@mabat and I've got another question, too — does the driver’s dome emit a spherical wavefront (except in the top octave)? Could that be used with ATH waveguides?

For example, a phase plug on the back of the driver (instead of the back cover) with channels like the ones in your ESP design, but without the need for bends?

For example, a phase plug on the back of the driver (instead of the back cover) with channels like the ones in your ESP design, but without the need for bends?

It would be cool if a guy offered a combo deal on all the Tritonia waveguides 😉

Dont have a clue on why I got painted into this corner but Im printing a Crowe ES600 with 0.12 layers and 20% infill for a guy and it takes 2 days and 20 hours. Pr horn half. So 8 days for a pair of horns 😳I'd be reluctant to print anything above ~10 hours 🙂

I think the better way is first epoxy than bitumenI bet it'd get even deader if you were to paint on top of that with two-part epoxy... then again, I'm not sure how well it would stick to that black stuff.

For additional stiffness, probably. But plastic - bitumen - epoxy (if it all adhered properly) would be better for damping since it would give you CLD.

hey guys, been doing a tonne of reading here, super excited to start working on my own horns, big issue is ive been trying to get the latest version 4.7.0 of ATH, but looks like the download link has been broken for a while, i found 4.6.0 but it refuses to open on both my pc's

anyone have the latest they could link me?

Cheers!

anyone have the latest they could link me?

Cheers!

Those are not compatible parts, Oleg. When you asked if an ESP can be used with a constant directivity horn, I understood the question as general - yes, but it would need to be designed together. So, you can try anything but it's all unpredictable in this case.@mabat I decided to try a constant-directivity WG with 1,4 driver. So I already bought A460D and ESP, I want to combine them.

Am I correct that I can use one of the adapters for the 1“ driver (so, which one?) and connect the ESP to it at the throat level where the throat is 1.4”? If I want to increase the horn slightly (like 10-%) would I still connect the output of the ESP at that throat level where the throat would also be 1.4 inches?

Last edited:

That's exactly with what I started a long time ago, but never made anything actually usable. It was not as easy as it seemed at first -@mabat and I've got another question, too — does the driver’s dome emit a spherical wavefront (except in the top octave)? Could that be used with ATH waveguides?

For example, a phase plug on the back of the driver (instead of the back cover) with channels like the ones in your ESP design, but without the need for bends?

It would need two lifetimes to pursue all these ideas. Maybe more...

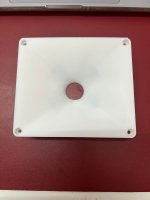

Hi, first time here. I've bought the Triotini_XS files for a DFM2535 build. The Horn has been printed, but I'm confused about choosing the flange type. I'm using FreecAD to view the files but can't make out how it fits.

Can someone help, please?

Can someone help, please?

Attachments

That was my plan for the summer, to try anything just for fun. I'm more than happy with the current sound, it just gets boring, and the printer starting to get dusty. 🙂 Besides, I wanted to buy something else to support your work with a couple cups of coffee!Those are not compatible parts, Oleg. When you asked if an ESP can be used with a constant directivity horn, I understood the question as general - yes, but it would need to be designed together. So, you can try anything but it's all unpredictable in this case.

And I'm certainly asking questions in general and realize that only devices fully developed as one unit work best. I don't really want to change my drivers, I like the way they sound, and I like low crossover better than perfect upper octave behavior. And I want to compare the difference in sound with constant directivity at least up to 8-10kHz. Even just a scaled device will allow to check it, I guess that's where I'll start.

Oh, I seem to have missed this post, or read earlier, forgot about it and reinvented the wheel once again 🙂That's exactly with what I started a long time ago,

The Horn has been printed, but I'm confused about choosing the flange type.

As the description says:

Compression driver mounting options with the provided flanges:

Flange type1:

- 4x M6 / ⌀76 mm

- 3x M6 / ⌀57 mm

- 2x M5 / ⌀57 mm

- 2x M3 / ⌀50 mm

Flange type2:

- 2xM4 / ⌀53 mm

There's also a "lower" version of the type1 flange, just in case that the tall flange would be too tight to fit into the thread (this is a bit difficult to control in advance with 3D printing). The lower one should fit more easily. At first I was a bit worried about the thread and the tolerances, but I think it turned out pretty well, I like this mounting method. You need a decent quality printer, of course, but that's already more a rule than exception these days.

Your prints look quite nice, BTW.

Last edited:

It would need two lifetimes to pursue all these ideas. Maybe more...

Geez, give the guy a break 😉. Mabat, you have done lot of amazing work here in a very short time. Amazing stuff. You should treat yourself and turn the notifications off for a few days.

Whenever there is diffraction there will be a reflection which can resonate back down the throat. This will yield coloration. The effect can often be seen in the electrical impedance as humps.Good off axis means that there is low diffraction (

Quite correct.(At least unless you cut holes in the walls and make additional resonance and diffraction chambers. Then I can no longer guarantee that quality.)

Hi Earl, nice to see you around. This reminds me one phenomenon which I haven't seen discussed anywhere: When measuring the electrical impedance I noticed that it is also affected by sound waves reaching the throat from the outside environment. This happens especially (virtually only?) with devices with an increased acoustic impedance (i.e. "long" horns) and mostly at midrange frequencies. I can imagine that such device then acts also as a sound collector/amplifier, modulating its impedance. Which can't be a good thing but I don't have a clue how significant it is. During playback in a room, there will be a lot of pretty loud sounds reaching the diaphragm, which are all correlated to the signal. What do you think? I can also imagine that you've never seen this in the impedances of your waveguides - they are not sensitive to this, as are not direct-radiating tweeters.Whenever there is diffraction there will be a reflection which can resonate back down the throat. This will yield coloration. The effect can often be seen in the electrical impedance as humps.

Here's a link with some data:

A460G2 / BMS 4554 (16 ohm), long adapter, electrical impedance.

What to take from this?

The "noise" between 700 Hz - 2.5 kHz is remarkably stable (averaging does nothing). It changes a little bit only with a different orientation of the waveguide relative to the environment. So this must be the driver picking up the sound field (?) and I guess the curve would be cleaner in an anechoic room.

Which leads me again to wonder how much is the impedance "modulated" by the picked-up signal of the reproduced sound field during playback. The driver acts as a microphone at the same...

What to take from this?

The "noise" between 700 Hz - 2.5 kHz is remarkably stable (averaging does nothing). It changes a little bit only with a different orientation of the waveguide relative to the environment. So this must be the driver picking up the sound field (?) and I guess the curve would be cleaner in an anechoic room.

Which leads me again to wonder how much is the impedance "modulated" by the picked-up signal of the reproduced sound field during playback. The driver acts as a microphone at the same...

Hello all,

I want to try a CP instead of dome and I can have a pair of 4550 second hand. I wanted to put it in a st260 (easy to print) but I'm not sure the exit angle is matching. Has any body finaly tried it ? (I went thru the thread with search function but I miss something).

I want to try a CP instead of dome and I can have a pair of 4550 second hand. I wanted to put it in a st260 (easy to print) but I'm not sure the exit angle is matching. Has any body finaly tried it ? (I went thru the thread with search function but I miss something).

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)