For a linear tacking tonearm with long arm tube, the difference in vertical and horizontal masses are inevitable. In fact, I am not sure how much the difference in masses will degrade the sound. It doesn't matter probably that much as most people think. On my air bearing arms, I have approved that the masses in vertical panel and horizontal panel are almost same for a short arm linear tacking. I believe it is true for passive linear tracking tonearms such as Niffy's design, too.

Last edited:

There are so called vestigal pivot arms, like Dynavector, with big difference between vertical and horizontal eff. masses. They seem to have their advantages.

As to linear bearings, there is a clever patented design with a float.

https://www.youtube.com/watch?v=-6jfcvt3WaA

There on video you can see a Russian patent number, and explore patent drawings through patent data.

On that video the arm works flawlessly, and is completely immune to turntable base vibrations and acoustical feedback. Friction is about zero. Servo arm positioning doesn't work while playing record- arm is completely passive pure mechanical design.

As to linear bearings, there is a clever patented design with a float.

https://www.youtube.com/watch?v=-6jfcvt3WaA

There on video you can see a Russian patent number, and explore patent drawings through patent data.

On that video the arm works flawlessly, and is completely immune to turntable base vibrations and acoustical feedback. Friction is about zero. Servo arm positioning doesn't work while playing record- arm is completely passive pure mechanical design.

Last edited:

Walter, could you write briefly, how does the arm float? Is there magnetic floating? IMHO the source of friction is always the guiding mechanism, be it roll bearings or any kind of rail. How is it avoided in this patent? (Sorry I can't read Russian, better said I can read but don't understand  )

)

)

)Actually, the rollers are still present, however, they are loaded just by the stylus drag, and you may expect negligible friction. On video we can see no any sign of the cantilever deflection with eccentric record played.

"I think the arm can be more compact without the dual vertical arm design just for aesthetic reason." Dd

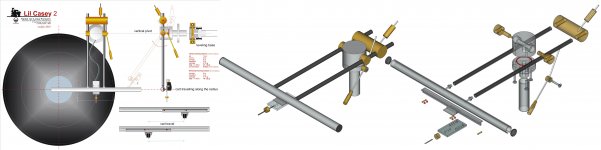

Another sketch, trying to follow your advice, with a more conventional look. Seems feasible, but the shafts become a bit longer

Some mods to headshell (question: better to align the tip or the joint of the cantilever?)

Some guesses on the weight of moving masses based on profiles at hand. Horizontal masses behave as in linears, while vertical like in traditional pivoted.

Thanks to all for your posts, hope this new sketch will be clearer to understand how it works (or it will not): a radial rail seems new to me, but who knows? seems so simple...

carlo

Another sketch, trying to follow your advice, with a more conventional look. Seems feasible, but the shafts become a bit longer

Some mods to headshell (question: better to align the tip or the joint of the cantilever?)

Some guesses on the weight of moving masses based on profiles at hand. Horizontal masses behave as in linears, while vertical like in traditional pivoted.

Thanks to all for your posts, hope this new sketch will be clearer to understand how it works (or it will not): a radial rail seems new to me, but who knows? seems so simple...

carlo

Attachments

Thanks. The purpose of parts 9 and 10 is still a secret for me (guide and sliding rail?). And since there are rolling parts, there is friction.Here it is in English

See PDF attachment

The nature of liquid kept secret.

There will be friction for the Russian arm. Air bearing is probably the only medium which has almost zero friction so far. Frankly speaking, I don't like it at all. I believe Niffy's design is much better than that.

The only thing, I think, can be better for Niffy's design is to improve the rail. However, for a diyer, it may be the best he can do.

The only thing, I think, can be better for Niffy's design is to improve the rail. However, for a diyer, it may be the best he can do.

Last edited:

Lcsaszar, yes, but they are working only while arm doesn't play a record. While playing, they have no contact with each other.

Super10018, as to friction, designer did measurements, and it is really negligible, pretty same as with air bearing.

As for me, I've never seen such an immune to vibration arm.

Anyway, it is an unusual design, and it is different from everything else. And, by the way, it seems to be working very well. Definitely no nonsense.

Super10018, as to friction, designer did measurements, and it is really negligible, pretty same as with air bearing.

As for me, I've never seen such an immune to vibration arm.

Anyway, it is an unusual design, and it is different from everything else. And, by the way, it seems to be working very well. Definitely no nonsense.

In my opinion, the major issue for designing linear arm and pivot arm alike is to deal with unwanted vibrations from groove, not external vibrations which are transmitted through the base of tonearm.

Yes, but if the arm is prone to excitement and resonances, it will get them both ways. And contrary...

Hello all,

~Thirty years ago, a man by the name of Watanabe patented a floating tone arm very much like the Russian one. It was quite sophisticated in that it used magnetic repulsion to keep the float from contacting the tub. At the bottom of the tub were three troughs filled with mercury and the bottom of the float had three electrodes in contact with the mercury for signal transmission. The liquid was a dielectric oil, to prevent shortening the mercury. I have the patent somewhere and when I find it, I'll post it. His name sounds Japanese, but he may be British because his English sounded that way when I corresponded with him.

Sincerely,

Ralf

~Thirty years ago, a man by the name of Watanabe patented a floating tone arm very much like the Russian one. It was quite sophisticated in that it used magnetic repulsion to keep the float from contacting the tub. At the bottom of the tub were three troughs filled with mercury and the bottom of the float had three electrodes in contact with the mercury for signal transmission. The liquid was a dielectric oil, to prevent shortening the mercury. I have the patent somewhere and when I find it, I'll post it. His name sounds Japanese, but he may be British because his English sounded that way when I corresponded with him.

Sincerely,

Ralf

a man by the name of Watanabe

Hello again,

I am going to sneak in here under the cover of darkness (it's 12:33 AM in Arizona) to correct a grave mistake I made. The inventor's name is Alexander R. Rangabe. He patented the floating tone arm (3,235,267A) in 1966 and his patent also proposed guide rollers like the Russian Patent.

I don't know how I came up with Watanabe, but he also was active as an inventor of tone arms and phono cartridges.

Mr. Rangabe, if you read this, my sincerest apologies.

Ralf

Last edited:

Chatter and rumble

Hi all. As to hearing and possibly measuring unwanted resonances, bearing and shell chatter and so on, I have used the simplest solution possible. It may be applied to tangent arms as well. Cartridge used was Ortofon VMS20, the stylus placed on the top of the arm.

Hi all. As to hearing and possibly measuring unwanted resonances, bearing and shell chatter and so on, I have used the simplest solution possible. It may be applied to tangent arms as well. Cartridge used was Ortofon VMS20, the stylus placed on the top of the arm.

Attachments

bathing tonearms

Here a well-known series of articles on a floating linear TA, online from several years: interesting considerations on motion geometry.

Here in Italy someone used the buoyancy of a front float instead of the rear counterweight in a pivoted tonearm. Funny

https://xyplo.blogspot.com/2016/10/b-diy-linear-tonearm.html

carlo

great Walter, better than my stethoscope

Here a well-known series of articles on a floating linear TA, online from several years: interesting considerations on motion geometry.

Here in Italy someone used the buoyancy of a front float instead of the rear counterweight in a pivoted tonearm. Funny

https://xyplo.blogspot.com/2016/10/b-diy-linear-tonearm.html

carlo

great Walter, better than my stethoscope

nocdplz, actually, my first attempt was with a tiny microphone, and it failed. MM cart appeared to be much more sensitive, and you can clearly hear everything in any location of the arm or turntable. As to floating arm, my first thought was to apply a magnet guide instead of rollers. However, with a liquid it is inevitably unstable...Russian patent rules IMO.

Walter, today one would rip the resonances from your second cartridge and subtract it digitally from the music of the first one, finally getting the pure sound of a CD...

no CD plz

no CD plz

nocdplz, actually, my first attempt was with a tiny microphone, and it failed. MM cart appeared to be much more sensitive, and you can clearly hear everything in any location of the arm or turntable. As to floating arm, my first thought was to apply a magnet guide instead of rollers. However, with a liquid it is inevitably unstable...Russian patent rules IMO.

That is very clever method. So, the stylus directly contacts the arm? I would like to try it later on.

About floating arm, I thought to make one which floated on a thin film of air. It doesn't need high pressure air at all since the load is very low. However, I gave up the idea because I think there is better solution already, why make things complicated. It is basically a moving pivot arm.

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm