super 10018, yes the stylus. I've been reading about the "sound of the arm tube", and bearing chatter, many times. And finally decided to hear it myself to make up my own opinion.

This is how I see the tangential pickup issue:

The stylus drag has a counter-force under static conditions. This counter-force shifts parallel to itself while the stylus travels across the disc. The attack point of this counter-force will also move, and there should be a guiding mechanism that determines the travel of the attack point. Since the attack point is fixed to the arm and moves along with same, it is in contact with various points of the guiding mechanism, i.e. slides or rolls on it. This involves friction, however small it might be.

The stylus drag has a counter-force under static conditions. This counter-force shifts parallel to itself while the stylus travels across the disc. The attack point of this counter-force will also move, and there should be a guiding mechanism that determines the travel of the attack point. Since the attack point is fixed to the arm and moves along with same, it is in contact with various points of the guiding mechanism, i.e. slides or rolls on it. This involves friction, however small it might be.

*eppur si muove...

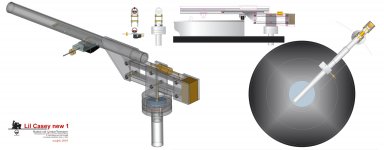

Radial tonearm starting to work - first rough proto, made on the principle - if even this works, after i can't do worse -

The carriage (same as used on Jr Casey #2368) now moves effortlessly at 1,5 VTF, with the rail at zero degrees (no use of tricky slant); having no torque on the carriage helps a lot, as expected.

The way to a good arm is still very long: the weight of rail + cart must be reduced to minimum (< 40 gr with cartridge), and the linear bearing should counteract as possible the vertical tilt . (even if this one was conceived to slide&rotate it still works, but eliminating the small CW would be better); reducing as possible the length of the two arms would benefit too, getting a lower effective mass.

Everything must be built extremely light, but absolutely rigid. I'm evaluating a rail made with a carbon fibre tube but don't know if inner finish would be adequate.

ciao - carlo

* and yet it moves...

Radial tonearm starting to work - first rough proto, made on the principle - if even this works, after i can't do worse -

The carriage (same as used on Jr Casey #2368) now moves effortlessly at 1,5 VTF, with the rail at zero degrees (no use of tricky slant); having no torque on the carriage helps a lot, as expected.

The way to a good arm is still very long: the weight of rail + cart must be reduced to minimum (< 40 gr with cartridge), and the linear bearing should counteract as possible the vertical tilt . (even if this one was conceived to slide&rotate it still works, but eliminating the small CW would be better); reducing as possible the length of the two arms would benefit too, getting a lower effective mass.

Everything must be built extremely light, but absolutely rigid. I'm evaluating a rail made with a carbon fibre tube but don't know if inner finish would be adequate.

ciao - carlo

* and yet it moves...

Attachments

Radial rail tonearm

(....) and saw the positive side of the video of that very flawed tonearm and you did not dismissed it right away. It can spawn some good ideas. (....) I think it opens up new thinking. -- #2359 Dd

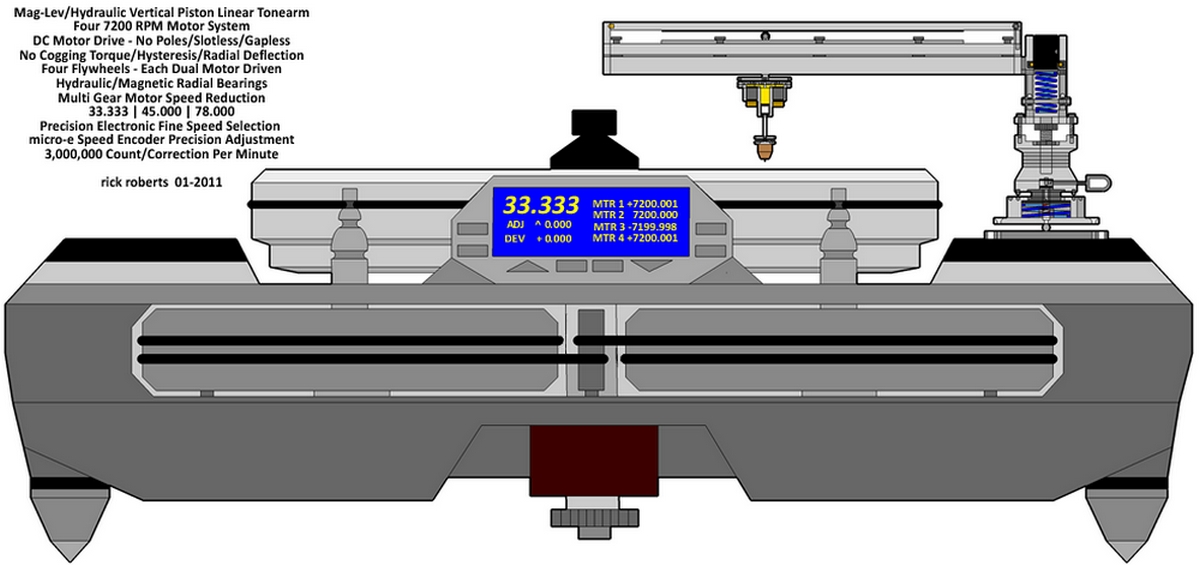

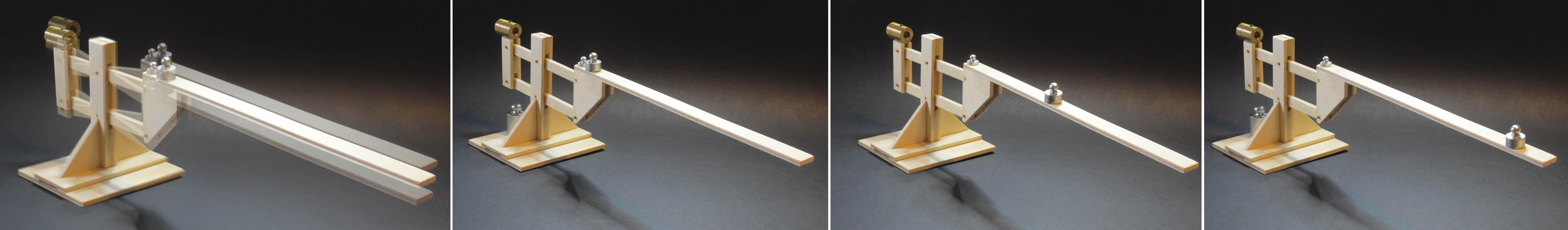

Maybe a new significant step: there is no need to place the vertical pivot as in #2355 and in my first test # 2383. The mechanism for the vertical movement can be aligned radially, but now it must shift using a parallelogram, not tilt on a pivot (sketch). This drastically reduces the vertical mass, and makes the arm more compact, positionable on plinth at a standard distance.

Having still some doubts that the sliding of the carriage would change the VTF, I made a quick check (photos). But there is no change: as in a scale the balance depends only from the distance of the pins from the fulcrum, not where you put the weights on the plates.

carlo

This tonearm is linear, but very different from normal linear trackers - Off topic? warn me, please

(....) and saw the positive side of the video of that very flawed tonearm and you did not dismissed it right away. It can spawn some good ideas. (....) I think it opens up new thinking. -- #2359 Dd

Maybe a new significant step: there is no need to place the vertical pivot as in #2355 and in my first test # 2383. The mechanism for the vertical movement can be aligned radially, but now it must shift using a parallelogram, not tilt on a pivot (sketch). This drastically reduces the vertical mass, and makes the arm more compact, positionable on plinth at a standard distance.

Having still some doubts that the sliding of the carriage would change the VTF, I made a quick check (photos). But there is no change: as in a scale the balance depends only from the distance of the pins from the fulcrum, not where you put the weights on the plates.

carlo

This tonearm is linear, but very different from normal linear trackers - Off topic? warn me, please

Attachments

Carlo, the last one seems to be a very promising design. The problem will be, how to put a record between the arm and platter, and do it conveniently.

Hi Carlo, referring to my post #2382, how do you reduce friction at your frontal linear tracker? Very ingenious idea, BTW

Sorry, Icsaszar; I thought you were referring to the floating linears others were talking about.

The problem of the rotating cart was mentioned in my posts, if you're referring to this. From measurements made in the other thread, the stylus drag was worth 3,5 mN or less, but sufficient to rotate - at start - a carriage conceived to slide and rotate like the one used - on purpose - in the test; however 2 gr of counterweight were enough to eliminate the problem.

The project will use a T carriage that runs on 4 balls inside the tube, and should be self-centering, but will certainly need many tests; the same for the parallelogram that has 6 (or 12) bearings (balls? jewells?)

Linear tonearms are really difficult to build: having eliminated the torque on carriage due to the length of the arm of the normal ones, and reduced vertical masses to reasonable limits is not bad, for now. First test is encouraging too.

Walter: there will be a base that rotates horizontally, bringing the rail outside the platter (as in # 2360); A solution similar to many linear trackers with a very short arm.

Damn warps: the parallelogram will be able to deal with? It needs just 50 gr of CW instead of >200 of the previous solution, so... For bad eccentrics the radial rail is a marvel: no stylus bending at all seen in the test.

carlo

The problem of the rotating cart was mentioned in my posts, if you're referring to this. From measurements made in the other thread, the stylus drag was worth 3,5 mN or less, but sufficient to rotate - at start - a carriage conceived to slide and rotate like the one used - on purpose - in the test; however 2 gr of counterweight were enough to eliminate the problem.

The project will use a T carriage that runs on 4 balls inside the tube, and should be self-centering, but will certainly need many tests; the same for the parallelogram that has 6 (or 12) bearings (balls? jewells?)

Linear tonearms are really difficult to build: having eliminated the torque on carriage due to the length of the arm of the normal ones, and reduced vertical masses to reasonable limits is not bad, for now. First test is encouraging too.

Walter: there will be a base that rotates horizontally, bringing the rail outside the platter (as in # 2360); A solution similar to many linear trackers with a very short arm.

Damn warps: the parallelogram will be able to deal with? It needs just 50 gr of CW instead of >200 of the previous solution, so... For bad eccentrics the radial rail is a marvel: no stylus bending at all seen in the test.

carlo

Carlo, you're on the right track. I've been thinking the same scheme for the last two weeks. But parallelogram will change horizontal distance. You have to make a vertical mechanism and use a lever to adjust VTF. There are many options and that's where the creativity comes in. You can also thunk about using strings and pulleys too. Lot of fun ideas to think about. We're on the same wavelength!

(....) and saw the positive side of the video of that very flawed tonearm and you did not dismissed it right away. It can spawn some good ideas. (....) I think it opens up new thinking. -- #2359 Dd

Maybe a new significant step: there is no need to place the vertical pivot as in #2355 and in my first test # 2383. The mechanism for the vertical movement can be aligned radially, but now it must shift using a parallelogram, not tilt on a pivot (sketch). This drastically reduces the vertical mass, and makes the arm more compact, positionable on plinth at a standard distance.

Having still some doubts that the sliding of the carriage would change the VTF, I made a quick check (photos). But there is no change: as in a scale the balance depends only from the distance of the pins from the fulcrum, not where you put the weights on the plates.

carlo

This tonearm is linear, but very different from normal linear trackers - Off topic? warn me, please

Forget the pivot. I don't see the reason to use a pivot. In fact, I can't see any advantages of PL arms.

Forget the pivot. I don't see the reason to use a pivot. In fact, I can't see any advantages of PL arms.

What a buzzkill...

Hi,

@#2384

Carlo, how does the arm design cope with the varying tracking force and dynamic mass?

I´d think that in this design a moving counterweight or some means of varying force is required to level out the different positions of the pickup.

As I understand Your sketches the tracking weight and the dynamic mass increase the closer the pickup comes to the end point of its travel across the disc.

jauu

Calvin

@#2384

Carlo, how does the arm design cope with the varying tracking force and dynamic mass?

I´d think that in this design a moving counterweight or some means of varying force is required to level out the different positions of the pickup.

As I understand Your sketches the tracking weight and the dynamic mass increase the closer the pickup comes to the end point of its travel across the disc.

jauu

Calvin

What a buzzkill...

I am just telling the truth. The pivot may act as a retrieval mechanism if the rail can be turned to right. Otherwise, I don't think it is necessary to have it.

Dd - a 4 -5 mm warp makes any LP unhearable - with such deviation the variation of hor. distance is <0.2 mm, and is compensated by the displacement of the cart (much easier than in traditional LT) just like a small eccentricity.

Using a linear mechanism involves higher weights and frictions (at least for my experience). But there is a lot of work to do. Thanks for appreciation

Rayma - Thanks, I didn't know it: very interesting, and reassuring - as I have already said sometimes, tonearm design (like potato peelers design) seems a continuous reinventing the wheel

Super10018 - Wich pivot? as in many commercial linear trackers there will be a snap lock (see exploded view # 2630, ) to prevent any involuntary rotation. For convenience the rotation is counterclockwise

Calvin - Exactly as in any linear, but not dissipating them in torque friction of the carriage.

Look carefully the photos, that show no VTF variation, as explained. When the carriage goes to the end of rail only the lower bearings of parallelogram sees more push, and upper more pull. I don't care at all.

carlo

Using a linear mechanism involves higher weights and frictions (at least for my experience). But there is a lot of work to do. Thanks for appreciation

Rayma - Thanks, I didn't know it: very interesting, and reassuring - as I have already said sometimes, tonearm design (like potato peelers design) seems a continuous reinventing the wheel

Super10018 - Wich pivot? as in many commercial linear trackers there will be a snap lock (see exploded view # 2630, ) to prevent any involuntary rotation. For convenience the rotation is counterclockwise

Calvin - Exactly as in any linear, but not dissipating them in torque friction of the carriage.

Look carefully the photos, that show no VTF variation, as explained. When the carriage goes to the end of rail only the lower bearings of parallelogram sees more push, and upper more pull. I don't care at all.

carlo

Last edited:

I am just telling the truth. The pivot may act as a retrieval mechanism if the rail can be turned to right. Otherwise, I don't think it is necessary to have it.

As to PLT I would disagree. There is a fundamental advantage in having a momentum of force with pivot arm. Momentum is huge, as up to several hundred times. So, with exactly same bearings, pivot arm may have many times less bearing friction resistance, applied to the stylus. So, Shroeder like PLT isn't nonesense, especially, if it has no skating force issues.

Another question is, if having a momentum is essential with the ultimate quality bearings...

Dd - a 4 -5 mm warp makes any LP unhearable - with such deviation the variation of hor. distance is <0.2 mm, and is compensated by the displacement of the cart (much easier than in traditional LT) just like a small eccentricity.

Using a linear mechanism involves higher weights and frictions (at least for my experience). But there is a lot of work to do. Thanks for appreciation

Carlo, you're probably right about the distance variation that is probably even smaller than regular warp. On a perfectly flat record, it would not matter. Parallelogram is probably the simplest for vertical pivot. A pure vertical pistonic motion would eliminate the need for tedious VTA adjustment, something I wonder about in another post. My own idea is to place the vertical pull at the center of the carriage via a string and a pulley and then a lever or seesaw with counterweight. Think of the 47 Labs Koma turnable. Don't have picture but see if you can graph one. And for sliding carriage, I would prefer using eight rollers to make four wheels on two horizontal rods as the carriage assembly, which resembles the original design of this thread. And I think it can reduce mass significantly.

The only example I've seen is the obviously flawed Simply Physics concept turntable. Hey, at least they were thinking outside of the box!

Anyway, I'm just excited that there's pursue in alternative vertical linear or pistonic bearing. All fun!

Roberval balance

What you have is a form of Roberval balance. Here's a video that demonstrates the phenomenon. I think this can aid designing a linear arm for pure vertical movement.

Having still some doubts that the sliding of the carriage would change the VTF, I made a quick check (photos). But there is no change: as in a scale the balance depends only from the distance of the pins from the fulcrum, not where you put the weights on the plates.

What you have is a form of Roberval balance. Here's a video that demonstrates the phenomenon. I think this can aid designing a linear arm for pure vertical movement.

sometimes, tonearm design (like potato peelers design) seems a continuous reinventing the wheel

It appears that this was not one of Marantz's better efforts, but it would have been nice if it had been.

Very minimal design, 1963 production.

Attachments

Last edited:

It appears that this was not one of Marantz's better efforts, but it would have been nice if it had been.

Very minimal design, 1963 production.

Very Rube Goldberg design.

Very Rube Goldberg design.

A magnet near the lower counterweight provides end of record arm lift.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm