I agree that forums are not used consistently. My opinion is that "Everything Else" is for technical, non-audio threads and "Lounge" is for non-technical threads.

My point was that long posts about reinstalling OS's on computers are derailing it, and arguably are not really a "repair" except in the broadest and useless sense.

My "reinstalling OS" comment was after a previous message concerning a failed hard disk drive. So wasn't a random message.

I hoped my message would convince others to make backups before anything was lost. An expensive lesson for me but hopefully a usefull tip for others ?

My two cents: it only takes a little grousing and grumbling to ruin the mood on a thread for everybody. It's like having one pissed-off person at the Thanksgiving table.

This is not a case of a blatant violation of anything. Repairing a PC is still a repair. Installing a new operating system is still a repair - just ask any computer repair shop.

That being the case, this is a simple case of a few posts not being to one or two people's taste, while also not breaking any diyAudio rules or guidelines.

Well, the world will never be to everyone's tastes. IMO, the simple solution is for those with ruffled feathers to take five slow breaths, let the feathers settle back down, and/or simply ignore the posts you don't want to see. You can always put specific members on your ignore list, if you wish.

There, I repaired this thread. Or at least, I tried to. 😀

-Gnobuddy

This is not a case of a blatant violation of anything. Repairing a PC is still a repair. Installing a new operating system is still a repair - just ask any computer repair shop.

That being the case, this is a simple case of a few posts not being to one or two people's taste, while also not breaking any diyAudio rules or guidelines.

Well, the world will never be to everyone's tastes. IMO, the simple solution is for those with ruffled feathers to take five slow breaths, let the feathers settle back down, and/or simply ignore the posts you don't want to see. You can always put specific members on your ignore list, if you wish.

There, I repaired this thread. Or at least, I tried to. 😀

-Gnobuddy

A post abut something audio being fixed will pop up soon enough, bringing the thread back to being strictly on topic. Think of other conversation as "music on hold".

-Chris

-Chris

Hi Chris,A post abut something audio being fixed will pop up soon enough, bringing the thread back to being strictly on topic. Think of other conversation as "music on hold".

-Chris

This is another case of "internet agitation", sometimes found in real life situations.

Allow me to explain....

You're sitting around a table in a restaurant, several of you, and discussing a particular topic.

As humans are, perhaps a certain topic leads someone to think of another topic, whether relevent or not, and of course the others reply, as the subjects flow.... a strictly natural thing of course.

One person at the table perhaps isn't interested in the topic, and so they speak up, perhaps in an attempt to discuss the topic previously discussed before the natural human "wandering" started.

As I mentioned, this is all natural, but can be at times as annoying as a person being for whatever reason, forceful, to put it nicely.

And I'm sure we've all experienced that in our lifetimes.

Ampeg SVT-CL

Not repair per se, one bad 6550, replaced two of the sextet checked the remaining four, biased her up and sat, drank coffee and played through it for an hour and returned to owner. Heard all went well for his gig over at Lake Buena Vista.

Best regards,

Terry

Not repair per se, one bad 6550, replaced two of the sextet checked the remaining four, biased her up and sat, drank coffee and played through it for an hour and returned to owner. Heard all went well for his gig over at Lake Buena Vista.

Best regards,

Terry

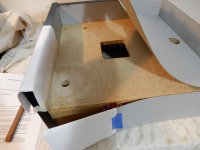

Although this wasn't strictly my latest repair, and it is an audio accessory, not strictly an audio device, it was a fairly extensive repair of a valuable piece of equipment.

I bought a nice condition VPI HW-17 record cleaning machine that was in need of some maintenance and cleaning, but I was so excited to use it to clean a lot of my records that I pressed it into service before going through it.

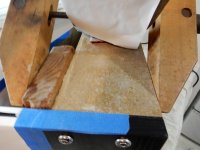

Turns out the fluid filler bung hole has a plastic insert that wasn't sealed to the particle board base, and having left just a bit too much fluid in the reservoir, it soaked into the particle board overnight and caused an expansion that separated the top Formica layer.

I had to partially disassemble the base, remove the motor, pump, mounts, etc., peel the Formica back, and re-surface the particle board deck, all without damaging the Formica. I then impregnated the particle board with penetrating epoxy, leveled it, and re-lay the Formica skin.

I also used penetrating epoxy on the underside of the deck to stabilize the particle board area above the reservoir tank. This was also a great time to replace the noisy gear motor and soft mounts, the motor capacitor, check/tighten all wire connections, and properly seal the reservoir tank and filler neck to the deck so this wouldn't happen again, if I was so stupid as to overfill again. The vacuum motor rust was minimal, so I just coated it. All of the top deck seams were then caulked with a grey hard silicone, and all fittings caulked with soft white silicone.

It gets a lot of use, and the wife has allowed it to be permanently placed on a wall cabinet, covered with some decorative cloths. Result!

I bought a nice condition VPI HW-17 record cleaning machine that was in need of some maintenance and cleaning, but I was so excited to use it to clean a lot of my records that I pressed it into service before going through it.

Turns out the fluid filler bung hole has a plastic insert that wasn't sealed to the particle board base, and having left just a bit too much fluid in the reservoir, it soaked into the particle board overnight and caused an expansion that separated the top Formica layer.

I had to partially disassemble the base, remove the motor, pump, mounts, etc., peel the Formica back, and re-surface the particle board deck, all without damaging the Formica. I then impregnated the particle board with penetrating epoxy, leveled it, and re-lay the Formica skin.

I also used penetrating epoxy on the underside of the deck to stabilize the particle board area above the reservoir tank. This was also a great time to replace the noisy gear motor and soft mounts, the motor capacitor, check/tighten all wire connections, and properly seal the reservoir tank and filler neck to the deck so this wouldn't happen again, if I was so stupid as to overfill again. The vacuum motor rust was minimal, so I just coated it. All of the top deck seams were then caulked with a grey hard silicone, and all fittings caulked with soft white silicone.

It gets a lot of use, and the wife has allowed it to be permanently placed on a wall cabinet, covered with some decorative cloths. Result!

Attachments

-

DSCN1223.jpg114.8 KB · Views: 170

DSCN1223.jpg114.8 KB · Views: 170 -

DSCN4814.jpg183.3 KB · Views: 82

DSCN4814.jpg183.3 KB · Views: 82 -

DSCN4765.jpg114.9 KB · Views: 80

DSCN4765.jpg114.9 KB · Views: 80 -

DSCN4768.jpg210.4 KB · Views: 86

DSCN4768.jpg210.4 KB · Views: 86 -

DSCN4750.jpg239.3 KB · Views: 77

DSCN4750.jpg239.3 KB · Views: 77 -

DSCN1253.jpg110.2 KB · Views: 77

DSCN1253.jpg110.2 KB · Views: 77 -

DSCN1250.jpg89.4 KB · Views: 165

DSCN1250.jpg89.4 KB · Views: 165 -

DSCN1230.jpg125.6 KB · Views: 169

DSCN1230.jpg125.6 KB · Views: 169 -

DSCN1228.jpg132.4 KB · Views: 174

DSCN1228.jpg132.4 KB · Views: 174 -

DSCN1226.jpg177.7 KB · Views: 168

DSCN1226.jpg177.7 KB · Views: 168

Hi PRR,

We got rid of all CFL lamps in the house as soon as LED lighting became stable. I still have some fixtures with circle-line bulbs. I also now have circular LED assemblies with ballasts. Guess what I'm going to do shortly? 🙂

They aren't a 1:1 replacement, so there will be some arranging and multiple LED assemblies used. Too bad that EL never amounted to the high brightness that LEDs can throw out. From playing with them, I discovered that the higher the current you can force through them, the brighter they are. A sine wave isn't going to do what you want. So you want to hit the panels with high frequency transients (in other words, not a sine wave). Now to figure out if a square wave, triangle wave or some other "peaky" waveform turns out to be most effective. One thing to remember, the panels sing with whatever wave form you hit them with.

-Chris

-Chris[/QUOTE]

Most leds are heavily de-rated in their applications due to thermal constraints, most can be driven much harder with heat sinking(copper core circuit boards). We chopped them at 28k for our purpose, never paid attention to the wave form however...

I just went through my passive crossovers in the car again, cleaned up the circuit and added a necessary resistor that I had left out the first time around. Now it has been repaired per the original jbl 4406 schematic, until I un-repair it that is.

Completed...

That VPI HW-17, I checked on it, and found out that it retailed for $1500.00 originally.

Now, be honest with me on this, isn't that an absolutely rediculous mark-up price for a lousy particle board box with a couple of inexpensive motors in it?

The Lamb single stage vacuum cleaner motor itself can be bought for about $75.

The gearbox motor for around $49.

The pump is perhaps another $75.

And I'm sure that quantity pricing is substantially less.

Toss in a couple of $2 toggle switches and some PVC tubing...

So, where's the high cost justified?

The outer cosmetics?

Was the laminated particleboard hand-cut by young virgin girls from some holyland, using glue that was blessed by Mother Theresa?

Nah.... it's pure GREED.

Like all the other products from VPI, among others, bloated pricing to line their pockets with.

And quite typical of those "high end" brand names.

Now that I've seen the undersides of that machine, I can confirm that they're just another "snake oil" company, taking advantage of the "audiophile" world with their crap.

I never liked their turntables either, sensing their typical overpriced adjenda.

This is the way it is today, folks.

Shameful sad state of affairs. 😱

The problem with using line for LEDs is the bloody flicker! I have a LED 100W flood lamp that I use to light up my bench. It eventually hurts my eyes but it works way better than the neon to set the speed on my turntable 😀

None of the lights I have ever used on the bench have bothered me so far. I have a ton of LED light concentrated on the bench right now. What you do have to watch out for is the electronic noise. I have a big spike near 50 KHz. Gee, I wonder what is causing that?

-Chris

-Chris

Holy crap! Is that ever low quality particle board. We called it "chip board". It should have been made with MDF at a minimum and sealed with plastic spray.

Anyway, you did an excellent job of repairing it. It might even be better than a new one now! However, if you ever have to take it apart again, use the existing panels as templates and make it out of MDF at a minimum. HDF is neat, but difficult to work with. It would probably result in a heavier, indestructible piece of equipment. You can mill that stuff and it will hold an edge.

Anyway, you did an excellent job of repairing it. It might even be better than a new one now! However, if you ever have to take it apart again, use the existing panels as templates and make it out of MDF at a minimum. HDF is neat, but difficult to work with. It would probably result in a heavier, indestructible piece of equipment. You can mill that stuff and it will hold an edge.

That VPI HW-17, I checked on it, and found out that it retailed for $1500.00 originally.

Now, be honest with me on this, isn't that an absolutely rediculous mark-up price for a lousy particle board box with a couple of inexpensive motors in it?

No question - especially considering this was made 20+ years ago. They apparently had the "best" rcm on the market at the time so asked stupid money for it. Pulling it apart, I could see the construction method was so inefficient that it must have been labor-intensive.

I bought if for less than 1/3 the original price. Same price as an Okki Nokki, which doesn't have the features I wanted.

The Lamb single stage vacuum cleaner motor itself can be bought for about $75.

The gearbox motor for around $49.

The pump is perhaps another $75.

You should see what they ask for these replacement parts at VPI! I refused to pay them. Instead I found the vacuum motor for about $60 and bought one as a backup, and bought 5 gear motors from a jobber for $6.50 each including shipping; one for me and 4 to sell to those with an HW-17 or an HW-16 with single-direction only motor who want to upgrade.

bloated pricing

What?!? You don't want to pay $30 for a 2mm TT belt that we can make for about $0.80? How about the synchronous motor in my VPI turntable; I bought it from a wholesaler for $37 or so, but VPI wanted over $120. Yikes.

Holy crap! Is that ever low quality particle board. We called it "chip board". It should have been made with MDF at a minimum and sealed with plastic spray.

Agreed, Chris. You should have heard me cursing them when I saw this. No proper sealing of the wood, no caulk at fittings on the deck, no proper drain for the vacuum motor that inevitably sucks up discarded fluid, etc.

It might even be better than a new one now! However, if you ever have to take it apart again, use the existing panels as templates and make it out of MDF at a minimum.

Thank you. Again, exactly what I was contemplating at the time - I came close. As I had all of the skills and materials from my days working on boats, I wasn't too intimidated, but boy, did I complain constantly about the crap materials and build quality. Now I can spill fluid all over the deck and it never makes it to the chip board, even overfill it with no ill effects.

Thank you, Coolnose. The seal of approval from the wife of the visuals and the job it does on our vinyl helped!

I think it is very appealing visually, great job of getting it back to life as well¡

And THAT is exactly what manufacturer's expect the consumer to think!

Visuals, appealing to the eye, without the internal GUTS to confirm any sign of QUALITY.

In other words..... superficiality, along with consumer ignorance, sells things.

This goes for many other products as well, always has, and I'm sure always will.

I learned, long ago, not to be swayed by "looks".

Having been a service technician for decades, I've been able to see the "guts" of thousands of consumer audio/video products.

And of automobiles as well as furniture, and the list goes on.

Duping people into buying such products disgusts me, because they deserve more, they deserve honesty, not shiny, sexy-looking crap.

They lay out good money for something, they should get the equal in return, anything less is what I call a form of cheating, stealing,..... greed.

I'm so glad that the majority of what I own isn't crap, and what little I do have with "lowered standards" isn't important or expensive.

However, in this day, it's very difficult to choose something worth the money.

GTKAUDIO:

I built a record cleaner back in the 1990's, and yes, it's an MDF box with a platter/motor and a compact vacuum motor.

The thing cost me maybe $8 in MDF, the motors I had laying around.

And a refillable spray bottle for my home-made cleaner fluid.

Does the same thing basically as that bloated VPI.

As for "looks", it doesn't need any, I keep it in the closet anyway.

I built a record cleaner back in the 1990's, and yes, it's an MDF box with a platter/motor and a compact vacuum motor.

The thing cost me maybe $8 in MDF, the motors I had laying around.

And a refillable spray bottle for my home-made cleaner fluid.

Does the same thing basically as that bloated VPI.

As for "looks", it doesn't need any, I keep it in the closet anyway.

And THAT is exactly what manufacturer's expect the consumer to think!

Visuals, appealing to the eye, without the internal GUTS to confirm any sign of QUALITY.

In other words..... superficiality, along with consumer ignorance, sells things.

This goes for many other products as well, always has, and I'm sure always will.

I learned, long ago, not to be swayed by "looks".

Having been a service technician for decades, I've been able to see the "guts" of thousands of consumer audio/video products.

And of automobiles as well as furniture, and the list goes on.

Duping people into buying such products disgusts me, because they deserve more, they deserve honesty, not shiny, sexy-looking crap.

They lay out good money for something, they should get the equal in return, anything less is what I call a form of cheating, stealing,..... greed.

I'm so glad that the majority of what I own isn't crap, and what little I do have with "lowered standards" isn't important or expensive.

However, in this day, it's very difficult to choose something worth the money.

While a lot holds true of this (high end audio makers who switched to class D included a large unpopulated heat sink because their customers expected to see one) there IS something to be said about an attractive layout.

This is why my latest designs are symmetrical. I lay out where the tube sockets should be and design around that. Besides someone who builds their own stuff because it's better, the average Joe who wants an amp cares more about the aesthetics than the functionality.

Kind of like I say about "audiophile" speaker wire. Most people couldn't tell the difference between 3000$ leads and barbed wire as long as it makes sound and it's loud. And don't get me started on the nonsense of the "golden power cord".

- Home

- Member Areas

- The Lounge

- What did you last repair?