Calcium carbonate compounds can make very successful structures and are found e.g. in eggshells. The matrix of eggshells is made of 90% calcium carbonate, and eggshells show some remarkable mechanical properties. So, then why calcium carbonate, as to my knowledge, has never been assessed as a material or compound for midrange or high frequency domes?

Textreme is carbon an epoxy. Epoxy is the binder for the otherwise flexible carbon fabric. And carbon acts as a «filler» for the epoxy resin, providing tensile strenght for the cured resin. Think in an analogy now: Instead of flexible carbon fabric, now take an eggshell as a static, calcium carbonate matrix filler for the epoxy resin. Simply think of teggstreme, so to say ...

As eggs include nicely dome-shaped parts, you could easily resort to an egg to assess the question, wheter calcium carbonate is suited fore midrange domes. An egg, as is, might result in an approx. 2-incher, then. So, lets make a midrange dome driver out of an egg, some drops of epoxy and of an outranged midbass driver. We will hopefulle end up with an eggcellent result. And for shure it will be an eggxeptional construction.

Lets go, then:

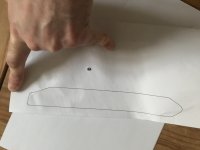

1. Choose an egg, take a handsaw and start smoothly sawing – if the egg is of decent quality from well-fed chickens, it will not brake. If instead several eggs brake, one after the other, then you may change your egg supplier. You will discover that the surface of a robust enough egg is quite resistant to a usual HSS saw blade, not unlike a ceramic surface, until you have managed to make a first groove. You have to be steady, delicate and patient.

2. Then you will have to take away all (!) skin structures from the inside of the egg shell. You can peel the main skin right away. But then you will have to scratch repetitively and for a quite long time the inside of the shell with your fingernails, until you really scratch on the calcium carbonate structure. Cleaning once and then with water from the tap helps. Let then the eggshell completely dry.

3. Carefully and smoothly sand the cutted edge with a sheet of sanding paper lying on a plane tabletop. 120- or 180-graded paper do well, no coarser, not to split small fragments away. Sand until the rim is more or less on one single plane.

4. As the eggshell is highly porous and fragile at the same time, you may reinforce it by applying epoxy into it. Do not laquer it, but gently work some expoxy into the eggshell by using your gloved (!) fingertips. Then wipe the spare epoxy away with a Cleenex or so.

5. When the epoxy has cured/hardened, the dome already is much more rubust and has gained some moderate elasticity. You may then apply a second, very thin layer of epoxy, then wait for it to get sticky, and then you may add some carbon rowing filaments.

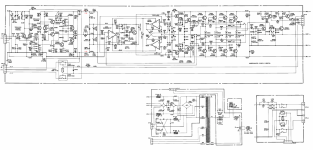

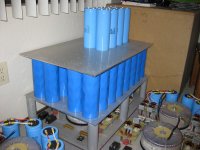

6. An eggshell alone does not make a midrange. For a first assembly, any standard cone driver can be dismantled. In this case, it was a 6.5-inch Audax HDA driver. With scissors, the membrane may be trimmed down to a residual cone slightly larger than the dome circumference. This residual bit of cone will then act as the dome carrier cone.

7. Glue the dome onto the carrier cone. To insure a neat fit, eventially stuff some carbon rowing, slightly moisted with epoxy, around the rim of the dome, into the groove between the outside of the dome and the carrier cone.

8. The moving assembly will never be dynamically symmetric. The asymmetry might be slight, but may produce substantial tilting forces and maybe even dynamic rub between the voice coil and the walls of the magnetic gap. In this case, you may try to hand-tune this asymmetry by adding a small weight at the right place into the groove formed by the dome and the carrier cone.

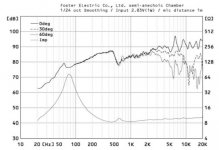

On the To-Do-List now are some measurements, which hopefully I will be able to perform in some days.

Apart from the fun, the immediate reward of this project was … the further processed, main waste of the membrane construction process: It became a delicious fried egg.