That's the rear chamber for the SB65 - I was going to make it based on the shape of a starfish to get 5 sealed tapered TL's to absorb the back wave radially vs straight back to keep the profile very flat.

Could you build a foam core labyrinth instead? Line one side with absorbing foam.

Could you build a foam core labyrinth instead? Line one side with absorbing foam.

I suppose a very small foam core Cornu TL would also work, where instead of the passages from the driver going out expand like a horn, they could contract to a point. That would work and would actually be faster than 3d printing it.

Sorry X, just me being impatient!

Funny enough I am probably going to go for the opposite aesthetic scheme to you with a mat black cabinet and a dark walnut veneered baffle.

I am hoping this will minimize the apparent size of the cabinet - I have some lovely black walnut veneer left over from a previous project. The walnut veneer will be a rectangle set back from the curved cabinet edge.

A little like this.

Funny enough I am probably going to go for the opposite aesthetic scheme to you with a mat black cabinet and a dark walnut veneered baffle.

I am hoping this will minimize the apparent size of the cabinet - I have some lovely black walnut veneer left over from a previous project. The walnut veneer will be a rectangle set back from the curved cabinet edge.

A little like this.

Attachments

Hi x. Those port adapter gaps cleaned up nicely. I really like the look of the mini injection ports. Perhaps paint the waveguide screws black for added stealthiness. Congrats to you and bushmeister on your builds and thanks for sharing the data. Trusting there will be stereo clips!

Hi x. Those port adapter gaps cleaned up nicely. I really like the look of the mini injection ports. Perhaps paint the waveguide screws black for added stealthiness. Congrats to you and bushmeister on your builds and thanks for sharing the data. Trusting there will be stereo clips!

Thanks! I like how it turned out too. The port repair job is located on upper side where it is less visible. It is hot melt glue lightly spray painted matte black to match waveguide. I might paint the screws on the WG black but like the look of the main ones on the baffle - breaks up the black monotony. I can't wait to hear how it sounds as a sealed cabinet. I am slowing down bit and taking more care to dampen contact surfaces. I added foam rubber gasket strip to the interface between the WG and baffle and it really made then clicks and rubbing noises go away in addition to providing an airtight seal. I can't find any of that recycled felt padding for the inside. My home improvement store has that nasty recycled foam chunks carpet padding only. Maybe I can put a layer of latex caulking on the inside with another thin layer of plywood for some wall sound damping.

Stereo sound clips depends on if and when I make a matching pair. I am more of a prototype builder and often stop at 1. 😀

Sorry X, just me being impatient!

Funny enough I am probably going to go for the opposite aesthetic scheme to you with a mat black cabinet and a dark walnut veneered baffle.

I am hoping this will minimize the apparent size of the cabinet - I have some lovely black walnut veneer left over from a previous project. The walnut veneer will be a rectangle set back from the curved cabinet edge.

A little like this.

The black walnut is a great look - one of my favorite looks for a speaker cabinet. Timeless and rich yet understated - not gawdy like one of the rare Aftican woods I can't pronounce right. 🙂

How is the WAF aspect on yours? I just realized with a rectangular grille of black speaker cloth and magnet mounts no one would even know it's a horn. But where is fun in that?

Good luck on the veneering.

hi x,

Very well done indeed.

Are you going to stick with the original plan on the bass section, or any other ideas?

Very well done indeed.

Are you going to stick with the original plan on the bass section, or any other ideas?

Thanks CLS. My original plan had a down firing woofer. It seems to have bass extension down to 50Hz and even lower just fine so don't need a separate woofer. It remains to be seen how low it can go.

Any idea on max SPL that you can get out of the current horn? I would suspect that it may have dropped from your original sims due to the smaller holes and the lower extension... Still, if it can go above 105dB it would certainly meet my expectations of a "bookshelf" speaker!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

If I left the volume of the box as is at circa 30liters, and wanted 50Hz bass extension, the DC200 woofers would hit 4.5mm xmax with 16.5v at about 95dB with a 50Hz BW2 HPF.

If I went with the original plan to go only to an f3 of 82Hz using a 12liter rear chamber and a 70Hz BW2 HPF, the xmax limited SPL is 109dB at 24v. However, that would exceed the 60w thermal limit by 26w. So could not be sustained.

107dB could be sustained to reach 60w max thermal limit at 20v, while still not exceeding xmax.

I would really have to add volume filler blocks to the box to take the volume way down to do this. For home listening, 95dB is actually fine so I may go this way until a need arises for 107dB.

If I went with the original plan to go only to an f3 of 82Hz using a 12liter rear chamber and a 70Hz BW2 HPF, the xmax limited SPL is 109dB at 24v. However, that would exceed the 60w thermal limit by 26w. So could not be sustained.

107dB could be sustained to reach 60w max thermal limit at 20v, while still not exceeding xmax.

I would really have to add volume filler blocks to the box to take the volume way down to do this. For home listening, 95dB is actually fine so I may go this way until a need arises for 107dB.

Keep it nearfield, I think it can take more aggressive EQ and go lower. Or, you might want to use 2 woofers per side for a more powerful -- and no longer bookshelf-- system. Either way, you'll be fine and get a pair of special and excellent speakers. SPL won't be a problem at all. You'll get more than you need anyway. 😀

the big question is does he like the one he's made enough to make a second?

can he put up with more evil sawdust to make a second?

what will X do?(cue sappy evil organ sound...)

can he put up with more evil sawdust to make a second?

what will X do?(cue sappy evil organ sound...)

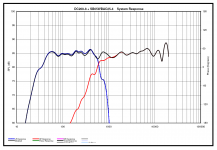

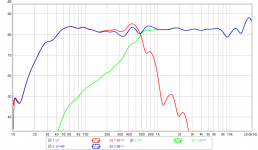

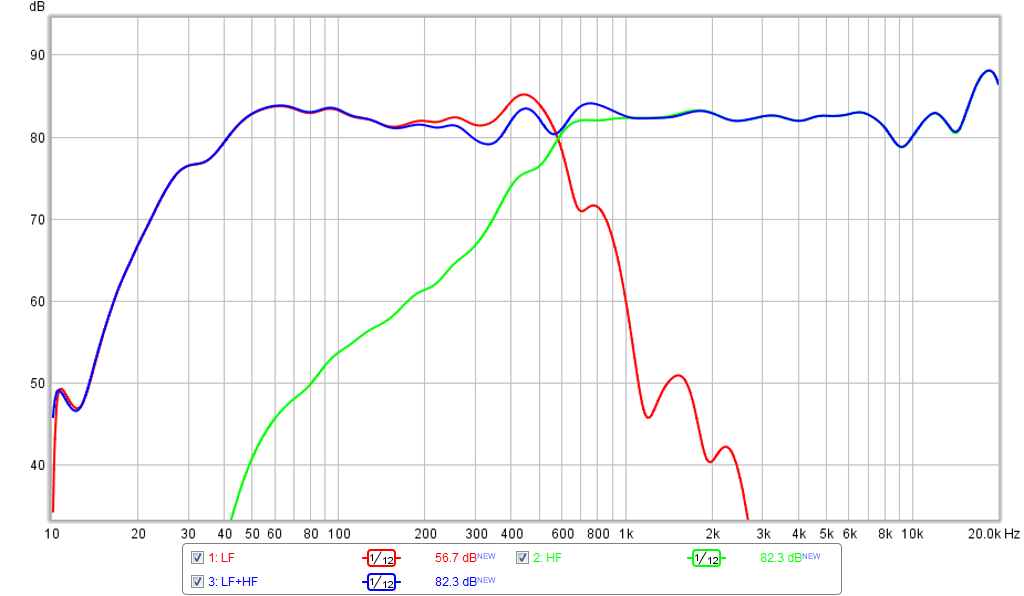

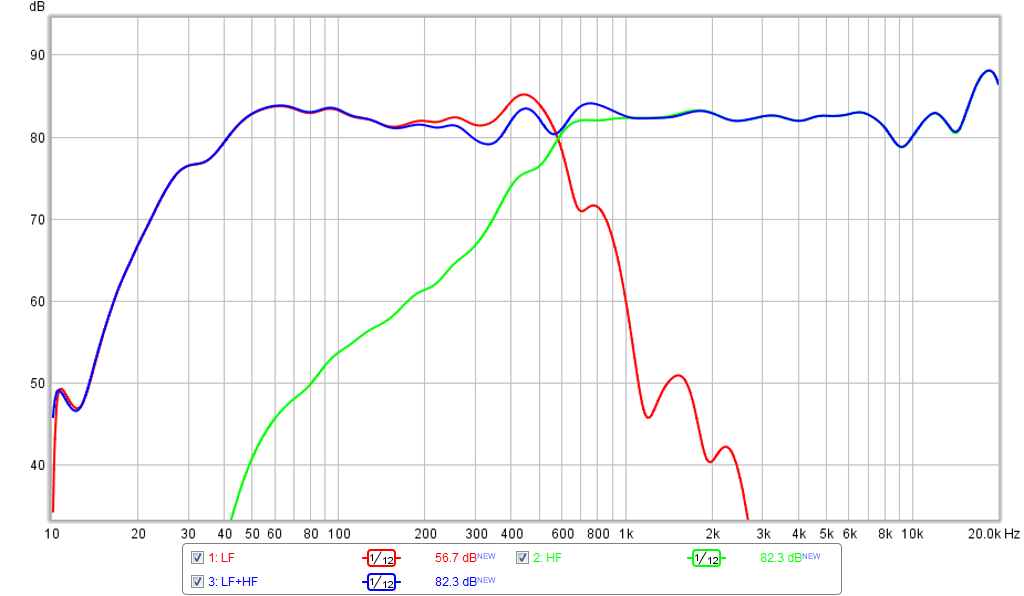

I am using PCD to develop the settings for the miniDSP Harsch XO. Here is the predicted PEQ-shaped response based on measured raw responses for a 600Hz XO frequency:

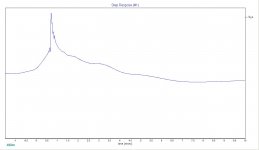

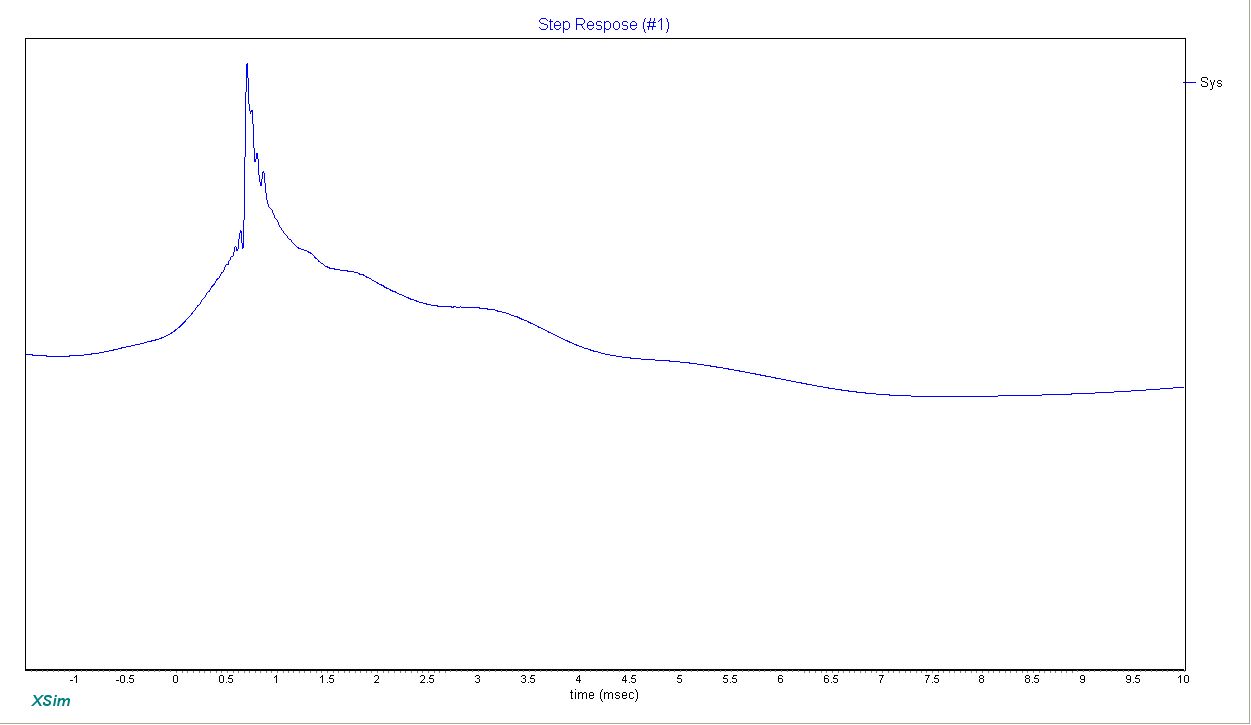

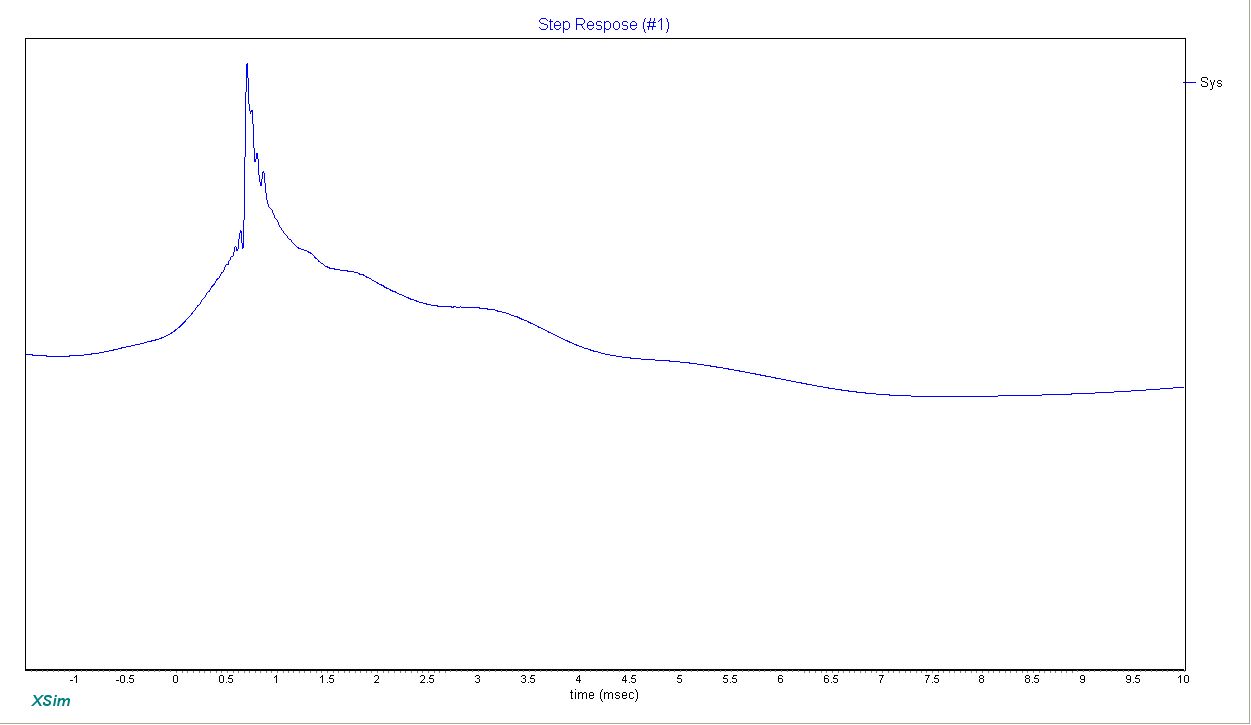

Here is the associated predicted step response from the PCD calculated output FRD file:

Here is the measured electro-acoustic frequency response showing the Harsch XO implemented with an electrical BW1 high pass on the SB65 and BW2 low pass on the DC200:

However, when implemented, I am having a problem with time alignment - I think I forgot to click the "Estimate IR delay" button in REW before exporting the minimum phase FRD to PCD. More work ahead but even so, it sounds pretty good once I manually tweaked the delay to resemble a Harsch XO - but far from perfect. There is also a box distortion that I need to work on removing with better dampening on the walls. Right now all I have is fiberglass stuffed in the box when it really needs either felt or foam lined walls. Also, there is no separate sealed rear chamber for the SB65 yet - all sharing a common volume so the woofers are probably pushing on the SB65.

In any case, music actually sounds quiet enjoyable. Here is a clip from E.C.'s unplugged album for you to get a sense of the bass capability and the percussion transients from an acoustic guitar. Change extension from asc to mp3 to listen.

Here is the associated predicted step response from the PCD calculated output FRD file:

Here is the measured electro-acoustic frequency response showing the Harsch XO implemented with an electrical BW1 high pass on the SB65 and BW2 low pass on the DC200:

However, when implemented, I am having a problem with time alignment - I think I forgot to click the "Estimate IR delay" button in REW before exporting the minimum phase FRD to PCD. More work ahead but even so, it sounds pretty good once I manually tweaked the delay to resemble a Harsch XO - but far from perfect. There is also a box distortion that I need to work on removing with better dampening on the walls. Right now all I have is fiberglass stuffed in the box when it really needs either felt or foam lined walls. Also, there is no separate sealed rear chamber for the SB65 yet - all sharing a common volume so the woofers are probably pushing on the SB65.

In any case, music actually sounds quiet enjoyable. Here is a clip from E.C.'s unplugged album for you to get a sense of the bass capability and the percussion transients from an acoustic guitar. Change extension from asc to mp3 to listen.

Attachments

Last edited:

That sound clip have good realism and a clear vibe, that said admit haven't track myself so have no reference but sound clip is much better than previous clip "SB65-LTH142-RS225-LR4-500Hz-FAST-clip-1.mp3" where horn with SB65 was XO'ed and laing upon a RS225-8 woofer in sealed box.

Nice box and clip x.

So this is a bit mad but I was thinking, because it seems hard to get the right horns in aus we could do something like this...

https://youtu.be/maH5Ech0wK8

Then I was thinking add mid and woofer mounting plates etc to the first plastic mould and apply add another plastic layer over that.

All I need now is plans for a horn profile that suits the job and I can spin the primary shape on my wood lathe.

Any thoughts?

I guess this is only going to be easy'ish for symmetrical shapes... Hmmm

So this is a bit mad but I was thinking, because it seems hard to get the right horns in aus we could do something like this...

https://youtu.be/maH5Ech0wK8

Then I was thinking add mid and woofer mounting plates etc to the first plastic mould and apply add another plastic layer over that.

All I need now is plans for a horn profile that suits the job and I can spin the primary shape on my wood lathe.

Any thoughts?

I guess this is only going to be easy'ish for symmetrical shapes... Hmmm

Last edited:

Thunk303,

Thanks. It has been a lot of fast and furious work but I think I am getting closer to an ideal speaker here.

The lure of this speaker is using a great off the shelf horn that a big company probably spent $M developing to leverage their hard earned development to save time and have a horn that produces an excellent polar response.

If you make your own, you lose that advantage. But if you must, look for Natehansen's threads on diy horns.

Thanks. It has been a lot of fast and furious work but I think I am getting closer to an ideal speaker here.

The lure of this speaker is using a great off the shelf horn that a big company probably spent $M developing to leverage their hard earned development to save time and have a horn that produces an excellent polar response.

All I need now is plans for a horn profile that suits the job and I can spin the primary shape on my wood lathe.

If you make your own, you lose that advantage. But if you must, look for Natehansen's threads on diy horns.

Last edited:

Nice box and clip x.

So this is a bit mad but I was thinking, because it seems hard to get the right horns in aus we could do something like this...

https://youtu.be/maH5Ech0wK8

Then I was thinking add mid and woofer mounting plates etc to the first plastic mould and apply add another plastic layer over that.

All I need now is plans for a horn profile that suits the job and I can spin the primary shape on my wood lathe.

Any thoughts?

I guess this is only going to be easy'ish for symmetrical shapes... Hmmm

Aren't you in the same country where the "Beyond the Ariel" horns are made? 🙂

- Home

- Loudspeakers

- Multi-Way

- A Bookshelf Multi-Way Point-Source Horn