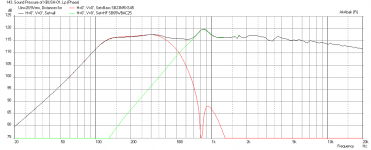

I have managed to more or less remove the cancellation dip. Took a few attempts with different techniques

Wow! Nice work Bushmeister!!!

This, I believe, is what they call a breakthrough. 🙂

Right off to bed! I am so satisfied with the results of my toils - I'm gonna be afraid to cut the woofer taps in!!

There's always Bondo filler for holes that don't work.

A 1-inch throat won't work well with a 2.5in dia full range cone. Maybe with a conventional compression driver but then we are just back to a standard synergy/unity with ports stuffed up as close as possible to throat with a 1.2k XO and correspondingly higher levels of HD that a compression driver has vs a cone driver in a WG.

Ah, you must have missed the part about adapting the throat size 🙂

An adapter implies you still have to go through a narrow 1in dia throat and that creates a bandpass duct for the full range thereby limiting upper HF extension and will probably cause cancellation dips.

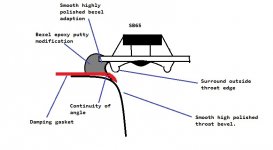

A quick photo of modifications. Doesn't come out well on the pics I am afraid.

Perhaps an oblique angle shot would help. I see the black open cell foam there - does that foam go just up to the inner lip of the bezel wall that you built-up, or does the driver bezel actually clamp over it? Or perhaps a sketch of the cross sectional view of the different layers where profile of the throat. It does look like you made the throat radius much smoother - would you say 0.25in radius?

The horn flange appears to show a white color from all your sanding? The specs actually says it is a based on foam and plastic covered? Are you getting down to the foam?

Last edited:

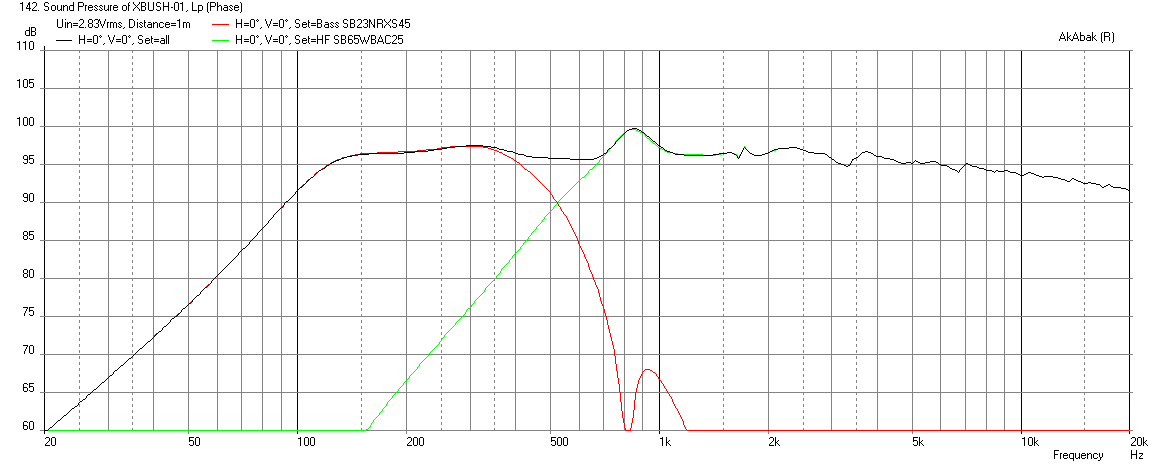

I was looking at other woofer possibilities and the Peerless 830869 8in HDS Nomex is interesting in that it can achieve a higher sensitivity, but still does not did deep like the SB23 - that driver has a unique combination of fs, Qts, and Vas that give it the ability to go to 82Hz in a sealed band pass injection. I am able to go to an f3 of 110Hz with the 830869 but sensitivity is up to 96.5dB.

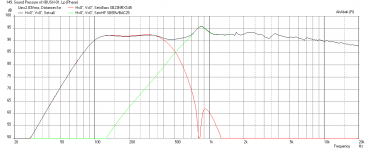

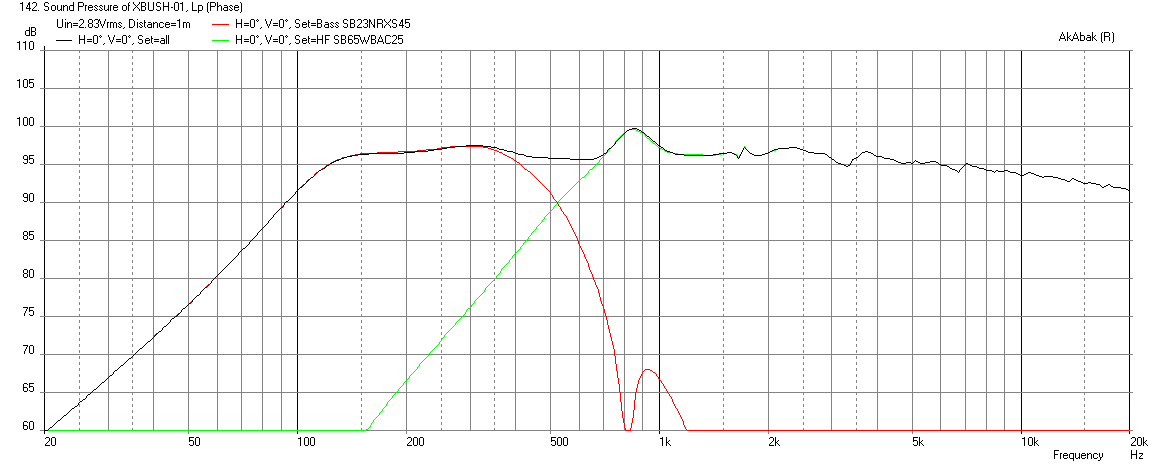

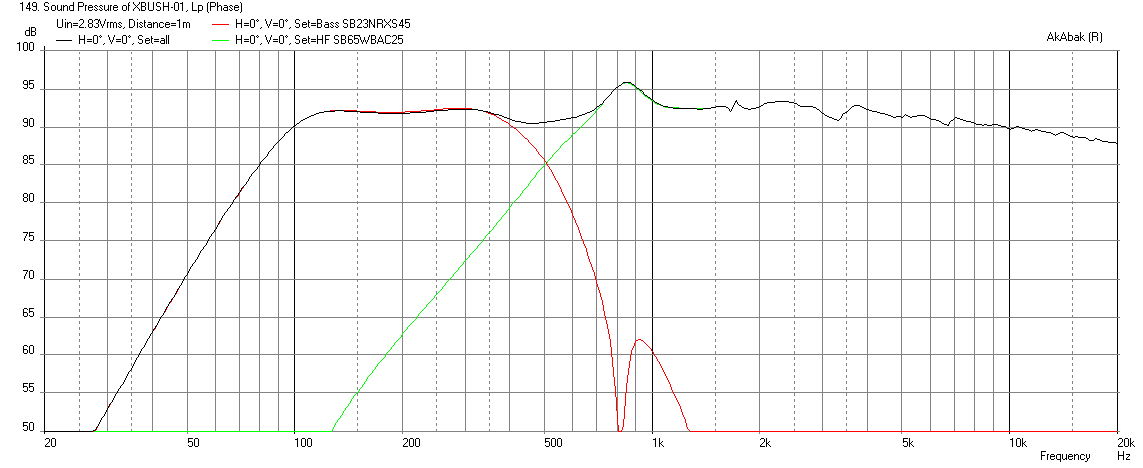

Here is predicted sensitivity at 2.83v (uses 5.5 liter rear chamber per driver) - I know, plot still shows SB23 - did not have time to change label:

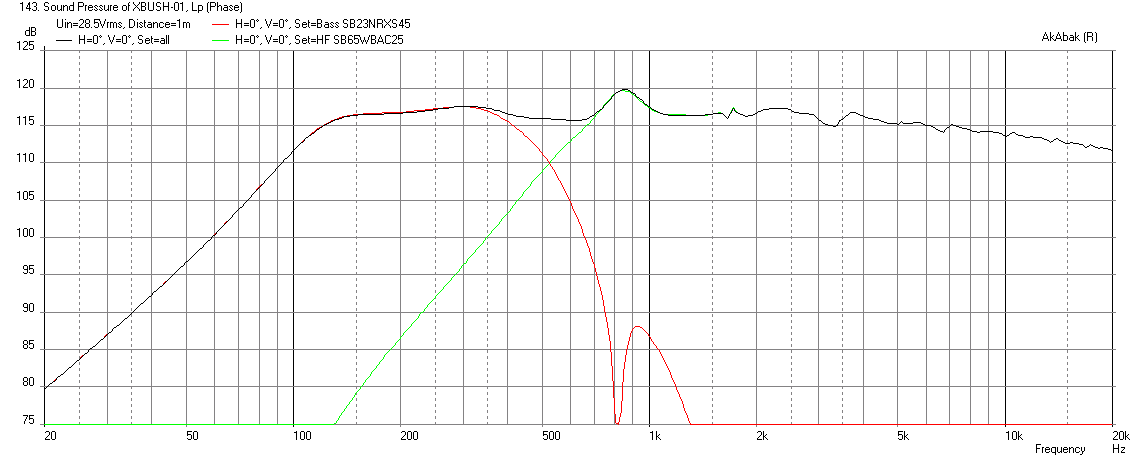

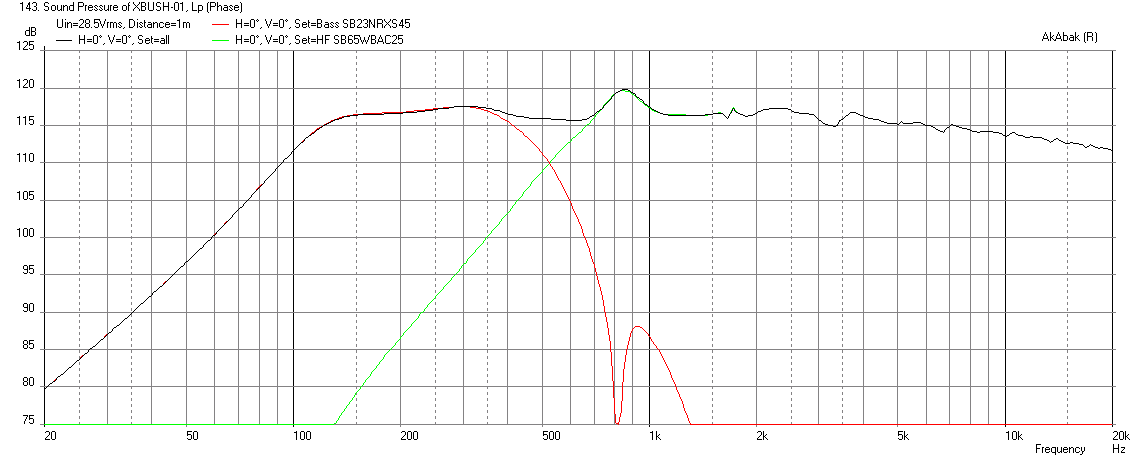

Here is predicted max SPL at xmax (of course thermal limits are violated by by about 2x):

Here is predicted sensitivity at 2.83v (uses 5.5 liter rear chamber per driver) - I know, plot still shows SB23 - did not have time to change label:

Here is predicted max SPL at xmax (of course thermal limits are violated by by about 2x):

Attachments

I would say almost 0.5 inch radius on throat. I tried a ring of damping which helped a little so this is an entire gasket which my modified bezel clamps down on. If you look at the close up shots of the bezel I made earlier in the thread, the ring of damping sits in the gap between the surround and bezel curve. Acting like stuffing in a sealed enclosure. It was my guess that if I could damp that space effectively it would eradicate the diffraction dip. I got lucky!

The sb23 really does seem to have been the best choice for my chosen application then.

Yes, I am having a hard time matching it with other drivers.

Although a really inexpensive Dayton Classic Series DC200-8, can get a lower f3 of about 94Hz, it has only 92dB sensitivity. But at $25 ea - may actually be a great "budget" alternative for some people.

This is with a 4.5 liter rear chamber so it can actually make for a very compact box if you make the box angled and curved to conform to the horn shape a bit.

I am also looking for an easily obtained and cost effective WG similar to the 18Sound you have chosen.

What do you think of the Faital Pro LTH142 60x50 deg tractrix elliptical? It is about the same physical envelope as the 18Sound.

https://www.parts-express.com/pedocs/specs/294-1042-faitalpro-lth142-4-bolt-specifications.pdf

Attachments

Last edited:

I would say almost 0.5 inch radius on throat. I tried a ring of damping which helped a little so this is an entire gasket which my modified bezel clamps down on. If you look at the close up shots of the bezel I made earlier in the thread, the ring of damping sits in the gap between the surround and bezel curve. Acting like stuffing in a sealed enclosure. It was my guess that if I could damp that space effectively it would eradicate the diffraction dip. I got lucky!

How thick is the foam - and is this the same type of open cell grey foam we see used to package electronics and such? Weltersys tried felt damping ring on his horn with a TC9FD and it made it worse.

Here is another cheap woofer that I have found to work quite well in Synergy sims it is a 6.5 inch Peerless

https://www.parts-express.com/peerless-sds-160f25pr01-08-6-1-2-paper-cone-woofer-speaker--264-1146

Has low Fs reasonable efficiency if used in multiples and doesn't need a huge rear chamber two in parallel gave me 99db and an f3 of 80Hz, obviously horn dependant.

Might be worth a try to sim and see if it works out OK with this waveguide.

Bushmeister do you plan on using more of the gasket material on the bezel of the sb23 woofers as they look to have a chamfered frame on the front which might be awkward to mount face down.

https://www.parts-express.com/peerless-sds-160f25pr01-08-6-1-2-paper-cone-woofer-speaker--264-1146

Has low Fs reasonable efficiency if used in multiples and doesn't need a huge rear chamber two in parallel gave me 99db and an f3 of 80Hz, obviously horn dependant.

Might be worth a try to sim and see if it works out OK with this waveguide.

Bushmeister do you plan on using more of the gasket material on the bezel of the sb23 woofers as they look to have a chamfered frame on the front which might be awkward to mount face down.

How thick is the foam - and is this the same type of open cell grey foam we see used to package electronics and such? Weltersys tried felt damping ring on his horn with a TC9FD and it made it worse.

Approx 3mm. But compresses down to 1.5mm when bezel screwed down. It is acoustic grade foam.

It is acoustic grade foam.

Do you have a link to this foam or a specification of material, porosity, etc? I think it may actually be very sensitive to the exact type of damping and how thick. It's not trivial to flatten out cancellation dips like that so this is an amazing discovery (accident or not). 🙂

Thanks.

Here is another cheap woofer that I have found to work quite well in Synergy sims it is a 6.5 inch Peerless

https://www.parts-express.com/peerless-sds-160f25pr01-08-6-1-2-paper-cone-woofer-speaker--264-1146

Has low Fs reasonable efficiency if used in multiples and doesn't need a huge rear chamber two in parallel gave me 99db and an f3 of 80Hz, obviously horn dependant.

Might be worth a try to sim and see if it works out OK with this waveguide.

Bushmeister do you plan on using more of the gasket material on the bezel of the sb23 woofers as they look to have a chamfered frame on the front which might be awkward to mount face down.

I just ran it through the sim, if you use qnty 4 in series parallel you get 92dB sensitivity and 100Hz f3. But very high SPL way beyond thermal. So maybe just two can work.

No sorry - I bought it years ago, and had some lying around in the garage. But I think the exact type isn't that important - I tried some felt too and it worked well, but didn't compress as well.

I think the important points are this:

1 Highly smooth transition from cone area to throat area - gentle curve.

2. Surround should be outside throat area - not visible on axis.

3. Gap between surround and bezel should have a smooth wall which transitions at the same angle into the throat curve so it is one single curve (hence important to create either a modified bezel or a very high tolerance molded gasket ring).

4. 3mm gap between surround edge and the bezel curve, filled with damping material which has decent absorption at cancellation dip - as up in the 6000hz range - most acoustic foams/felts have good absorption here.

5. Damping material must be compressible so you don't lift the bezel up too high, or a larger chamber is created between surround and throat and the problem is worsened.

I think the important points are this:

1 Highly smooth transition from cone area to throat area - gentle curve.

2. Surround should be outside throat area - not visible on axis.

3. Gap between surround and bezel should have a smooth wall which transitions at the same angle into the throat curve so it is one single curve (hence important to create either a modified bezel or a very high tolerance molded gasket ring).

4. 3mm gap between surround edge and the bezel curve, filled with damping material which has decent absorption at cancellation dip - as up in the 6000hz range - most acoustic foams/felts have good absorption here.

5. Damping material must be compressible so you don't lift the bezel up too high, or a larger chamber is created between surround and throat and the problem is worsened.

Can you explain point #3? in more detail Maybe a sketch would be useful as I am having a hard time seeing which angle needs to be similar or tangent to what object.

Thanks.

Thanks.

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn