Got a Technics RS-671US cassette deck running decently for a friend. All 4 belts replaced, cleaning of spindle/bushing, pots and switches, followed by speed & circuit adjustments. That thing is built like a tank...so much steel. Cool front loading deck.

A Peavey Bass Top Mark III from 1978 was on my bench.

It produced a loud annoying buzz - mhm -

generally this is no good sign as probably this indicates burned power transistors.

So I checked these with a DVM without finding any suspects.

This amp is a quasi-complementary BJT class ab-amp

fitted with motorola transistors with custom markings,

so there is very little chance to find replacements nowadays.

Next I powered it up using the bulb tester, which did not show a full short circuit.

But looking at the supplies the neg rail sagged extremely,

so I had a look at the bulk capacitor 5000uF/55V.

The tester read 93,55nF!

Although the pos cap looked fine, I replaced both -

and - success!

Btw I found it remarkable to learn that this baby already had a built-in limiter.

It produced a loud annoying buzz - mhm -

generally this is no good sign as probably this indicates burned power transistors.

So I checked these with a DVM without finding any suspects.

This amp is a quasi-complementary BJT class ab-amp

fitted with motorola transistors with custom markings,

so there is very little chance to find replacements nowadays.

Next I powered it up using the bulb tester, which did not show a full short circuit.

But looking at the supplies the neg rail sagged extremely,

so I had a look at the bulk capacitor 5000uF/55V.

The tester read 93,55nF!

Although the pos cap looked fine, I replaced both -

and - success!

Btw I found it remarkable to learn that this baby already had a built-in limiter.

Last edited:

One can generally just put in ON MJ15024’s in place of Je ne sais quoi NPN outputs for amplifiers of that vintage, as long as doping out the circuit doesn’t reveal that they are darlingtons (which would be unusual for Peavey). So there would have been recourse. But if the caps are bad, the caps are bad. Back then stuff was designed to be fixed, and not to cascade fail and take half the circuit board out in a flameball.

It’s not really a built in limiter, is what the power supply does when there isn’t enough capacitance. Whats remarkable is that the amp was still well behaved with only one supply dropping. That can often result in latch up and send the opposite DC to the speaker.

It’s not really a built in limiter, is what the power supply does when there isn’t enough capacitance. Whats remarkable is that the amp was still well behaved with only one supply dropping. That can often result in latch up and send the opposite DC to the speaker.

thank you for the kind comment, meanwhile I measured full output just into clipping, and yes, no limiter is in between.

Indeed this old stuff looks quite robust and repair-friendly.

Indeed this old stuff looks quite robust and repair-friendly.

Long update to the Mora clock project

Having cleaned up the exterior of the Swedish Mora Clock I bought my wife and given it to her (she loves it by the way).

I could then do a full clean of movement and re-oil with the right stuff.

Cleaning was done with switch/contact cleaning fluid on cotton buds to remove old gunk in the bearings.

Then filling the bearing pots with the right grade oil, that just sits there, even when the movement is vertical.

I had to raise and fix down the mechanism and set the face to the right height.

The movement is the same (pretty crude, but effective) one I've seen on many Mora clocks of this age.

Right down to the wooden weight pulleys and crude mounting board.

The face however looks suitably rustic but the holes would never quite line up with the movement's winders.

Probably come from somewhere/thing else?

I made some brass ferrules to sort that out. Aged the brass with a blow torch.

The clock runs fine.

The two chime bells were sitting ontop of each other so the strikers only made one dull sound.

Should be a distinct 2 pling chime, not a bim-bam.

I'm currently playing with different weights as the over that came with it (cast iron) seem excessively heavy!

6kgs for the chimes and 6.8 for the time movement.

Heavy heavy fuel

The chimes run too fast on 6 kgs.

I'm testing at 4kgs.

2kgs was too light to always activate the mech and when it did, too slow🙂

4 seems about right and runs reliably.

The time movement seems fine on the 6kgs weight.

It would stop on 3, 3.5, 4 and 5kgs!

Not sure they are supposed to be this heavy?

Plenty of different weights at all manner of kgs on the internet.

I also made a winder from one my dad had kept but with the right size square, machined in

Quite a fun hobby clock tinkering.

Having cleaned up the exterior of the Swedish Mora Clock I bought my wife and given it to her (she loves it by the way).

I could then do a full clean of movement and re-oil with the right stuff.

Cleaning was done with switch/contact cleaning fluid on cotton buds to remove old gunk in the bearings.

Then filling the bearing pots with the right grade oil, that just sits there, even when the movement is vertical.

I had to raise and fix down the mechanism and set the face to the right height.

The movement is the same (pretty crude, but effective) one I've seen on many Mora clocks of this age.

Right down to the wooden weight pulleys and crude mounting board.

The face however looks suitably rustic but the holes would never quite line up with the movement's winders.

Probably come from somewhere/thing else?

I made some brass ferrules to sort that out. Aged the brass with a blow torch.

The clock runs fine.

The two chime bells were sitting ontop of each other so the strikers only made one dull sound.

Should be a distinct 2 pling chime, not a bim-bam.

I'm currently playing with different weights as the over that came with it (cast iron) seem excessively heavy!

6kgs for the chimes and 6.8 for the time movement.

Heavy heavy fuel

The chimes run too fast on 6 kgs.

I'm testing at 4kgs.

2kgs was too light to always activate the mech and when it did, too slow🙂

4 seems about right and runs reliably.

The time movement seems fine on the 6kgs weight.

It would stop on 3, 3.5, 4 and 5kgs!

Not sure they are supposed to be this heavy?

Plenty of different weights at all manner of kgs on the internet.

I also made a winder from one my dad had kept but with the right size square, machined in

Quite a fun hobby clock tinkering.

"New" McIntosh MC245 power amp reservoir cap repair : better here or in

https://www.diyaudio.com/community/threads/mcintosh-rubycon.413119/ ?

https://www.diyaudio.com/community/threads/mcintosh-rubycon.413119/ ?

My homebuilt tube buffer ( fm1 ) sometimes dropped sound in one channel. It could be cured by tapping

or disconnecting/connecting some of the RCA connectors.

Eventually i decided to fix this. Using coolspray gave nothing. I had problem reproducing the problem but later it

happened that i lifted a corener of the chassies on the workbench i could ( sometimes) provoke the problem.

Looking at solder gave nothing. Then i decided to replace old carbon-comp resistors, they can "break". No cure,

problem remained. Then i started substitute capacitors ( they also can loose internal contact). THEN i notised

the problem, one cap was unsatifactory soldered by me 15 years ago. Anyway i replaced it and reassebled the

unit.

I considered myself a competent solderer. How wrong i was !

or disconnecting/connecting some of the RCA connectors.

Eventually i decided to fix this. Using coolspray gave nothing. I had problem reproducing the problem but later it

happened that i lifted a corener of the chassies on the workbench i could ( sometimes) provoke the problem.

Looking at solder gave nothing. Then i decided to replace old carbon-comp resistors, they can "break". No cure,

problem remained. Then i started substitute capacitors ( they also can loose internal contact). THEN i notised

the problem, one cap was unsatifactory soldered by me 15 years ago. Anyway i replaced it and reassebled the

unit.

I considered myself a competent solderer. How wrong i was !

Try to watch a BluRay disk last week, and surprise my Oppo BDP-83 player was dead, indicating 'NO DISC' error. I tried a normal CD, same error. Since BluRay and normal CD use two different laser led, and that this player was lightly used (and plugged into a good Monster Cable Power Bar with Surge protection), I thought it has something to do with the mechanism.

Today opened the unit, same error with both CD types, checked supplies, are were ok, no sign of burn parts. I can see that the CD is not spining, no wonder it doesn't see the CD!

Removed the CD mechanism and opened the top cover. Tried to move th laser head on its rails, bingo was almost stucked in place, difficult to move. Clean the rails and applied a tin film of light oil (from my old stock), exercised the head back and forth a few time, now it was moving free.

Re-assembled and inserted a CD, no problem it worked! Tried a BluRay CD, it worked too. Player repaired and good for an other few years of service.

Again it was a case of dead cd player with not enough use, always play a disk in your player one a week minimum to prevent this premature death.

SB

Today opened the unit, same error with both CD types, checked supplies, are were ok, no sign of burn parts. I can see that the CD is not spining, no wonder it doesn't see the CD!

Removed the CD mechanism and opened the top cover. Tried to move th laser head on its rails, bingo was almost stucked in place, difficult to move. Clean the rails and applied a tin film of light oil (from my old stock), exercised the head back and forth a few time, now it was moving free.

Re-assembled and inserted a CD, no problem it worked! Tried a BluRay CD, it worked too. Player repaired and good for an other few years of service.

Again it was a case of dead cd player with not enough use, always play a disk in your player one a week minimum to prevent this premature death.

SB

Good point as my oppo 203 doesn’t get much use these days in my HT. I used to rent a Blu-ray every week for years

On end thru Redbox, but now their bankrupt and everything is streaming now, but without the superior uncompressed video quality of a bluray

Disc. And they are starting to disappear also, alas…

Didn’t really care for the audio quality of cd on the 203 for whatever reason, but the video side is stellar

On end thru Redbox, but now their bankrupt and everything is streaming now, but without the superior uncompressed video quality of a bluray

Disc. And they are starting to disappear also, alas…

Didn’t really care for the audio quality of cd on the 203 for whatever reason, but the video side is stellar

Last edited:

Model Trains O gauge repairs... A small "Le Rapide" locomotive from 1935 :

T

T

Quite a fun hobby clock tinkering.

Yes, like you @Speedysteve7 : I ventured in the clock field too, and a gift for my wife also 😎... Oh, that's 27 years ago now ! She still doing fine... Since 1880 🤔 - the clock, I mean. And my wife too, of course ! 🤣

OK - not my last repair, that's true... 😉

T

Eventually i decided to fix this. .

THEN i noticed

the problem, one cap was unsatisfactory soldered by me 15 years ago.

You are a legend! 15 years spent tapping and bending and cool-spraying to make it work 'for now'Anyway i replaced it and reassembled the

unit.

I considered myself a competent solderer. How wrong i was !

That's dedication to the end and not the means..!! 🙂

You enjoyed the music all that time. Well done you.

Model Trains O gauge repairs... A small "Le Rapide" locomotive from 1935 :

T

I watched Superman Returns for the millionth time a couple days ago. Ultimate train set in that movie.

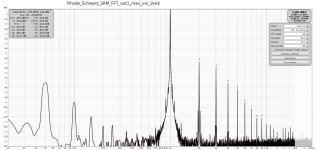

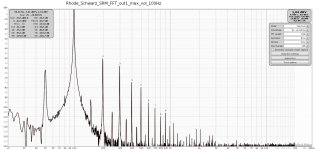

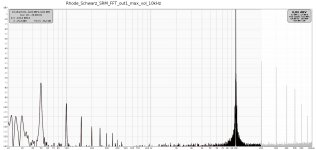

A customer brought in a Rhode&Schwarz signal generator with a cut mains cable.

So I replaced that cable, made adapters for the old fashioned PL- outputs, and voilà -

it works. I should mention that

-this is a bulb regulated wein bridge

-frequency range from 30Hz ~ 300kHz

-no electrolytics, even the main bulk caps arel film capacitors

-surprisingly precise frequency

-introduced 1951

All in all a fine old instrument in a mint condtion,

I suppose this apparatus has been decommisioned routinely because of age.

So I replaced that cable, made adapters for the old fashioned PL- outputs, and voilà -

it works. I should mention that

-this is a bulb regulated wein bridge

-frequency range from 30Hz ~ 300kHz

-no electrolytics, even the main bulk caps arel film capacitors

-surprisingly precise frequency

-introduced 1951

All in all a fine old instrument in a mint condtion,

I suppose this apparatus has been decommisioned routinely because of age.

Attachments

-

IMG_20240718_004206884.jpg123.2 KB · Views: 63

IMG_20240718_004206884.jpg123.2 KB · Views: 63 -

IMG_20240718_004524016.jpg62.7 KB · Views: 61

IMG_20240718_004524016.jpg62.7 KB · Views: 61 -

IMG_20240717_215654211.jpg90.4 KB · Views: 63

IMG_20240717_215654211.jpg90.4 KB · Views: 63 -

Rhode_Schwarz_SRM_FFT_out1_max_vol_1kHz.jpg367.1 KB · Views: 60

Rhode_Schwarz_SRM_FFT_out1_max_vol_1kHz.jpg367.1 KB · Views: 60 -

Rhode_Schwarz_SRM_FFT_out1_max_vol_100Hz.jpg369.2 KB · Views: 57

Rhode_Schwarz_SRM_FFT_out1_max_vol_100Hz.jpg369.2 KB · Views: 57 -

Rhode_Schwarz_SRM_FFT_out1_max_vol_10kHz.jpg316.6 KB · Views: 61

Rhode_Schwarz_SRM_FFT_out1_max_vol_10kHz.jpg316.6 KB · Views: 61

-surprisingly precise frequency

Wien bridges are of an amazing precision and stability when properly set up ! They are not counter, but resonators.

My (French Army) FERISOL C901 15Hz-150kHz tube Audio Generator from 1953 stays at 1000.0Hz over continous operation during 24Hours...

T

I replaced the bouncy switches in two computer mice with Omron D2FC-F-7N(60M). The original switches wore out in seven years. I am hoping these will last longer.

Ed

Ed

Been developing a model railway dcc controller.

I only had one Hornby loco to test it with but managed to get the software working right.

Or so I thought.

I bought a ESU lok pilot decoder based loco and I couldnt set the loco address.

Turned out I had been sending 0,0,0,0 data to put it in program mode.

I should have been sending 0,0,0.

The same loco always caused an overload when programming its ID.

It was taking a lot of current.

So had to increrase time constant on overload input.

Next problem was read control variables.

Hornby worked fine but ESU didnt.

The ESU wants you to send more than one read cv command before it gives up its data.

These are the joys of working with many different loco manufacturers who all interpret spec differently.

Add to that errors in the spec. The read cv starts with 0xe0 in one spec pdf and 0x70 in another spec !

I only had one Hornby loco to test it with but managed to get the software working right.

Or so I thought.

I bought a ESU lok pilot decoder based loco and I couldnt set the loco address.

Turned out I had been sending 0,0,0,0 data to put it in program mode.

I should have been sending 0,0,0.

The same loco always caused an overload when programming its ID.

It was taking a lot of current.

So had to increrase time constant on overload input.

Next problem was read control variables.

Hornby worked fine but ESU didnt.

The ESU wants you to send more than one read cv command before it gives up its data.

These are the joys of working with many different loco manufacturers who all interpret spec differently.

Add to that errors in the spec. The read cv starts with 0xe0 in one spec pdf and 0x70 in another spec !

Found an oak floor under a fake wood floor in my kitchen. The new floor was installed for a reason, but the damage on the oak was 2 m2, so I decided to repair. Not cheap but worth it. Real oak is just so much more satisfying.

- Home

- Member Areas

- The Lounge

- What did you last repair?