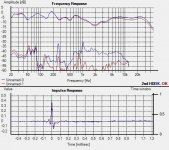

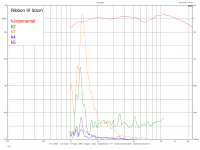

Were all these measurements with your spaced-magnet geometry?Digging through the measurement archive I compiled this comparison showing the harmonics for three flat ribbons and a corrugated ribbon

Do you have a feel for how much the spaced-magnets reduce distortion?

While in a local hobby store over the weekend, I noticed that they sell aluminum leaf for rather cheap prices.

25 sheets of < 1µm aluminum for $8. I couldn't resist picking some up to try.

Can't get much closer to "essentially" massless than that.

Amazon.com: Speedball Mona Lisa Composition Silver Leaf, 25 Sheet Pack: Arts, Crafts & Sewing

Now I just need to remember where I stuck the magnet assembly when I was done testing with it...😱

Were all these measurements with your spaced-magnet geometry?

Do you have a feel for how much the spaced-magnets reduce distortion?

While in a local hobby store over the weekend, I noticed that they sell aluminum leaf for rather cheap prices.

25 sheets of < 1µm aluminum for $8. I couldn't resist picking some up to try.

Can't get much closer to "essentially" massless than that.

Amazon.com: Speedball Mona Lisa Composition Silver Leaf, 25 Sheet Pack: Arts, Crafts & Sewing

Now I just need to remember where I stuck the magnet assembly when I was done testing with it...😱

Yes, all with the spaced magnet motor. This comparison was to show why corrugation (or some other pattern) is necessary to reduce higher order distortion and why kitchen foil is not recommended.

I'm currently building another steels frame ribbon with the spaced magnet motor design, this will allow a comparison between the two motor designs. I hope this new design will have significantly lower distortion which will allow for a lower crossover. We shall see.🙂

regards,

Gerrit

Bolserst,

There was another thread describing aluminum leaf as a ribbon material. Perhaps you're already familiar with it. In any case, my recollection is that the poster created long ribbons by adhering pieces of leaf together without adhesives. This may not be relevant if you're building a short ribbon anyway but I thought I'd alert folks to the existence of other leaf-based techniques.

I'll see if I can find the thread so I can provide a link.

Few

There was another thread describing aluminum leaf as a ribbon material. Perhaps you're already familiar with it. In any case, my recollection is that the poster created long ribbons by adhering pieces of leaf together without adhesives. This may not be relevant if you're building a short ribbon anyway but I thought I'd alert folks to the existence of other leaf-based techniques.

I'll see if I can find the thread so I can provide a link.

Few

Just wanna show the difference between 10u alu ribbon with 4 uM mylar backing (red trace) and without mylar(blue trace).

2nd harmonics is shown...-60dB equals 0.1%.

Gerrits Ribbon Cable Corrugator is used in both cases...

The difference is very audible!

2nd harmonics is shown...-60dB equals 0.1%.

Gerrits Ribbon Cable Corrugator is used in both cases...

The difference is very audible!

Attachments

Very interesting!Just wanna show the difference between 10u alu ribbon with 4 uM mylar backing (red trace) and without mylar(blue trace).

2nd harmonics is shown...-60dB equals 0.1%.

Gerrits Ribbon Cable Corrugator is used in both cases...

The difference is very audible!

How did you glue the foil to the mylar and what mylar did you use?

My new steel frame ribbons with the spaced magnet motor are nearly finished:

Testing will start tomorrow.

regards,

Gerrit

Very interesting!

How did you glue the foil to the mylar and what mylar did you use?

My new steel frame ribbons with the spaced magnet motor are nearly finished:

View attachment 505996

View attachment 505997

Testing will start tomorrow.

regards,

Gerrit

I bought it here : Products

and I used diluted water based contact glue Casco Contact 3880

Shall be interesting to see how your new ribbons are working, maybe with or without mylar?

Last edited:

That's weird , with Mylar and glue yields lower distortion?

Very wierd.....maybe it has to do with some kind damping...

If you grab one end of the alu/mylar ribbon and shake it, its totally silent.

If you do the same with the naked alu ribbon there's a lot of prizzel and prazzel

noise going on.

Actually I would have thought it weird if the mylar laminated version did NOT have lower distortion. As Jonas suggested, the mylar and glue should damp resonances in the ribbon and help it vibrate more simply (pistonically) in the same way that corrugation helps prevent break-up modes in the ribbon and reduces the "prizzel and prazzel" noises. The extra weight of the mylar and glue will reduce the sensitivity but if the mylar backing makes it possible to run multiple lengths of the conductor in the magnetic field then you can regain some of the sensitivity that was lost.

At least that's the way I think about it...

Few

At least that's the way I think about it...

Few

Actually I would have thought it weird if the mylar laminated version did NOT have lower distortion. As Jonas suggested, the mylar and glue should damp resonances in the ribbon and help it vibrate more simply (pistonically) in the same way that corrugation helps prevent break-up modes in the ribbon and reduces the "prizzel and prazzel" noises. The extra weight of the mylar and glue will reduce the sensitivity but if the mylar backing makes it possible to run multiple lengths of the conductor in the magnetic field then you can regain some of the sensitivity that was lost.

At least that's the way I think about it...

Few

The increase in weight is about 15%, but it also increases the mechanical strength 500% making it possible to use the speaker outdoors!

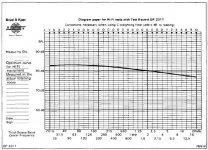

It also has the benefit that the frequency curve gets more of the Bruel & Kjaer look..

I drive my ribbons directly via 6 Ohm and 22uF in series, so I have plenty of headroom to manipulate sensitivity of the ribbon....

Attachments

@ Few: thanks for links to the thread on the aluminum leaf, I had not seen that.

Concerning "prizzel and prazzel" noises, I had the same thoughts as you that a laminated ribbon structure would provide damping which JonasKarud has nicely shown 🙂

@ Gerrit Boers: New steel frame ribbon structure is looking very nice! Based on your previous experience, how much sensitivity do you expect to pick up?

I located my old Neo8 magnet test structure last night stuck to the back leg of my work bench in the garage...totally do not remember putting it there. I hope to get some measurements with the aluminum leaf this weekend. I did measure the thickness using a few different methods and multiple layers. On average it is 0.65µm thick. 😱

Concerning "prizzel and prazzel" noises, I had the same thoughts as you that a laminated ribbon structure would provide damping which JonasKarud has nicely shown 🙂

@ Gerrit Boers: New steel frame ribbon structure is looking very nice! Based on your previous experience, how much sensitivity do you expect to pick up?

I located my old Neo8 magnet test structure last night stuck to the back leg of my work bench in the garage...totally do not remember putting it there. I hope to get some measurements with the aluminum leaf this weekend. I did measure the thickness using a few different methods and multiple layers. On average it is 0.65µm thick. 😱

Thank you 🙂@ Few: thanks for links to the thread on the aluminum leaf, I had not seen that.

Concerning "prizzel and prazzel" noises, I had the same thoughts as you that a laminated ribbon structure would provide damping which JonasKarud has nicely shown 🙂

@ Gerrit Boers: New steel frame ribbon structure is looking very nice! Based on your previous experience, how much sensitivity do you expect to pick up?

I located my old Neo8 magnet test structure last night stuck to the back leg of my work bench in the garage...totally do not remember putting it there. I hope to get some measurements with the aluminum leaf this weekend. I did measure the thickness using a few different methods and multiple layers. On average it is 0.65µm thick. 😱

The first results are in. The ribbon:

The filter, amp, series resistors, spare ribbons and tools:

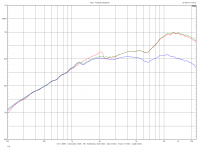

The first ribbon (red) had a serious resonance, the second (green) significantly less so I applied some filtering to this one to smoothen the response (blue):

This graph shows the response and current:

At 2kHz 1A results in 81dBSPL, this is 6 dB more than the minimal ribbon.

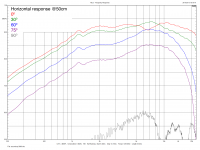

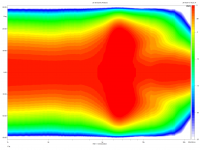

The response for several angles:

The normalised directivity:

Not bad, not bad at all 🙂

regards,

Gerrit

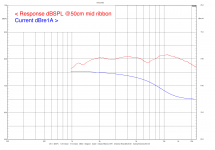

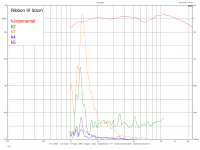

The harmonics:

Fundamental in dBSPL, scale on the left. Harmonics in %, scale on the right. Apart from the peaks at 1.5kHz it's pretty good.

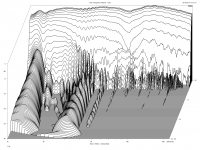

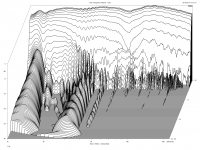

The spectral decay:

Still some resonance issues but the rest is very clean. It will be interesting to try Jonas' recipe with the mylar to see if this will get rid of the resonance while simultaneously reducing the distortion.

regards,

Gerrit

Fundamental in dBSPL, scale on the left. Harmonics in %, scale on the right. Apart from the peaks at 1.5kHz it's pretty good.

The spectral decay:

Still some resonance issues but the rest is very clean. It will be interesting to try Jonas' recipe with the mylar to see if this will get rid of the resonance while simultaneously reducing the distortion.

regards,

Gerrit

Sorry guys for being away from thread...

Thanks Gerrit for posting great results, new ribbon looks awesome (and measurements)!

Mylar quasi ribbons really do eliminate all the harshness in sound of pure alu ribobns, and also can have exactly the right resistance if you calculate alu strip width correctly. Sonically to me they are better suited for midrange drivers, as they can't reproduce all the lightning fast nuances in treble region that small pure alu ribbon can. It's always compromise. Again, looking at , for example, magnepan designs, they also use them as midrange drivers, not as tweeters.

For that small driver i think that you Geritt already got great results with pure alu ribbon.

Jonas, you should try making one quasi ribbon with alu strips and get right resistance, as you have long ribbon that would be really benefit from being quasi one.

Thanks Gerrit for posting great results, new ribbon looks awesome (and measurements)!

Mylar quasi ribbons really do eliminate all the harshness in sound of pure alu ribobns, and also can have exactly the right resistance if you calculate alu strip width correctly. Sonically to me they are better suited for midrange drivers, as they can't reproduce all the lightning fast nuances in treble region that small pure alu ribbon can. It's always compromise. Again, looking at , for example, magnepan designs, they also use them as midrange drivers, not as tweeters.

For that small driver i think that you Geritt already got great results with pure alu ribbon.

Jonas, you should try making one quasi ribbon with alu strips and get right resistance, as you have long ribbon that would be really benefit from being quasi one.

Thanks, Gerrit, for the advise of slow etching!

I'm now trying to make a ribbon with 3-4uM alu glued to 2uM mylar...

Should come down to less than 50% of the weight of a 10uM Alu-ribbon

Mx, I see what you mean, I've been there, but i don't need the extra sensitivity multi traces give.

I prefer a to keep the ribbon structure as simple as possible...

I'm now trying to make a ribbon with 3-4uM alu glued to 2uM mylar...

Should come down to less than 50% of the weight of a 10uM Alu-ribbon

Mx, I see what you mean, I've been there, but i don't need the extra sensitivity multi traces give.

I prefer a to keep the ribbon structure as simple as possible...

Attachments

Thanks, Gerrit, for the advise of slow etching!

I'm now trying to make a ribbon with 3-4uM alu glued to 2uM mylar...

Should come down to less than 50% of the weight of a 10uM Alu-ribbon

Mx, I see what you mean, I've been there, but i don't need the extra sensitivity multi traces give.

I prefer a to keep the ribbon structure as simple as possible...

If you have than thin aluminium, you can make maybe only two very wide traces on it and get prefered resistance, with only small gap between them. It is basically the same ribbon, i don't know what would be better if you had only one strip of aluminium. But it should be fun to make that thin ribbon, it will probably sound very nice, keep us posted!

I dug up a small calculator program that i made years ago for calculating ribbon sensitivity, mass, resistance and width of alu strips on mylar. I think it will be useful for everybody, as you can quickly check if some type of membrane is useful in reality before building. View attachment RIBBON5.zip

Happy building!

Happy building!

Ok, it sure sounds interesting, I already have a splittable second current return path from top down. See post #99

I will give it a try...maybe I end up in

I will give it a try...maybe I end up in

- Home

- Loudspeakers

- Planars & Exotics

- DIY ribbon dipole tweeter, reductio ad minimum