I haven't had such thoughts 🙂what were your thoughts on how to achieve stiffness of the baffle?

I think it's already good enough, actually. The baffle is pretty thick and can be printed really stiff, if desired. It's just a toy, this is not rocket science. Anyway, I'd be perfectly happy even with the (mostly hollow) PLA prototype.

Last edited:

What do you mean by toy, is it not intended to be used as a final speaker?

I know that a thin and resonant baffle made from plastic is commonly accepted with PA-type cabinets, but surprised to see it in a HiFi speaker.

I know that a thin and resonant baffle made from plastic is commonly accepted with PA-type cabinets, but surprised to see it in a HiFi speaker.

The overall thickness is 44 mm, which is really what makes it stiff. It's like holding a piece of wood, only much lighter. This is nothing like an injection molding, if that's what you mean by a "thin and resonant baffle made from plastic". Did you ever try to actually print anything?

Every loudspeaker is a toy, isn't it.

Every loudspeaker is a toy, isn't it.

Last edited:

I've been playing with a 5 inch wavguide idea.

keep in mind that (in particular with this WG size+ crossover frequency combination) it's essential to consider the whole baffle (speaker) to be part of the waveguide.but crossover will be around 2.1-2.5kHz or so.

a 5" driver will just start being directional at around 2 kHz, of course depending on the baffle shape.

I guess you can find lots of good waveguide examples for dome tweeters at www.somasonus.net

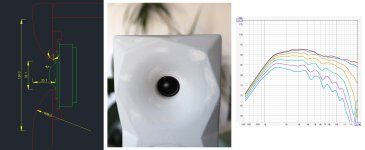

I can show my very rudimentary "hand carved" version:

the faceted "roundovers" are mostly for visual pleasure, but they optimize the directivity. roundovers would probably be even better.

EDIT: and never mind if you were asking for a CD waveguide!

Last edited:

You can always try to scale down the Tritonia XS even further (and make it a bit more open), but frankly I don't see the point. The smaller you make it, the more attention you will need to pay to the enclosure (edge roundings, etc.). The current XS has 120° nominal beamwidth, which seems just fine to me for that kind of design. It's not so easy to make it wider than that.

Yes, i am talking about a waveguide 🙂EDIT: and never mind if you were asking for a CD waveguide!

I’ve been fighting my printer lately. Sometimes it feels like more of a hassle than a convenience…

Do you think your horn flare would be beneficial for a midrange horn? I was going to try and build one with a b&c 8pe21 that would be crossed at 150. I was also thinking of trying to create a phase plug that resembles your spherical wavefront guide. Your opinion is appreciated.

Do you think your horn flare would be beneficial for a midrange horn? I was going to try and build one with a b&c 8pe21 that would be crossed at 150. I was also thinking of trying to create a phase plug that resembles your spherical wavefront guide. Your opinion is appreciated.

The basic understanding of horns always applies: a horn/waveguide going that low will be either inefficient or very big. Hence, "beneficial" is likely to require a large device. In which case, yes, it would be beneficial.Do you think your horn flare would be beneficial for a midrange horn? I was going to try and build one with a b&c 8pe21 that would be crossed at 150.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)