It's absolutely not a difference in semantics.Please don't get too hung up on semantic discussions. 🙂

I suspect you are discussing without agreeing on the definition of terms.

It's fundamentally different things and mostly just lack of understand fundamentals.

There is a fundamental difference if things cause interference problems by baffle edges (= diffraction) or if a source is a full sphere or semi sphere.

We are not even talking about how insanely complicated such inference interaction between multiple points gets (= non-linear).

Which is extremely important to understand to tackle and understand such problems.

For example, you can't EQ diffraction problems since it's a function of the angle to the source, but you can EQ the difference in spherical radiation.

This concept is also extremely important when measuring things, in particular for a Klippel NFS system.

In fact, there is not one single FEM/BEM approach till this day simulating and predicting these insanely complex diffraction problems combined.

I know that a lot of people all stick this under the same umbrella.

I guess from now on we might as well just mix up current and voltage?

It would be a lot more respectful and professional when people ACTUALLY came up with arguments.

(btw, zero offense to you stv! 🙂 )

I came across an interesting video using pvc tubes and 3D printed parts for a motion system.

The curved camera gantry that was shown in one part of the video got me thinking on a mechanism to make spherical measurements like Weinrich did.

I gotta get one of these glorified hot glue guns. They are actually getting rather useful. And reasonably fast with reasonable quality products.

Ok, so the full measurement routine would look something like this:

fs = 44100; % sample rate s = mataa_signal_generator ('sweep', fs, 0.2, [50 20000]); % test signal r = [1,2]; % radii of inner and outer sphere theta = [-180:10:180]; % theta angle phi = [-180:10:180]; % phi angLE h = []; % init empty data matrix for rr = r for tt = theta for pp = phi system (<gcode cmd rr tt pp>); % move microphone to (rr,tt,pp) coordinate h = [ h ; mataa_measure_IR (s, fs, ... ) ]; % measure impulse response and add to data matrix end end end

I basically did the above (2D, no actual audio measuring yet). Nothing fancy, just to give you guys an update.

I am having trouble finding the lazy susan bearing ( properly called a slewing bearing ) with a gear in North America. So, it's either a long belt around the exterior with tensioner pulley best to be spring loaded to provide a constant grip on the exterior of the bearing. Or I find the same slewing bearing. I have an existing bearing in Aluminum.

https://www.hafele.ca/en/product/tu...-360-load-bearing-capacity-300-kg/P-00898133/

I may be able to but from Haafele.

Cabinetmaking supplies I do have connections with, one of which is a distributor for Haafele.

https://www.hafele.ca/en/product/tu...-360-load-bearing-capacity-300-kg/P-00898133/

I may be able to but from Haafele.

Cabinetmaking supplies I do have connections with, one of which is a distributor for Haafele.

This might help:So, it's either a long belt around the exterior with tensioner pulley best to be spring loaded to provide a constant grip on the exterior of the bearing.

https://github.com/MGX3D/Turntable/tree/master?tab=readme-ov-file

Yeah! Thanks Tom. I already have a bearing. 20 inch actually. Bought it about 6 years ago. This has been on the back burner for a long time. I do measure some larger speakers so I like the concept, and the instructions, but this will need some adaptations.This might help:

Thanks for the link. It is adding more things to consider and refine.

I just got the Hafele version, it is functionally equivalent. I bought the silver one in your link. These are good for spinning the speaker. If the speaker is stationary on a pole and the mic is spinning I don't think these slewing bearings make as much sense. You can buy GT2 or XL timing belt pulleys with a good number of teeth to have some gearing. Ordinary lazy susan bearings or two sheets of melamine faced board or form ply can be used as the rotating surface.I am having trouble finding the lazy susan bearing ( properly called a slewing bearing ) with a gear in North America.

I built my original GT2 gear to spin around a central pole by putting a 1" bearing in it, using one of those fancy hot glue gun machines 🙂

Yeah

I'm still tied up in the shop with counter tops. But I will be making some pics and videos shortly hoping to get something going.

Stationary speaker. I still have the rotate the speaker brain fart. So a 1 inch 25.4mm I.D. bearing. You plan on using a pipe to pass the wiring through, probably a platform and 3 decent sized contact points to allow the wires to fit under the loudspeaker cabinet and pass through the pipe.I just got the Hafele version, it is functionally equivalent. I bought the silver one in your link. These are good for spinning the speaker. If the speaker is stationary on a pole and the mic is spinning I don't think these slewing bearings make as much sense. You can buy GT2 or XL timing belt pulleys with a good number of teeth to have some gearing. Ordinary lazy susan bearings or two sheets of melamine faced board or form ply can be used as the rotating surface.

I built my original GT2 gear to spin around a central pole by putting a 1" bearing in it, using one of those fancy hot glue gun machines 🙂

I'm still tied up in the shop with counter tops. But I will be making some pics and videos shortly hoping to get something going.

The 1" bearing was what I used because I had some 1" pipe and the bearing was available at the local hardware store. This was still designed for spinning the speaker.

I don't think the 1" pipe would be strong enough to cover all speaker types when it is a metre long or more. I was looking at 30mm alu pipe with a 3mm wall thickness or 50mm pipe the same. For those I would look at 4 bolt flange bearings like these

https://www.skf.com/au/products/mounted-bearings/ball-bearing-units/flanged-ball-bearing-units

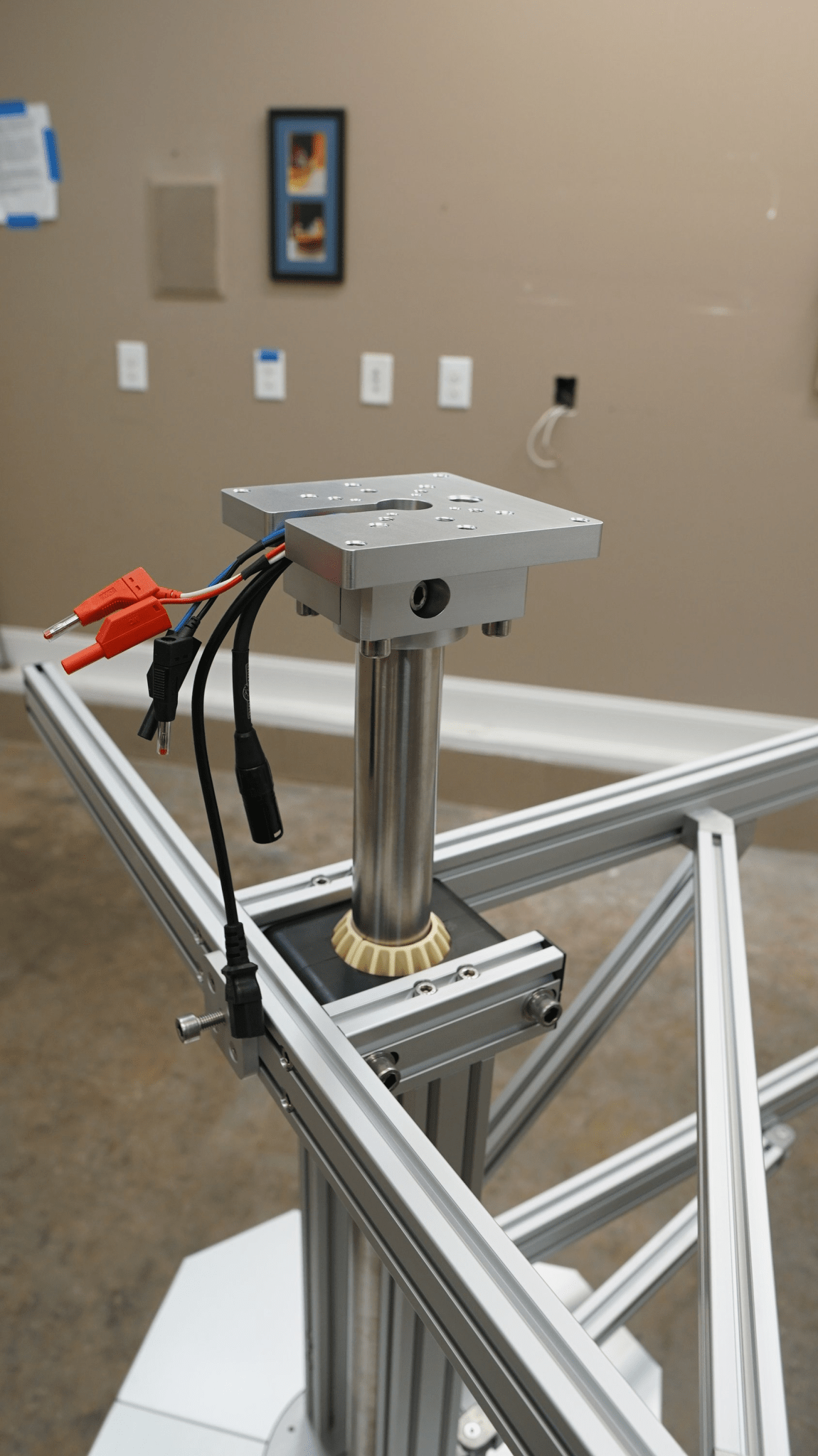

Klippel looks like they have some sort of plastic bushing

I don't think the 1" pipe would be strong enough to cover all speaker types when it is a metre long or more. I was looking at 30mm alu pipe with a 3mm wall thickness or 50mm pipe the same. For those I would look at 4 bolt flange bearings like these

https://www.skf.com/au/products/mounted-bearings/ball-bearing-units/flanged-ball-bearing-units

Klippel looks like they have some sort of plastic bushing

I designed loudspeaker stands almost exactly like this in the late 80's. My first commercial work. It's a great way to allow wires to pass through unobstructed to binding posts on the loudspeaker under test.

Yes that is a bushing. Probably from IGUS. Your flanged bearing idea is a good one. If you go that route you need upper and lower bearings. Otherwise you will have a very wobbly setup for the moving mic. There are a number of ways to make this work. PVC pipe, American schedule 80 is thick enough to support considerable weight when it is in a 50 or 75mm diameter. There are readily available flanges for toilet mounting that are robust enough to fasten the bottom of the pipe and allow a large enough platform for the DUT. This could serve easily as the central post to mount the loudspeaker and allow easy access for the cables. 75mm pipe is not that expensive. And lastly the pipe and the fittings are not expensive. With PVC you have pipe easily cut with common wood working equipment. And another trick is possible. Run steam through the pipe and you will soften it enough to bend it. Another way is to use a hot air gun. This will allow an easily made curved mic arm. Our mic arm can be attached to our Slewing bearing. I think that the key for us keeping this open source is ease of manufacture. I'll get this together soon and make some mock ups. Our base needs to be wide enough to provide a stable foundation to the test structure with a high centre of gravity. So the use of concrete pavers as a ballast may be an idea. Or simply a half sheet of material of choice.

Now cable management. That is something that i have not thought about. Listening to all of the Klippel tester videos there are multiple hours required for the tests. Some claiming 8 to 12 hours. Allowing mic cable to have freedom of 360 degree movement is going to maybe require a rotary slip ring and brush contact? Like on a alternator, or starter? Maybe someone has a simpler idea, but I am thinking thin PCB with thick tracks and some brushes wrapped around the circumference of the pipe, making the contact for the three wires of the mic cable.

That hotglue gun is really talking to me. Hmmmm. I know Bamboolab has some competition now. And even they are not atrociously expensive. I would just like a larger capacity.

Yes that is a bushing. Probably from IGUS. Your flanged bearing idea is a good one. If you go that route you need upper and lower bearings. Otherwise you will have a very wobbly setup for the moving mic. There are a number of ways to make this work. PVC pipe, American schedule 80 is thick enough to support considerable weight when it is in a 50 or 75mm diameter. There are readily available flanges for toilet mounting that are robust enough to fasten the bottom of the pipe and allow a large enough platform for the DUT. This could serve easily as the central post to mount the loudspeaker and allow easy access for the cables. 75mm pipe is not that expensive. And lastly the pipe and the fittings are not expensive. With PVC you have pipe easily cut with common wood working equipment. And another trick is possible. Run steam through the pipe and you will soften it enough to bend it. Another way is to use a hot air gun. This will allow an easily made curved mic arm. Our mic arm can be attached to our Slewing bearing. I think that the key for us keeping this open source is ease of manufacture. I'll get this together soon and make some mock ups. Our base needs to be wide enough to provide a stable foundation to the test structure with a high centre of gravity. So the use of concrete pavers as a ballast may be an idea. Or simply a half sheet of material of choice.

Now cable management. That is something that i have not thought about. Listening to all of the Klippel tester videos there are multiple hours required for the tests. Some claiming 8 to 12 hours. Allowing mic cable to have freedom of 360 degree movement is going to maybe require a rotary slip ring and brush contact? Like on a alternator, or starter? Maybe someone has a simpler idea, but I am thinking thin PCB with thick tracks and some brushes wrapped around the circumference of the pipe, making the contact for the three wires of the mic cable.

That hotglue gun is really talking to me. Hmmmm. I know Bamboolab has some competition now. And even they are not atrociously expensive. I would just like a larger capacity.

Indeed. I like what Klippel have done by using the Extrusions to form a box around the central rod. The turn table and mic arm then connect to that box.Your flanged bearing idea is a good one. If you go that route you need upper and lower bearings. Otherwise you will have a very wobbly setup for the moving mic.

I bought a Creality K1 Max in the Black Friday sale for that same reason, the other option is the QIDI X-MAX. A guy I am doing some design work with just bought a P1S and is cranking out nice prints like no tomorrow.That hotglue gun is really talking to me. Hmmmm. I know Bamboolab has some competition now. And even they are not atrociously expensive. I would just like a larger capacity.

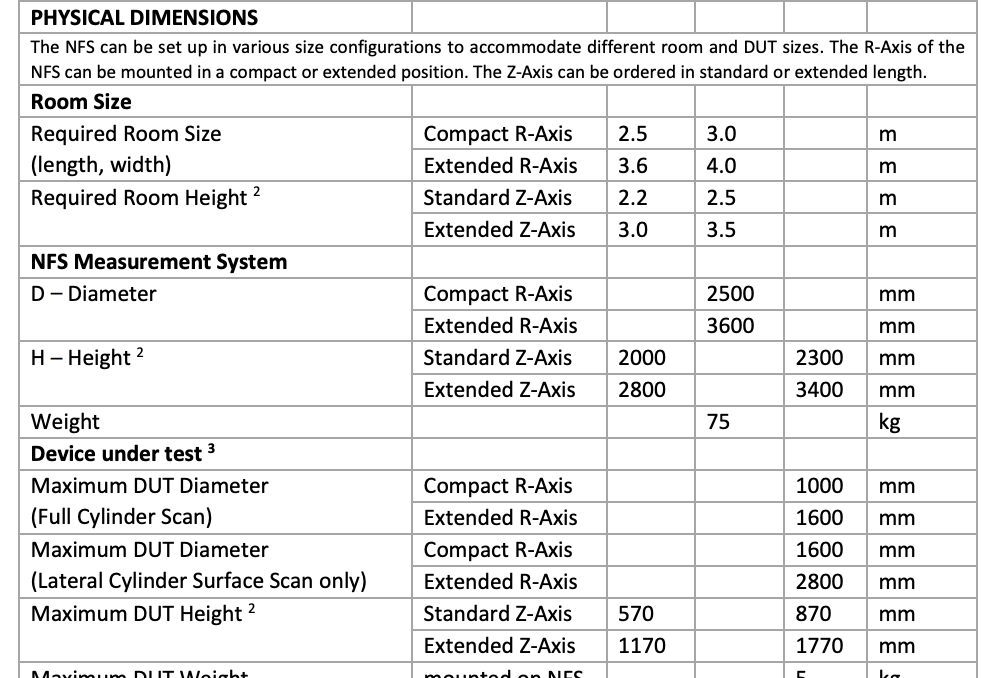

I am following this thread with interest, a question: would this scanner work in a room of size 4.5x3x2.4m ?

You would be limited on the size of speaker you could measure based on the furthest distance the arm can rotate.I am following this thread with interest, a question: would this scanner work in a room of size 4.5x3x2.4m ?

You can get a better idea from looking at Klippel's datasheet. The compact R axis would fit in that room and they give maximum dimensions for the speaker it can measure

https://www.klippel.de/fileadmin/kl...D_System/PDF/C8 Near Field Scanner System.pdf

https://www.klippel.de/fileadmin/kl...D_System/PDF/C8 Near Field Scanner System.pdf

- Home

- Design & Build

- Software Tools

- Klippel Near Field Scanner on a Shoestring