A nice guy offered to fix my good looking but dead Yamaha DX7ii. I tried to help but whatever we did gave no result. With Gray Matter installed the synth received MIDI-streams but to sound. With it removed and a EPROM with the original s/w it made noises but no MIDI ...

The issue was me mounting the replacement battery in a fashion it was shorted when the lid came on.

Gray Matter surgically removed, new EPROM battery fix and ...

The issue was me mounting the replacement battery in a fashion it was shorted when the lid came on.

Gray Matter surgically removed, new EPROM battery fix and ...

Didnt repair it...

Ryobi gas trimmer, FREE at yard sale. Guy said "carburetor". How hard can it be? I was about to be shown...

Problem actually was weak spark. Never got even a single pop outta the thing.

Took it apart and noticed a discernable shift in the coil mounting, where one side of the magnet armature circuit was practically touching the rotor magnet, the other waaay off, maybe 3/16".

So I adjusted it using a thick piece of paper to even things up. Gap even and close, no touch. Magnet strong - can feel its force. Put it all back together and expected a start on first pull. Nothing.

Off switch grounds the coil, check its open in run position and operational. Disconnect the wires completely, still nothing. Noticed the armature of the coil suspended on plastic washers, replaced with metal. Still nothing but a faint spark when pulled hard and fast. Observed in two different plugs.

Put it all back together, FREE sign, down by the side of the boulevard it goes, with proper diagnosis written "no spark". Good Luck, to whomever picks it. They can buy a new coil; pretty sure if I did and replaced it, still nothing. 2020 manufacture date, unit in overall nice shape too.

Decided I just dont have the time in life anymore to chase ghosts in cheap machinery.

Ryobi gas trimmer, FREE at yard sale. Guy said "carburetor". How hard can it be? I was about to be shown...

Problem actually was weak spark. Never got even a single pop outta the thing.

Took it apart and noticed a discernable shift in the coil mounting, where one side of the magnet armature circuit was practically touching the rotor magnet, the other waaay off, maybe 3/16".

So I adjusted it using a thick piece of paper to even things up. Gap even and close, no touch. Magnet strong - can feel its force. Put it all back together and expected a start on first pull. Nothing.

Off switch grounds the coil, check its open in run position and operational. Disconnect the wires completely, still nothing. Noticed the armature of the coil suspended on plastic washers, replaced with metal. Still nothing but a faint spark when pulled hard and fast. Observed in two different plugs.

Put it all back together, FREE sign, down by the side of the boulevard it goes, with proper diagnosis written "no spark". Good Luck, to whomever picks it. They can buy a new coil; pretty sure if I did and replaced it, still nothing. 2020 manufacture date, unit in overall nice shape too.

Decided I just dont have the time in life anymore to chase ghosts in cheap machinery.

Ignition coil trigger circuit, may be points or electronic. Faults in those could have been the issue.

Corrosion in wires is a known issue, and spare parts are so expensive that you did the right thing, only cheap way is to salvage parts from a unit with a different fault...if you have the time and patience.

Replaced the fan motor capacitor on my ancient (1992) window air conditioner.

Took some time, there were joints between flying leads of motor and the capacitor, which was soldered to its lugs.

So soldered leads, and found more work.

Did a decent job, put sleeves on joints, later will open the soldering, make proper joint to flying leads, heat shrink tube over that.

It is back in action, a relief when it is 42 C ambient.

Corrosion in wires is a known issue, and spare parts are so expensive that you did the right thing, only cheap way is to salvage parts from a unit with a different fault...if you have the time and patience.

Replaced the fan motor capacitor on my ancient (1992) window air conditioner.

Took some time, there were joints between flying leads of motor and the capacitor, which was soldered to its lugs.

So soldered leads, and found more work.

Did a decent job, put sleeves on joints, later will open the soldering, make proper joint to flying leads, heat shrink tube over that.

It is back in action, a relief when it is 42 C ambient.

Not repaired.... Used a new DAC with my Pass XA160.5 diy version......

Wondered about hum noise.... Opened the case and wondered about those jumpers at the UGS module...

Took these out and after switching on again hum was gone...

Seems I used the amp for about 8 years with bridged dc blocker....

Wondered about hum noise.... Opened the case and wondered about those jumpers at the UGS module...

Took these out and after switching on again hum was gone...

Seems I used the amp for about 8 years with bridged dc blocker....

burnt headphone amp Magni 3+

Hi! I going to repair Magni 3+, does anybody knows which is a type of resistors to buy the same ones ? The size is 2512.

This sounds like it may become a rough read. Let's start with how much electronic experience have you had, and what tools are available to you. You will need reference to probably at least a schematic, and own a multi-meter.

I have not really won the battle yet. This is a picture of an air conditioning clutch on my oldest kids car. Was the one car out of four we have that had working AC. Just had to post the lovely photo after I pulled the pulley out.

My youngest kid drove it from Denver to Arizona and had the alternator light go on about 600 miles away. Initial diagnosis over the phone was there was no alternator belt. He wound up stuck in some small town on a holiday weekend so I jumped in the car with an alternator and a spare belt. Turns out the compressor clutch froze and the belt went bye bye. Had to get a belt that would bypass the compressor though the closest was another 60 miles away. Got the car working and the kid was able to complete his mission.

The bearing race is still stuck on the compressor and may take some gentle drilling/grinding to get off.

My youngest kid drove it from Denver to Arizona and had the alternator light go on about 600 miles away. Initial diagnosis over the phone was there was no alternator belt. He wound up stuck in some small town on a holiday weekend so I jumped in the car with an alternator and a spare belt. Turns out the compressor clutch froze and the belt went bye bye. Had to get a belt that would bypass the compressor though the closest was another 60 miles away. Got the car working and the kid was able to complete his mission.

The bearing race is still stuck on the compressor and may take some gentle drilling/grinding to get off.

I think it may be a good idea to buy another compressor, and get it replaced by a technician with gas recovery system, the existing one may be worn out or damaged for the mechanism to be frozen this way.

A frozen sealed bearing means it is at least 5 years old, there is rust on the splines as well.

My car has a double pulley, one is for A/c, the other for water pump and alternator.

Long back, different car, A/c belt broke, was able to get home at night after removing broken belt bits.

If you have access to CO2 gas, or nitrogen, spary to freeze the metal, it will shrink ever so slightly and come off easily. Better if you have a puller.

Then check the compressor, you may lose the gas, expensive, so suggested technician.

A frozen sealed bearing means it is at least 5 years old, there is rust on the splines as well.

My car has a double pulley, one is for A/c, the other for water pump and alternator.

Long back, different car, A/c belt broke, was able to get home at night after removing broken belt bits.

If you have access to CO2 gas, or nitrogen, spary to freeze the metal, it will shrink ever so slightly and come off easily. Better if you have a puller.

Then check the compressor, you may lose the gas, expensive, so suggested technician.

I find it admirable in this day that someone goes to the length that you did to make it work for the time being. We live in an age where some people will drive on a flat tire to the point that they ruin the rim, to a tire shop so that a professional can do the rest. We have all seen it.

The clutch was $35 on amazon. I had the hope that I could just replace the clutch and not mess with recovery and a charge. Maybe the new compressor option was better though.

I will give it another go after I re roof part of my house. Just 600 square feet and I also have 18 and 25 year old kids to help.

I will give it another go after I re roof part of my house. Just 600 square feet and I also have 18 and 25 year old kids to help.

Man, I took advantage of my 3 kids when they were younger for help like that. Couldn't have done that stuff without them. Roofing is tough no matter how it's done. It seems that just about any project that I choose to tackle becomes way more than first thought. That is just life. You want it done right, you are on your own. My latest project was the placing of a fence. post. 3 days later, I'm done. Done right. Solid as a rock.

Attachments

If the compressor has failed, check the maker's data, some compressor families have the same housing, but slightly different displacement (given as volume per rotation).

Put a bigger volume unit, it will cool faster.

Or you could salvage one at the breaking yard (or its equivalent). Good choice for an old car you intend to replace in the near future.

Put a bigger volume unit, it will cool faster.

Or you could salvage one at the breaking yard (or its equivalent). Good choice for an old car you intend to replace in the near future.

Another failed attempt.

Gave son a old GE microwave to take to his apartment at university. Worked for 6 mos, then he reports suddenly "no heat". Brought back here. Had a look, HV diode checks good, cap checks good, magnetron shows virtually short circuit conductivity between the two connector pins, open circuit from those pins to chassis. I no longer have equipment (TV CRT anode probe) to measure 5kV...

Sounds like it's pulling power and putting it into something when run, giving the usual humm when the controller energizes the magnetron, a moment after starting up. Just like the identical unit we use daily. No burn, no smoke, no odor anywhere inside - fan spins, clean inside. I havent measured the AC current draw, which I could at least do - safely.

I could just shot-gun the magnetron, for ~$50 - and hope. I wish I could understand the failure mechanism root cause first. When I was a kid I remember my father shot-gunned the CRT of our 1st GE color television, when it ultimately turned out to be a bad HV diode.

There's a thermal switch; paperwork says it's to shutdown if there's a fire in the chamber. There's a humidity sensor.

Any ideas of how to diagnose further? A YT video mentions that the two pin connector on the magnetron is actually a feedthrough capacitor, but I measure open circuit on my Fluke DMM on those pins to ground.

Gave son a old GE microwave to take to his apartment at university. Worked for 6 mos, then he reports suddenly "no heat". Brought back here. Had a look, HV diode checks good, cap checks good, magnetron shows virtually short circuit conductivity between the two connector pins, open circuit from those pins to chassis. I no longer have equipment (TV CRT anode probe) to measure 5kV...

Sounds like it's pulling power and putting it into something when run, giving the usual humm when the controller energizes the magnetron, a moment after starting up. Just like the identical unit we use daily. No burn, no smoke, no odor anywhere inside - fan spins, clean inside. I havent measured the AC current draw, which I could at least do - safely.

I could just shot-gun the magnetron, for ~$50 - and hope. I wish I could understand the failure mechanism root cause first. When I was a kid I remember my father shot-gunned the CRT of our 1st GE color television, when it ultimately turned out to be a bad HV diode.

There's a thermal switch; paperwork says it's to shutdown if there's a fire in the chamber. There's a humidity sensor.

Any ideas of how to diagnose further? A YT video mentions that the two pin connector on the magnetron is actually a feedthrough capacitor, but I measure open circuit on my Fluke DMM on those pins to ground.

The two pin connector on the maggie is the filament (and - HV cathode connection). I'm not sure what magnetron is in the microwave, but if it's something like a 2M137 (a typical 1.2kW microwave oven maggie), the filament is rated 4.4 V @ 14 A, so it would be on the order of 0.3 Ω, so the near dead short resistance there checks out.

Tough to troubleshoot further without measurements, but it's likely either a bad maggie, or the voltage doubler cap. The cap could possibly be shorting at the higher voltage it encounters in operation (any possibility of putting it on a megger to check dielectric resistance?), but I'd be more inclined to suspect the maggie. It likely goes without saying to be EXTREMELY careful working on microwaves, as the high voltage WILL end you if you screw up.

Given the cost of new microwave ovens, unless it's a really good oven (helped a friend years ago with a really nice stainless steel chambered one he had), it might make more sense to just buy a new one.

-Pat

Tough to troubleshoot further without measurements, but it's likely either a bad maggie, or the voltage doubler cap. The cap could possibly be shorting at the higher voltage it encounters in operation (any possibility of putting it on a megger to check dielectric resistance?), but I'd be more inclined to suspect the maggie. It likely goes without saying to be EXTREMELY careful working on microwaves, as the high voltage WILL end you if you screw up.

Given the cost of new microwave ovens, unless it's a really good oven (helped a friend years ago with a really nice stainless steel chambered one he had), it might make more sense to just buy a new one.

-Pat

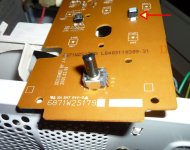

Braun tuner CE501 sold on 'bay as broken.

Was a BF184 in the MF stage. Also installed new ligt bulbs and 3 psu caps. Now it works just fine and connects the newsfeed to my speakers.

Was a BF184 in the MF stage. Also installed new ligt bulbs and 3 psu caps. Now it works just fine and connects the newsfeed to my speakers.

My precious ~25 year old BOSCH microwave (an ebay purchase in like new condition for <1/10 retail price at that time including shipping..):

16kg, inside out built like a tank, still looks like new altough it gets used every day several times, nice clean (no) "design", can be operated without reading a 250 page manual...even wife can, anything with more than 2 - 3 knobs or controls is way too complicated for her...🙂.

Did not turn on anymore. Took me more than an hour to figure out how to disassemble and gain access to the PCB that carries the operating controls on the front. When I got there (thankfully) seemed like only a tiny momentary push-button was worn out.

Looked up old parts bins. Found an old donor PCB with lots of similar buttons on it. Turned out the bodies of those as well the button itself where a tiny bit less tall. Shoved and glued some plastic sheet underneath the miniature switch and also something on top of it. Removed the old, desoldered and soldered in the "new" switch. Reassembled. Works again like a charm.

Cost: zero. Probably good for another 25+ years (will likely survive me, unless I make it to 90+...).

16kg, inside out built like a tank, still looks like new altough it gets used every day several times, nice clean (no) "design", can be operated without reading a 250 page manual...even wife can, anything with more than 2 - 3 knobs or controls is way too complicated for her...🙂.

Did not turn on anymore. Took me more than an hour to figure out how to disassemble and gain access to the PCB that carries the operating controls on the front. When I got there (thankfully) seemed like only a tiny momentary push-button was worn out.

Looked up old parts bins. Found an old donor PCB with lots of similar buttons on it. Turned out the bodies of those as well the button itself where a tiny bit less tall. Shoved and glued some plastic sheet underneath the miniature switch and also something on top of it. Removed the old, desoldered and soldered in the "new" switch. Reassembled. Works again like a charm.

Cost: zero. Probably good for another 25+ years (will likely survive me, unless I make it to 90+...).

Attachments

RCA LMI-32216A mono vacuum tube power amplifier.

Not too many about these days. Also have the LMI-32215 preamp and tuner next up.

Not too many about these days. Also have the LMI-32215 preamp and tuner next up.

- Home

- Member Areas

- The Lounge

- What did you last repair?