You got it...Sure, I'd like a Garrard 301, but Not for what they go for Now...But, if I happen to find one in a Garage...Yeah, Right..

Yeah, I think that I'll run it like This for a While...On the Mat...

Seeing your good taste in music, reminded me of the Tull that was released a year after "Too old to rock ......", "songs from the wood"

Do you see the resemblance?

Steen

Good for a base and if you find a dark and light wood combo would turn into a very unique project.

Anyhow I have managed to upload a pic of the clonker 🙂

Hi,

Unique ? Yes. A good idea arguable. I'm not knocking what you

are doing, each to their own and live and learn. Just trying to

say there are other options in the approach taken which

may be more useful to the general observer in this thread.

e.g. for an extreme example of using those two boards

consider copying the basic principles of SME turntables,

if you did, you simply wouldn't go too far wrong.

rgds, sreten.

Hi,

Unique ? Yes. A good idea arguable. I'm not knocking what you

are doing, each to their own and live and learn. Just trying to

say there are other options in the approach taken which

may be more useful to the general observer in this thread.

e.g. for an extreme example of using those two boards

consider copying the basic principles of SME turntables,

if you did, you simply wouldn't go too far wrong.

rgds, sreten.

Show us sreten...

Regards

Show us sreten...

Regards

Hi,

Ideas don't need realization to exist, same with good design.

If your not interested in design principles and the fundamental

aspects of the performance of turntables, you too can produce

a very flashy looking turntable that doesn't do what it looks like.

rgds, sreten.

sreten; said:... an extreme example of using those two boards

consider copying the basic principles of SME turntables,

if you did, you simply wouldn't go too far wrong.

rgds, sreten.

I am aware of the SME turntables and love the look of the same. The principal of suspending the deck was one of the reasons for my asking about a sprung deck or a fixed deck. What would be the better option? The Saturn has a suspended platform using a different system than the SME. The Garrard had the deck sprung into the plinth to suspend/separate the motor/platter/tonearm from the plinth. Other designs have the chassis hard fixed to the plinth but make the plinth a solid lump construction. Sonically what is the best option?

A little long and a minor rant...

Sorry for the length of this post....

Squiffy: here's my 2¢ worth. I think one ought to consider that a well designed and tuned suspension can be a pretty complex thing to design. I'm not saying impossible, but it can be difficult. I have chosen to make a plinth out of "a solid lump" for ease. Idlers and DD turntables have done well in these somewhat "massy" plinths. It is not to say that a suspended idler would be a bad thing...

If I were starting with a new suspension design, I would start with something like the Oracle or the SME. (or Gyrodeck, or better yet the Pedersen suspension mod for Michell turntables). Hung "suspensions" are more stable than any that push up against the turntable's top plate or sub-chassis with coil springs.

sreten:

Very true, else we might still be in the dark ages. My thought has always been that good design does not cost more, whether for performance or aesthetic reasons. The later is much easier to do in comparison with the former.

And this is the very crux of so many things. "Flash sells" would be another way of saying it (just look at all the flashy junk sold in the early 80's until present). Then seek out anything that was designed for a specific purpose like the Ekornes Stressless chair, Stickley furntiture, Le Corbusier furntiture, Frank Lloyd Wright buildings, Charles and Ray Eames office products, et al. Look at audio: McIntosh amplifiers; Thorens turntables; Quad ESLs and current dumping amplifiers; BBC LS 3/5A monitor speakers, etc. (I can't list everything, but you get my drift). It just so happens that the form has followed function and good industrial design and aesthetics were later applied. As I have always stated: good stuff when it was new, will always be good (if maintained). The worst that can be said is that it is old good stuff. But new junk will never be anything more than junk, whether new or old.

Sorry for the rant. I suspect this is one of the reasons that sreten has suggested starting with something a little better than an old BSR. If the same effort to build a good performing plinth is required, wouldn't one want to use (at least) a reasonable turntable as a start? I do agree with him on this. I only suggested use what you have as a starting point, not wanting folks to run out and purchase whatever turntable to experiment with. Anything you can accomplish with a klunker can then be applied to something less klunky.

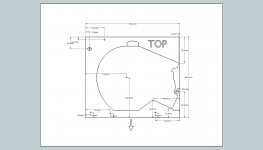

I did manage to finish a template diagram, that when used to cut out a top layer for a solid BB ply plinth for the Garrard Lab 60 allows clearance of everything. If any are interested, I'll post a dimensioned diagram of it. Once I fix a few minor mistakes in cutting, I'll post a picture of the top layer as cut.

Sorry for the length of this post....

I am aware of the SME turntables and love the look of the same. The principal of suspending the deck was one of the reasons for my asking about a sprung deck or a fixed deck. What would be the better option? The Saturn has a suspended platform using a different system than the SME. The Garrard had the deck sprung into the plinth to suspend/separate the motor/platter/tonearm from the plinth. Other designs have the chassis hard fixed to the plinth but make the plinth a solid lump construction. Sonically what is the best option?

Squiffy: here's my 2¢ worth. I think one ought to consider that a well designed and tuned suspension can be a pretty complex thing to design. I'm not saying impossible, but it can be difficult. I have chosen to make a plinth out of "a solid lump" for ease. Idlers and DD turntables have done well in these somewhat "massy" plinths. It is not to say that a suspended idler would be a bad thing...

If I were starting with a new suspension design, I would start with something like the Oracle or the SME. (or Gyrodeck, or better yet the Pedersen suspension mod for Michell turntables). Hung "suspensions" are more stable than any that push up against the turntable's top plate or sub-chassis with coil springs.

sreten:

Ideas don't need realization to exist, same with good design.

Very true, else we might still be in the dark ages. My thought has always been that good design does not cost more, whether for performance or aesthetic reasons. The later is much easier to do in comparison with the former.

If your not interested in design principles and the fundamental

aspects of the performance of turntables, you too can produce

a very flashy looking turntable that doesn't do what it looks like.

rgds, sreten.

And this is the very crux of so many things. "Flash sells" would be another way of saying it (just look at all the flashy junk sold in the early 80's until present). Then seek out anything that was designed for a specific purpose like the Ekornes Stressless chair, Stickley furntiture, Le Corbusier furntiture, Frank Lloyd Wright buildings, Charles and Ray Eames office products, et al. Look at audio: McIntosh amplifiers; Thorens turntables; Quad ESLs and current dumping amplifiers; BBC LS 3/5A monitor speakers, etc. (I can't list everything, but you get my drift). It just so happens that the form has followed function and good industrial design and aesthetics were later applied. As I have always stated: good stuff when it was new, will always be good (if maintained). The worst that can be said is that it is old good stuff. But new junk will never be anything more than junk, whether new or old.

Sorry for the rant. I suspect this is one of the reasons that sreten has suggested starting with something a little better than an old BSR. If the same effort to build a good performing plinth is required, wouldn't one want to use (at least) a reasonable turntable as a start? I do agree with him on this. I only suggested use what you have as a starting point, not wanting folks to run out and purchase whatever turntable to experiment with. Anything you can accomplish with a klunker can then be applied to something less klunky.

I did manage to finish a template diagram, that when used to cut out a top layer for a solid BB ply plinth for the Garrard Lab 60 allows clearance of everything. If any are interested, I'll post a dimensioned diagram of it. Once I fix a few minor mistakes in cutting, I'll post a picture of the top layer as cut.

... Then seek out anything that was designed for a specific purpose like the Ekornes Stressless chair,

... Anything you can accomplish with a klunker can then be applied to something less klunky.

I did manage to finish a template diagram, that when used to cut out a top layer for a solid BB ply plinth for the Garrard Lab 60 allows clearance of everything. If any are interested, I'll post a dimensioned diagram of it. Once I fix a few minor mistakes in cutting, I'll post a picture of the top layer as cut.

I had a pair of Stressless chairs many moons ago and they were the most comfortable chairs you could ever wish to relax in. My recommendation for a turntable listening chair.

The Klunker comment is the reason for my project. I experiment with cheap parts and see how I get on. I may end up with something quite good from the bits that I have and if so take that forward to a 'real' project later. I can use the experiment to try out things without the worry of messing up componants that I have paid good money for.

So far I have ditched the cheap rubbish on the BSR and have left the motor, bearing, idler setup, top plate and switches. The top plate is metal and of a reasonable thickness to be solid. Cleaned up and sorted it shouldn't be too bad. The motor will never be top end but it's quiet now it's in the plinth. The idler setup does its job well and happily spins up the new platter arrangement at all speeds. The bearing allows the platter to spin and, again, now it's in the plinth and the new platter arrangement is setup with the extra weight of the top of the original platter the bearing noise is very quiet. This may be changed if I find a suitable replacement.

As previously mentioned the two boards used are of a size that suits this project but would not be suitable for a normal size turntable. The price has allowed me to experiment, to play with what I've got and to improve what I had to start with.

I will setup the arm and see how it sounds. I may look at a system of suspending the top board of the plinth (one or two ideas have been in the back of my mind).

For this thread this has been and will continue to be my little experiment. Taking ideas, throwing in ideas, and producing something from next to nothing. The next one will be something different and if funds allow will have a better quality start point.

realization

I'm with Turbon: show us, don't merely blow us off. T Edison had a ratio of inspiration to perspiration that suggests that unrealized ideas are just opinions.

I'm with Turbon: show us, don't merely blow us off. T Edison had a ratio of inspiration to perspiration that suggests that unrealized ideas are just opinions.

In defence of sreten...

er, guys...

I find myself in a position that requires me to defend sreten here. sreten may very well have much more experience and insight that all of us combined. Just as I donned my "policeman's persona" a while back, I am again doing so. Not that I am trying to stifle any, but let's try to attempt to keep any comments as non-personal (in apparent tone or in direct use of language). I know I am perhaps the most guilty of all here, so this is not a "look who's calling the kettle black" statement. I want this thread to be as inclusive as possible. There is no need to be confrontational. I am actually quite pleased that he has chosen to engage in this thread. If only to counter my enthusiasm, but also a lot of what he states is quite sound advice, for various reasons. I'd like him to continue to do so.

Perhaps sreten could provide a quick sketch showing what he suggests? Or if he has a good example of what he has done to illustrate his point.

My plinth drawing is quite different from the Garrard outline cutout as I discovered when I looked at the Garrard 50/60 (or Lab 50/60 depending on where the turntables were marketed): pink= Garrard cutout diagram; blue=my diagram.

My diagram clears everything that I left intact: the bearing; the speed change mechanism; and the motor switch mechanism. The Garrard diagram assumes that the deck will remain as supplied with the springs left intact. My diagram assumes that the turntable will be hard mounted to a more "massy" plinth. Also for the sake of comparison I have restricted the dimensions of my diagram to those of the original so that a meaningful comparison can be done. The diagram is not dimensioned, I'll post a dimensioned one later today once I get the component depths included.

er, guys...

I find myself in a position that requires me to defend sreten here. sreten may very well have much more experience and insight that all of us combined. Just as I donned my "policeman's persona" a while back, I am again doing so. Not that I am trying to stifle any, but let's try to attempt to keep any comments as non-personal (in apparent tone or in direct use of language). I know I am perhaps the most guilty of all here, so this is not a "look who's calling the kettle black" statement. I want this thread to be as inclusive as possible. There is no need to be confrontational. I am actually quite pleased that he has chosen to engage in this thread. If only to counter my enthusiasm, but also a lot of what he states is quite sound advice, for various reasons. I'd like him to continue to do so.

Perhaps sreten could provide a quick sketch showing what he suggests? Or if he has a good example of what he has done to illustrate his point.

My plinth drawing is quite different from the Garrard outline cutout as I discovered when I looked at the Garrard 50/60 (or Lab 50/60 depending on where the turntables were marketed): pink= Garrard cutout diagram; blue=my diagram.

My diagram clears everything that I left intact: the bearing; the speed change mechanism; and the motor switch mechanism. The Garrard diagram assumes that the deck will remain as supplied with the springs left intact. My diagram assumes that the turntable will be hard mounted to a more "massy" plinth. Also for the sake of comparison I have restricted the dimensions of my diagram to those of the original so that a meaningful comparison can be done. The diagram is not dimensioned, I'll post a dimensioned one later today once I get the component depths included.

Attachments

Hi,

Ideas don't need realization to exist, same with good design.

If your not interested in design principles and the fundamental

aspects of the performance of turntables, you too can produce

a very flashy looking turntable that doesn't do what it looks like.

rgds, sreten.

No need to be flashy. I only expect it do do what it's supposed to do. 🙂

Maybe this will do: http://www.stereophile.com/content/bamboo-turntable

Regards

Last edited:

This is a 1/2" piece of 6061-t6 alum. and a SOTA star plinth (22lbs.) without platter

The SME mentioned uses a thicker piece of the same. I know SME uses a fluid and O ring suspension and when you bolt everything together you would get a reduction of resonance through the plinth, but it seems you would need more than this to really quench everything. Don,t know what there doing but it gets great reviews

My goal is a wider plinth to accept a certain type of tone arm (linear) where the aluminum is Swiss cheesed and a piece of 3/4" acrylic is bolted or glued on top to absorb vibrations.

The SOTA plinth is mundane 1/2" MDF but,.,there's so much lead that it becomes unimportant what is used as long as you keep a decent ratio of all materials to kill anything.

aluminium SME style plinth.

AVWERK: If and when I get a "killer" idler wheel set-up or make my own, something like that would be on my wish list🙂 Your turntable project looks very good. Is it posted in any threads?

This is a 1/2" piece of 6061-t6 alum. and a SOTA star plinth (22lbs.) without platter

The SME mentioned uses a thicker piece of the same. I know SME uses a fluid and O ring suspension and when you bolt everything together you would get a reduction of resonance through the plinth, but it seems you would need more than this to really quench everything. Don,t know what there doing but it gets great reviews

My goal is a wider plinth to accept a certain type of tone arm (linear) where the aluminum is Swiss cheesed and a piece of 3/4" acrylic is bolted or glued on top to absorb vibrations.

The SOTA plinth is mundane 1/2" MDF but,.,there's so much lead that it becomes unimportant what is used as long as you keep a decent ratio of all materials to kill anything.

AVWERK: If and when I get a "killer" idler wheel set-up or make my own, something like that would be on my wish list🙂 Your turntable project looks very good. Is it posted in any threads?

Not yet. I have a few of these and the reason for modification is to accept a linear TA with a 1.4"' tone arm length (Versa-dynamics) style

with a possible 12" future arm and have it fit within the outside dimensions and at the same time make a more stable platform due to the wider dims.

The idler " transmission" style is an interesting idea and seems plausible , but for right now I,m planning the Cosmos mounting idea where the motor is on the moving plinth instead of separate.

I,m not sure it's a good idea but will make it dead enough using sorbothane (duro30) mounting pads to keep it disconnected as much possible

My goal and hope it's yours that what ever you do think about only the needle moving and nothing else.

Simplicity is a complicated thing!

Regards

David

with a possible 12" future arm and have it fit within the outside dimensions and at the same time make a more stable platform due to the wider dims.

The idler " transmission" style is an interesting idea and seems plausible , but for right now I,m planning the Cosmos mounting idea where the motor is on the moving plinth instead of separate.

I,m not sure it's a good idea but will make it dead enough using sorbothane (duro30) mounting pads to keep it disconnected as much possible

My goal and hope it's yours that what ever you do think about only the needle moving and nothing else.

Simplicity is a complicated thing!

Regards

David

finally a dimensioned drawing...

...it should show up here. Hope there is enough information for any wanting to do a similar project.

added comment: additional dims may be required. If so I'll do the remainder and post a copy of it. The markup on the drawing was getting a little extensive.

The actual top plate isn't square. My skills suck.

...it should show up here. Hope there is enough information for any wanting to do a similar project.

added comment: additional dims may be required. If so I'll do the remainder and post a copy of it. The markup on the drawing was getting a little extensive.

The actual top plate isn't square. My skills suck.

Attachments

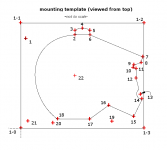

Just too many dimensions...

...it was SO confusing (a rat's nest of dimension lines, etc). So rather than confuse more folks than need be I drew out an outline as a jpg (saved as a png), and added location markers. Then wrote out a co-ordinate list and saved it as a pdf. This is a lot less confusing than the drawing ended up being. I hope it helps any that might want it.

Now I did make a fatal error when cutting out the piece. I marked it out and cut it out, but failed to remember to mark the template "this side up". Not the end of the world until you realize that there is no room for a tonearm on the RHS of the plinth. Any way, my error. If wanting to have a single plinth without a separate arm "pod" the RHS of the plinth should be extended to about 495mm from the left hand edge (or if using the pdf list, the x dimensions for pts 1-2 and 1-3 need to be extended to 495mm) if wanting to mount a 12" arm on it. Else size accordingly.

...it was SO confusing (a rat's nest of dimension lines, etc). So rather than confuse more folks than need be I drew out an outline as a jpg (saved as a png), and added location markers. Then wrote out a co-ordinate list and saved it as a pdf. This is a lot less confusing than the drawing ended up being. I hope it helps any that might want it.

Now I did make a fatal error when cutting out the piece. I marked it out and cut it out, but failed to remember to mark the template "this side up". Not the end of the world until you realize that there is no room for a tonearm on the RHS of the plinth. Any way, my error. If wanting to have a single plinth without a separate arm "pod" the RHS of the plinth should be extended to about 495mm from the left hand edge (or if using the pdf list, the x dimensions for pts 1-2 and 1-3 need to be extended to 495mm) if wanting to mount a 12" arm on it. Else size accordingly.

Attachments

Is the diagram understandable?

All: Does it make sense to use a diagram with a table.? When I drew out the template using sketchup, the dimensions were just way too crowded. What do you think?

sled: ...er ongoing revisions....

All: Does it make sense to use a diagram with a table.? When I drew out the template using sketchup, the dimensions were just way too crowded. What do you think?

sled: ...er ongoing revisions....

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- The Nanook turntable thread