I would be in for this if the 4" was this: 4NDF34 LF Drivers - B&C Speakers

Yes....that would be very nice indeed. I thought about suggesting a co-entrant version as well but figured it's a hard sell for a small operation.

Maybe make just some flat parts that would allow 3D printed adapter and cutting a hole through the wall would be an option?

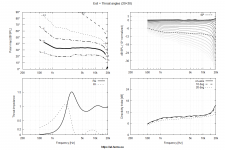

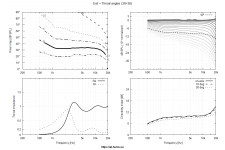

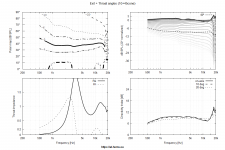

Sure -Marcel, can you show what a 10° exit on a 10° mouth does in your simulation? Just out of interest.

Attachments

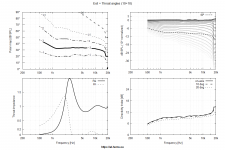

10° CD exit + 90° conical WG (k=0), i.e. with a sharp edge at the throat -

Attachments

Last edited:

As for the injection molded waveguides, I would like to make it from clear (UV stable) plastic. Probably as a two-part product to keep the mold simple, with a separate aluminum mounting flange. Should not the transparent look be preferred, painted from the back side it could make a high-gloss quality finish with minimum effort.

I'm going to start a crowdfunding project soon, somewhere.

I'm going to start a crowdfunding project soon, somewhere.

Last edited:

I'd rather have sand. Plastic is so 80's and it is not a stylish look (anymore).... sorry. But I suppose one can paint the rest of the wg.

//

//

Sand is not an option here, sorry.

- But as I've just learned, they can't make it in the required thickness and guarantee the quality, so probably this is the end of it anyway. I can't risk it to be too flimsy.

- But as I've just learned, they can't make it in the required thickness and guarantee the quality, so probably this is the end of it anyway. I can't risk it to be too flimsy.

Last edited:

I can still order the epoxy-coated sand prints, or make something of the CE series using this technology, but only locally (i.e. Czechia) as the shipping is quite a hassle - it's heavy and too brittle, I'm afraid. Too much work to pack it properly, not something I would be eager to do again.

If somebody living around here were willing to do it, I have no problem ordering these directly to him/her to ship it further.

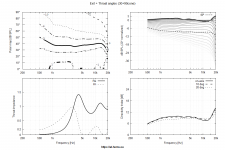

Measured SPL data: #7402

If somebody living around here were willing to do it, I have no problem ordering these directly to him/her to ship it further.

Measured SPL data: #7402

Attachments

Last edited:

I forgot one option - casting it from aluminum. Basically, the sand printing is primarily used for making molds for metal casting. So this is an option, I think the price was around 600 EUR/piece, i.e. a "rough" aluminum, 12 mm wall thickness. I could ship those, perhaps. 🙂

Products | MODELARNA LIAZ

Products | MODELARNA LIAZ

Last edited:

Probably it could be casted as two (thinner) aluminum pieces, put together as constrained layer damped (?).

If you go for a sandwich I suggest that you make the two alu layers a bit different in thickness. Then maybe fill it with expanding "build foam" from a long straw to start the expansion from the root to get a real proper fill.

Manufacturing is hard.

//

Manufacturing is hard.

//

I'm a bit surprised there haven't been that many reports form the sand horn receivers. Maybe it was only to you - are they happy? 🙂

//

//

Probably it could be casted as two (thinner) aluminum pieces, put together as constrained layer damped (?).

This would be ideal, but probably quite expensive. Once I had the mold, casting with polyurethane cost only about $50/each. These had between 1" and 4" of wall thickness (1" at mouth, 4" at mounting,) and with the glass fill were extremely dead.

I'm quite reluctant to buy an expensive mold to produce the waveguides manually by myself, that's something I don't feel like doing at the moment, honestly. So I just think about how to let it made in high enough quality so it wouldn't cost a fortune. There are really not many options I guess.

- Regarding vibrations and damping, I wonder how is the situation different when free standing (attached to a driver stand via the narrow end) compared to when mounted in a box, which can vibrate by itself in quite a complicated pattern. Is it supposed to be more critical or less critical when free standing?

- Regarding vibrations and damping, I wonder how is the situation different when free standing (attached to a driver stand via the narrow end) compared to when mounted in a box, which can vibrate by itself in quite a complicated pattern. Is it supposed to be more critical or less critical when free standing?

As far as I know they are quite happy 🙂 There are not many yet.I'm a bit surprised there haven't been that many reports form the sand horn receivers. Maybe it was only to you - are they happy? 🙂

//

More on this, what's actually the biggest source of mechanical vibrations and resonances in waveguides? I would think the vibrations from a compression driver itself are miniscule, not something to worry about. So is it the bass driver, causing vibrations on the surrounding objects? Is it then possible to isolate a free standing waveguide by a damped (or completely separated) mounting? This would by my intuition. Or is it the sound itself? Wouldn't be aluminum alone satisfactory, if heavy enough?- Regarding vibrations and damping, ...

Last edited:

As to the actual level of the vibrations in a waveguide itself, I don't have a feeling for how critical it is, so I just made them dead as that can never be the wrong thing to do.

Free standing will have lower resonances than in a box. It's like a cantilever and those are always lower frequency resonances than a clamped beam. How much of a difference this makes is unknown. Even free standing, I would clamp the mouth to something and damp the mounts on both ends.

Free standing will have lower resonances than in a box. It's like a cantilever and those are always lower frequency resonances than a clamped beam. How much of a difference this makes is unknown. Even free standing, I would clamp the mouth to something and damp the mounts on both ends.

I suppose the sheer energy moving the lower/higher pressure wave will start to suck/push the walls in the WG. Movements are not desirable. On the other hand, ringing is not so nice either...

//

//

It would be interesting to investigate how and how much does this contribute to the total sound radiation for different waveguide materials and their properties, when driven only by a sound wave at the throat. This would be a task for a FEM modeling I guess, which is out of my reach at the moment. My guess is that it would take an extremely flimsy device to have a substantial effect. Thin glass, maybe, I don't know - they do break with sound 🙂

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)