side question, are the keyring loops there to limit lateral movement on your towers?

No. The resistance from air tubing and wires is very low and negligible if that is what you menant by keyring loops.

side question, are the keyring loops there to limit lateral movement on your towers?

Sorry, I was confused. I thought there are no keyring loops on the arm. But I looked the photos again. I realized I put keyring loops on the suspension towers of sub-chassis of the table. Putting keyring loops on the towers is not to limit the lateral movements of sub-chassis. The sub-chassis is floating on 5 40 cm flat round air bearings. The suspension towers hold the sub-chassis in place loosely. I use a brass outer ring to reduce warp. The keyring loops hold the rubber rings of suspension tower so the rubber rings won't touch the brass outer ring.

Last edited:

Hi Jim,

What a beautiful arm. I think it's the best looking arm you've made so far. I love the wood accents. (or are they damping panels?). Lots of very white looking metal, is the entire arm made of magnesium? It looks like you have repurposed the borosilicate glass tube from your ballrace linear tracker as a damping trough.

The lower limit of the arm/cartridge resonance is chosen because of warps. Warp typically occur with a frequency range from 0.55hz to 5-6hz. The higher frequency warps tend to have lower amplitude, warps above 5hz are little more than wrinkles in the surface of the vinyl and have very small amplitudes. Putting the resonance at 10hz puts it an octave above warps and an octave below the lowest groove modulation. This is a slightly simplistic approach that doesn't look at how effective mass effects things above 20hz. Of course warps only effect the vertical motion of the arm so is only applicable to setting vertical effective mass. Lateral motion is limited by eccentricity which occurs at a much lower frequency so lateral arm/cartridge resonance can be set to a much lower frequency.

As your system has excellent warp flattening clamping and damping the arm/cartridge resonance can be tuned to a lower frequency than normal. With your system I would say that this will be beneficial so your frequency of 8-9hz is perfect.

Hi Rayma, at 33 1/3rpm the record rotates at 0.55hz, a lot lower than nearly 2hz.

Hi sq225917, the lower bound isn't chosen due to the frequency of the suspension of the deck. You still have to put the resonance at a sensible frequency on a solid plinth deck. However putting the arm/cartridge resonance a reasonable distance above the frequency of the suspension is not a bad idea.

Niffy

What a beautiful arm. I think it's the best looking arm you've made so far. I love the wood accents. (or are they damping panels?). Lots of very white looking metal, is the entire arm made of magnesium? It looks like you have repurposed the borosilicate glass tube from your ballrace linear tracker as a damping trough.

The lower limit of the arm/cartridge resonance is chosen because of warps. Warp typically occur with a frequency range from 0.55hz to 5-6hz. The higher frequency warps tend to have lower amplitude, warps above 5hz are little more than wrinkles in the surface of the vinyl and have very small amplitudes. Putting the resonance at 10hz puts it an octave above warps and an octave below the lowest groove modulation. This is a slightly simplistic approach that doesn't look at how effective mass effects things above 20hz. Of course warps only effect the vertical motion of the arm so is only applicable to setting vertical effective mass. Lateral motion is limited by eccentricity which occurs at a much lower frequency so lateral arm/cartridge resonance can be set to a much lower frequency.

As your system has excellent warp flattening clamping and damping the arm/cartridge resonance can be tuned to a lower frequency than normal. With your system I would say that this will be beneficial so your frequency of 8-9hz is perfect.

Hi Rayma, at 33 1/3rpm the record rotates at 0.55hz, a lot lower than nearly 2hz.

Hi sq225917, the lower bound isn't chosen due to the frequency of the suspension of the deck. You still have to put the resonance at a sensible frequency on a solid plinth deck. However putting the arm/cartridge resonance a reasonable distance above the frequency of the suspension is not a bad idea.

Niffy

Thanks for the explanation, Niffy!

All the white metal are 6061 aluminum with glass bead blasting surface except head shell and tail for counter weight. I found 2024 aluminum is best sounding material for head shell. I would love to use titanium for head shell, but it is just beyond my reach. The tail for counter weight is made with magnesium. My other two arms have carbon fiber tubing for counter weights. I prefer magnesium over carbon fiber. Magnesium is light and sound deadening material. I feel it definitely makes contribution to the quietness of arm.

The wood I used is iron wood. It is hard and has nice grain. It is for good look only.

The damping though is made with plastic tube. In my opinion, vertical damping is even more important than lateral damping, so I use plastic for the paddle of damping device. The damping fluid is about 800 CST which is much lower than I used for other two arms. I use about 1500 CST for other two arms.

The air bearing is just about 4 mm above the surface of record and I can adjust the gap based on different cartridges. I can also adjust the height of whole arm or just the height of shaft. So, it is very versatile for different cartridges.

Jim

All the white metal are 6061 aluminum with glass bead blasting surface except head shell and tail for counter weight. I found 2024 aluminum is best sounding material for head shell. I would love to use titanium for head shell, but it is just beyond my reach. The tail for counter weight is made with magnesium. My other two arms have carbon fiber tubing for counter weights. I prefer magnesium over carbon fiber. Magnesium is light and sound deadening material. I feel it definitely makes contribution to the quietness of arm.

The wood I used is iron wood. It is hard and has nice grain. It is for good look only.

The damping though is made with plastic tube. In my opinion, vertical damping is even more important than lateral damping, so I use plastic for the paddle of damping device. The damping fluid is about 800 CST which is much lower than I used for other two arms. I use about 1500 CST for other two arms.

The air bearing is just about 4 mm above the surface of record and I can adjust the gap based on different cartridges. I can also adjust the height of whole arm or just the height of shaft. So, it is very versatile for different cartridges.

Jim

Super,

I have read your journey with great pleasure and it's great you were so kind to share your findings with us and document every detail so we could use your documentation to make also our own version.

You are obviously much more knowledgeable than me and many other people thus I am sure my questions will definitely sound stupid to you.

First of all, I have high compliance carts and my best one is Clearaudio Goldfinger statement.

Currently I am using Terminator arm and I am feeling I am not getting the best out of it and that is why I wanted to change type of design from a low air pressure design such as Terminator to a high pressure stiffer design like Kuzma style.

Now, given the weigh and compliance of the cartridge, simple resonance calculation suggests my arm mass to be around 15gr to place the resonance at around 9-10Hz.

Since you have made 3 different versions, first off, which one would be most suitable for the goldfinger?

I have also followed your work on the damping methods and I have read that Kuzma only relies on the tubing's stiffness to provide the necessary damping. You mentioned that the arm with such a damping method would fail to track properly, but I don't recall having seen any review nor complaint from any Kuzma used about the arm not being able to track.

In the other end of the spectrum, intuitively, I would want both air tubing and tonearm wires to follow the toneram and pose zero friction or interference with it.

Is there anything wrong with my thinking?

Also in reading the thread, I have noticed that a two air bushings was brought up and a Chinese user has implemented and claims it surpassed sonically EMT linear tonearm.

Also the Walker audio arm was brought up. This seems to be using a two separate bushings one next to the other with the counterweight placed at the end.

From an experience user who compared kuzma to Walter, he reported that the walker audio is the best air bearing arm he has tried.

Unfortunately these approaches haven't been developed. You mentioned the problem is the tolerance on the shaft, but doesn't newwayairbearings provide calibrated shafts as well? Wouldn't these be very low tolerance?

Do you still think the 1" bushing arrangement with its greater area surface offer the best performance from outer to inner groove compared to smaller diameter bushings?

Regarding the extremely short wand you are using, could this pose issues with warps?

I noticed that you use outer ring and clamp, but my concern is that these devices have been shown in certain cases to kill the sound though they do a good job with warps. In case anyone would decide not to use outer rings nor clamp but use instead cones to isolate the LP from the platter to keep max isolation, would you recommend a longer wand?

If so, were can I find a similar taper wand similar to the Kuzma? Does it have to be worked/CNC from solid aluminum bar or something off the shelf can be found?

One thing I don't understand...looking at the Kuzma's overall construction, I can't understand how the arm tube is connected/attached to the bushing. There is a structure around the bushing but I just don't get how everytthing is assembled. I was hoping you could light up a bit this for me.

With hollow armtube, wouldn't this cause ringing thus coloration of the sound? Maybe special painting process can dampen these vibrations?

I probably had too many questions, but this thread is extremely exciting and I am a complete newbie to this.,I hope you can help me navigate through this.

Thank you in advance for your patient and attention.

Best Regard,

Stefano.

I have read your journey with great pleasure and it's great you were so kind to share your findings with us and document every detail so we could use your documentation to make also our own version.

You are obviously much more knowledgeable than me and many other people thus I am sure my questions will definitely sound stupid to you.

First of all, I have high compliance carts and my best one is Clearaudio Goldfinger statement.

Currently I am using Terminator arm and I am feeling I am not getting the best out of it and that is why I wanted to change type of design from a low air pressure design such as Terminator to a high pressure stiffer design like Kuzma style.

Now, given the weigh and compliance of the cartridge, simple resonance calculation suggests my arm mass to be around 15gr to place the resonance at around 9-10Hz.

Since you have made 3 different versions, first off, which one would be most suitable for the goldfinger?

I have also followed your work on the damping methods and I have read that Kuzma only relies on the tubing's stiffness to provide the necessary damping. You mentioned that the arm with such a damping method would fail to track properly, but I don't recall having seen any review nor complaint from any Kuzma used about the arm not being able to track.

In the other end of the spectrum, intuitively, I would want both air tubing and tonearm wires to follow the toneram and pose zero friction or interference with it.

Is there anything wrong with my thinking?

Also in reading the thread, I have noticed that a two air bushings was brought up and a Chinese user has implemented and claims it surpassed sonically EMT linear tonearm.

Also the Walker audio arm was brought up. This seems to be using a two separate bushings one next to the other with the counterweight placed at the end.

From an experience user who compared kuzma to Walter, he reported that the walker audio is the best air bearing arm he has tried.

Unfortunately these approaches haven't been developed. You mentioned the problem is the tolerance on the shaft, but doesn't newwayairbearings provide calibrated shafts as well? Wouldn't these be very low tolerance?

Do you still think the 1" bushing arrangement with its greater area surface offer the best performance from outer to inner groove compared to smaller diameter bushings?

Regarding the extremely short wand you are using, could this pose issues with warps?

I noticed that you use outer ring and clamp, but my concern is that these devices have been shown in certain cases to kill the sound though they do a good job with warps. In case anyone would decide not to use outer rings nor clamp but use instead cones to isolate the LP from the platter to keep max isolation, would you recommend a longer wand?

If so, were can I find a similar taper wand similar to the Kuzma? Does it have to be worked/CNC from solid aluminum bar or something off the shelf can be found?

One thing I don't understand...looking at the Kuzma's overall construction, I can't understand how the arm tube is connected/attached to the bushing. There is a structure around the bushing but I just don't get how everytthing is assembled. I was hoping you could light up a bit this for me.

With hollow armtube, wouldn't this cause ringing thus coloration of the sound? Maybe special painting process can dampen these vibrations?

I probably had too many questions, but this thread is extremely exciting and I am a complete newbie to this.,I hope you can help me navigate through this.

Thank you in advance for your patient and attention.

Best Regard,

Stefano.

Hi Stefano,

I will try my best to answer your questions.

The compliance for Goldfinger is 15 μ/mN. Total mass of arm should be around 80 grams if you use short arm which is similar to mine. My last arm has almost 90 grams and arm/cartridge resonance is 7-8 Hz. You should use a 3/4” air bushing.

Here is one thing I can’t figure it out. According to Kuzma, the total mass of their air line arm is only 80 grams. I can’t figure out how they did that. It seems impossible for me.

Actually, Kuzma has a silicone damping tough as option. Relying on air tubing for damping is not good method. Ideally, air tubing should have no resistance at all. I believe the air tubing I am using is better than Kuzma’s. Kuzma’s air tubing looks like a 1/16 PVC. When you are ready, pm me your address. I can send you a foot or two.

In my case, I prefer Kuzma’s style, or I call it moving bearing arm. You can make a custom precision shaft and use two air bushings, but the shaft will be very expensive. If you decide to make two air bushing style arm, or I call it moving shaft, please let me know. I have two spare 1/2” air bushings and can save you some money. Moving shaft arm has one advantage over moving bearing, i.e., it doesn't need to deal with resistance of air tubing.

I can’t say it for sure now. The cartridges on my 1” air bearing arms are Koetsu Rosewood Signature and a modified Denon DL 103r. Both are low compliance cartridges. On my 3/4” air bearing arm, it is Ortofon A90 which is medium compliance cartridge. I prefer the sound comes out from 1” air bearing/low compliance cartridges comb more than 3/4” air bearing arm/medium compliance cartridge. However, I may try low compliance cartridge on 3/4” air bearing arm later on. Although I have never tested the tacking ability of my arms, I can tell my latest arm with 3/4" air bearing has superior tacking ability. It is better than 1" air bearing arms.

No. I have no problems with warps.

I personally prefer the sound with outer ring and tried many times with and without the ring.

I don’t recommend a long arm.

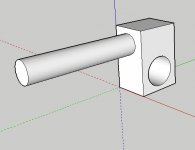

Please see the images. I did a simple sketch to show you the construction of Kuzma arm.

No. You should’t use hollow arm tube. One thing I can think about is to use insulation spray foam sealant to fill the inside of arm tube. You may get it from your local hardware store.

I hope I answered all your questions clearly. Good luck with your build.

Jim

I will try my best to answer your questions.

Now, given the weigh and compliance of the cartridge, simple resonance calculation suggests my arm mass to be around 15gr to place the resonance at around 9-10Hz.

Since you have made 3 different versions, first off, which one would be most suitable for the goldfinger?

The compliance for Goldfinger is 15 μ/mN. Total mass of arm should be around 80 grams if you use short arm which is similar to mine. My last arm has almost 90 grams and arm/cartridge resonance is 7-8 Hz. You should use a 3/4” air bushing.

Here is one thing I can’t figure it out. According to Kuzma, the total mass of their air line arm is only 80 grams. I can’t figure out how they did that. It seems impossible for me.

I have also followed your work on the damping methods and I have read that Kuzma only relies on the tubing's stiffness to provide the necessary damping.

Actually, Kuzma has a silicone damping tough as option. Relying on air tubing for damping is not good method. Ideally, air tubing should have no resistance at all. I believe the air tubing I am using is better than Kuzma’s. Kuzma’s air tubing looks like a 1/16 PVC. When you are ready, pm me your address. I can send you a foot or two.

Also in reading the thread, I have noticed that a two air bushings was brought up and a Chinese user has implemented and claims it surpassed sonically EMT linear tonearm.

Also the Walker audio arm was brought up. This seems to be using a two separate bushings one next to the other with the counterweight placed at the end.

From an experience user who compared kuzma to Walter, he reported that the walker audio is the best air bearing arm he has tried.

Unfortunately these approaches haven't been developed. You mentioned the problem is the tolerance on the shaft, but doesn't newwayairbearings provide calibrated shafts as well? Wouldn't these be very low tolerance?

In my case, I prefer Kuzma’s style, or I call it moving bearing arm. You can make a custom precision shaft and use two air bushings, but the shaft will be very expensive. If you decide to make two air bushing style arm, or I call it moving shaft, please let me know. I have two spare 1/2” air bushings and can save you some money. Moving shaft arm has one advantage over moving bearing, i.e., it doesn't need to deal with resistance of air tubing.

Do you still think the 1" bushing arrangement with its greater area surface offer the best performance from outer to inner groove compared to smaller diameter bushings?

I can’t say it for sure now. The cartridges on my 1” air bearing arms are Koetsu Rosewood Signature and a modified Denon DL 103r. Both are low compliance cartridges. On my 3/4” air bearing arm, it is Ortofon A90 which is medium compliance cartridge. I prefer the sound comes out from 1” air bearing/low compliance cartridges comb more than 3/4” air bearing arm/medium compliance cartridge. However, I may try low compliance cartridge on 3/4” air bearing arm later on. Although I have never tested the tacking ability of my arms, I can tell my latest arm with 3/4" air bearing has superior tacking ability. It is better than 1" air bearing arms.

Regarding the extremely short wand you are using, could this pose issues with warps?

No. I have no problems with warps.

I noticed that you use outer ring and clamp, but my concern is that these devices have been shown in certain cases to kill the sound though they do a good job with warps. In case anyone would decide not to use outer rings nor clamp but use instead cones to isolate the LP from the platter to keep max isolation, would you recommend a longer wand?

I personally prefer the sound with outer ring and tried many times with and without the ring.

I don’t recommend a long arm.

One thing I don't understand...looking at the Kuzma's overall construction, I can't understand how the arm tube is connected/attached to the bushing. There is a structure around the bushing but I just don't get how everytthing is assembled. I was hoping you could light up a bit this for me.

Please see the images. I did a simple sketch to show you the construction of Kuzma arm.

With hollow armtube, wouldn't this cause ringing thus coloration of the sound? Maybe special painting process can dampen these vibrations?

No. You should’t use hollow arm tube. One thing I can think about is to use insulation spray foam sealant to fill the inside of arm tube. You may get it from your local hardware store.

I hope I answered all your questions clearly. Good luck with your build.

Jim

Attachments

Last edited:

I would like to add one more point for moving shaft arm. The shaft for moving shaft arm can't be solid one because it will be too heavy. It is also highly desirable to use hollow shaft made with aerospace aluminum alloys or ceramic. In order to keep optimum weigh of shaft, you also need to keep wall of hollow shaft minimized. This is why it is difficult to obtain such precision shaft for moving shaft arm. Once you can get the shaft done, you also have to think how to lay out the arm. The layout of Walker audio Proscenium may be the only good one and the only option you have. You also need to design a mechanism to adjust the positions of air bearings.

Super you are awesome! Thank you very much for your answer!

About the tubing I will pm you so I can purchase some from you when I get to a more mature development point.

Based on what you are saying I will be going with the Kuzma style, the moving shaft arrangement seems to be too complicated for a newbie like me at the first project.

When I wrote the post few days ago, I didn't realize Kuzma had an update for dampening. I am sure they have probably seen your work and figured out they needed one.

My basic thinking leads me to believe you as close to zero interaction from the wiring and tubing as possible and then the fluid dampens symmetrically the horizontal motion. My intention will be to try to minimize interaction of the wiring and tubing (your tubing seems to be optimum) as much as possible.

Accordingly to your suggestion a 3/4" bushing would be the ideal spot for the Kuzma style. You have also mentioned that having a precision shaft is imperative. Is the same supplier capable of providing a high precision matching shaft or do I have to go to a dedicated manufacturer to get one?

How much would bushing and ultra precision solid shaft be?

All the other parts, supports counterweigh etc. will be machined from aluminum and b-blasted and black anodized or powder painted (any recommendation for material and finish process? I know special paintings can help dampen unwanted vibrations, have you looked into it?)

I usually employ a Chinese shop for my metal work but I am not sure I can trust that manufacturer for such precision parts, do you have any shop you have used in the past here in the US?

I am located in Southern California so if it happens you are near me we can meet up and talk in person.

Regarding my question about how they attached the structure that holds the tonearm and the threaded bar for the counterweight around the bushing, allow me to show you a picture. The yellow arrow points to the block around the bushing. Is that a one piece aluminum or two pieces and screwed together? If it is one piece, how do they precisely fit it over the bushing? I assume it is critical to get most centering position, do you need a fixture to perfectly center it?

Moreover, looking at the red arrow: how do they connect the end block to the shaft and secure the rest of the assembly?

The manual says that in order to remove the bushing for cleaning, you only need to unscrew the top screw highlighted in red.

How can that remove the ending block from the rest of the assembly or in other words, secure the structure? I couldn't find a definitive answer by just looking at online pictures and pictures on the manual.

Once I understand how all the parts assemble one with another I will start making solidworks drawing and share them, but first I need to understand how everything connects.

Finally regarding the armtube, the terminator has a short wand and it is not too friendly to change vinyl and few times I have slightly scratched some vinyls against the carrier because of lack of clearance, so it's a hard call whether to have a short wand or a longer this time.

I assume that either Kuzma or Walker audio or eminent or any other arm, have a hollow armtube unfilled since they can rewire inside.

You mention that you don't recommend hollow arm tube, but how do you reconcile all these other manufacturers have been using hollow structures? Eminent offers a $200 Magnesium armwand for the 2.5 version, have you ever looked at it? If so, what do you think?

By the way, With my Terminator, I have a carbon fiber wand and an aluminum wand for the terminator and even though the wand is not hollow, the aluminum version rings if I tap with my fingernails on it which left me really surprised as I didn't expect to ring at all.

Just a curiosity, have you ever had a chance to compare your tonearm to a terminator style? What are your thoughts in this matter?

Thank you very much for your attention.

About the tubing I will pm you so I can purchase some from you when I get to a more mature development point.

Based on what you are saying I will be going with the Kuzma style, the moving shaft arrangement seems to be too complicated for a newbie like me at the first project.

When I wrote the post few days ago, I didn't realize Kuzma had an update for dampening. I am sure they have probably seen your work and figured out they needed one.

My basic thinking leads me to believe you as close to zero interaction from the wiring and tubing as possible and then the fluid dampens symmetrically the horizontal motion. My intention will be to try to minimize interaction of the wiring and tubing (your tubing seems to be optimum) as much as possible.

Accordingly to your suggestion a 3/4" bushing would be the ideal spot for the Kuzma style. You have also mentioned that having a precision shaft is imperative. Is the same supplier capable of providing a high precision matching shaft or do I have to go to a dedicated manufacturer to get one?

How much would bushing and ultra precision solid shaft be?

All the other parts, supports counterweigh etc. will be machined from aluminum and b-blasted and black anodized or powder painted (any recommendation for material and finish process? I know special paintings can help dampen unwanted vibrations, have you looked into it?)

I usually employ a Chinese shop for my metal work but I am not sure I can trust that manufacturer for such precision parts, do you have any shop you have used in the past here in the US?

I am located in Southern California so if it happens you are near me we can meet up and talk in person.

Regarding my question about how they attached the structure that holds the tonearm and the threaded bar for the counterweight around the bushing, allow me to show you a picture. The yellow arrow points to the block around the bushing. Is that a one piece aluminum or two pieces and screwed together? If it is one piece, how do they precisely fit it over the bushing? I assume it is critical to get most centering position, do you need a fixture to perfectly center it?

Moreover, looking at the red arrow: how do they connect the end block to the shaft and secure the rest of the assembly?

The manual says that in order to remove the bushing for cleaning, you only need to unscrew the top screw highlighted in red.

How can that remove the ending block from the rest of the assembly or in other words, secure the structure? I couldn't find a definitive answer by just looking at online pictures and pictures on the manual.

Once I understand how all the parts assemble one with another I will start making solidworks drawing and share them, but first I need to understand how everything connects.

Finally regarding the armtube, the terminator has a short wand and it is not too friendly to change vinyl and few times I have slightly scratched some vinyls against the carrier because of lack of clearance, so it's a hard call whether to have a short wand or a longer this time.

I assume that either Kuzma or Walker audio or eminent or any other arm, have a hollow armtube unfilled since they can rewire inside.

You mention that you don't recommend hollow arm tube, but how do you reconcile all these other manufacturers have been using hollow structures? Eminent offers a $200 Magnesium armwand for the 2.5 version, have you ever looked at it? If so, what do you think?

By the way, With my Terminator, I have a carbon fiber wand and an aluminum wand for the terminator and even though the wand is not hollow, the aluminum version rings if I tap with my fingernails on it which left me really surprised as I didn't expect to ring at all.

Just a curiosity, have you ever had a chance to compare your tonearm to a terminator style? What are your thoughts in this matter?

Thank you very much for your attention.

Attachments

Hi Stefanno,

I bought my 3/4” air bursting from MotionUSA and paid $356 if I remembered it correctly. They also charged $25 for 1” stainless steel shaft. You may also contact Oav air bearing directly. I like Oav air bearing’s shaft. They use non magnetic stainless steel for shaft. This is preferred material.

You should buy shaft from specialty company only. The rest can be made by any qualified machine shop. I will pm you the info of a machine shop I used here in CT. He is very capable to make any parts you may need. I would not recommend any anti-vibrate paint since it may be revisable. I would like glass bead blasting and anodized. I used regular spray paints on two of my arm just for look. The machine shop I use can do glass bead blasting. If you want to anodize your parts, it should be nice too. I find an anodizing service in Texas. The prices are very reasonable and they are happy to do small jobs, but I never actually did it because I was lazy to send the parts back forth.

Anodizing Graphics of Texas

I am not sure how Kuzma did it in detail. However, it is not necessary to do same as Kuzma’s. Here is a sketch of my suggestion for your reference if you want to do long arm wand.

It looks to me just a set screw to fasten the piece on the shaft. Again, I don’t see the need to do exactly same as Kuzma’s. I attached the part on the air bearing by using epoxy. A while ago, someone said it was not elegant design. In fact, I think it is very elegant way to do it especially for short arm wand. It minimizes the distance from LP to the center of bearing and total mass of the arm.

A short arm wand requires a retrieving mechanism. This complicates the construction.

I am highly against hollow arm tube without any filling. It is simply not good design. You still can fill with some kind anti-vibration material with wire through the tube. To leave wire free inside of arm tube is not good either.

I have never listen to a terminator style arm.

Jim

Accordingly to your suggestion a 3/4" bushing would be the ideal spot for the Kuzma style. You have also mentioned that having a precision shaft is imperative. Is the same supplier capable of providing a high precision matching shaft or do I have to go to a dedicated manufacturer to get one? How much would bushing and ultra precision solid shaft be?

I bought my 3/4” air bursting from MotionUSA and paid $356 if I remembered it correctly. They also charged $25 for 1” stainless steel shaft. You may also contact Oav air bearing directly. I like Oav air bearing’s shaft. They use non magnetic stainless steel for shaft. This is preferred material.

All the other parts, supports counterweigh etc. will be machined from aluminum and b-blasted and black anodized or powder painted (any recommendation for material and finish process? I know special paintings can help dampen unwanted vibrations, have you looked into it?) I usually employ a Chinese shop for my metal work but I am not sure I can trust that manufacturer for such precision parts, do you have any shop you have used in the past here in the US?

I am located in Southern California so if it happens you are near me we can meet up and talk in person.

You should buy shaft from specialty company only. The rest can be made by any qualified machine shop. I will pm you the info of a machine shop I used here in CT. He is very capable to make any parts you may need. I would not recommend any anti-vibrate paint since it may be revisable. I would like glass bead blasting and anodized. I used regular spray paints on two of my arm just for look. The machine shop I use can do glass bead blasting. If you want to anodize your parts, it should be nice too. I find an anodizing service in Texas. The prices are very reasonable and they are happy to do small jobs, but I never actually did it because I was lazy to send the parts back forth.

Anodizing Graphics of Texas

The yellow arrow points to the block around the bushing. Is that a one piece aluminum or two pieces and screwed together? If it is one piece, how do they precisely fit it over the bushing? I assume it is critical to get most centering position, do you need a fixture to perfectly center it?

I am not sure how Kuzma did it in detail. However, it is not necessary to do same as Kuzma’s. Here is a sketch of my suggestion for your reference if you want to do long arm wand.

Moreover, looking at the red arrow: how do they connect the end block to the shaft and secure the rest of the assembly?

The manual says that in order to remove the bushing for cleaning, you only need to unscrew the top screw highlighted in red.

How can that remove the ending block from the rest of the assembly or in other words, secure the structure? I couldn't find a definitive answer by just looking at online pictures and pictures on the manual.

It looks to me just a set screw to fasten the piece on the shaft. Again, I don’t see the need to do exactly same as Kuzma’s. I attached the part on the air bearing by using epoxy. A while ago, someone said it was not elegant design. In fact, I think it is very elegant way to do it especially for short arm wand. It minimizes the distance from LP to the center of bearing and total mass of the arm.

Finally regarding the armtube, the terminator has a short wand and it is not too friendly to change vinyl and few times I have slightly scratched some vinyls against the carrier because of lack of clearance, so it's a hard call whether to have a short wand or a longer this time.

A short arm wand requires a retrieving mechanism. This complicates the construction.

I assume that either Kuzma or Walker audio or eminent or any other arm, have a hollow armtube unfilled since they can rewire inside.

You mention that you don't recommend hollow arm tube, but how do you reconcile all these other manufacturers have been using hollow structures? Eminent offers a $200 Magnesium armwand for the 2.5 version, have you ever looked at it? If so, what do you think?

I am highly against hollow arm tube without any filling. It is simply not good design. You still can fill with some kind anti-vibration material with wire through the tube. To leave wire free inside of arm tube is not good either.

Just a curiosity, have you ever had a chance to compare your tonearm to a terminator style? What are your thoughts in this matter?

I have never listen to a terminator style arm.

Jim

Attachments

Thanks again for your kind reply.

Air Bearings: I have seen researching around there are more than one manufacturer making these devices. They all look alike but reading each description it seems they bear slightly different technology.

Is this true? Is there really any difference between these different air bearings?

Shafts: There are many dedicated manufacturers making shafts. You have suggested OAV as they use non magnetic stainless steel. I have seen also ceramic coated shafts around. Which material in your opinion offers greatest stiffness/ minimum resonant behavior while maintaining extremely low machining tolerance?

Based on your successful build and recommendation I too am very inclined to go for a short wand.

I like the Simon Yorke design I have attached here. My intention would be to make the block that goes over the air bushing a one piece including the shaft for the counterweight in order to increase rigidity.

The problem I see with this construction is that it doesn't allow azimuth adjustment and it needs a retrieving mechanism.

I need to think how to make the arm easily be leveled, adjust azimuth having a solid one piece construction (perhaps impossible? The only thing I can think is the classic headshell attached to the main structure secured with set screws that can be rotated to achieve proper azimuth setting, but this would decrease rigidity of course).

What would you suggest for these features? Once I have in mind how to accomplish I will make drawings for your to critique.

Whenever is most convenient to you, please email me the contact for the machinist you have used in the past directly to my private email.

Best,

Stefano.

stefano_rumori@yahoo.it

Air Bearings: I have seen researching around there are more than one manufacturer making these devices. They all look alike but reading each description it seems they bear slightly different technology.

Is this true? Is there really any difference between these different air bearings?

Shafts: There are many dedicated manufacturers making shafts. You have suggested OAV as they use non magnetic stainless steel. I have seen also ceramic coated shafts around. Which material in your opinion offers greatest stiffness/ minimum resonant behavior while maintaining extremely low machining tolerance?

Based on your successful build and recommendation I too am very inclined to go for a short wand.

I like the Simon Yorke design I have attached here. My intention would be to make the block that goes over the air bushing a one piece including the shaft for the counterweight in order to increase rigidity.

The problem I see with this construction is that it doesn't allow azimuth adjustment and it needs a retrieving mechanism.

I need to think how to make the arm easily be leveled, adjust azimuth having a solid one piece construction (perhaps impossible? The only thing I can think is the classic headshell attached to the main structure secured with set screws that can be rotated to achieve proper azimuth setting, but this would decrease rigidity of course).

What would you suggest for these features? Once I have in mind how to accomplish I will make drawings for your to critique.

Whenever is most convenient to you, please email me the contact for the machinist you have used in the past directly to my private email.

Best,

Stefano.

stefano_rumori@yahoo.it

Attachments

Air Bearings: I have seen researching around there are more than one manufacturer making these devices. They all look alike but reading each description it seems they bear slightly different technology.

Is this true? Is there really any difference between these different air bearings?

There are two kinds of air bushings. One uses porous material such as New Way and Oav. The other kind of air bearing uses small air channels such as Mager. I am not an expert on air bearings, but I do believe Newway’s claim that porous material is superior to small channels.

Shafts: There are many dedicated manufacturers making shafts. You have suggested OAV as they use non magnetic stainless steel. I have seen also ceramic coated shafts around. Which material in your opinion offers greatest stiffness/ minimum resonant behavior while maintaining extremely low machining tolerance?

I don’t see the reason why to use ceramic coated one.

Based on your successful build and recommendation I too am very inclined to go for a short wand.

I like the Simon Yorke design I have attached here. My intention would be to make the block that goes over the air bushing a one piece including the shaft for the counterweight in order to increase rigidity.

The problem I see with this construction is that it doesn't allow azimuth adjustment and it needs a retrieving mechanism.

I wouldn’t advise to follow Simon Yorke’s design. It is simply not a good design at all. He doesn’t know what he is doing. Kuzma is the guy who knows what he is doing. So is Walker Audio. V.Y.G.E.R. is another good looking but not a good design to follow. In Michael Fremer’s review, he couldn’t find arm/cartridge resonance for their arm. And, their reaction to Michael Fremer’s review was groundless.

Analog Corner #96 | Analog Planet

I need to think how to make the arm easily be leveled, adjust azimuth having a solid one piece construction (perhaps impossible? The only thing I can think is the classic headshell attached to the main structure secured with set screws that can be rotated to achieve proper azimuth setting, but this would decrease rigidity of course).

What would you suggest for these features? Once I have in mind how to accomplish I will make drawings for your to critique.

I have two kind structures to adjust azimuth. If you want to buy head shell, I highly recommend Audio Technica Technihard head shell. For me, I use 2024 aluminum alloy for everything touchs head shell. I prefer 2024 aluminum over magnesium and carbon fiber.

Whenever is most convenient to you, please email me the contact for the machinist you have used in the past directly to my private email.

Email sent.

Jim

Last edited:

Thanks Jim for the explanations. I will use the New Way bearing and OAV shaft as you suggested.

I have read the review for the VYAGER and the answers from the manufacturer were absolutely ridiculous.

Do you think I am wrong by saying that basically down the core all these airline designs look identical using the same bushing same pressure same shaft?

If they so different instead one from another, then my basic logic says it all must come down to the armwand design otherwise, beside aesthetical differences I don't see any other functional difference.

I am sure I am missing something here.

I thought you would have liked the Simon Yorke's short arm design.

Why do you think it is not good?

Reading the disappointing review received from Vyager this makes me wonder if I can do any better than that.

I am sure the guy who designed this system although not as competent as the designer at kuzma, he is still certainly much more competent than me.

Anyway, is there any particular consideration I should keep in mind when designing the arm section with its counterweight system to not run into a failure like the vyager?

I have read the review for the VYAGER and the answers from the manufacturer were absolutely ridiculous.

Do you think I am wrong by saying that basically down the core all these airline designs look identical using the same bushing same pressure same shaft?

If they so different instead one from another, then my basic logic says it all must come down to the armwand design otherwise, beside aesthetical differences I don't see any other functional difference.

I am sure I am missing something here.

I thought you would have liked the Simon Yorke's short arm design.

Why do you think it is not good?

Reading the disappointing review received from Vyager this makes me wonder if I can do any better than that.

I am sure the guy who designed this system although not as competent as the designer at kuzma, he is still certainly much more competent than me.

Anyway, is there any particular consideration I should keep in mind when designing the arm section with its counterweight system to not run into a failure like the vyager?

Hi Stefano

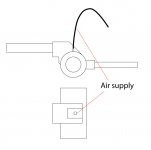

When I saw Simon Yorker’s arm first time, I said to myself he didn’t know what he was doing. From the photo, he uses 1/8” latex tubing. Latex tubing’s max working pressure is about 30 psi. His arm uses low air pressure, 22 psi, it is ok. But laying the tubing in such fashion won’t help. I have tried many different tubings including latex, and many different tubing arrangements. Hanging the tubing high won’t help. It will make thing worse. To use wires like his is completely unnecessary. The air bushing should be close to the surface of LP as much as possible. I checked his web site. He sounds like his arm needs to be adjusted all the time. In fact, a well designed air bearing arm doesn’t need this much of adjustments at all. The only reason an air bearing arm needs to be adjusted all the time is its poor design. I don’t know what he is talking about on his web site. I don’t like his headshell design either.

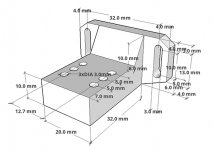

Here are some of things I did.

1, Headshell should be attached on top half of air bushing only.

2, Try to control the total mass of arm about 80 grams. You will not too far off for short arm.

3, The distance between air inlet on air bushing and air supply outlet should be about 2” if you use same tubing as mine.

4, Keep headshell as heavy and solid as possible.

5, I use two slots to attach headshell. So, if you change cartridge, you can adjust the gap between LP and air bushing. This gap should be as short as possible. Mine is about 5 mm. The two slots can be used for adjusting azimuth, too. Please see the image.

Jim

I thought you would have liked the Simon Yorke's short arm design.

Why do you think it is not good?

When I saw Simon Yorker’s arm first time, I said to myself he didn’t know what he was doing. From the photo, he uses 1/8” latex tubing. Latex tubing’s max working pressure is about 30 psi. His arm uses low air pressure, 22 psi, it is ok. But laying the tubing in such fashion won’t help. I have tried many different tubings including latex, and many different tubing arrangements. Hanging the tubing high won’t help. It will make thing worse. To use wires like his is completely unnecessary. The air bushing should be close to the surface of LP as much as possible. I checked his web site. He sounds like his arm needs to be adjusted all the time. In fact, a well designed air bearing arm doesn’t need this much of adjustments at all. The only reason an air bearing arm needs to be adjusted all the time is its poor design. I don’t know what he is talking about on his web site. I don’t like his headshell design either.

Anyway, is there any particular consideration I should keep in mind when designing the arm section with its counterweight system to not run into a failure like the vyager?

Here are some of things I did.

1, Headshell should be attached on top half of air bushing only.

2, Try to control the total mass of arm about 80 grams. You will not too far off for short arm.

3, The distance between air inlet on air bushing and air supply outlet should be about 2” if you use same tubing as mine.

4, Keep headshell as heavy and solid as possible.

5, I use two slots to attach headshell. So, if you change cartridge, you can adjust the gap between LP and air bushing. This gap should be as short as possible. Mine is about 5 mm. The two slots can be used for adjusting azimuth, too. Please see the image.

Jim

Attachments

Last edited:

These are great tips! Based on those I can see why you don’t like the yorke as they attach the head shell in the low half and counterweight in the top half of the bushing and this consequently pushes the distance between the air bushing and LP greater than your ideal 5mm number.

Your suggestions are very clear.

I still have to figure out how I will adjust the level of the arm. Kuzma seems not to have this adjustment.

When you say not to exceed 80gr of moving mass...I assume this includes armwand shell counterweight bar and counterweight itself right?

Your suggestions are very clear.

I still have to figure out how I will adjust the level of the arm. Kuzma seems not to have this adjustment.

When you say not to exceed 80gr of moving mass...I assume this includes armwand shell counterweight bar and counterweight itself right?

He wrote:" The one glaring omission in the Air Line's design is a damping trough. A linear design—even one using a stationary rail—must laterally move a large mass. The grooves of most LPs are not concentric because of pressing inconsistencies, which means the groove is constantly shifting the tonearm's mass back and forth. Because the stylus is at the end of a spring mechanism (the cantilever's suspension), if you use a cartridge with too high a compliance—too floppy a spring—you can have the tail wagging the dog, in that the motion of the groove spiral will move the cantilever from its central position. The risk is then that with a frictionless bearing the stylus might be slammed from one groove wall to the other."

These are great tips! Based on those I can see why you don’t like the yorke as they attach the head shell in the low half and counterweight in the top half of the bushing and this consequently pushes the distance between the air bushing and LP greater than your ideal 5mm number.

Your suggestions are very clear.

I still have to figure out how I will adjust the level of the arm. Kuzma seems not to have this adjustment.

When you say not to exceed 80gr of moving mass...I assume this includes armwand shell counterweight bar and counterweight itself right?

Yes. It should include counter weight. Kuzma's is a long arm so its VTA adjustment mechanism is to adjust the level. Please note that Kuzma's air bushing is lower than LP surface. His arm wand is on the top of air bushing. He knows what he is doing.

Jim

The one glaring omission in the Air Line's design is a damping trough. A linear design—even one using a stationary rail—must laterally move a large mass. The grooves of most LPs are not concentric because of pressing inconsistencies, which means the groove is constantly shifting the tonearm's mass back and forth. Because the stylus is at the end of a spring mechanism (the cantilever's suspension), if you use a cartridge with too high a compliance—too floppy a spring—you can have the tail wagging the dog, in that the motion of the groove spiral will move the cantilever from its central position. The risk is then that with a frictionless bearing the stylus might be slammed from one groove wall to the other."

First, all the tonearms, including regular pivot arms, will have so called the tail wagging the dog phenomenon because both air bearing arm and pivot arm have a spring mechanism in front and large mass in the back and both air bearing and pivot are frictionless if such phenomenon exists.

Secondly, stylus will not be slammed from one groove wall to the other. Such thing doesn't exist. If large mass in back cause front stylus overshot, it will bend the cantilever only. The stylus will stay in the groove. If the stylus is slammed from wall to wall, it means the arm can't track the groove. It is different matter.

Jim

Last edited:

Yes. It should include counter weight. Kuzma's is a long arm so its VTA adjustment mechanism is to adjust the level. Please note that Kuzma's air bushing is lower than LP surface. His arm wand is on the top of air bushing. He knows what he is doing.

Jim

I was referring to leveling the bearing on the horizontal axes not the VTA for the cartridge.

I assume if the level is not perfect and the arm is virtually tilted in one direction this can add drag and improper reading. I haven't seen this regulation on the Kuzma. I wonder why it was omitted, maybe because they mount the arm on a dedicated turret?

When I will get to dimensioning, I will probably need your help to make a determination on the balancing of the arm size of counterweight and length of shafts. Based on your comment I see the advantage of a longer wand is also to be able to place the bushing below the LP level that can't be done with short wand.

Last edited:

I really like this wand, it's pricy but it looks well made and suitable. The only thing is to understand mechanical drawings and especially if it can be easily rewired. This is designed for the moving shaft so that it has a 4 pole connector with the internal wiring that plugs on the side of the shaft.

In our case we need to exit long to be able to go to either a junction box or long direct wiring.

http://www.eminent-tech.com/carbon fiber arm wand.html

I have inquired the manufacturer for these info.

In our case we need to exit long to be able to go to either a junction box or long direct wiring.

http://www.eminent-tech.com/carbon fiber arm wand.html

I have inquired the manufacturer for these info.

- Home

- Source & Line

- Analogue Source

- DIY Air Bearing Linear Arm