The explanation is that our brain perceive things differently depending on the phase of the harmonic distortion. Excerpt from Nelson Pass in the H2 Harmonic Generator article :

“So why is the phase important? Well, it's a subtle thing. I don't suppose everyone can hear it, and fewer particularly care, but from listening tests we learn that there is a tendency to interpret negative phase 2nd as giving a deeper soundstage and improved localization than otherwise. Positive phase seems to put the instruments and vocals closer and a little more in-your-face with enhanced detail.”

Interesting.. I guess trust your own ears!

As I go through your guide again (thanks, by the way!) I followed your lead and bought a pair of XLR-to-RCA adapters (female RCAs for me, where the ones in your cart appear to be male RCAs). But I anticipate some folks putting both RCAs and XLRs on their case backs as I've seen on some others. Since RCAs need the jumper, are folks who are doing both using a switch to accommodate either config?

The adapter seems like the option less likely to pick up noise from anywhere. Less wire = less antenna. 🙂

The adapter seems like the option less likely to pick up noise from anywhere. Less wire = less antenna. 🙂

I have both on the back, but I don't use a switch. I use a shorting plug. If your adapter cable already shorts pins 1 and 3 (most do), you don't need to worry about it.

I have both on the back, but I don't use a switch. I use a shorting plug. If your adapter cable already shorts pins 1 and 3 (most do), you don't need to worry about it.

Right on. One less thing.🙂

Cornell Dubilier 15000mF capacitors

Hi,

finished B1K nutube pre and preparing myself to this project.

I already have eight Cornell Dubilier 15000mF capacitors 50V 20% tollerance snap-in, manufacturer number 380LX153M050A042.

Are they Ok for the Aleph J PSU?

northernsky

Hi,

finished B1K nutube pre and preparing myself to this project.

I already have eight Cornell Dubilier 15000mF capacitors 50V 20% tollerance snap-in, manufacturer number 380LX153M050A042.

Are they Ok for the Aleph J PSU?

northernsky

If you order a new one, get the AS- series, as they have the shield.

AS-3218, AS-3220, AS-4218, AS-4220 are all currently in stock.

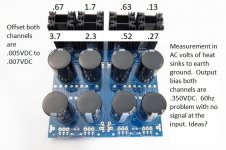

New transformer with purple ground wire installed. No 120hz coming through speakers but now a 60hz tone is coming through with no signals at the inputs. Biased at about .350VDC. Offset is to the third decimal to the right of about .005VDC.

If I touch the signal + connection where the wire attaches to the inside of the RCA connection it definitely gives a very loud, "Yes I can amplify".

Trying to measure ACV somewhere to explain the 60hz tone coming through. The heat sinks are anodized?? and is why hard to get a good ACV reading to earth ground but the attachment show what I got. Some of the readings are up and down and not steady. Maybe these reading mean nothing. Have twisted wires where I could.

Any help appreciated. Thanks

Attachments

Hi,

finished B1K nutube pre and preparing myself to this project.

I already have eight Cornell Dubilier 15000mF capacitors 50V 20% tollerance snap-in, manufacturer number 380LX153M050A042.

Are they Ok for the Aleph J PSU?

northernsky

...hmmmm

The caps you chose are rated at 85degC.

I have been checking the capacitor's temperature in my Aleph J with plenty of air circulation around it - my caps (with the lid on) run as hot as the heatsinks (especially the group of 4 caps located closer to the rectifying diodes' little heatsinks).

Maybe choosing the caps rated for 105degC is a better option...??

... or, just replace the whole power supply PCB and caps... every few years; this could be a great excuse to tinker with your amp... every now and then... 🙂

Is that an MCap Supreme in your C1 position? And Audio Note bipolars? Apart from power supply caps I think you may be waiting a bit given that one. I put a CDE 940C in mine. Also had CLC supply. I would say at least 100+ hours.

...hmmmm

The caps you chose are rated at 85degC.

I have been checking the capacitor's temperature in my Aleph J with plenty of air circulation around it - my caps (with the lid on) run as hot as the heatsinks (especially the group of 4 caps located closer to the rectifying diodes' little heatsinks).

Maybe choosing the caps rated for 105degC is a better option...??

... or, just replace the whole power supply PCB and caps... every few years; this could be a great excuse to tinker with your amp... every now and then... 🙂

Thank you for the suggestion. I checked Mouser and the caps suggested in the BOM (Nichicon rated at 105degC) are not available.

I'll try the one I have we'll see...

northernsky

Yes they do. And the 380LX caps appear to be used in the FW F8.

https://6moons.com/wp-content/uploads/audioreviews/firstwatt8/07.jpg

https://6moons.com/wp-content/uploads/audioreviews/firstwatt8/07.jpg

Cornell Dubilier has a really good capacitor life calculator here: Cornell Dubilier Plug-In Thermal / Life Calculator

The 3 biggest factors appear to be actual working voltage vs rated, ripple current, and temperature. Even inexpensive caps specified with short life spans can achieve very long lifetimes if derated.

The 3 biggest factors appear to be actual working voltage vs rated, ripple current, and temperature. Even inexpensive caps specified with short life spans can achieve very long lifetimes if derated.

The easiest way to de-rate electrolytic capacitors is to use ones with a higher voltage rating. Either 85 °C or 105 °C rated caps work fine for our usual applications. I prefer 50V rated caps for longer life on the ususal 24V power rails, and will go with 63V or higher rating for higher voltage PSUs.

Q re soldering zenor diode to Aleph board

The noob guide says to solder them flush to the pcb, but does not say why. Aren’t pieces generally soldered above the board to provide air circulation around the piece? 6L6 does not mention how the zenor diodes should be soldered in his guide. I am in the middle of propagating the board now and do not want to put them in incorrectly. Could someone give me advice on this?

Thank you

The noob guide says to solder them flush to the pcb, but does not say why. Aren’t pieces generally soldered above the board to provide air circulation around the piece? 6L6 does not mention how the zenor diodes should be soldered in his guide. I am in the middle of propagating the board now and do not want to put them in incorrectly. Could someone give me advice on this?

Thank you

There are two primary reasons I've seen for leaving a bit of space under the parts / having longer leads.

Heat - The 3W resistors or other parts that get hot (and aren't on heatsinks) can sit above the PCB to allow a little air-flow. Helps keep the boards nice. Not sure if the part will last longer or operate any better.

It's nice to leave a bit of space for parts used as measurement points. You may want to attach alligator clips or other types of leads to the legs vs. hitting the pad with a probe.

It keeps your hands free and reduces the potential for slipping with a probe and shorting something etc.

On to your actual question - The zeners won't get warm enough to matter, and you likely won't need to attach leads to them for any period of time. So, they are fine to solder against the board. However, soldering them with a bit of space under them won't hurt anything at all. FWIW, I soldered mine flush to the board, and based on the pics I've seen, many others do also.

Heat - The 3W resistors or other parts that get hot (and aren't on heatsinks) can sit above the PCB to allow a little air-flow. Helps keep the boards nice. Not sure if the part will last longer or operate any better.

It's nice to leave a bit of space for parts used as measurement points. You may want to attach alligator clips or other types of leads to the legs vs. hitting the pad with a probe.

It keeps your hands free and reduces the potential for slipping with a probe and shorting something etc.

On to your actual question - The zeners won't get warm enough to matter, and you likely won't need to attach leads to them for any period of time. So, they are fine to solder against the board. However, soldering them with a bit of space under them won't hurt anything at all. FWIW, I soldered mine flush to the board, and based on the pics I've seen, many others do also.

jazzzman, have you heard the saying, "this isn't rocket science"?

Don't believe it. Check the advice from NASA:

NASA Workmanship Standards - Through-Hole Soldering General Requirements

Go to the 2nd info panel, where the following guidance is given:

One simple approach is to squeeze a match stick or tooth pick underneath the component to help you get a consistent stand off height. Probably better / alternate methods.

Also, personally, I use masking tape to keep components in place. You might find that helps too.

Others may offer their thoughts.

Don't believe it. Check the advice from NASA:

NASA Workmanship Standards - Through-Hole Soldering General Requirements

Go to the 2nd info panel, where the following guidance is given:

PREFERRED HEAT PRODUCING PARTS

Parts which dissipate heat in quantities of 1 Watt or greater, or in quantities sufficient to damage the laminate shall be mounted with sufficient standoff [ > 1.5mm (0.060 in.) ]

You can find other guidance out there but I'd expect that you'll find a common theme with the advice above.

One simple approach is to squeeze a match stick or tooth pick underneath the component to help you get a consistent stand off height. Probably better / alternate methods.

Also, personally, I use masking tape to keep components in place. You might find that helps too.

Others may offer their thoughts.

Last edited:

- Home

- Amplifiers

- Pass Labs

- Aleph J build guide for noobs