Wouldn't the additional force be cancelled by the additional weight?

regards,

Gerrit

That's a tricky one, and I think You're right to some degree.

Maybe the thicker strip will be down in dB:s, but it will be up again due to increased current.

But the net result would be a more equalized bending force on the corrugations. (I think)

But current stays the same with different membrane weight, only distribution of current is somewhat different on the surface of ribbon and therefore forces involved. And resistance is lower, so you end up with lower efficiency.

Another interesting thing is that Apogee used to do quite the opposite thing, check out their quasi ribbon http://mjalazard.smugmug.com/Other/Apogee-Ribbon-re-build/P4030148/827686834_YAKAz-L.jpg . Strips closer to the magnet are wider than the ones in the middle.

Another interesting thing is that Apogee used to do quite the opposite thing, check out their quasi ribbon http://mjalazard.smugmug.com/Other/Apogee-Ribbon-re-build/P4030148/827686834_YAKAz-L.jpg . Strips closer to the magnet are wider than the ones in the middle.

But current stays the same with different membrane weight, only distribution of current is somewhat different on the surface of ribbon and therefore forces involved. And resistance is lower, so you end up with lower efficiency.

Another interesting thing is that Apogee used to do quite the opposite thing, check out their quasi ribbon http://mjalazard.smugmug.com/Other/Apogee-Ribbon-re-build/P4030148/827686834_YAKAz-L.jpg . Strips closer to the magnet are wider than the ones in the middle.

Watching the picture, I also see that the membrane is much narrower than distance between poles, leaving out the most distortion generating areas close to the poles....

Enough of this, it's all theories, and I feel that we have hijacked Gerrit's thread......🙁

No problem 🙂 I like the discussion.Watching the picture, I also see that the membrane is much narrower than distance between poles, leaving out the most distortion generating areas close to the poles....

Enough of this, it's all theories, and I feel that we have hijacked Gerrit's thread......🙁

It was my intention also to try different width ribbons to study the effect on the performance. With a long ribbon you could afford to lose some radiating surface if it significantly reduces distortion, at some point the increased excursion required to compensate for the surface loss will lead to an increase of the distortion. As is so often the case, it is a matter of finding the right compromise.

regards,

Gerrit

Yes, Apogee did have large gaps between membrane and magnets. It's probably the best, easiest and cheapest way to avoid distortion without much complications, and then make normal tweeter membrane in between. But with Apogee Centaurs that i listened, membranes stretched a lot, and that's the problem with corrugated ribbons. They sound nice but are too fragile in the lightest wind, and after stretching then they must be replaced.

@Gerrit Since you've done most detailed measurements that i saw on forum, if you have interest/time, measure freq. response and distortion of embossed membrane in same magnetic structure with same foil. It would be interesting to do relative comparison between the two once and for all. But somehow I assume decca/magnepan/apogee/fountek/raven/aurum cantus and many others, certainly know why they are making corrugated ribbons. So taken all things into consideration, your ribbon on page 1 is probably the best possible optimal design, and making another 5% better performance would mean a lot more magnetic structure/ribbon making complications that would cost a lot more time and money.

And please stop us if we are taking discussion away from your topic, I'am sorry if we deviated a lot from your original post.

@Gerrit Since you've done most detailed measurements that i saw on forum, if you have interest/time, measure freq. response and distortion of embossed membrane in same magnetic structure with same foil. It would be interesting to do relative comparison between the two once and for all. But somehow I assume decca/magnepan/apogee/fountek/raven/aurum cantus and many others, certainly know why they are making corrugated ribbons. So taken all things into consideration, your ribbon on page 1 is probably the best possible optimal design, and making another 5% better performance would mean a lot more magnetic structure/ribbon making complications that would cost a lot more time and money.

And please stop us if we are taking discussion away from your topic, I'am sorry if we deviated a lot from your original post.

What could be used for masking aluminium foil so that we can get clean edges after etching?"

Which gives me an idea: Mask off a central strip with photo resist on both sides before etching.

I don't want to get offtopic, but small quasi ribbons are something that i would also like to try. Probably not worth doing, because they can be bought cheaply nowadays, but nevertheless etching is interesting. With thin lines of alu, i don't know if masking tape would prevent leaking of acid underneath the tape. For wider surfaces, like you wanted to mask parts of ribbon, that would probably be good solution. If you try that, please share with us.Maybe some easy removable tape?

After some searching, these are the cheapest micrometers i found on aliexpress. They should be useful for checking etched foil thicknesses, as they have good enough resolution and accuracy.

High quality Micron Outside micrometer 0 25mm 0.001mm calibration micrometer 0.001mm paper thickness micrometer-in Micrometers from Industry & Business on Aliexpress.com | Alibaba Group

Freeshipping 25mm/0.001mm Electronic Digital Micrometer Measuring Tools,dropshipping-in Micrometers from Industry & Business on Aliexpress.com | Alibaba Group

This one would be ideal http://www.aliexpress.com/item/F-NF..._5,201527_2_3_2_1_5_4_71_72_73_74_75,201409_1

Another interesting tool for embossing. We could make special Santa edition of ribbons with included christmas tree pattern 🙂 , but there is also normal corrugated one.

http://www.aliexpress.com/item/Free..._5,201527_2_3_2_1_5_4_71_72_73_74_75,201409_1

High quality Micron Outside micrometer 0 25mm 0.001mm calibration micrometer 0.001mm paper thickness micrometer-in Micrometers from Industry & Business on Aliexpress.com | Alibaba Group

Freeshipping 25mm/0.001mm Electronic Digital Micrometer Measuring Tools,dropshipping-in Micrometers from Industry & Business on Aliexpress.com | Alibaba Group

This one would be ideal http://www.aliexpress.com/item/F-NF..._5,201527_2_3_2_1_5_4_71_72_73_74_75,201409_1

Another interesting tool for embossing. We could make special Santa edition of ribbons with included christmas tree pattern 🙂 , but there is also normal corrugated one.

http://www.aliexpress.com/item/Free..._5,201527_2_3_2_1_5_4_71_72_73_74_75,201409_1

Last edited:

But current stays the same with different membrane weight, only distribution of current is somewhat different on the surface of ribbon and therefore forces involved. And resistance is lower, so you end up with lower efficiency.

Another interesting thing is that Apogee used to do quite the opposite thing, check out their quasi ribbon http://mjalazard.smugmug.com/Other/Apogee-Ribbon-re-build/P4030148/827686834_YAKAz-L.jpg . Strips closer to the magnet are wider than the ones in the middle.

I've been thinking on this Apogee speaker, when it hit 😱me that the signal current is the same through all six series coupled conductors!

And because the conductors closest to the poles are wider, current density is lower where it is needed!

I've been thinking on this Apogee speaker, when it hit 😱me that the signal current is the same through all six series coupled conductors!

And because the conductors closest to the poles are wider, current density is lower where it is needed!

Yes, that's absolutely right! Because of wider strips at the end, same force from same current that other series connected strips have, is distributed on wider area. And also there is a little more weight at the end strips.

I still think that is easier to make very homogeneous field from side to side, and that the bigger problem are end points of ribbon. But on quasi ribbon design it is easy to play with aluminium strip width.

With 2 x 10 minutes at room temperature in 0.1N NaOH it was 5.6µm, with 2 x 12 minutes 4.6µm. The etching was done in two steps to be able to use clean solution for the second and to clean the ribbon between etching steps. With 3 x 10minutes you should end up with 2-3µm.How long etch in NaOH? I've built ribbon mic and need less than 5 microns.

regards,

Gerrit

How long etch in NaOH? I've built ribbon mic and need less than 5 microns.

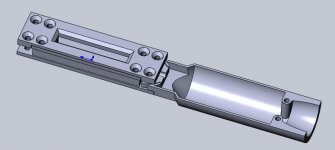

Is that 3D printed? Looks very well designed! I am also thinking about buying some 3d printer as it seems like a great tool for small ribbon horn making.

Here is recipe from main chef in this thread:

Just try the etching method. 2 x 10min in a 0.1N NaOH solution will bring 10µm kitchen foil down to about 6µm.

regards,

Gerrit

Too late 🙂

With 2 x 10 minutes at room temperature in 0.1N NaOH...

Have you tried ultrasonic cleaner to speed up things?

Have you tried ultrasonic cleaner to speed up things?

If I wanted to speed up thing I would have raised the temperature, the idea behind taking it slowly is to ensure an even reduction of the thickness over the whole surface.

regards,

Gerrit

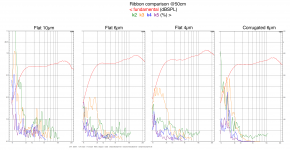

Digging through the measurement archive I compiled this comparison showing the harmonics for three flat ribbons and a corrugated ribbon:

Some dipole correction and high pass filtering was applied, same setting for all measurements.

The harmonics are in percent, 5% full scale. Despite the differences the overall response is about the same for all ribbons. As expected the level increased for thinner ribbons. The level for 6µm corrugated ribbon is a bit below the 6µm flat ribbon, probably because of the extra mass (length).

Compared to the 10µm flat ribbon the 6µm and 4µm flat ribbons have significantly less distortion, especially around 3-4kHz. Although 0.5% 2nd and 3rd harmonic above 2.5kHz might seem acceptable, the level of the higher harmonics is not.

At first glance the corrugated ribbon looks worse but that is only the range below 2.5kHz, above 2.5kHz the corrugated ribbon seriously outperforms the flat ribbons. The higher harmonics are more than an order of magnitude lower for the corrugated ribbon. The distortion peaks below 2kHz are related to the ribbon resonance due to the corrugation, reducing them is a matter of finding the right combination of corrugation and ribbon tension.

regards,

Gerrit

Some dipole correction and high pass filtering was applied, same setting for all measurements.

The harmonics are in percent, 5% full scale. Despite the differences the overall response is about the same for all ribbons. As expected the level increased for thinner ribbons. The level for 6µm corrugated ribbon is a bit below the 6µm flat ribbon, probably because of the extra mass (length).

Compared to the 10µm flat ribbon the 6µm and 4µm flat ribbons have significantly less distortion, especially around 3-4kHz. Although 0.5% 2nd and 3rd harmonic above 2.5kHz might seem acceptable, the level of the higher harmonics is not.

At first glance the corrugated ribbon looks worse but that is only the range below 2.5kHz, above 2.5kHz the corrugated ribbon seriously outperforms the flat ribbons. The higher harmonics are more than an order of magnitude lower for the corrugated ribbon. The distortion peaks below 2kHz are related to the ribbon resonance due to the corrugation, reducing them is a matter of finding the right combination of corrugation and ribbon tension.

regards,

Gerrit

Gerrit, I tested your Corrugator, big difference! Thanks!

I also tried the old Apogee trick with a ribbon return current conductor close to

the ribbon, distortion went down a few dB, mostly below 2 kHz...

Great to hear that it works! 🙂

It could be that the ribbon is now more sensitive to draft, definitely a point of concern with large ribbons.

regards,

Gerrit

- Home

- Loudspeakers

- Planars & Exotics

- DIY ribbon dipole tweeter, reductio ad minimum