The shown pcb allows to use RECOM RAC02, RAC03, RAC04 or RAC10 series.

I will try both variants during measurements to test for added noise levels...

Should be interesting. Mark Johnson had started a thread regarding small low-leakage transformers for use in an "auxiliary supply" for a power amp. I had asked why he wouldn't consider such RECOM parts for the job and he had replied that he would not consider them due to EMI. Maybe such an aux PSU needs to be well-shielded from the east of the amp. (Even if so, you know I like the idea of just one small aux PSU powering the MCU, output relays and such rather than a bunch of them in an amp.)

Should be interesting. Mark Johnson had started a thread regarding small low-leakage transformers for use in an "auxiliary supply" for a power amp. I had asked why he wouldn't consider such RECOM parts for the job and he had replied that he would not consider them due to EMI. Maybe such an aux PSU needs to be well-shielded from the east of the amp. (Even if so, you know I like the idea of just one small aux PSU powering the MCU, output relays and such rather than a bunch of them in an amp.)

If I want a low leakage transformer (for preamps), I use 400V transformers. 400/2x24V is ok to use for +/-12V regulated PSU.

Sajti

The RECOM parts have ultra low EMI.

Only one small power supply is needed for the MCU board and is well shielded inside an iron "wall".

Only one small power supply is needed for the MCU board and is well shielded inside an iron "wall".

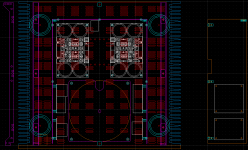

SA2015 4 channel VMOS - case layout

CAD top view.

All needed metal parts are now in production. Will take some weeks to get them all. Laser/CNC cutting, powder coating, anodizing...

CAD top view.

- red colored: bottom 2.5mm stainless steel plate with ventilation slots.

All needed metal parts are now in production. Will take some weeks to get them all. Laser/CNC cutting, powder coating, anodizing...

Attachments

The RECOM parts have ultra low EMI.

Only one small power supply is needed for the MCU board and is well shielded inside an iron "wall".

Are you using my SMD and modified version of your MCU so that only one supply is needed? (MCU controls onward delivery of power to output relays etc)

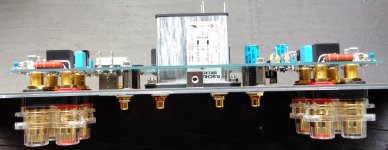

... backpanel assembled.

Have fun , Toni

The amp is looking great so far! It's nice to see a chassis that is properly designed for an amplifier not a big box with parts stuffed into it.

Nice. Why the stainless steel second layer?

The answer is in #2438.

Best regards!

Nice. Why the stainless steel second layer?

Toni mentioned in an earlier post he preferred the double panel to conceal hardware. I mill my rear panels from 1/2" aluminum bar stock and use blind holes to do the same. The laser cut panels are a lot less work though.

Ah I see. A lot of expense to hide some M3 screws but very professional looking. And I thought I was fussy! I have just had a lot of them countersunk so the screws I don't want to be prominent at least sit flush.

Is the entire enclosure a custom build? I see you mentioned the heat sink and front panel mounting helpers are "universal". It wasn't clear to me that you meant they were purchased as is or designed by you and fabricated for you. I have spent a good while at times cursing the design and quality of Modu's case assembly fixings. Especially in a deeper enclosure where reaching the bottom and corner fixings is nearly impossible with anything installed inside the enclosure. I found myself resorting to J B Weld to bind nuts to their fixings so that the case could be assembled entirely from the outside and never did find a solution for the front panels.

Please show detailed pics of this as you proceed. Perhaps including a top down shot of the rear panel sandwich. I am intrigued how the outer layer will sit flush against the heat sinks given it appears from the photos that the inner layer is of the same dimensions.

Extraordinary attention to detail!

Please show detailed pics of this as you proceed. Perhaps including a top down shot of the rear panel sandwich. I am intrigued how the outer layer will sit flush against the heat sinks given it appears from the photos that the inner layer is of the same dimensions.

Extraordinary attention to detail!

Last edited:

Many thx!

All parts are designed and (c) by me using qcad. Only the anodized front panel is original modu. All other parts are manufactured using my dxf files by different vendors:

The main reason to design a completely new case variant:

I don't like the top and back panels being mounted above or overlapped over the heatsinks.

BR, Toni

All parts are designed and (c) by me using qcad. Only the anodized front panel is original modu. All other parts are manufactured using my dxf files by different vendors:

- heatsinks: cooltec.com

- heatsink cnc and anodizing: schaeffer-ag.de

- laser cutted stainless steel and iron parts: cutworks.com

- aluminium panels: schaeffer-ag.de

- powder coating for iron plates: wolfmair.at

The main reason to design a completely new case variant:

I don't like the top and back panels being mounted above or overlapped over the heatsinks.

BR, Toni

Last edited:

SA2015 - 4 channel VMOS

... more details from backpanel "sandwich" ...

... more details from backpanel "sandwich" ...

Attachments

Great work Toni!backpanel: higher resolution picture.

The dual back panel sandwich is a nice idea,especially when a lot of screws must be hidden.

Thx Jan and Thimios!

The backpanel "sandwich" is in sum 3mm thick and very stable. Of course you could do a 10 - 12mm thick aluminium backpanel and add blind holes to mount the parts. CNC milling the thick panel is more complex if you add those parts like I am using.(USB port; 3mm headphone socket; Schurter 230VAC EMI filter with fuses and switch ...) but of course would look also extremely professional.

The "sandwich" costs are moderat:

The 1.5mm aluminium backpanel cnc milled and printed in multicolor costs 80 EUR and the 1.5mm laser cutted stainless steel inner backpanel part costs about 30 EUR including shipping.

Have fun, Toni

The backpanel "sandwich" is in sum 3mm thick and very stable. Of course you could do a 10 - 12mm thick aluminium backpanel and add blind holes to mount the parts. CNC milling the thick panel is more complex if you add those parts like I am using.(USB port; 3mm headphone socket; Schurter 230VAC EMI filter with fuses and switch ...) but of course would look also extremely professional.

The "sandwich" costs are moderat:

The 1.5mm aluminium backpanel cnc milled and printed in multicolor costs 80 EUR and the 1.5mm laser cutted stainless steel inner backpanel part costs about 30 EUR including shipping.

Have fun, Toni

Last edited:

- Home

- Amplifiers

- Solid State

- 2stageEF high performance class AB power amp / 200W8R / 400W4R