I have a 40cmx40cmx1cm eps panel that is 58g.

Supposedly this is 36.25 kg/m3.

It is a very Rigid panel.

It has a bit of a split in it as I fell on it a few weeks ago 😅

But this is easily fixed with a little pva.

Supposedly this is 36.25 kg/m3.

It is a very Rigid panel.

It has a bit of a split in it as I fell on it a few weeks ago 😅

But this is easily fixed with a little pva.

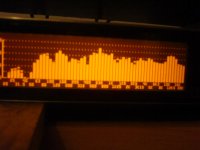

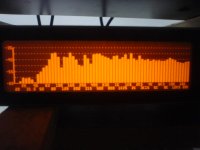

These pictures are from my gallery over on the AudioCircle forum .

They are of the 40cm vh grade I was testing

The first picture is before removing the 10k or so peak .

Anyone can look through my gallery pictures to see what panels I was building back then.

I believe they were measured at about 30cm in front of the panel exciter area.

Steve.

They are of the 40cm vh grade I was testing

The first picture is before removing the 10k or so peak .

Anyone can look through my gallery pictures to see what panels I was building back then.

I believe they were measured at about 30cm in front of the panel exciter area.

Steve.

Attachments

A note on a different topic which may be of interest to some...

I tend to dabble with different materials to see if I can come up with a useful idea.

In this case, I wanted to try to make a viscoelastic material for panel mounting.

I took a new kitchen sponge, approx 10mm thick. New ones are treated with something to keep them from drying out in the packaging.

I cut it into strips about 12mm wide. You can discern the top and bottom from the sides by the bubble sizes.

I then massaged messy, black butyl mastic into the strips. The mastic skins, but does not harden. I left the strips to skin for about 2 days and found that the foam "bounce" had been effectively quelled. I then glued the strips to a panel and it's super frame and it appears to be performing very well

Subsequently, I tried something extra...I took RTV silicone and the mastic, and mixed some together at 1:1. It mixed very well, and 2 days later I have a viscoelastic putty which can be kneaded easily, recovers after squishing, and although a bit tacky, does not leave a black mess on your hands.

With a bit more experimenting, I think this material will be a great way to terminate panels, either by

1/direct mixing and applying as a "glue",

2/ by casting in a mould and then gluing with a thin layer of suitable adhesive (probably silicone)

3/ Using the sponge again but with the silicone/mastic mix (this may be the easiest)

I'm squishing a bit around as I write this. Could be catching😁

PS.. Butyl mastic is also available in white

Cheers

Eucy

I tend to dabble with different materials to see if I can come up with a useful idea.

In this case, I wanted to try to make a viscoelastic material for panel mounting.

I took a new kitchen sponge, approx 10mm thick. New ones are treated with something to keep them from drying out in the packaging.

I cut it into strips about 12mm wide. You can discern the top and bottom from the sides by the bubble sizes.

I then massaged messy, black butyl mastic into the strips. The mastic skins, but does not harden. I left the strips to skin for about 2 days and found that the foam "bounce" had been effectively quelled. I then glued the strips to a panel and it's super frame and it appears to be performing very well

Subsequently, I tried something extra...I took RTV silicone and the mastic, and mixed some together at 1:1. It mixed very well, and 2 days later I have a viscoelastic putty which can be kneaded easily, recovers after squishing, and although a bit tacky, does not leave a black mess on your hands.

With a bit more experimenting, I think this material will be a great way to terminate panels, either by

1/direct mixing and applying as a "glue",

2/ by casting in a mould and then gluing with a thin layer of suitable adhesive (probably silicone)

3/ Using the sponge again but with the silicone/mastic mix (this may be the easiest)

I'm squishing a bit around as I write this. Could be catching😁

PS.. Butyl mastic is also available in white

Cheers

Eucy

Last edited:

Yes, this topic is of interest to me. Thanks for sharing your experiments. Just to understand - you are trying to create a viscoelastic material. In layman terms - a soft pliable (the viscous property) material that bounces back to its original form (the elastic property). The quest is to find the perfect balance between these two properties I assume? I.e. how soft and how elastic?

So many materials can fall in this category, but the one most often mentioned/used in this thread is weather strip foam. But Veleric had good/better results with Sorbothane. Unfortunately, Sorbothane sheets in my part of the world is way too expensive to experiment with. I am planning on trying Latex tubing. But it all depends on how it is used to hold and dampen the panel.

So, why is Sorbothane good? I think it has a lot to do with the “softness”. This can of course be measured. Here is some info off the web:

Sorbothane is softer than rubber and most other polymers. Sorbothane is measured on the Shore “00” scale. Most types of rubber and other polymers are specified using the Shore “A” or Shore “D” scales. Sorbothane parts are normally cast between 30 and 70 durometer on the Shore “00” scale. For special applications (at increased cost) Sorbothane® can be cast as low as 20 durometer (limited strength) and as high as 80 durometer (limited visco-elastic properties).

What I am getting at – Eucyblues, I think you are on the right track. If you are considering to cast your own strips, then you can look into silicone casting systems. For example Ecoflex silicone casting rubber from Smooth-On and can be as soft as 10 durometer. See here:

https://www.smooth-on.com/product-line/ecoflex/

But silicone rubber poses another big challenge – it cannot be glued easily. You can probably cast the silicone around the panel edge so that it binds with the panel material. I have been thinking about this the last couple of months and how to practically implement this.

Personally, I think the way to go is to lightly clamp (or sandwich) the panel edges with soft strips and not to glue the strips to the panel and frame. DMLBES started this sandwich system way back. See post #639.

So many materials can fall in this category, but the one most often mentioned/used in this thread is weather strip foam. But Veleric had good/better results with Sorbothane. Unfortunately, Sorbothane sheets in my part of the world is way too expensive to experiment with. I am planning on trying Latex tubing. But it all depends on how it is used to hold and dampen the panel.

So, why is Sorbothane good? I think it has a lot to do with the “softness”. This can of course be measured. Here is some info off the web:

Sorbothane is softer than rubber and most other polymers. Sorbothane is measured on the Shore “00” scale. Most types of rubber and other polymers are specified using the Shore “A” or Shore “D” scales. Sorbothane parts are normally cast between 30 and 70 durometer on the Shore “00” scale. For special applications (at increased cost) Sorbothane® can be cast as low as 20 durometer (limited strength) and as high as 80 durometer (limited visco-elastic properties).

What I am getting at – Eucyblues, I think you are on the right track. If you are considering to cast your own strips, then you can look into silicone casting systems. For example Ecoflex silicone casting rubber from Smooth-On and can be as soft as 10 durometer. See here:

https://www.smooth-on.com/product-line/ecoflex/

But silicone rubber poses another big challenge – it cannot be glued easily. You can probably cast the silicone around the panel edge so that it binds with the panel material. I have been thinking about this the last couple of months and how to practically implement this.

Personally, I think the way to go is to lightly clamp (or sandwich) the panel edges with soft strips and not to glue the strips to the panel and frame. DMLBES started this sandwich system way back. See post #639.

Hi two cents

A couple of points:

The viscous part is more than just soft ..it really relates to not flowing easily. So it's contribution to the mix is that it slows down the movement, and what we need is to maintain flexibility but actually remove or seriously slow the bounce part... Just like memory foam (this would also work but hard to find outside pillows and the like)

Why? because as well as supporting the panel we need to absorb the vibrations and prevent reflection. Softness by itself will not be as effective.

The problem with soft silicone by itself is that it is elastic, not viscoelastic.

Silicone actually can be stuck, by using silicone 😊

I think the sandwich approach has merit, with very light clamping... That will give slight movement in both directions without pulling on the mountings on the positive stroke. The devil is in the detail.

Now, just how much of the panel perimeter is to be treated??. That may be an even bigger question.

Cheers

Eucy

A couple of points:

The viscous part is more than just soft ..it really relates to not flowing easily. So it's contribution to the mix is that it slows down the movement, and what we need is to maintain flexibility but actually remove or seriously slow the bounce part... Just like memory foam (this would also work but hard to find outside pillows and the like)

Why? because as well as supporting the panel we need to absorb the vibrations and prevent reflection. Softness by itself will not be as effective.

The problem with soft silicone by itself is that it is elastic, not viscoelastic.

Silicone actually can be stuck, by using silicone 😊

I think the sandwich approach has merit, with very light clamping... That will give slight movement in both directions without pulling on the mountings on the positive stroke. The devil is in the detail.

Now, just how much of the panel perimeter is to be treated??. That may be an even bigger question.

Cheers

Eucy

TwocentsVeleric had good/better results with Sorbothane.

I’m glad you remembered my tests but that’s not exactly what I measured. In fact it was exactly the opposite. Sorbothane was surprisingly poor in my testing. I expected it to be much better, considering both the advertising and the cost.

Rather it was Poron 92 that was particularly good at damping in my tests. Probably that’s what you were thinking of.

Eric

The slow rebound properties are noted in the Poron literature..A key factor I believeTwocents

I’m glad you remembered my tests but that’s not exactly what I measured. In fact it was exactly the opposite. Sorbothane was surprisingly poor in my testing. I expected it to be much better, considering both the advertising and the cost.

Rather it was Poron 92 that was particularly good at damping in my tests. Probably that’s what you were thinking of.

Eric

Eric... Where did you finally land on the extent of the panel perimeter to be treated..?

Eucy

Last edited:

Maybe if you stand in front of a mirror and ask again politely, he'll tell you 😁😁

If he does, then of course you'll have to share the details with us .👍😊

If he does, then of course you'll have to share the details with us .👍😊

He was actually correct once, when he said that mounting a plate to a good damping material around the perimeter was a good idea. But since then I have seen no indication that he knows anything worth knowing. Why people keep thinking he does is beyond me.Maybe if you stand in front of a mirror and ask again politely, he'll tell you 😁😁

If he does, then of course you'll have to share the details with us .👍😊

Eric

Ah me oh mi.... At least it keeps interest in a dying thread....😵💫

So Eric, whole perimeter missing corners or part?

Eucy

So Eric, whole perimeter missing corners or part?

Eucy

Thank you all for setting the records straight and helping me to understand the physics a bit better. Looks like I was heading down the wrong rabbit hole. Latex and silicone is indeed very elastic compared to the slow rebound nature of weather strip foam, Poron, yoga mats (EVA foam), and probably memory foam. I think I understand the physics behind damping better now.

Yes, sorry Eric – it was Poron that gave the better measurements. I should have checked, but it is somewhere in another thread I think.

I also tried to source memory foam, but other than buying a (gel infused memory foam) mattress topper and cutting it up, it is not sold in other form here.

Yes, sorry Eric – it was Poron that gave the better measurements. I should have checked, but it is somewhere in another thread I think.

I also tried to source memory foam, but other than buying a (gel infused memory foam) mattress topper and cutting it up, it is not sold in other form here.

Yes, and some are not willing to share their demons.The devil is in the detail

I looked up one product called Duct Sealant... That one is acrylic and usually acrylic dries out too much over time... You'd have to test it outDuct Seal fits the description that you provide

same name different product. IN North America Duct seal is used to waterproof external electrical outlet boxes and to pack conduits to water seal the cables in the pipe.Duct seal is also used by HVAC to seal aie ducts. It does not dry out stays compliant for a Very long time does not smell like most mastic products can. Duct seal is a gray thick putty like material. This is probably not going to be easy to find but start with HVAC and electricians and see if you have any luck.

https://electgo.com/pd-ds1

https://electgo.com/pd-ds1

I bought this butyl rope a while ago: https://www.amazon.com/Butyl-Sealant-Tape-Automotive-Installing/dp/B09KBKB9S2/

I think it will work pretty good for sandwiching between panel and frame. I've been too busy to try it though.

I also bought some CLD damping tape (butyl with thick aluminum foil one side) to try as an alternative or combo on edges, or maybe even on face of panel near the edges (not sandwiched). I think there's excellent potential with both of these ideas, with harder panels with low internal damping being improved the most.

Lately I've just been enjoying my ugly test frames in the living room as they are, I don't have much motivation to improve them right now 😛 I have not even swapped my ol' Dayton thruster testing junkers for the new Xcite drivers sitting on my shelf...

I think it will work pretty good for sandwiching between panel and frame. I've been too busy to try it though.

I also bought some CLD damping tape (butyl with thick aluminum foil one side) to try as an alternative or combo on edges, or maybe even on face of panel near the edges (not sandwiched). I think there's excellent potential with both of these ideas, with harder panels with low internal damping being improved the most.

Lately I've just been enjoying my ugly test frames in the living room as they are, I don't have much motivation to improve them right now 😛 I have not even swapped my ol' Dayton thruster testing junkers for the new Xcite drivers sitting on my shelf...

Eric... Where did you finally land on the extent of the panel perimeter to be treated..?

Eucy

Eucy,

Sorry it took me so long to respond. My preference lately is to mount my panels to a frame with a good damping material around the entire perimeter.

There are two reasons for this. First, I believe that this approach provides the maximum possible damping without damping the panel itself (say, by adding constrained layer damping to the panel) which would add weight and hurt efficiency. Secondly, full perimeter support (combined with high panel aspect ratio) provides close and regular spacing of the natural frequencies at the low end of the panel's frequency range.

But that's not to say that there are not other approaches that could be as good or even better.

Eric

Butyl rubber does seem to be a pretty good damping material, particularly at low frequencies, according to the testing I did here:I bought this butyl rope a while ago: https://www.amazon.com/Butyl-Sealant-Tape-Automotive-Installing/dp/B09KBKB9S2/

I think it will work pretty good for sandwiching between panel and frame. I've been too busy to try it though.

https://www.diyaudio.com/community/...ing-of-dml-speaker-panels.394465/post-7258557

This post was based on an early version of my damping test device. I now have a better (I think) version of the test based on impedance, but I can't recall if I ever retested butyl rubber with the latest version of the test. I'll have to look for that when I get back home. If not, I should retest it, but as I recall I've used up all the butyl rubber gasket I had, so I'd have to get more.

Eric

I have been going for materials that re more flexible and sponge-like than butyl. I'm sure it dampens well, but the question is how much damping you want? I'm chasing high efficiency, but also like the sound of a less constrained plate as long as it not completely free to swing around. In my first attempts at constraining I had long strips at all sides, and found that the less contact I had the better the plates sounded and the more efficient they become.

I have only tested that on the GPS plates with four exciters in cluster though, and perhaps I'm overlooking some variables and have jumped to conclusions...am I the only one that experienced that minimal perimeter constraints both sounds best and is more efficient?

I have only tested that on the GPS plates with four exciters in cluster though, and perhaps I'm overlooking some variables and have jumped to conclusions...am I the only one that experienced that minimal perimeter constraints both sounds best and is more efficient?

so what thickness and overall size is this square panel and is it a single exciter or does it use multiple panels? Is this mounted in a frame with a motor strut?Sounds good!I used headphones to listen and it sounds really good. Maybe too good to be true?

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker