Hi Y'all,

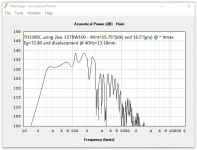

Here is the version w/ the reduced L45, and associated changes. This would be what I'd go w/ if I were to build this kind of double TH for the 18TBW100. Within the range of TRY_3 (Post #518) and this one the simulation seems to be quite stable.

There are still a lot of little things to be worked out, like the bracing, and possible suggestion for filling around the driver/throat, but this is pretty much it. I think it goes without sayin, that the suggested 3/4" plywood is a little on the light side, 1" Baltic birch would be better (and heavier...); maybe top and bottom from 1", and the rest from 3/4"?

Regards,

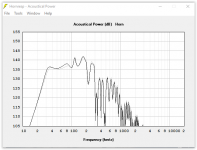

This looks pretty cool! I'm looking for a ~40hz TH around 8-12 cubes gross for the pair of 15TBW100 I've already got. Should I go off and sim this with a 16.5" internal width?

Hi turbodawg,

Like this....

Regards,

Awesome, will take a look at it when I get home! Thanks!!!!

Hi Y'all,

Post #539: "...I let you know when I have build the prototype..."

Here are a few more notes/dimensions that may help w/ the layout.

Regards,

Oh! thank you Oliver. This saves me some valuable time.

One Question: is it possible to reduce the internal Height to 535mm?

Last edited:

Reducing W_int of TH218SC

Hi USRFobiwan,

Post #546: "...is it possible to reduce the internal Height to 535mm?"

I would think so. Here is a listing of W_int v. compression ratio:

22.5625"[573.1mm] = 2.5

21.0625"[535.0mm] = 2.68

18.5"[46.99mm] = 3.05

You'll loose a little of low end extension, and Hornresp does not reflect compression related losses.

Regards,

P.S.: Always check my math... 🙂

Hi USRFobiwan,

Post #546: "...is it possible to reduce the internal Height to 535mm?"

I would think so. Here is a listing of W_int v. compression ratio:

22.5625"[573.1mm] = 2.5

21.0625"[535.0mm] = 2.68

18.5"[46.99mm] = 3.05

You'll loose a little of low end extension, and Hornresp does not reflect compression related losses.

Regards,

P.S.: Always check my math... 🙂

Attachments

Last edited:

Thanks OliverHi Y'all,

Post #539: "...I let you know when I have build the prototype..."

Here are a few more notes/dimensions that may help w/ the layout.

Regards,

Is it ok to use 18NW100?

Hi panjilaras,

Post #548: "...Is it ok to use 18NW100?"

From the data and the simulation I cannot see a reason why not.

The 18NW100 is roughly 6db lower in output @ Xmax than the 18SW115 as a result of the much higher power handling of the 18SW115; @ Eg=2.00 the SPL curves almost track.

Take a look at it in Hornresp. Maybe one of our PA pros has used the 18NW100, and has an opinion on it's applicability?

Regards,

Post #548: "...Is it ok to use 18NW100?"

From the data and the simulation I cannot see a reason why not.

The 18NW100 is roughly 6db lower in output @ Xmax than the 18SW115 as a result of the much higher power handling of the 18SW115; @ Eg=2.00 the SPL curves almost track.

Take a look at it in Hornresp. Maybe one of our PA pros has used the 18NW100, and has an opinion on it's applicability?

Regards,

I have a attached a cut list/panel layout for 5'x5' (1524 mm x 1524 mm) sheets, with the order of cuts annotated in red. It is optimized for table saw/circular saw, not CNC panel cuts. It has a 1/8" saw blade kerf allowance, but the layout makes the kerf irrelevant, as long as you cut in the proper order.

One small anomaly from the original CAD 2d drawing in post #1 is panel A seems to be dimensioned wrong. The dimension line at the intersection of A&B is wrong, making the panel dimension about 8 mm off. Not sure it matters.

One small anomaly from the original CAD 2d drawing in post #1 is panel A seems to be dimensioned wrong. The dimension line at the intersection of A&B is wrong, making the panel dimension about 8 mm off. Not sure it matters.

Attachments

Last edited:

Last status of PAL12 2D CAD drawing.

Hi nikmartin,

Post #550: "...One small anomaly from the original CAD 2d drawing in post #1 is panel A seems to be dimensioned wrong. The dimension line at the intersection of A&B is wrong, making the panel dimension about 8 mm off. Not sure it matters."

Here is a pdf w/ the last status of the drawing and dimensions; I changed the upper dimension reference point for panel 'A'. I agree small differences should not matter (see: note as to depth), except in the S2 area.

Please, let me know if there is something else that needs to be changed.

Regards,

Hi nikmartin,

Post #550: "...One small anomaly from the original CAD 2d drawing in post #1 is panel A seems to be dimensioned wrong. The dimension line at the intersection of A&B is wrong, making the panel dimension about 8 mm off. Not sure it matters."

Here is a pdf w/ the last status of the drawing and dimensions; I changed the upper dimension reference point for panel 'A'. I agree small differences should not matter (see: note as to depth), except in the S2 area.

Please, let me know if there is something else that needs to be changed.

Regards,

Attachments

Hi nikmartin,

Here is a PDF w/ the last status of the drawing and dimensions; I changed the upper dimension reference point for panel 'A'. I agree small differences should not matter (see: note as to depth), except in the S2 area.

Regards,

Awesome, thank you! That's a much cleaner CAD drawing with more detail. I wish there was a way to get mRgSr to update post #1 with your version and my cutlist.

Attached is an updated and a bit simpler cutlist. If anyone wants a 4x8 sheet cutlist, let me know. Personally, I'm building 2 PAL12s for my DJ business and have a cutlist using 3 sheets of 4'x8'x3/4" BB and the cutlist is quite efficient that way.

Attachments

Last edited:

Hi nikmartin,

Here is a pdf w/ the last status of the drawing and dimensions; I changed the upper dimension reference point for panel 'A'. I agree small differences should not matter (see: note as to depth), except in the S2 area.

Please, let me know if there is something else that needs to be changed.

Regards,

Would it be possible to post the DXF?

Hi nikmartin,

P.S.: I'm interested in the 4'x8' cut list.

Attachments

Here's my build:

PAL12 Build - Album on Imgur

Used an Eminence LAB12C, and it sounds great! Managed by a Behringer DCX2496 and powered by an iNuke 3000 bridged 4 ohm mono. When I build the second, and run it unbridged mono since the iNuke will do 2 ohms, but it's not a huge fan of 2ohm loads.

PAL12 Build - Album on Imgur

Used an Eminence LAB12C, and it sounds great! Managed by a Behringer DCX2496 and powered by an iNuke 3000 bridged 4 ohm mono. When I build the second, and run it unbridged mono since the iNuke will do 2 ohms, but it's not a huge fan of 2ohm loads.

In my experience the iNukes are plenty happy to do low (2ohm) loads, unlike a lot of Class AB amps which can overheat.the iNuke will do 2 ohms, but it's not a huge fan of 2ohm loads.

This is what I have seen and my presumption of what happens:

Low impedance loads allow the amplifier section to try to put out more power than the power supply section can feed into it when the gain and signal are sufficiently high. This can cause the amp to go into protect mode.

On higher impedance loads the output stage clips before the power supply hits its limits.

Behold: The Beatsie Boys

Here's my finished pair. I'm a DJ, and these are paired with a set of powered tops, controlled by a Behringer DCX2496, and powered by a Behringer iNuke 3000 configured as 4 ohm mono. I have a 32 Hz high pass 48db BW filter, and a 110 Hz 18db BW low pass, sending the rest up to the tops. It sounds great, but the 3" polyurethane wheels rattle when the bass hits, so I have a pair of bungee cords to wrap around them when playing. I had a naming contest on Facebook, and so far "The Beatsie Boys" are in the lead.

One cool part about these subs is with them paired together configured as L-C-R, they are the perfect height to serve as my DJ console! Not sure my laptop HD will be pleased with all the shaking though.

Here's my finished pair. I'm a DJ, and these are paired with a set of powered tops, controlled by a Behringer DCX2496, and powered by a Behringer iNuke 3000 configured as 4 ohm mono. I have a 32 Hz high pass 48db BW filter, and a 110 Hz 18db BW low pass, sending the rest up to the tops. It sounds great, but the 3" polyurethane wheels rattle when the bass hits, so I have a pair of bungee cords to wrap around them when playing. I had a naming contest on Facebook, and so far "The Beatsie Boys" are in the lead.

One cool part about these subs is with them paired together configured as L-C-R, they are the perfect height to serve as my DJ console! Not sure my laptop HD will be pleased with all the shaking though.

An externally hosted image should be here but it was not working when we last tested it.

Attachments

- Home

- Loudspeakers

- Subwoofers

- $325 Lab 12 based PA tapped horn ~ 35Hz extension