Christian, they were the "clack to clack" max mechanical strokes under DC battery hookupHello Eucy,

Is it the maximum mechanical stroke on each direction or is it under the same amount of current?

Christian

Eucy

That is you favorite mystery person playing some lovely sounds on his dml panels🤣

Steve.

Steve.

Scrapper4 have you considered investing some time to find a commercial panel which you like? Buy a pair and reverse engineer them and when you are happy with the results of your handy work sell the commercial panels on the used market place. If you get a good deal and you don't take a long time you should not take a big hit when you sell the commercial panels off.

That's what he did initially

https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-5960411

https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-5960411

We'll never know what it is... That's the thing..😵💫sounds like you ought to be happy with this what ever it is?

That's too bad. I think that for every person here who is invested in building a pair of dml there is going to be a different design to meet their idea of what they are looking for. That makes this thread so much more interesting.

If you are referring to my canembert cheese box panel ?Steve you need to make a recording of the Coaster's playing on your coasters.

This wooden panel is 11cm and the thickness is somewhere between .5mm and 1mm ?

Les than 1mm , that is as accurate as my device and eyes can go 😳

If someone has an old two way speaker with a blown tweeter, this could be a good way to have a dml speaker for free, with electronic EQ ,of course.

The XO was about 500hz if I remember correctly.

This was just a bit of fun, but it does work.

Steve.

Attachments

Steve I was just getting lunch ready and stood and stared at a butcher pack of hamburger. The tray is one of those large pre moulded white styrene trays about 27.5cm long by 22.5cmm wide and 3.5cm deep at a guess the tray material is approx 3mm thick, this would hold about 1- 1.5kg of ground beef. the bottom of the tray that is flat is about 20cm x 15cm so big enough to make a flat panel say 5.5" x 7.5" close to your 6" x 9" card stock panels. Did you ever try this as a panel material? The whole tray only weighs14 grams all up. Any thoughts? This has a smooth skin, do you figure that would need to be sanded off?

Thank you for the input Scrapper I am away from home and not able to build where I am now won't get home till the fall this year. This seems more robust than double layer cereal box card stock and Steve has built plenty of fine sounding panels with that so I think when I get home it ought to be on my try and see list of materials.

You said that he styrene panels are too soft. but I am thinking that the skins can be sanded off and replaced with a layer of pva adhesive which can additionally be made harder and stiffer by adding gypsum powder (Plaster of Paris). This can be varied from a 50/50 wash to a full strength coating if desired. You mentioned 1 lb density EPS as better but you did not mention thicjess. So what would you choose as a first choice material? Than you again I appreciate the feedback.

You said that he styrene panels are too soft. but I am thinking that the skins can be sanded off and replaced with a layer of pva adhesive which can additionally be made harder and stiffer by adding gypsum powder (Plaster of Paris). This can be varied from a 50/50 wash to a full strength coating if desired. You mentioned 1 lb density EPS as better but you did not mention thicjess. So what would you choose as a first choice material? Than you again I appreciate the feedback.

This was a xps 3mm pizza base panel i made way back on NXT Rubbish forum.

You cannot get xps pizza bases anymore in the UK, card only.

the pizza panel (as I called it) was so light that I just mounted it onto the coil only.

The panel is yellow because I coated it in shellac, I think.

Could I improve this panel , with what I know now ?

Maybe.

adding plaster to a pva mix will increase the weight of the panel considerably.

It also prevents the pva soaking into the sanded xps, causing a thick coating.

I still have some pizza bases under the stairs, I know this because I broke one trying to find something today 😅

I put on a few pounds getting those pizza bases.🙄

You cannot get xps pizza bases anymore in the UK, card only.

the pizza panel (as I called it) was so light that I just mounted it onto the coil only.

The panel is yellow because I coated it in shellac, I think.

Could I improve this panel , with what I know now ?

Maybe.

adding plaster to a pva mix will increase the weight of the panel considerably.

It also prevents the pva soaking into the sanded xps, causing a thick coating.

I still have some pizza bases under the stairs, I know this because I broke one trying to find something today 😅

I put on a few pounds getting those pizza bases.🙄

Steve no matter what you use to stiffen a panel you will add weight so it all comes down to does the added weight pay off as a benefit to sound reproduction of the panel. I was thinking about adding 20 - 25% plaster of Paris by volume. No reason you could not apply this as a 50/50 wash coat, you could also build up coats to see what worked best. A base wash coat of 50/50 without any plaster could be used first as a base sealer coat then apply thin light coats with plaster layered up on top of that. The same process could be used on card stock as well. While the plaster adds weight it hardens the glue and it becomes stiffer so you could have a stiffer coating with less overall mass than just using pva alone with no plaster trying to achieve the same stiffness.

You did say the pva was not to damp but rather to stiffen so a lighter but stiffer application of modified pva would seem to fit the bill or am I missing something?

You did say the pva was not to damp but rather to stiffen so a lighter but stiffer application of modified pva would seem to fit the bill or am I missing something?

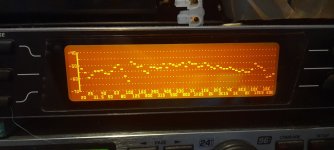

The first picture with the peak at 10k , is an untreated low grade EPS panel at 20cm in front of the exciter area.

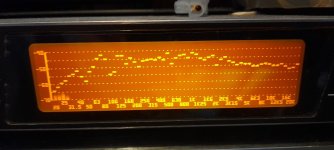

The second picture is with the peak removed and the panel coated in a 50x50 mix of pva.

The hf above 10k comes mainly from 2 or 3 inches area ,in front of the exciter area .

Where is the hf problem on this low grade EPS panel ?

I have made low grade panels for many years now, way back on the NXT Rubbish forum.

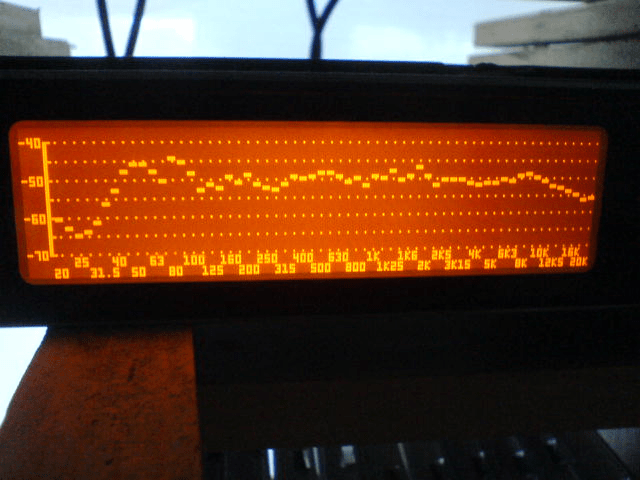

This picture is of a 70grade 1inch eps panel from the nxt rubbish forum, 12inches from the panel.

I prefer the sound of the lighter lower density eps panels.

But it is all down to personal tastes.

Steve.

I inserted this picture last in the last minute, so have probably mucked up the order,sorry 🤗

The second picture is with the peak removed and the panel coated in a 50x50 mix of pva.

The hf above 10k comes mainly from 2 or 3 inches area ,in front of the exciter area .

Where is the hf problem on this low grade EPS panel ?

I have made low grade panels for many years now, way back on the NXT Rubbish forum.

This picture is of a 70grade 1inch eps panel from the nxt rubbish forum, 12inches from the panel.

I prefer the sound of the lighter lower density eps panels.

But it is all down to personal tastes.

Steve.

I inserted this picture last in the last minute, so have probably mucked up the order,sorry 🤗

Attachments

what is the average size panel you are building with this material? I am curious when panels get small in size say 6x9 inches are there issues with spider sag at all? It would always be useful to know panel thickness along with density panel size and weight.If the core material is to soft it will hinder the high frequencies regardless if the skins are hard.

High density (3lbs) EPS -1/2inch thickness is currently my foundation choice of mostly all my DML designs.

Steve is this what 70 grade refers to? " 70 kPa (10 psi) Compressive strength" What would be the density of 70 grade one inch EPS foam? What size panel would you reduce panel thickness from one inch material to half inch? What material thickness in EPS do you use for a small panel such as 6x9 inches? Do you have a weight cut off point with small panels to prevent spider sag or has that even ever been an issue for you ? Thanks.This picture is of a 70grade 1inch eps panel from the nxt rubbish forum, 12inches from the panel.

could you weigh a square of this material say 8"x8" would be fine so I can look and see if I can find it locally as shipping is typically at least double the material asking price.If the core material is to soft it will hinder the high frequencies regardless if the skins are hard.

High density (3lbs) EPS -1/2inch thickness is currently my foundation choice of mostly all my DML designs.

I see others recommending heavier density EPS as much as 25 kg/m3. Have you experimented with EPS of this density? I am still looking for local supplier of 5mm thick composite floor underlayment. If I can find local vendor I can save money. Thanks.

Hi moray James.

Choose a grade and it will tell you the dentist 😉

https://www.custompac.co.uk/polystyrene-cut-to-size

Choose a grade and it will tell you the dentist 😉

https://www.custompac.co.uk/polystyrene-cut-to-size

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker