Somewhat basic question. I have some tube pin cooler connectors that keep seizing the internal threads. I believe they are aluminum and the screws seem to chrome(ish) plated brass. After a month or so of running for a few hours per day, the screws are impossible to remove without snapping the heads off rendering them useless. Interestingly, the steel set screws that clamp the parts on to the tube pins seem to not be effected. Usually, I can back the screws in question out about 1/2 a turn before the problem sets in. I could try some aluminum screws and I have some anti-seize compound I could try but any other ideas?

The connectors in question are expensive and hard to source.

The connectors in question are expensive and hard to source.

Have you tried heating the aluminum with a heat gun before trying to remove the screws so that it expands?

Very often what I resorted to with seized steel suspension hardware passing through aluminum control arms.

Timing can be important…you don’t want to heat it too long so as to prevent the hardware from also getting hot.

P.S. You want to obviously handle the aluminum with gloves…or better yet, clamp it in a padded vise.

Very often what I resorted to with seized steel suspension hardware passing through aluminum control arms.

Timing can be important…you don’t want to heat it too long so as to prevent the hardware from also getting hot.

P.S. You want to obviously handle the aluminum with gloves…or better yet, clamp it in a padded vise.

last time I did use a heat gun with pretty good results but you can see in the picture the threads are mangled to some extent. I'll try some anti-seize compound but I may also try some aluminum studs with anti seize so that I don't need to remove the stud once final assembly.Have you tried heating the aluminum with a heat gun before trying to remove the screws so that it expands?

Very often what I resorted to with seized steel suspension hardware passing through aluminum control arms.

Timing can be important…you don’t want to heat it too long so as to prevent the hardware from also getting hot.

P.S. You want to obviously handle the aluminum with gloves…or better yet, clamp it in a padded vise.

I have both.Anti-seize compound should work or if you find the grease they use on the brakes for cars.

PC

You may also want to use 18-8 (or better) stainless screws, just for the increased strength over plated brass.

jeff

jeff

stainless steel is more preferred fastener. brass or untreated steel will practically weld itself to aluminum.

and you still apply anti seize.

anti seize compound base, will evaporate over time in high heat.

it then depends on the metal or graphite content to help still save the bolt.

so as mentioned, spray penetrating oil onto the fastener and apply heat

to remove the screw and reapply anti sieve once in awhile.

and you still apply anti seize.

anti seize compound base, will evaporate over time in high heat.

it then depends on the metal or graphite content to help still save the bolt.

so as mentioned, spray penetrating oil onto the fastener and apply heat

to remove the screw and reapply anti sieve once in awhile.

Use Copper Ease or similar copper containing anti seize compound - graphite based anti-seize is not so effective with aluminium threads

Having cut my DIY teeth on a car with an aluminium engine block, I can say this stuff works every time...

Having cut my DIY teeth on a car with an aluminium engine block, I can say this stuff works every time...

At least with a stronger fastener like SS, you've got a fighting chance even if there's some galling or galvanic corrosion. Use an anti-sieze compound regardless.

jeff

jeff

Aluminium is incompatible with many metals. The reason is that the electrode potential of pure aluminium is -1.67 volts, whereas the most other metals used for fixings have a near zero or positive electrode potential (e.g. chrome -0.76, iron -0.44V, copper +0.34V, gold +1.5V). The result is that galvanic corrosion occurs within the threads and aluminium is deposited in the threads of the other metal, making extraction very difficult or impossible.

Anti-seize does not stop the corrosion, so is of limited use. Engine head bolts are usually made from chrome molybdenum steel which has a relatively low galvanic potential, whilst aluminium alloys for engine blocks contain elements to raise the galvanic potential, and the two alloys are not dissimilar enough in galvanic potential to cause the thread corrosion problem in aluminium cylinder blocks.

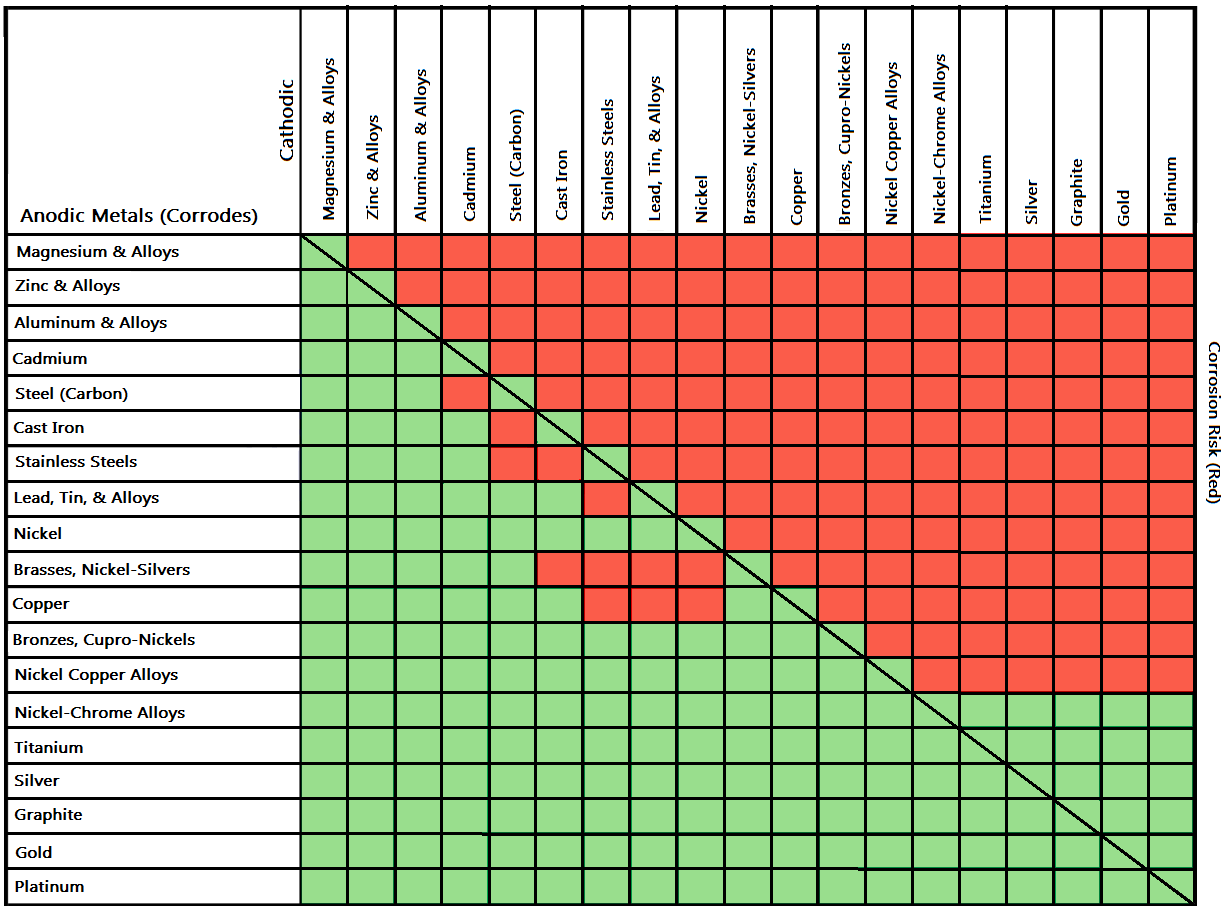

Below is a metal compatibility table.

Anti-seize does not stop the corrosion, so is of limited use. Engine head bolts are usually made from chrome molybdenum steel which has a relatively low galvanic potential, whilst aluminium alloys for engine blocks contain elements to raise the galvanic potential, and the two alloys are not dissimilar enough in galvanic potential to cause the thread corrosion problem in aluminium cylinder blocks.

Below is a metal compatibility table.

What seems very odd to me is that these are the supplied fasteners. Only the ones attaching the grid wire to the grid seems to have problems. The plate connection seems OK According to the chart steel, brass and stainless seem compatible if the green areas are acceptable.

You don't live close to the ocean by any chance, where there is a lot of humidity?

jeff

jeff

Last edited:

Nope. Inland in the Detroit area. I thought it was a fluke the first time but it's happened twice since the all with new components.

In your first post you said "I believe they are aluminum and the screws seem to chrome(ish) plated brass." If the metals are compatible some high temperature (silver, nickel or copper based) anti-seize should work..What seems very odd to me is that these are the supplied fasteners. Only the ones attaching the grid wire to the grid seems to have problems. The plate connection seems OK According to the chart steel, brass and stainless seem compatible if the green areas are acceptable.

Because items are supplied together you would hope they are compatible. In Australia the Australian Standard for solar installations requires by law that stainless steel bolts are used with the aluminium frames, rails and brackets that hold the panels. This is a disaster and can cause premature failure of the fixings, as well as making it near impossible to disassemble a solar array without damaging the component parts. It's hard to believe that after >>100 years of metallurgical science that such a stupid proclamation could be made.

I'd suggest a low strength grade of Loctite.

It would completely seal the threads.

Check the datasheets for the most suitable product.

'Loctite 577 leaves no particles to foul valves '. LOL.

It would completely seal the threads.

Check the datasheets for the most suitable product.

'Loctite 577 leaves no particles to foul valves '. LOL.

- Home

- Design & Build

- Construction Tips

- Advice to Prevent Seizing