fixed rail, and therefore I'm looking for solutions starting from "corkscrew carriage": for now I'm just realizing the problems and making some calcs.

I posted this solution, that we all already know, but that can be lost in sight while chasing details only secondary for now. Why look for the best bearing in the world, if you can do without it?

However, I know two things: if the line is single and continuous (and rigid as the dyneema) you give the tension (with a screw?) and then set the two plates perfectly parallel. At that point lock the line into its holes with a drop of loctite - That's all; spectra or dyneema will no longer move.

If instead we want to remove the counterweight (how complicated are simple things) we must use something a bit elatic

(nylon monofilament or, better, the dacron - dental floss) in two sections, to be tightened separately.

Wouldn't this just tilt the cartridge? Karsten

Sure, but now we have to design two fine tuning, that allows us to have them perfectly parallel at the right VTF.

Hoping that 1-2 mm of warp won't change things too much (i can't bet on this)

carlo

new sketch

May work really fine Karsten, and it'much simpler too; but 2 levers again (without ball bearings, though 🙂)

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm