3 Way Bullet Build - Official epic awesome office build thread

I think I'm about 3 months into this project so far but I'm now going to start the build thread.

This build consists of 3 way nearfield monitors and a coffee table that is also a push-push bass reflex subwoofer.

This is in no way an "optimal" build. It was never supposed to be. It is meant to be an outlandish, exotic, fun build. I wanted to use different drivers, different configurations, different methods, different everything. I can build a two studio monitor and have it play back accurate. This is not that. That I could just buy. This is building something you cannot just buy. Something you'd have to make. Something you'd have to explain to even someone into audio.

OBJECTIVE:

Create an awesome 3 way setup with a sub that goes from 18 hz to 40K hz. Distorion under 2% for everything 200 hz and up. It needed it fit under my triple monitors and not take up too much office space. By making the coffee table for my office couch the sub I have succeeded for the sub. The 3 ways are pretty big but they tuck under the monitors which is dead space anyways. Budget was under $500. I think I might end up a little over with the crossover but we will see

Monitors:

Tweeter - GRS RT1.R - 5K hz and up $60 (on sale)

I hear good things about these ribbons. This is the first time I am using a ribbon tweeter. Hoping there isn't too steep of a learning curve. I took the measurements with a 45 uf cap. The sweep sounds insanely clean.

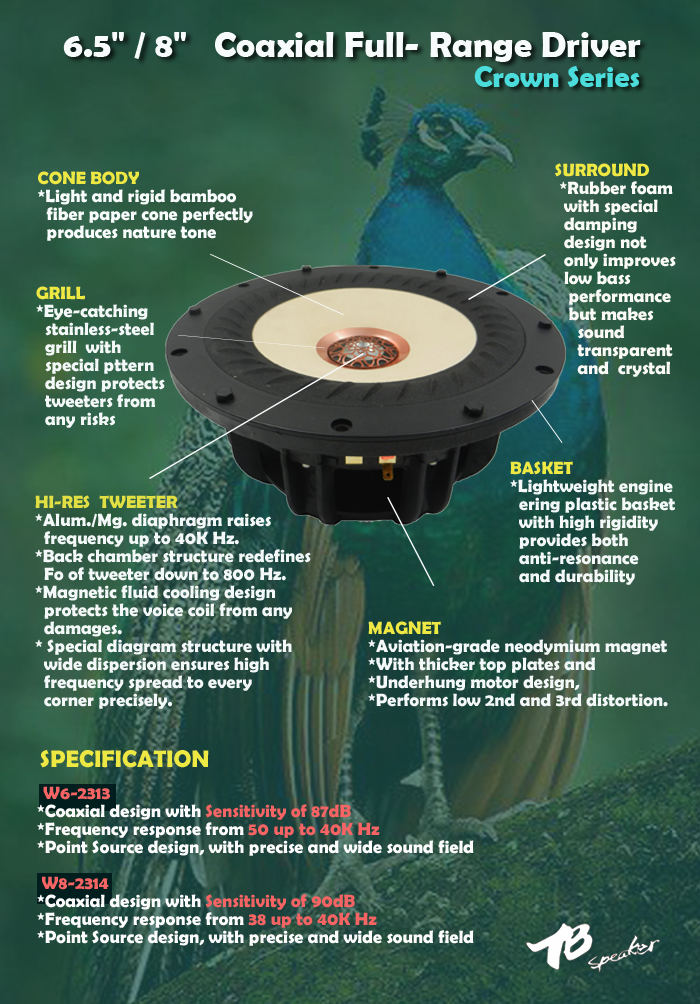

MID: - GRS 8" Mid Planar - 800-5k hz $55 (on sale)

This is another first, I have never used anything other than a cone driver for a mid so far. I did spent a ridiculous amount of time 3d printing horns. I learned a lot. I can get it go down to 500 hz cleanly but it requires a massive horn and that isn't the direction I wanted to go.

WOOFER: - Epique 5.5" MMAG Woofer $70 (on sale with coupon)

I was hesistant to go with this driver. It has measured out very well. With the port its hitting down into the 30s with ease. Impressive little thing. I got it on sale so not so bad. It has an incredible amount of XMAX. Interested to start working with this thing

Subwoofer: - GRS 12" High Excursion Paper Cone

Nothing special here. I have simulated these before and wondered how anyone could have a use for them since they require such a large box. Well, a coffee table is around 13000 inch square. So two of them work perfectly here.

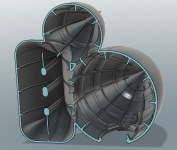

ENCLOSURE:

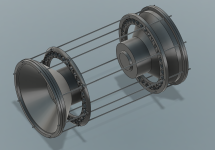

This is a 3d printed enclosure. The filament used here is carbon fiber infused PETG. It is dense, heavy, and rings super low. I have so much bracing in this unit and the walls are so thick I'm pretty sure I could park my Acura RSX on it without it failing. I'll throw up some pictures for you to see. This part was printed on a very large 3d printer and it took 3 days to print. In total it is 6 pounds of filament. This isn't your friends 3d printing. This is industrial grade. I have a few of these at work and use them all the time. This required the largest one we have.

The Planar Mid is sandwiched inside the enclosure between the face and the body. Behind the mid planar is a diffusion array. I tested a bunch of these. This one works the best by a long shot. Not exactly sure why. The back cup is filled with polyfill. There is a sheet of microfiber cloth between the fill and the planar so the poly fill fibers do not end up inside of the driver.

The enclosure is exactly 0.38' cube. I forget how long the port is but it is exact to what I wanted. Do not underestimate the amount of time it took me to create this model to EXACTLY 0.38' cube volume AND have the port the exact length. The port is the stand. It still in prototype stage but with eventually be 3d printed in the same black filament as the body.

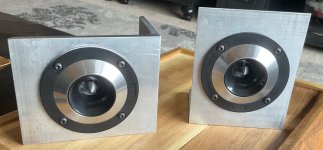

Coffee Table Subwoofer:

So this became of me just screwing around one night with WINISD. I needed a coffee table and didn't want a boring one. I run the fab shop of an engineering consulting company so I figured I might was well make the coffee table a sub and show off some fab skills. The volume is 13000" square. I forget the port length but there are two of them and they are 4" diameter. That is as wide of diameter as I could go without adding bends which I didn't want to do. They fire at the floor. The table will be 2" off of the floor. I won't get past the max port velocity until 200 watts so I think I am ok. I'll be powering it with a 200 watt RMS amplifier. I will run them in series for an 8 ohm impedence. This is an office so that should be sufficient. I'm not trying to shake the building down here.

The woofers will be sandwiched between the middle bracing and the outer walls. They are more than snug. I already fitted that up. They will not be screwed to the sides. There will be 8 M5 threaded rods running through the entirety of the cabinet to link the two woofers. There are also some reinforcing rings midway so that the threaded rod doesn't try to bow as they run a decent distance.

I think the bracing is sufficient if not a little overboard. Again, I can probably park my Acura on this without it breaking.

The big party trick here is the top will be clear Acrylic. It will be screwed on with gasket on all the bracing to seal it. No way am I doing all this crazy engineering and then hiding it. Nope, I want everyone to see what is going on.

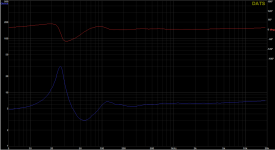

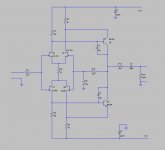

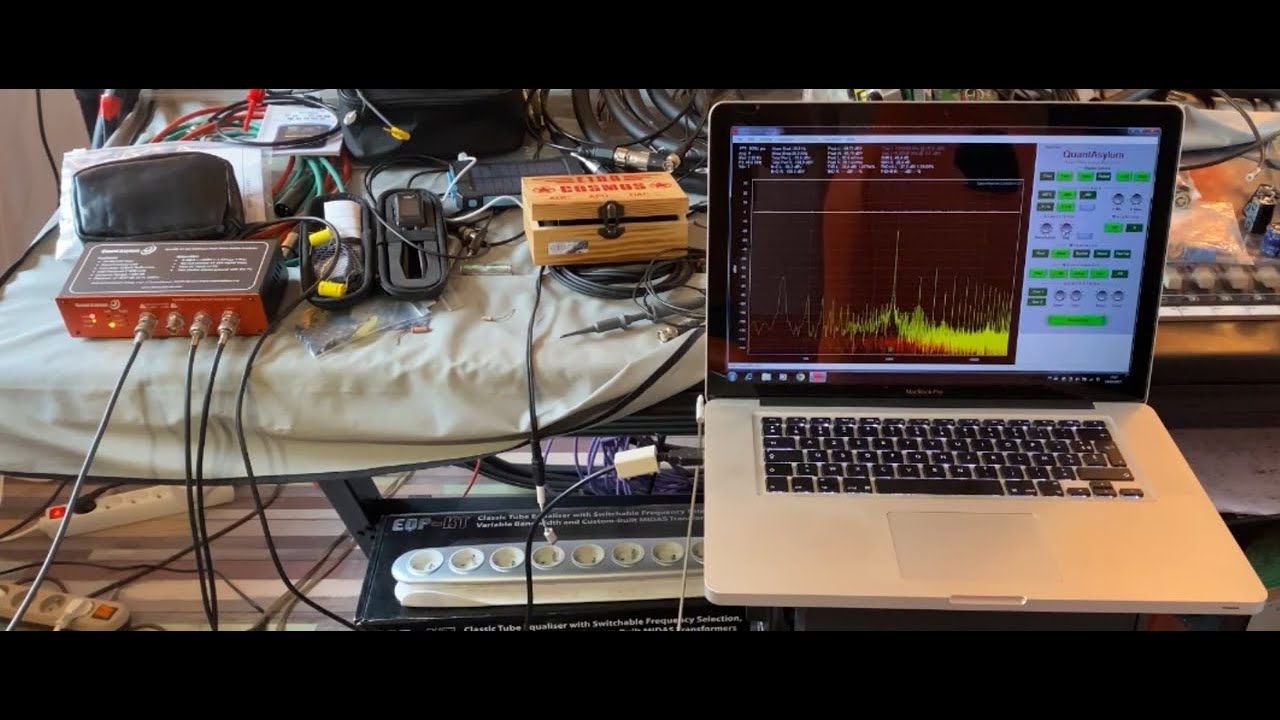

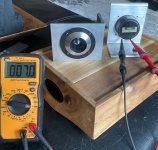

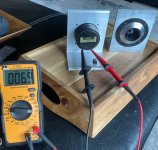

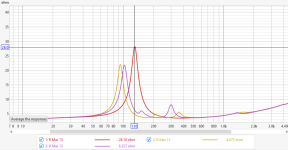

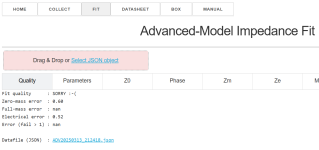

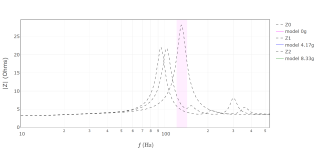

Measurements:

These will be coming soon. I just took them today. I will get them into VituixCAD and start messing with the crossover. I'll probably go with a 3 way series crossover. I like the flexibility of the series crossover. Less need for a bunch of components in the form of notch filters. The Mid planar and the Ribbon will both require some notches. I can already tell from the measurements. They do all measure very clean. These are much lower distortion drivers than anything I have used before. Anyways, coming soon, I am running out of time before I have to head out to dinner.

Thanks for reading. I should be done with the sub next week and the crossover within the next 2 weeks.

This build consists of 3 way nearfield monitors and a coffee table that is also a push-push bass reflex subwoofer.

This is in no way an "optimal" build. It was never supposed to be. It is meant to be an outlandish, exotic, fun build. I wanted to use different drivers, different configurations, different methods, different everything. I can build a two studio monitor and have it play back accurate. This is not that. That I could just buy. This is building something you cannot just buy. Something you'd have to make. Something you'd have to explain to even someone into audio.

OBJECTIVE:

Create an awesome 3 way setup with a sub that goes from 18 hz to 40K hz. Distorion under 2% for everything 200 hz and up. It needed it fit under my triple monitors and not take up too much office space. By making the coffee table for my office couch the sub I have succeeded for the sub. The 3 ways are pretty big but they tuck under the monitors which is dead space anyways. Budget was under $500. I think I might end up a little over with the crossover but we will see

Monitors:

Tweeter - GRS RT1.R - 5K hz and up $60 (on sale)

I hear good things about these ribbons. This is the first time I am using a ribbon tweeter. Hoping there isn't too steep of a learning curve. I took the measurements with a 45 uf cap. The sweep sounds insanely clean.

MID: - GRS 8" Mid Planar - 800-5k hz $55 (on sale)

This is another first, I have never used anything other than a cone driver for a mid so far. I did spent a ridiculous amount of time 3d printing horns. I learned a lot. I can get it go down to 500 hz cleanly but it requires a massive horn and that isn't the direction I wanted to go.

WOOFER: - Epique 5.5" MMAG Woofer $70 (on sale with coupon)

I was hesistant to go with this driver. It has measured out very well. With the port its hitting down into the 30s with ease. Impressive little thing. I got it on sale so not so bad. It has an incredible amount of XMAX. Interested to start working with this thing

Subwoofer: - GRS 12" High Excursion Paper Cone

Nothing special here. I have simulated these before and wondered how anyone could have a use for them since they require such a large box. Well, a coffee table is around 13000 inch square. So two of them work perfectly here.

ENCLOSURE:

This is a 3d printed enclosure. The filament used here is carbon fiber infused PETG. It is dense, heavy, and rings super low. I have so much bracing in this unit and the walls are so thick I'm pretty sure I could park my Acura RSX on it without it failing. I'll throw up some pictures for you to see. This part was printed on a very large 3d printer and it took 3 days to print. In total it is 6 pounds of filament. This isn't your friends 3d printing. This is industrial grade. I have a few of these at work and use them all the time. This required the largest one we have.

The Planar Mid is sandwiched inside the enclosure between the face and the body. Behind the mid planar is a diffusion array. I tested a bunch of these. This one works the best by a long shot. Not exactly sure why. The back cup is filled with polyfill. There is a sheet of microfiber cloth between the fill and the planar so the poly fill fibers do not end up inside of the driver.

The enclosure is exactly 0.38' cube. I forget how long the port is but it is exact to what I wanted. Do not underestimate the amount of time it took me to create this model to EXACTLY 0.38' cube volume AND have the port the exact length. The port is the stand. It still in prototype stage but with eventually be 3d printed in the same black filament as the body.

Coffee Table Subwoofer:

So this became of me just screwing around one night with WINISD. I needed a coffee table and didn't want a boring one. I run the fab shop of an engineering consulting company so I figured I might was well make the coffee table a sub and show off some fab skills. The volume is 13000" square. I forget the port length but there are two of them and they are 4" diameter. That is as wide of diameter as I could go without adding bends which I didn't want to do. They fire at the floor. The table will be 2" off of the floor. I won't get past the max port velocity until 200 watts so I think I am ok. I'll be powering it with a 200 watt RMS amplifier. I will run them in series for an 8 ohm impedence. This is an office so that should be sufficient. I'm not trying to shake the building down here.

The woofers will be sandwiched between the middle bracing and the outer walls. They are more than snug. I already fitted that up. They will not be screwed to the sides. There will be 8 M5 threaded rods running through the entirety of the cabinet to link the two woofers. There are also some reinforcing rings midway so that the threaded rod doesn't try to bow as they run a decent distance.

I think the bracing is sufficient if not a little overboard. Again, I can probably park my Acura on this without it breaking.

The big party trick here is the top will be clear Acrylic. It will be screwed on with gasket on all the bracing to seal it. No way am I doing all this crazy engineering and then hiding it. Nope, I want everyone to see what is going on.

Measurements:

These will be coming soon. I just took them today. I will get them into VituixCAD and start messing with the crossover. I'll probably go with a 3 way series crossover. I like the flexibility of the series crossover. Less need for a bunch of components in the form of notch filters. The Mid planar and the Ribbon will both require some notches. I can already tell from the measurements. They do all measure very clean. These are much lower distortion drivers than anything I have used before. Anyways, coming soon, I am running out of time before I have to head out to dinner.

Thanks for reading. I should be done with the sub next week and the crossover within the next 2 weeks.

Attachments

-

PXL_20241228_205117938.jpg452.1 KB · Views: 351

PXL_20241228_205117938.jpg452.1 KB · Views: 351 -

PXL_20241228_205126020.jpg400 KB · Views: 311

PXL_20241228_205126020.jpg400 KB · Views: 311 -

1000006017.jpg437.9 KB · Views: 279

1000006017.jpg437.9 KB · Views: 279 -

PXL_20241228_154029416.jpg524.8 KB · Views: 277

PXL_20241228_154029416.jpg524.8 KB · Views: 277 -

PXL_20241228_143957886.jpg674.3 KB · Views: 287

PXL_20241228_143957886.jpg674.3 KB · Views: 287 -

PXL_20241228_143959632.jpg686.1 KB · Views: 294

PXL_20241228_143959632.jpg686.1 KB · Views: 294 -

PXL_20241228_205119786.jpg406.7 KB · Views: 304

PXL_20241228_205119786.jpg406.7 KB · Views: 304 -

PXL_20241228_163426459.jpg555.6 KB · Views: 334

PXL_20241228_163426459.jpg555.6 KB · Views: 334 -

Screenshot 2024-12-28 162141.png547.6 KB · Views: 307

Screenshot 2024-12-28 162141.png547.6 KB · Views: 307 -

Screenshot 2024-12-28 162120.png1,009.1 KB · Views: 310

Screenshot 2024-12-28 162120.png1,009.1 KB · Views: 310 -

Screenshot 2024-12-28 165647.png850.6 KB · Views: 316

Screenshot 2024-12-28 165647.png850.6 KB · Views: 316 -

Screenshot 2024-12-28 165624.png1.2 MB · Views: 348

Screenshot 2024-12-28 165624.png1.2 MB · Views: 348