Mic distance ~ 1 m. I didn't measure the voltage. Don't look at the absolute SPL values, it's not calibrated (and probably even not comparable between the HF1440 and ND3T, as I probably I touched the level in the meantime).

- The Faital normalized to 10 deg (measured in the 7" test jig):

- The Faital normalized to 10 deg (measured in the 7" test jig):

Attachments

Last edited:

Last edited:

This is primarily for measuring higher modes in the exit wavefronts of the drivers. It can be very small for this purpose, as it's all HF stuff.

(Thinking about it, maybe I'll add a back cover.)

(Thinking about it, maybe I'll add a back cover.)

Well that depends more on its build volume than the price 😀Wonder how big I can get away with in a $2,000 printer....

Last edited:

I'm quite reluctant to buy an expensive mold to produce the waveguides manually by myself, that's something I don't feel like doing at the moment, honestly. So I just think about how to let it made in high enough quality so it wouldn't cost a fortune. There are really not many options I guess.

- Regarding vibrations and damping, I wonder how is the situation different when free standing (attached to a driver stand via the narrow end) compared to when mounted in a box, which can vibrate by itself in quite a complicated pattern. Is it supposed to be more critical or less critical when free standing?

To me it seems the easiest way to make these available is to just have people 3D print them.

I've had numerous people 3D print my waveguides, about as many as I sold myself.

If you'd like to be compensated for your designs I'd be happy to start a gofundme and contribute.

Cute lol.

Wonder how big I can get away with in a $2,000 printer....

It's funny, I've actually pivoted back to using small 3D printers.

I found that the big ones had more issues. I'm guessing that the larger print volumes create tolerance issues. IE, if you have an edge of the print that's curling up by 1% and the bed size is 200mm, that's less of a problem than if the bed size is 400mm.

I see. Maybe printing halves or sections might be the way to go for larger horn.

Like the throat up to a point, then print the rest in two halves.

Like the throat up to a point, then print the rest in two halves.

Here are the STL files for the test jig (WG + mounting set) for 1" drivers: https://at-horns.eu/ext/SWG25.zip

Mind you, the waveguide is design to be printed without any supports, in one piece as it is (some supports will be needed for the holder). I use it on a Hercules speaker stand. Any other mounting can be easily adapted and printed I guess.

I printed it all on Anycubic i3 Mega S without issues, both PLA and PETG.

Mind you, the waveguide is design to be printed without any supports, in one piece as it is (some supports will be needed for the holder). I use it on a Hercules speaker stand. Any other mounting can be easily adapted and printed I guess.

I printed it all on Anycubic i3 Mega S without issues, both PLA and PETG.

Attachments

Last edited:

It's funny, I've actually pivoted back to using small 3D printers.

I found that the big ones had more issues. I'm guessing that the larger print volumes create tolerance issues. IE, if you have an edge of the print that's curling up by 1% and the bed size is 200mm, that's less of a problem than if the bed size is 400mm.

Man, I should reach out locally. I have a decent large format 3D printer (Folgertech FT5) with a lot of aftermarket structural parts such as CNC aluminum components for the printer head, gantry, z-axis bed, etc. If someone could help me get it going I would be happy to run it stateside for diyaudio people wanting prints at cost.

Maybe I should visit you John. Are you in Vegas now? Last I checked you were in San Diego..

Last edited:

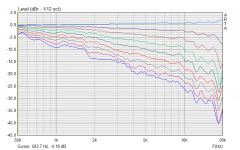

My first measurement of Faital HF1440 on the test jig (#7299). I think it will shine in a large waveguide. Measured SPL for the both pieces I have.

Mabat, did you ever consider the Eminence N314X compression driver? That’s what I was leaning towards until you mentioned your purchase of the FaitalPro HF1440 drivers.

You know, you could sell physical horns by handling the sending and printing to local print-houses. We pay you, you administer print locally, we collect... In this way you don't need to distribute the print files to the buyer and no duplication can be made (NDA with prinshop?) ... you could even place tiny unique watermark on each wg... and we save the transport cost. Everybody happy. Quite a lot of quotation job maybe....

//

//

Most of the print shops won't handle large prints. And if they do it's very expensive. The sand printing is actually pretty cheap compared to that, based on the quotations I had.

Hmm - yes... Do them in say 4 pieces with a sturdy way of assembling the parts and to be filled with gypsum/concrete/sand-epoxy by the user? Some sort of half-fabricate where maybe parts of the printed structure remains in the finished wg and some are to be removed and some very light finishing job on some spots remain...

These size parts might be possible to send to local shop...

//

These size parts might be possible to send to local shop...

//

My first measurement of Faital HF1440 on the test jig (#7299). I think it will shine in a large waveguide. Measured SPL for the both pieces I have.

Marcel, did you work out why the Faitals rung out so long at 800hz?

That just doesn't look right to me.

That's just tied to the amplitude response, i.e. there's simply a resonance somewhere inside the driver. After EQ it should not ring anymore but I don't know the exact cause and agree that it's not pretty.

Last edited:

Is it really possible to EQ a somewhat higher Q resonance to behave, in all aspects (phase, GD, impedance, dispersion etc etc), exactly as a system without that resonance - I doubt it but don't have any mathematical evidence 🙂

//

//

It is possible, as long as the system is linear and time invariant, which it is to a large degree. It's a common task in crossover design and it works quite well for an EQ like this, which is still not a particularly high Q, IMHO.

It doesn't affect dispersion. Phase, GD and amplitude response are really one and the same thing for a minimum phase system, which again it is - get one of those flat and all the other will be flat as well.

It doesn't affect dispersion. Phase, GD and amplitude response are really one and the same thing for a minimum phase system, which again it is - get one of those flat and all the other will be flat as well.

Last edited:

Resonance itself is still a perfectly linear phenomenon. Linear means that it does not depend on level and that a superposition principle works.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)