Woofer mount adapter success

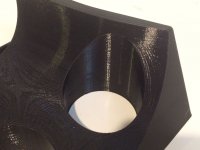

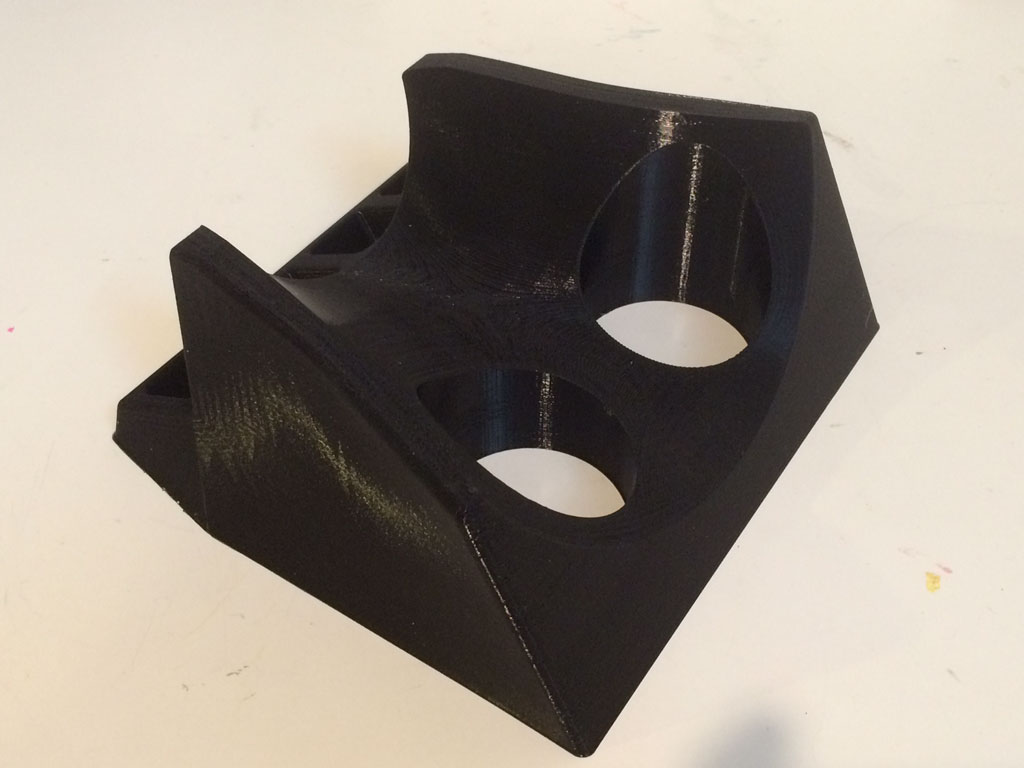

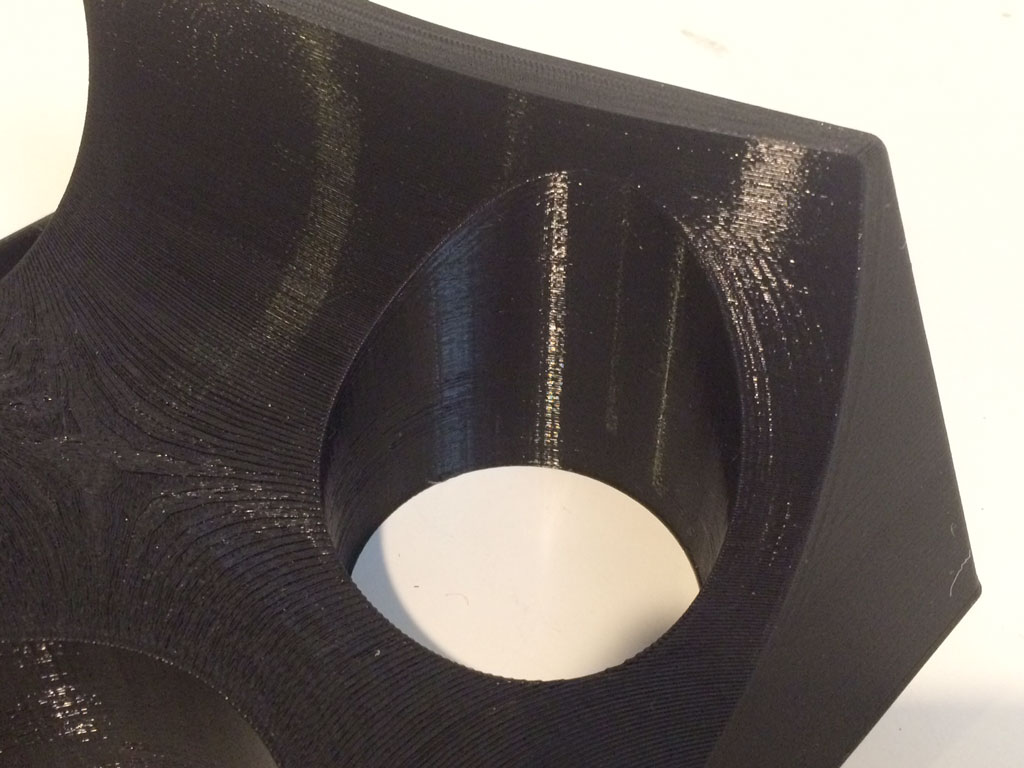

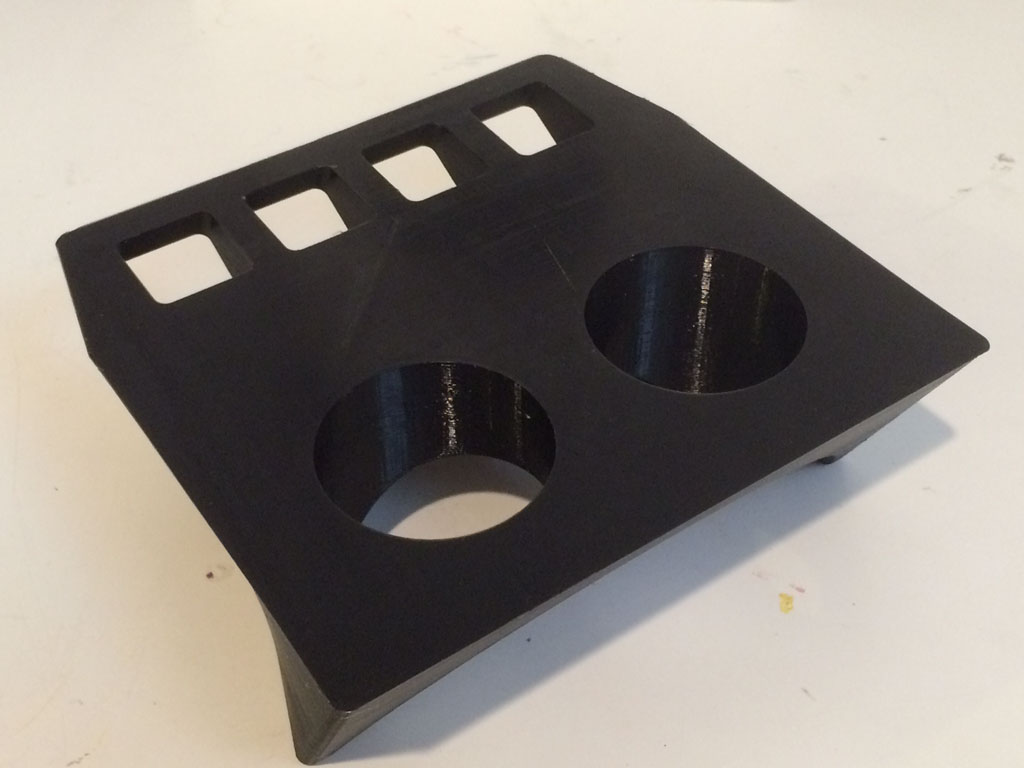

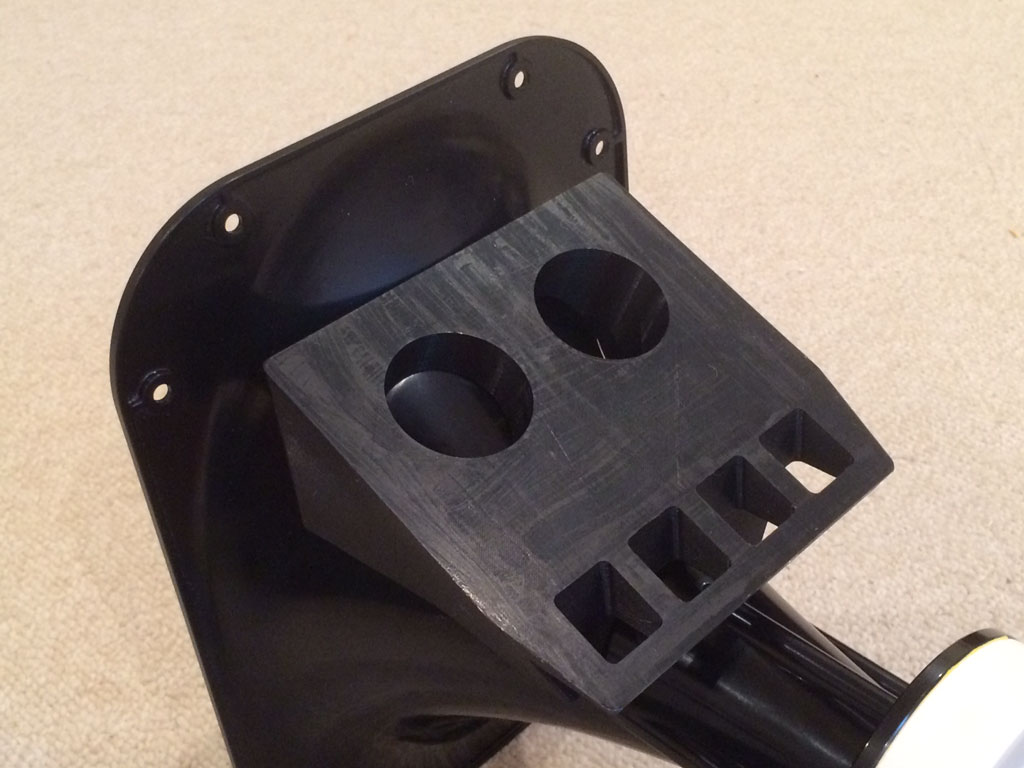

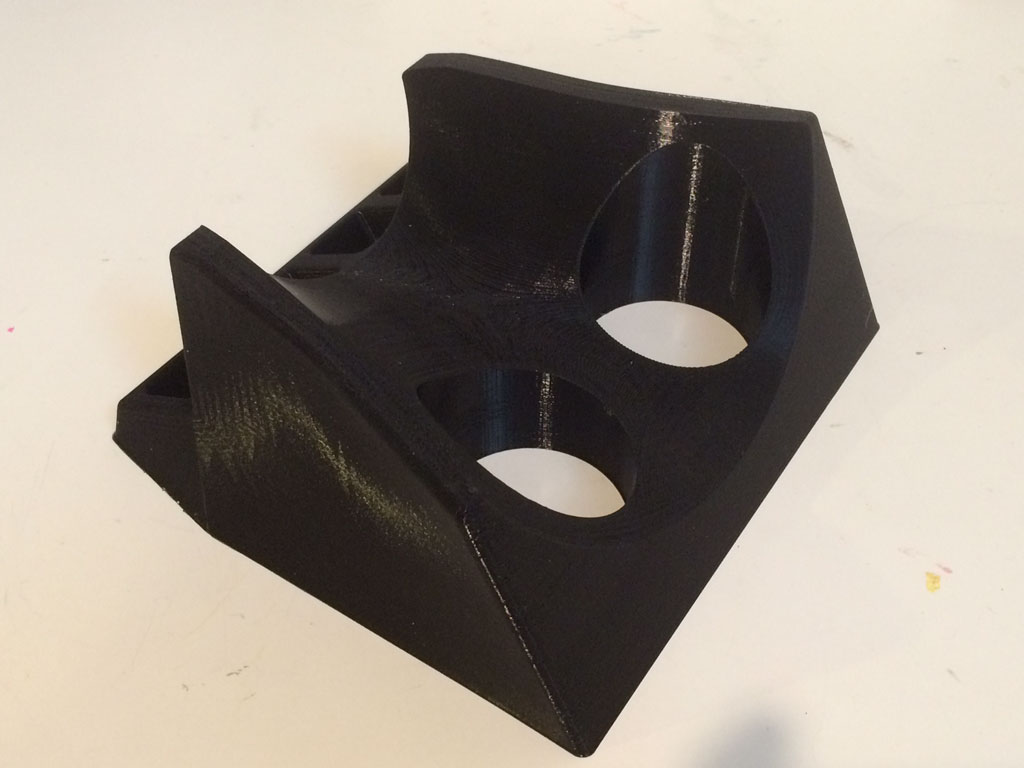

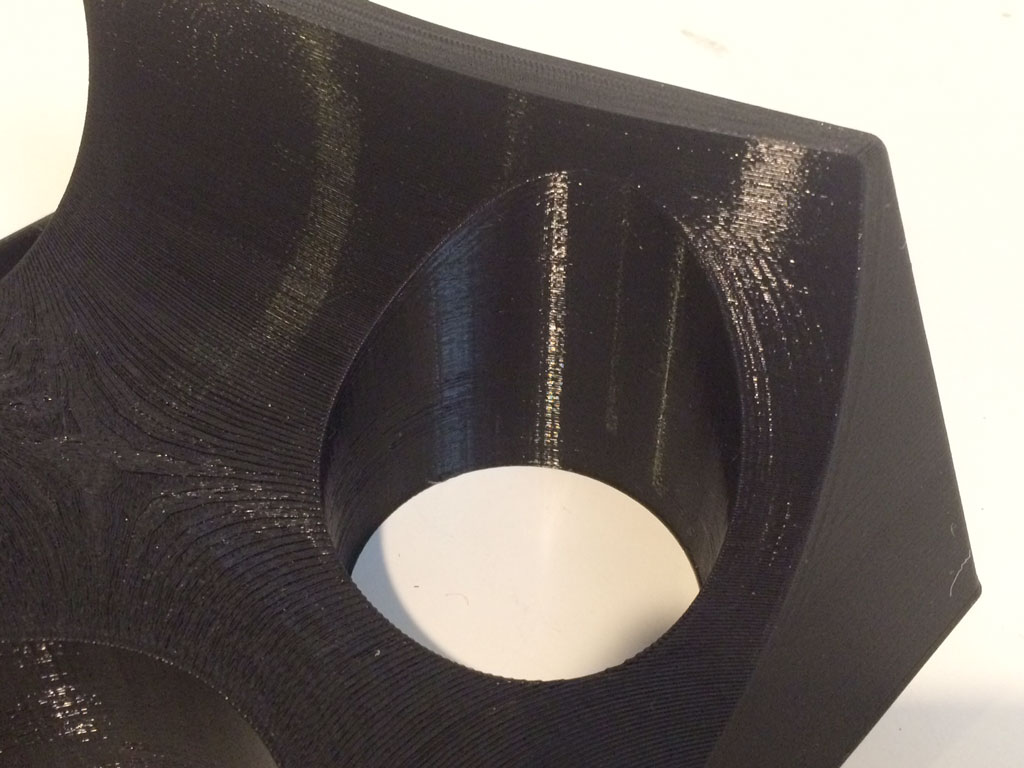

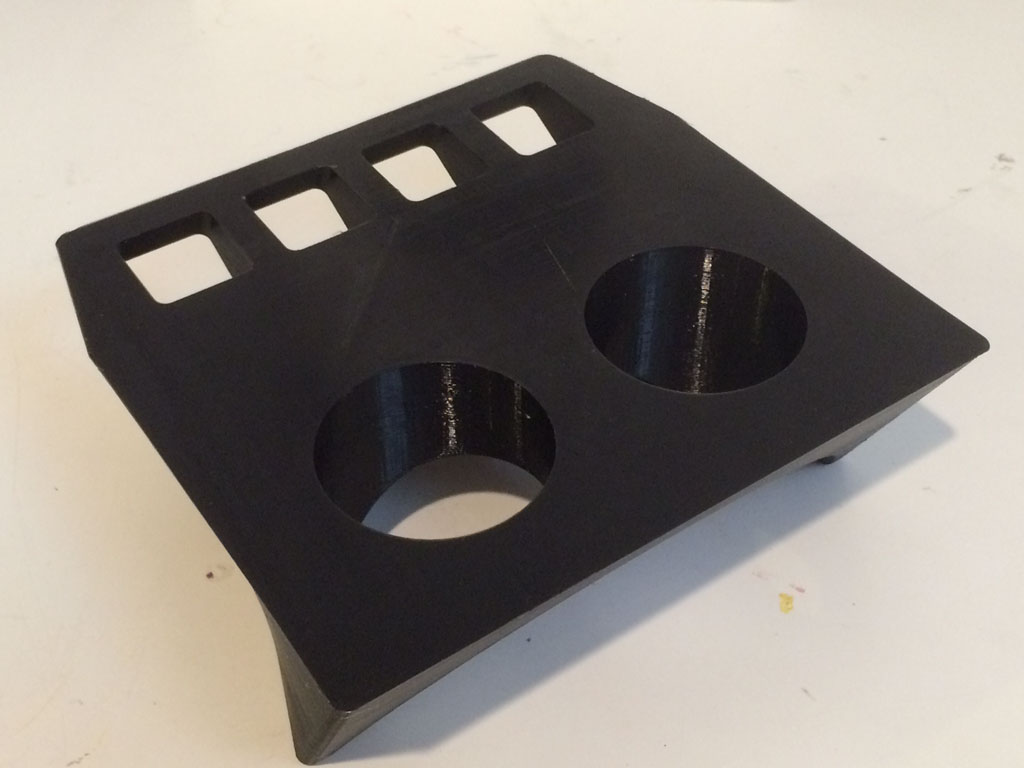

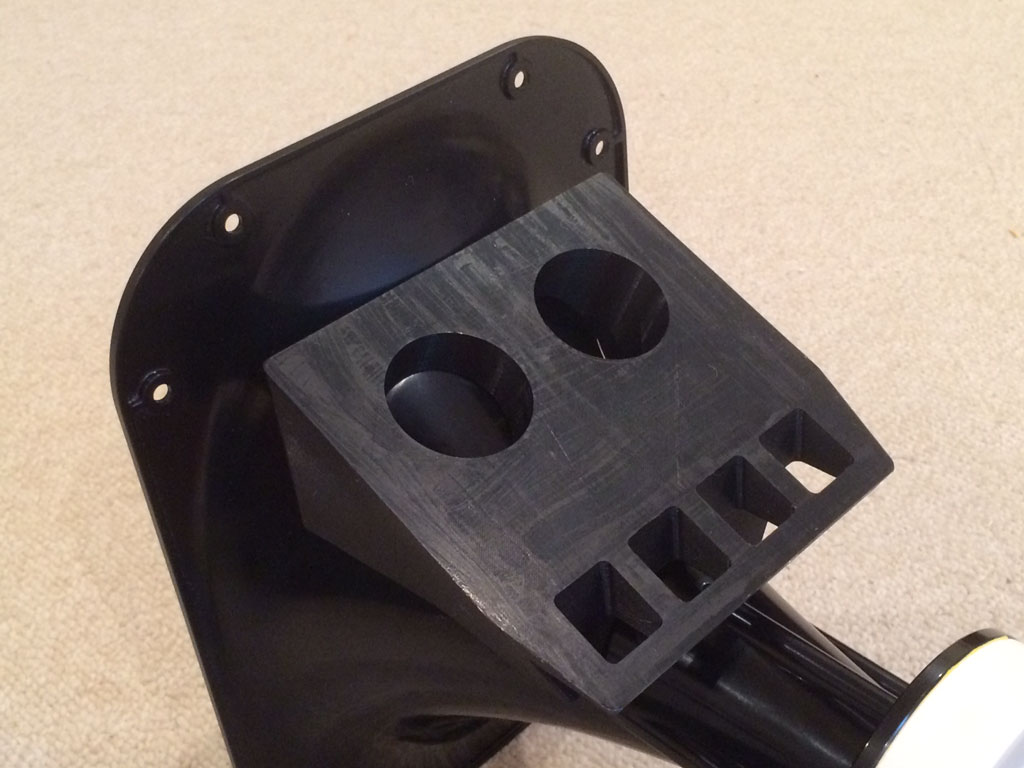

These are photos of the part fresh off the printer with no post cleanup or sanding - as is. Looks great and very stiff and strong. Fit is excellent with maybe 1-2mm gap between horn wall and adapter that should fill up nicely with adhesive/caulking or glue.

I will use 0.5in plywood board mounted on top of the adapter, a standoff ring will be used to prevent surround bumping into plywood and a 3d printed conformal shape cone volume filler will be used to reduce chamber volume to push bandwidth up in HF.

These are photos of the part fresh off the printer with no post cleanup or sanding - as is. Looks great and very stiff and strong. Fit is excellent with maybe 1-2mm gap between horn wall and adapter that should fill up nicely with adhesive/caulking or glue.

I will use 0.5in plywood board mounted on top of the adapter, a standoff ring will be used to prevent surround bumping into plywood and a 3d printed conformal shape cone volume filler will be used to reduce chamber volume to push bandwidth up in HF.

Attachments

Last edited:

I think I will go ahead and print as the fit looks excellent and it takes 11 hours (easy hours as I start it in the evening, go to bed and ready in the morning). I will make sure woofer fits and all that though with the first one. It's amazing what very small changes in the temperature profile and nozzle can do - it's like new and different printer. The PVA base coat is also a major improvement - I had a bit of a hard time removing part as it was bonded onto the glass pretty securely!

Woofer cone volume filler

Here is a 3d model of a conformal woofer cone volume filler for the DC200-8 fitted with the two 50mm ducts for the horn. It has a calculated volume reduction of 242 cc's - that is a significant reduction that will hopefully help to push the HF extension up a bit for a better XO slope. Again, paper and scissors to transfer profile.

Here is a 3d model of a conformal woofer cone volume filler for the DC200-8 fitted with the two 50mm ducts for the horn. It has a calculated volume reduction of 242 cc's - that is a significant reduction that will hopefully help to push the HF extension up a bit for a better XO slope. Again, paper and scissors to transfer profile.

Attachments

The volume filler also extends the port length considerably, will be interesting to see what that does to the response.Here is a 3d model of a conformal woofer cone volume filler for the DC200-8 fitted with the two 50mm ducts for the horn. It has a calculated volume reduction of 242 cc's - that is a significant reduction that will hopefully help to push the HF extension up a bit for a better XO slope.

I wish I could print the outside enclosure 😛OK seriously this is getting cool.

I hate cutting plywood. What a mess. Maybe I live with fatter looking box to stick with XPS foam.

The volume filler also extends the port length considerably, will be interesting to see what that does to the response.

I just ran the sims, the average port length including 3d adapter, 3d volume filler, and 11/32 plywood is about 60mm vs 12mm assumed before. I will suffer a -1.3dB hit to sensitivity but the bass extension (f3) goes from 89Hz to 82Hz, assuming an 11 liter common rear chamber. I think this is not too bad a hit. Upper frequency extension is usable up to 730Hz.

Last edited:

I wish I could print the outside enclosure[emoji14]

I'd like to print the whole horn with woofer mounts.

Can be done.

Sent from my GT-I8200 using Tapatalk

I wish I could print the outside enclosure 😛

I hate cutting plywood. What a mess. Maybe I live with fatter looking box to stick with XPS foam.

Noooo, Give it a proper wood cabinet. 😉

Faital attraction, or Soldermizer wants to perpetrate a horn...

OK gentlemen. I am interested enough to do a simpler "pre-designed" (e.g. you guys already have done the heavy thinking and research) horn. Probablly xrk971's Trynergy. Or even a simpler (?) Maltese a la Weltersys.

A Little Bit of Tymphany

I have on order some of the all-purpose Tymphany TC9FD00-04. Will these really go down to 250 Hz? Won't even need to make a Synergy then 🙂

I'm "good" for existing sub woofer ("good" in the sense that it works mostly, not "good" as in build quality.) For your amusement, I still use the Frankenclosure of few years past as sub/foot rest.

http://www.diyaudio.com/forums/subw...build-his-1st-tapped-horn-11.html#post3878733

Currently I am worming my way through the " Presenting the Trynergy - a full range tractrix synergy" epic 🙂

Thanks for your efforts in these designs -- and in suffering poseurs like me 🙂

OK gentlemen. I am interested enough to do a simpler "pre-designed" (e.g. you guys already have done the heavy thinking and research) horn. Probablly xrk971's Trynergy. Or even a simpler (?) Maltese a la Weltersys.

A Little Bit of Tymphany

I have on order some of the all-purpose Tymphany TC9FD00-04. Will these really go down to 250 Hz? Won't even need to make a Synergy then 🙂

I'm "good" for existing sub woofer ("good" in the sense that it works mostly, not "good" as in build quality.) For your amusement, I still use the Frankenclosure of few years past as sub/foot rest.

http://www.diyaudio.com/forums/subw...build-his-1st-tapped-horn-11.html#post3878733

Currently I am worming my way through the " Presenting the Trynergy - a full range tractrix synergy" epic 🙂

Thanks for your efforts in these designs -- and in suffering poseurs like me 🙂

Noooo, Give it a proper wood cabinet. 😉

I will think about seriously. Maybe slow down on this one.

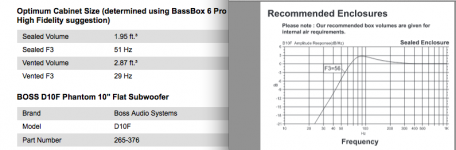

I have so much volume inside the box and the DC200's only need 11 liters. I just ordered a cheap but well regarded 94dB Boss D10F Phantom driver designed for sealed enclosures in a car. Supposedly all it needs is 0.5cu ft to reach 50Hz. I probanly have close to 1cu ft. Could mount it on bottom to save baffle real estate like my original design. It would make a nice 3 way.

Soldermizer, you might want to re-think that order...

Your proposed TC9 FD00-04 (x-max 1.6 mm):

The multi purpose TC9 FD18-08 (x-max 2.55 mm):

I'd pick the FD18-08, actually I did....

Your proposed TC9 FD00-04 (x-max 1.6 mm):

The multi purpose TC9 FD18-08 (x-max 2.55 mm):

I'd pick the FD18-08, actually I did....

Attachments

Last edited:

.5 cube results in a +3dB bump at 90 Hz and a F3 of 56 Hz according to the ownersmanual. According to Bass box Pro, needs almost 2 cubic feet for a 51 Hz F3.I will think about seriously. Maybe slow down on this one.

I have so much volume inside the box and the DC200's only need 11 liters. I just ordered a cheap but well regarded 94dB Boss D10F Phantom driver designed for sealed enclosures in a car. Supposedly all it needs is 0.5cu ft to reach 50Hz. I probanly have close to 1cu ft. Could mount it on bottom to save baffle real estate like my original design. It would make a nice 3 way.

Attachments

They are a bit longer than I anticipated - although I recall the model was not very sensitive to this - it actually pushes the bass extension lower. I will make a volume filler plug that matches the cone profile to reduce the volume of the band pass chamber to push the HF extension higher.

I guess I should run a sim with the new port lengths to make sure it is all good.

Maybe some peaks and dips? less flat, reflections.

nice thing such a printer.

I have a the stuff for a cnc router, but no time to make it.

You say make the hf extension higher is this for the bas units? these go to 500 hz max then the front chamber wil do not much harm

but this small horns maybe needs higher bassmid extentsion..

regards

Last edited:

The longer port made the first peak after the dip higher as well as the general bandpass peak is higher. But all that is easy to EQ. I need higher extension on bass in order to cross over with main full range horn. 500Hz works for LR4 but I need BW2 slope for Harsch XO. May need to move to 600Hz.

.5 cube results in a +3dB bump at 90 Hz and a F3 of 56 Hz according to the ownersmanual. According to Bass box Pro, needs almost 2 cubic feet for a 51 Hz F3.

We might just have to Linkwitz Transform it to a desired response.

I will think about seriously. Maybe slow down on this one.

I have so much volume inside the box and the DC200's only need 11 liters. I just ordered a cheap but well regarded 94dB Boss D10F Phantom driver designed for sealed enclosures in a car. Supposedly all it needs is 0.5cu ft to reach 50Hz. I probanly have close to 1cu ft. Could mount it on bottom to save baffle real estate like my original design. It would make a nice 3 way.

Ok, just made a HD run (for those not in the States, HD stands for Home Depot), I have 15/32 plywood for the sides and 3/4in ply for the front baffle, 11/32 for the woofer mounting boards which will extend as flat panels all the way to the sides and serve as bracing. Still debating whether or not to make it a 3 way with the Phantom D10F as that would require the cabinet to be 3in taller making it 21.5in high - a solid stand mount speaker. Current minimum internal dimensions without 10in sub are coming in at 9.3in wide x 12in deep x 17.5in high. I have an idea for the rear chamber on the full range to make it only 2in deep and still absorb the back wave (think starfish).

I also got a holesaw (those are pricey but I guess every toolbox needs one). Some Loctite PL adhesive for bonding the horn to the adapter (in addition to some strategic epoxy points). Some black latex sealant for the vent holes, and some sand paper. Bracing myself for the cutting wood.

The D10F just arrived - an impressive driver for $36 - well built. This sub has one of the stiffest suspensions I have ever felt. Maybe that and a fat magnet is how they get 94dB sensitivity? It's got an alloy frame, a huge half-roll surround, nickel plated spring loaded terminals, and a very low profile at 3in deep. Ugly graphics on cone but if I aim it at the bottom, no harm done.

Will put it through DATS for some real TS parameters and maybe an OB to see how high up it can go. might be a good FAST driver in general.

Attachments

Last edited:

Great work X! A lot less messy that my technique.

Yours sure was faster though 🙂

...and provides damping of resonances in horn wall.

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn